ASTM C99-87(2000)

(Test Method)Standard Test Method for Modulus of Rupture of Dimension Stone

Standard Test Method for Modulus of Rupture of Dimension Stone

SCOPE

1.1 This test method covers the determination of the modulus of rupture of all types of dimension stone except slate.

1.2 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C99–87(Reapproved2000)

Standard Test Method for

Modulus of Rupture of Dimension Stone

ThisstandardisissuedunderthefixeddesignationC 99;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope as long as the width of the specimen. The loading knife edge

may be of either the rocker or rigid type.

1.1 This test method covers the determination of the modu-

lus of rupture of all types of dimension stone except slate.

6. Sampling

1.2 This standard does not purport to address all of the

6.1 Select the sample to represent a true average of the type

safety concerns, if any, associated with its use. It is the

or grade of stone under consideration and of the quality

responsibility of the user of this standard to establish appro-

supplied to the market under the type designation to be tested.

priate safety and health practices and determine the applica-

The sample may be selected by the purchaser or his authorized

bility of regulatory limitations prior to use.

representativefromthequarriedstoneortakenfromthenatural

2. Referenced Documents ledge and shall be of adequate size to permit the preparation of

the desired number of test specimens. When perceptible

2.1 ASTM Standards:

variations occur, the purchaser may select as many samples as

C119 Terminology Relating to Dimension Stone

are necessary for determining the variations in modulus of

3. Terminology

rupture.

3.1 Definitions—All definitions are in accordance with Ter-

7. Test Specimens

minologyC119.

7.1 The specimens shall be approximately 4 by 8 by 2 ⁄4 in.

4. Significance and Use (101.6 by 203.2 by 57.2 mm) in size.They shall be sawed from

the sample and finished by grinding to smooth surfaces. The 4

4.1 This test method is useful in indicating the differences in

by 8-in. faces shall be as nearly plane and parallel as practi-

modulus of rupture between the various dimension stones.This

cable. For loading perpendicular to the rift (Note 1) five

test method also provides one element in comparing stones of

specimens shall be prepared with the 4 by 8-in. faces parallel

the same type.

to the rift planes (see A in Fig. 1), and for loading parallel to

5. Apparatus

the rift, five specimens shall be prepared with the 4 by 2 ⁄4-in.

(101.6 by 57.2 mm) faces parallel to the rift (Note 2). When

5.1 Testing Machine— The accuracy of the testing machine

tests are desired on the stone in both the wet and dry condition,

shall be within 1 % for the range from 10 to 1000 lbf (44 to

ten specimens shall be prepared for each direction of loading;

4450 N).

that is, five for tests dry, perpendicular to the rift, five for tests

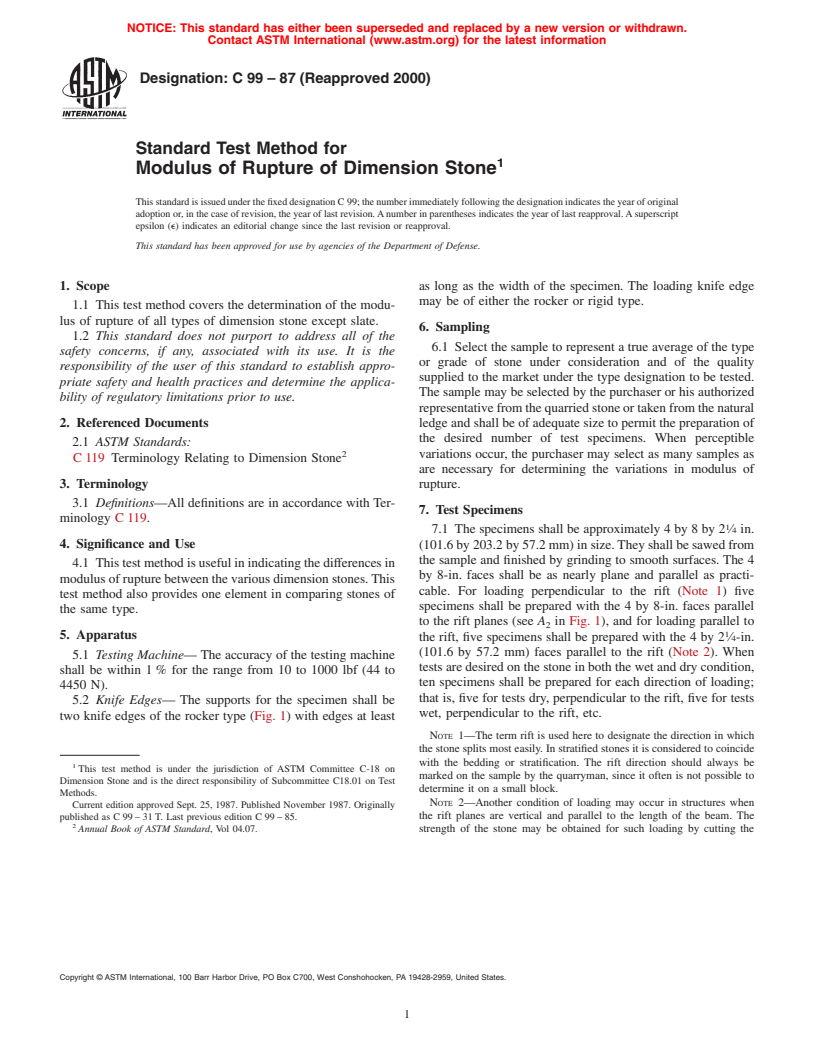

5.2 Knife Edges— The supports for the specimen shall be

wet, perpendicular to the rift, etc.

two knife edges of the rocker type (Fig. 1) with edges at least

NOTE 1—The term rift is used here to designate the direction in which

the stone splits most easily. In stratified stones it is considered to coincide

with the bedding or stratification. The rift direction should always be

This test method is under the jurisdiction of ASTM Committee C-18 on

marked on the sample by the quarryman, since it often is not possible to

Dimension Stone and is the direct responsibility of Subcommittee C18.01 on Test

determine it on a small block.

Methods.

NOTE 2—Another condition of loading may occur in structures when

Current edition approved Sept. 25, 1987. Published November 1987. Originally

the rift planes are vertical and parallel to the length of the beam. The

published as C 99 – 31 T. Last previous edition C 99 – 85.

Annual Book of ASTM Standard, Vol 04.07. strength of the stone may be obtained for such loading by cutting the

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

C99–87 (2000)

A —Specimen in position for testing. a—Span lines.

A —Specimen for test perpendicular to the rift. b—Center lines.

A —Specimen for test parallel to the rift. c—Supporting knife edges.

(Dotted lines on A and A indicate the rift direction) d—Loading knife edge.

2 3

FIG. 1 Specimens and Preferred Type of Knife Edges for Determining the Modulus of Rupture of Building Stone

specimens with the 2 ⁄4 by 8-in. (57.2 by 203.2-mm) face parallel to the

9. Conditioning

rift. The meager data available for this condition of loading indicates that

9.1 Before testing the specimens in a dry condition, dry

the strength is at least as high as when the load is applied perpendicular

them for 48 h at 60 6 2°C (140 6 4°F). At the 46th, 47th and

to the rift

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.