ASTM D1648-86(2003)

(Specification)Standard Specification for Basic Lead Silicochromate Pigment

Standard Specification for Basic Lead Silicochromate Pigment

SCOPE

1.1 This specification covers two types of pigment commercially known as basic lead silicochromate.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 1648 – 86 (Reapproved 2003)

Standard Specification for

Basic Lead Silicochromate Pigment

This standard is issued under the fixed designation D 1648; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

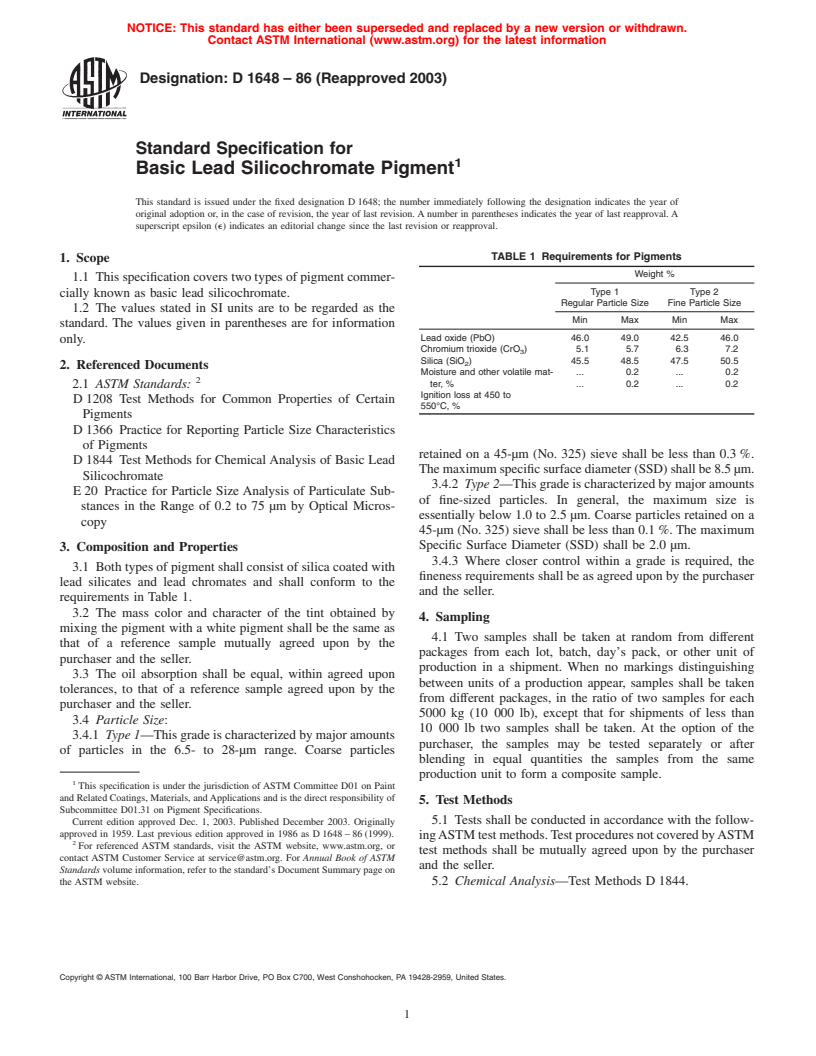

TABLE 1 Requirements for Pigments

1. Scope

Weight %

1.1 This specification covers two types of pigment commer-

Type 1 Type 2

cially known as basic lead silicochromate.

Regular Particle Size Fine Particle Size

1.2 The values stated in SI units are to be regarded as the

Min Max Min Max

standard. The values given in parentheses are for information

Lead oxide (PbO) 46.0 49.0 42.5 46.0

only.

Chromium trioxide (CrO ) 5.1 5.7 6.3 7.2

Silica (SiO ) 45.5 48.5 47.5 50.5

2. Referenced Documents

Moisture and other volatile mat- . 0.2 . 0.2

ter, % . 0.2 . 0.2

2.1 ASTM Standards:

Ignition loss at 450 to

D 1208 Test Methods for Common Properties of Certain

550°C, %

Pigments

D 1366 Practice for Reporting Particle Size Characteristics

of Pigments

retained on a 45-µm (No. 325) sieve shall be less than 0.3 %.

D 1844 Test Methods for Chemical Analysis of Basic Lead

Themaximumspecificsurfacediameter(SSD)shallbe8.5µm.

Silicochromate

3.4.2 Type 2—This grade is characterized by major amounts

E 20 Practice for Particle Size Analysis of Particulate Sub-

of fine-sized particles. In general, the maximum size is

stances in the Range of 0.2 to 75 µm by Optical Micros-

essentially below 1.0 to 2.5 µm. Coarse particles retained on a

copy

45-µm (No. 325) sieve shall be less than 0.1 %. The maximum

Specific Surface Diameter (SSD) shall be 2.0 µm.

3. Composition and Properties

3.4.3 Where closer control within a grade is required, the

3.1 Both types of pigment shall consist of silica coated with

fineness requirements shall be as agreed upon by the purchaser

lead silicates and lead chromates and shall conform to the

and the seller.

requirements in Table 1.

3.2 The mass color and character of the tint obtained by

4. Sampling

mixing the pigment with a white pigment shall be the same as

4.1 Two samples shall be taken at random from different

that of a reference sample mutually agreed upon by the

packages from each lot, batch, day’s pack, or other unit of

purchaser and the seller.

production in a shipment. When no markings distinguishing

3.3 The oil absorption shall be equal, within agreed upon

between units of a production appear, samples shall be taken

tolerances, to that of a reference sample agreed upon by the

from different packages, in the ratio of two samples for each

purchaser and the seller.

5000 kg (10 000 lb), except that for shipments of less than

3.4 Particle Size:

10 000 lb two samples shall be taken. At the option of the

3.4.1 Type 1—This grade is characterized by major

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.