ASTM D6825-02(2008)e1

(Guide)Standard Guide for Placement of Riprap Revetments

Standard Guide for Placement of Riprap Revetments

SIGNIFICANCE AND USE

Riprap is a commonly used form of scour protection and general slope protection. Riprap provides a long term solution when properly sized and installed. Riprap has structural flexibility so it will conform to irregular surfaces and adapt to minor subgrade settlement. It is often appropriate for use in conjunction with soil bioengineering (vegetation establishment) alternatives. In some environments, riprap may provide habitat for benthic organisms and fish.

Revetments provide a facing or lining to armor a surface; and the layer thickness is typically minimized while providing the necessary resistance to scour. In this case, standardized practices to obtain consistent coverage having acceptable thickness tolerances and voids become important.

This guide may be used by owners, installation contractors, regulatory agencies, inspection organizations, and designers and specifiers who are involved in the construction of riprap revetments. Modifications may be required for specific job conditions.This guide is not intentded for construction specifications on large projects, but may be referenced where preparation of job specific construction specifications are not justified. If this practice is included by reference in contract documents, the specifier must provide a list of supplemental requirements.

SCOPE

1.1 This guide covers methods to place riprap with associated filters for erosion control purposes. This guide does not recommend a specific course of action because of the diverse methods and procedures that are capable of producing a functional product. This guide identifies favorable riprap qualities and recommends practices best suited to obtain those qualities. The production of rock, use of recycled materials, rock with cut dimensions, and engineering and design is beyond the scope of this guide. Special forms of riprap, including hand placed riprap, grouted riprap, or keyed (plated) riprap that is tamped into place to smooth the surface, are also beyond the scope of this guide.

1.2 This guide offers an organized collection of information or a series of options and does not recommend a specific course of action. This document cannot replace education or experience and should be used in conjunction with professional judgment. Not all aspects of this guide may be applicable in all circumstances. This ASTM standard is not intended to represent or replace the standard of care by which the adequacy of a given professional service must be judged, nor should this document be applied without consideration of a project's many unique aspects. The word “Standard” in the title of this document means only that the document has been developed and approved through the ASTM consensus process

1.3 This standard may involve hazardous operations and equipment. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory requirements prior to use. ^REFERENCE:

ASTM Standards:

C 33 Specification for Concrete Aggregates

C 136 Test Method for Sieve Analysis of Fine and Coarse Aggregates

D 75 Practice for Sampling Aggregates

D 653 Terminology Relating to Soil, Rock, and Contained Fluids

D 4992 Practice for Evaluation of Rock to be Used for Erosion Control

D 5519 Test Methods for Particle Size Analysis of Natural and Man-Made Riprap Materials

D 6092 Practice for Specifying Standard Sizes of Stone for Erosion Control

AASHTO Standard:

M 288–2000 Geotextile Specification for Highway Applications ^KEYWORDS: bedding; erosion protection; geotextile; revetment; riprap; scour protection ^INDEX TERMS: Bedding; Erosion control materials/applications; Erosion-resistant revetment; Geotextiles; Revetments; Riprap; Scour protection; Soil bioengineering ^STATUS: Dn Cn Sn Nn Mn ^APPROVAL: 20080101 ^PAGES: 7 ^CO...

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: D6825 − 02(Reapproved 2008)

Standard Guide for

Placement of Riprap Revetments

This standard is issued under the fixed designation D6825; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

´ NOTE—Sections X1.1-X1.3 were corrected editorially in February 2008.

1. Scope 2. Referenced Documents

2.1 ASTM Standards:

1.1 This guide covers methods to place riprap with associ-

C33Specification for Concrete Aggregates

ated filters for erosion control purposes. This guide does not

C136Test Method for Sieve Analysis of Fine and Coarse

recommend a specific course of action because of the diverse

Aggregates

methods and procedures that are capable of producing a

D75Practice for Sampling Aggregates

functionalproduct.Thisguideidentifiesfavorableriprapquali-

D653Terminology Relating to Soil, Rock, and Contained

ties and recommends practices best suited to obtain those

Fluids

qualities. The production of rock, use of recycled materials,

D4992Practice for Evaluation of Rock to be Used for

rock with cut dimensions, and engineering and design is

Erosion Control

beyond the scope of this guide. Special forms of riprap,

D5519Test Methods for Particle Size Analysis of Natural

including hand placed riprap, grouted riprap, or keyed (plated)

and Man-Made Riprap Materials

riprap that is tamped into place to smooth the surface, are also

D6092Practice for Specifying Standard Sizes of Stone for

beyond the scope of this guide.

Erosion Control

1.2 This guide offers an organized collection of information

2.2 AASHTO Standard:

oraseriesofoptionsanddoesnotrecommendaspecificcourse

M288–2000Geotextile Specification for HighwayApplica-

of action. This document cannot replace education or experi-

tions

ence and should be used in conjunction with professional

judgment.Notallaspectsofthisguidemaybeapplicableinall

3. Terminology

circumstances. This ASTM standard is not intended to repre-

3.1 Terminologyusedinthisguide,whichisnotincludedor

sent or replace the standard of care by which the adequacy of

notcompletelydefinedinTerminologyD653,isdefinedbelow.

a given professional service must be judged, nor should this

3.2 Definitions of Terms Specific to This Standard:

documentbeappliedwithoutconsiderationofaproject’smany

3.2.1 bedding—an aggregate mixture placed below the rip-

unique aspects. The word “Standard” in the title of this

rap.Beddingmaterialisusuallysandandgravelsized,butmay

document means only that the document has been developed

include cobble sized material. If placed without a geotextile,

and approved through the ASTM consensus process

the bedding material may be used as a filter. If placed in

1.3 This standard may involve hazardous operations and

conjunction with a geotextile, the bedding may provide a

equipment. This standard does not purport to address all of the

cushionforprotectionofthegeotextileduringriprapplacement

safety concerns, if any, associated with its use. It is the

andprovideconfinementofthegeotextile.Itispossibletohave

responsibility of the user of this standard to establish appro-

more than one bedding layer.

priate safety and health practices and determine the applica-

3.2.2 chinking—the practice of filling riprap surface voids

bility of regulatory requirements prior to use.

with smaller sized rock or aggregate.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

ThisguideisunderthejurisdictionofASTMCommitteeD18onSoilandRock contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

and is the direct responsibility of Subcommittee D18.17 on Rock for Erosion Standards volume information, refer to the standard’s Document Summary page on

Control.

the ASTM website.

Current edition approved Jan. 1, 2008. Published February 2008. Originally

Available from American Association of State Highway and Transportation

´2

approved in 2002. Last previous edition approved in 2002 as D6825–02 . DOI:

Officials (AASHTO), 444 N. Capitol St., NW, Suite 249, Washington, DC 20001,

10.1520/D6825-02R08E01.

http://www.transportation.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

D6825 − 02 (2008)

3.2.3 clam shell—a bucket tool that is operated from a preparation of job specific construction specifications are not

dragline or crane. The bucket is hinged at the top and opens justified. If this practice is included by reference in contract

like a clam so that rock can be placed without dropping it. documents, the specifier must provide a list of supplemental

requirements.

3.2.4 D —the particle diameter at which x% by weight

x

(dry) of the particles of a particular sample are finer.

5. Planning for Riprap Placement

3.2.5 filter—any substance, as geotextile or layer of sand/

5.1 Site conditions, level of protection required, construc-

aggregate, placed to provide separation and retention of mate-

tion methods, and equipment may affect the sizing, thickness,

rials, while allowing water to pass.

and lateral extent of a riprap revetment. For some small

3.2.6 floater—a individual rock within the riprap layer that

projects, riprap may be dumped with minimal analysis or

is not interlocked with the surrounding rocks.

quality control, and still fulfill the intended purpose. For larger

3.2.7 maximum aspect ratio—the ratio of the greatest to the

projects and critical structures, engineering, careful placement,

leastdimension,measuredacrossmutuallyperpendicularaxes,

and quality control become increasingly justified to minimize

for any piece of rock; synonym, slabbiness.

material costs and reduce the chance of failure. The degree of

control appropriate should be appropriate for each project.The

3.2.8 orange peel—a bucket tool that is operated from a

methods for placement and quality control should be compat-

draglineorcraneandresemblestheshapeofanorangepeeling.

iblewiththelevelofsiteinvestigationandotherconsiderations

The sides lift up and out so that rock can be placed without

included in Table 1. Table 1 includes factors which should be

dropping it.

considered, but are beyond the scope of this guide. Some

3.2.9 pit run material—rock that has been blasted but not

recommended publications for further information on these

processed to remove undersize pieces; synonym, shot rock or

factors and engineering criteria are given in the References

quarry run.

section. Designing the revetment is beyond the scope of this

3.2.10 revetment—bank protection by armor, that is, by

guide.

facing of a bank or embankment with erosion-resistant mate-

NOTE 1—Slope stability should always be considered. If it is not

investigatedanalyticallybyaqualifiedprofessional,thenitshouldatleast

rial.

be considered subjectively in light of the site conditions and surrounding

3.2.11 riprap—material generally less than 2 tons (1.8

conditions (riverbanks, shorelines, or landforms). Many agencies have

tonnes) in mass, specially selected and graded. When properly

generalized maximum allowable slopes (usually in the range of 1.5H:1V

placed, riprap prevents erosion through minor wave action, or to3H:1V);however,thesemustberecognizedassitespecific.Limitations

of the foundation, bank, material interfaces, seepage conditions, or toe

strong currents and thereby preserves the shape of a surface,

scour may lead to instability.

slope, or underlying structure. Riprap may be specifically

produced for the intended purpose, or it may be a by-product

6. Riprap Materials

from a mining operation, structure demolition, or industrial

6.1 Stone Sources and Evaluation—Rock must be durable

process.

material. In some cases, a source may be established based on

3.2.12 rock—any naturally formed aggregate of mineral

rock classification, geologic evaluation, and observations of

matter occurring in large masses or fragments. Rock may be

existing installations showing that the rock is durable. If a

either insitu or excavated material.

history of rock durability is not established, sampling and

testing the rock may be required. Acceptable material proper-

4. Significance and Use

ties for rock is dependent on the conditions (such as abrasion

4.1 Riprapisacommonlyusedformofscourprotectionand

and saturation frequency due to wave run-up) and climate in

general slope protection. Riprap provides a long term solution

thevicinityofwhereitwillbeused.Sourceselectionmustalso

when properly sized and installed. Riprap has structural flex-

consider the material properties available from local sources.

ibility so it will conform to irregular surfaces and adapt to

Riprapismostcommonlyproducedataquarry,butitmayalso

minor subgrade settlement. It is often appropriate for use in

be screened from a gravel pit operation, processed from rock

conjunction with soil bioengineering (vegetation establish-

collected from some other source, or manufactured from

ment) alternatives. In some environments, riprap may provide

crushed hydraulic-cement (recycled) concrete.

habitat for benthic organisms and fish.

NOTE 2—Borrowing stone, cobbles or gravel from stream or lake beds

4.2 Revetments provide a facing or lining to armor a that do not otherwise need to be disturbed may have environmental

consequences and may not be allowed under state and federal permits.

surface; and the layer thickness is typically minimized while

providing the necessary resistance to scour. In this case,

6.1.1 Sampling and Testing Rock Sources— Practice D4992

standardized practices to obtain consistent coverage having

provides guidance on sampling a source rock. Criteria for

acceptable thickness tolerances and voids become important.

acceptance should consider criteria in EM 1110-2-2302, but

may also consider characteristics of rock found in nearby

4.3 This guide may be used by owners, installation contrac-

quarries. Information provided with rock samples should

tors,regulatoryagencies,inspectionorganizations,anddesign-

include the location from which the sample was taken, and the

ersandspecifierswhoareinvolvedintheconstructionofriprap

stratigraphy for samples obtained at quarries. (See Note 3).

revetments. Modifications may be required for specific job

conditions.This guide is not intentded for construction speci-

NOTE 3—Due to the relative cost of producing and transporting riprap

fications on large projects, but may be referenced where in relation to placing it at the site, there is a potential for disputes where

´1

D6825 − 02 (2008)

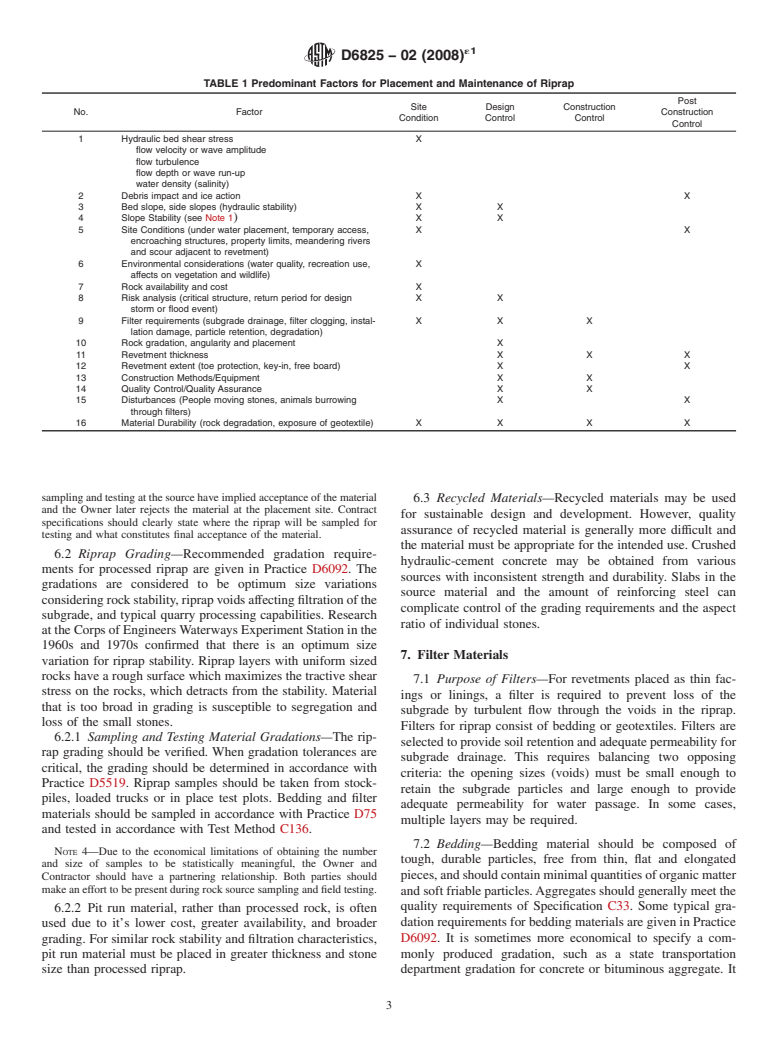

TABLE 1 Predominant Factors for Placement and Maintenance of Riprap

Post

Site Design Construction

No. Factor Construction

Condition Control Control

Control

1 Hydraulic bed shear stress X

flow velocity or wave amplitude

flow turbulence

flow depth or wave run-up

water density (salinity)

2 Debris impact and ice action X X

3 Bed slope, side slopes (hydraulic stability) X X

4 Slope Stability (see Note 1) XX

5 Site Conditions (under water placement, temporary access,XX

encroaching structures, property limits, meandering rivers

and scour adjacent to revetment)

6 Environmental considerations (water quality, recreation use, X

affects on vegetation and wildlife)

7 Rock availability and cost X

8 Risk analysis (critical structure, return period for design XX

storm or flood event)

9 Filter requirements (subgrade drainage, filter clogging, instal- XX X

lation damage, particle retention, degradation)

10 Rock gradation, angularity and placement X

11 Revetment thickness X X X

12 Revetment extent (toe protection, key-in, free board) X X

13 Construction Methods/Equipment X X

14 Quality Control/Quality Assurance X X

15 Disturbances (People moving stones, animals burrowing XX

through filters)

16 Material Durability (rock degradation, exposure of geotextile) X X X X

samplingandtestingatthesourcehaveimpliedacceptanceofthematerial

6.3 Recycled Materials—Recycled materials may be used

and the Owner later rejects the material at the placement site. Contract

for sustainable design and development. However, quality

specifications should clearly state where the riprap will be sampled for

assurance of recycled material is generally more difficult and

testing and what constitutes final acceptance of the material.

the material must be appropriate for the intended use. Crushed

6.2 Riprap Grading—Recommended gradation require-

hydraulic-cement concrete may be obtained from various

ments for processed riprap are given in Practice D6092. The

sources with inconsistent strength and durability. Slabs in the

gradations are considered to be optimum size variations

source material and the amount of reinforcing steel can

consideringrockstability,riprapvoidsaffectingfiltrationofthe

complicate control of the grading requirements and the aspect

subgrade, and typical quarry processing capabilities. Research

ratio of individual stones.

attheCorpsofEngineersWaterwaysExperimentStationinthe

1960s and 1970s confirmed that there is an optimum size

7. Filter Materials

variation for riprap stability. Riprap layers with uniform sized

rocks have a rough surface which maximizes the tractive shear

7.1 Purpose of Filters—For revetments placed as thin fac-

stress on the rocks, which detracts from the stability. Material

ings or linings, a filter is required to prevent loss of the

that is too broad in grading is susceptible to segregation and

subgrade by turbulent flow through the voids in the riprap.

loss of the small stones.

Filters for riprap consist of bedding or geotextiles. Filters are

6.2.1 Sampling and Testing Material Gradations—The rip-

selectedtoprovidesoilretentionandadequatepermeabilityfor

rap grading should be verified. When gradation tolerances are

subgrade drainage. This requires balancing two opposing

critical, the grading should be determined in accordance with

criteria: the opening sizes (voids) must be small enough to

Practice D5519. Riprap samples should be taken from stock-

retain the subgrade particles and large enough to provide

piles, loaded trucks or in place test plots. Bedding and filter

adequate permeability for water passage. In some cases,

materials should be sampled in accordance with Practice D75

multiple layers may be required.

and tested in accordance with Test Method C136.

7.2 Bedding—Bedding material should be composed of

NOTE 4—Due to the economical limitations of obtaining the number

tough, durable particles, free from thin, flat and elongated

and size of samples to be statistically meaningful, the Owner and

pieces,andshouldcontainminimalquantitiesoforganicmatter

Contractor should have a partnering relationship. Both parties should

makeanefforttobepresentduringrocksourcesa

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.