ASTM D6856/D6856M-23

(Guide)Standard Guide for Testing Fabric-Reinforced “Textile” Composite Materials

Standard Guide for Testing Fabric-Reinforced “Textile” Composite Materials

SIGNIFICANCE AND USE

4.1 This guide is intended to serve as a reference for the testing of textile composite materials.

4.2 The use of this guide ensures that proper consideration is given to the unique characteristics of these materials in testing. In addition, this guide also assists the user in selecting the best currently available ASTM test method for measurement of commonly evaluated material properties.

SCOPE

1.1 This guide is applicable to the testing of textile composites fabricated using fabric preforms, such as weaves, braids, stitched preforms, and so forth, as the reinforcement. The purpose of this guide is to:

1.1.1 Ensure that proper consideration is given to the unique characteristics of these materials in testing.

1.1.2 Assist the user in selecting the best currently available ASTM test method for the measurement of commonly evaluated material properties for this class of materials.

1.2 Areas where current ASTM test methods do not meet the needs for testing of textile composites are indicated.

1.3 It is not the intent of this guide to cover all test methods which could possibly be used for textile composites. Only the most commonly used and most applicable standards are included.

1.4 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system are not necessarily exact equivalents; therefore, to ensure conformance with the standard, each system shall be used independently of the other, and values from the two systems shall not be combined.

1.4.1 Within the text the inch-pound units are shown in brackets.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory requirements prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D6856/D6856M − 23

Standard Guide for

1

Testing Fabric-Reinforced “Textile” Composite Materials

This standard is issued under the fixed designation D6856/D6856M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

A variety of fabric-reinforced composite materials have been developed for use in aerospace,

automotive, civil, construction, and other applications. These composite materials are reinforced with

continuous fiber yarns that are formed into two-dimensional or three-dimensional fabrics. Various

fabric constructions, such as woven, braided, stitched, and so forth, can be used to form the fabric

reinforcement. Due to the nature of the reinforcement, these materials are often referred to as “textile”

composites.

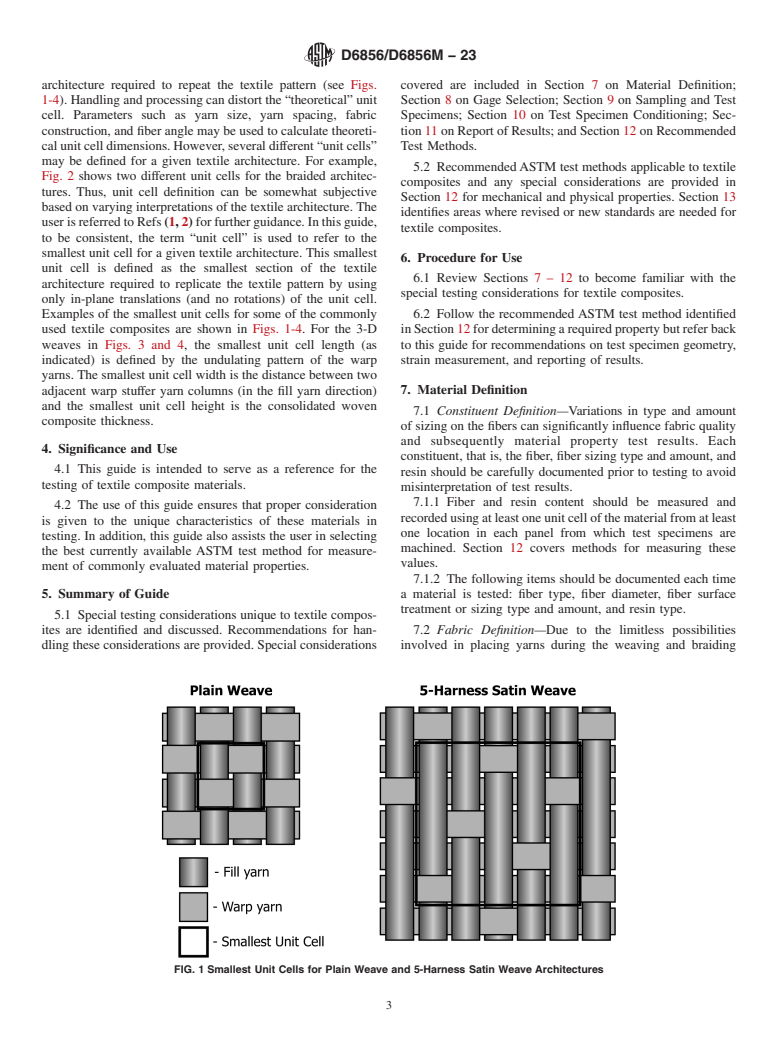

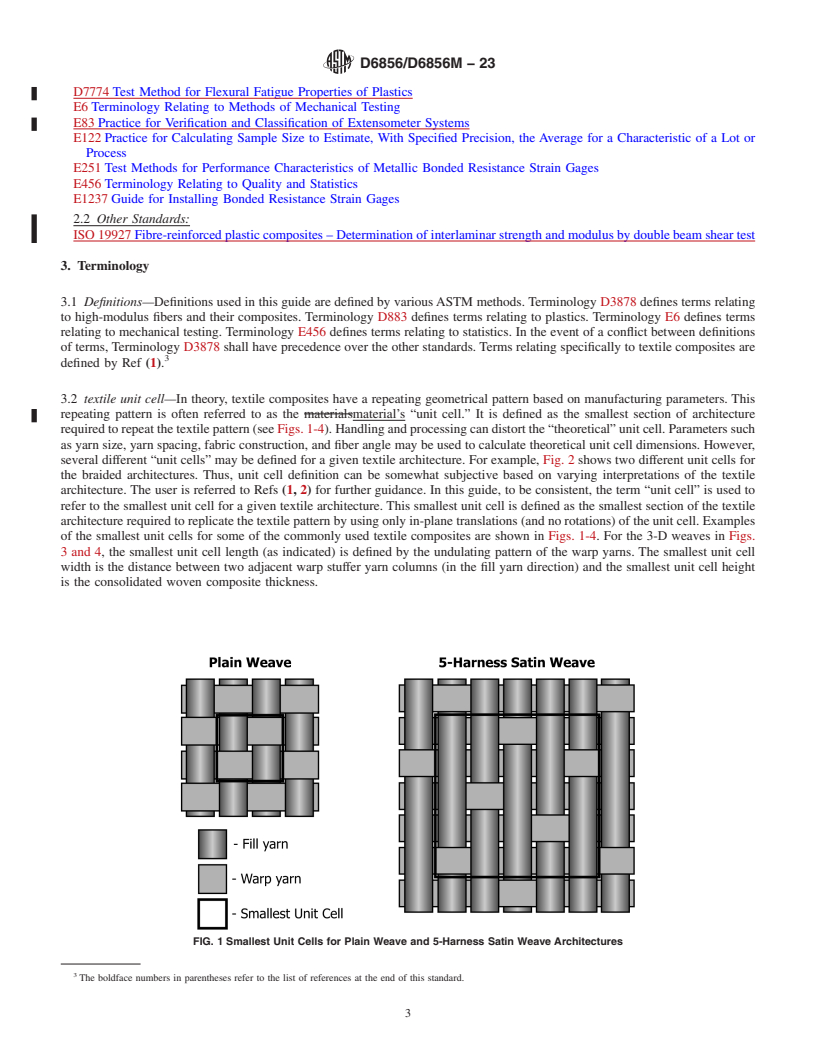

Textile composites can be fabricated from 2-dimensional (2-D) or 3-dimensional (3-D) fabrics.

Stitched preforms and 3-D fabrics contain through-thickness yarns, which can lead to greater

delamination resistance. Textile composites are also amenable to automated fabrication. However, the

microstructure (or fiber architecture) of a textile composite, which consists of interlacing yarns, can

lead to increased inhomogeneity of the local displacement fields in the laminate. Depending upon the

size of the yarns and the pattern of the weave or braid, the inhomogeneity within a textile composite

can be large compared to traditional tape laminates.

Thus, special care should be exercised in the use of the current ASTM standards developed for high

performance composites. In many cases, the current ASTM standards are quite adequate if proper

attention is given to the special testing considerations for textile composites covered in this guide.

However, in some cases, current standards do not meet the needs for testing of the required properties.

This guide is intended to increase the user’s awareness of the special considerations necessary for the

testing of these materials. It also provides the user with recommended ASTM standards that are

applicable for evaluating textile composites. The specific properties for which current ASTM

standards might not apply are also highlighted in this guide.

1. Scope 1.1.2 Assist the user in selecting the best currently available

ASTM test method for the measurement of commonly evalu-

1.1 This guide is applicable to the testing of textile com-

ated material properties for this class of materials.

posites fabricated using fabric preforms, such as weaves,

braids, stitched preforms, and so forth, as the reinforcement. 1.2 Areas where current ASTM test methods do not meet

The purpose of this guide is to: the needs for testing of textile composites are indicated.

1.1.1 Ensure that proper consideration is given to the unique

1.3 It is not the intent of this guide to cover all test methods

characteristics of these materials in testing.

which could possibly be used for textile composites. Only the

most commonly used and most applicable standards are

included.

1

This guide is under the jurisdiction of ASTM Committee D30 on Composite

Materials and is the direct responsibility of Subcommittee D30.04 on Lamina and

1.4 The values stated in either SI units or inch-pound units

Laminate Test Methods.

are to be regarded separately as standard. The values stated in

Current edition approved Nov. 1, 2023. Published November 2023. Originally

each system are not necessarily exact equivalents; therefore, to

approved in 2003. Last previous edition approved in 2016 as D6856 – 03 (2016).

DOI: 10.1520/D6856_D6856M-23. ensure conformance with the standard, each system shall be

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D6856/D6856M − 23

used independently of the other, and values from the two Strength of Polymer Matrix Composite Laminates

systems shall not be combined. D5961/D5961M Test Method for Bearing Response of Poly-

1.4.1 Within the text the inch-pound units are shown in mer Matrix Composite Laminates

brackets. D6115 Test Method for Mode I Fatigue Delamination

Growth Onset of Unidirectional Fiber-Reinforced Poly-

1.5 This standard does not purport to address all of the

mer Matrix Composites

safety concerns, if any, associated with its use. It is the

D6415/D6415M Test Method for Measuring the Curved

responsibility of the user of this standard to establish appro-

Beam Strength of a Fib

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D6856/D6856M − 03 (Reapproved 2016) D6856/D6856M − 23

Standard Guide for

1

Testing Fabric-Reinforced “Textile” Composite Materials

This standard is issued under the fixed designation D6856/D6856M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

A variety of fabric-reinforced composite materials have been developed for use in aerospace,

automotive, civil, construction, and other applications. These composite materials are reinforced with

continuous fiber yarns that are formed into two-dimensional or three-dimensional fabrics. Various

fabric constructions, such as woven, braided, stitched, and so forth, can be used to form the fabric

reinforcement. Due to the nature of the reinforcement, these materials are often referred to as “textile”

composites.

Textile composites can be fabricated from 2-dimensional (2-D) or 3-dimensional (3-D) fabrics.

Stitched preforms and 3-D fabrics contain through-thickness yarns, which can lead to greater

delamination resistance. Textile composites are also amenable to automated fabrication. However, the

microstructure (or fiber architecture) of a textile composite, which consists of interlacing yarns, can

lead to increased inhomogeneity of the local displacement fields in the laminate. Depending upon the

size of the yarns and the pattern of the weave or braid, the inhomogeneity within a textile composite

can be large compared to traditional tape laminates.

Thus, special care should be exercised in the use of the current ASTM standards developed for high

performance composites. In many cases, the current ASTM standards are quite adequate if proper

attention is given to the special testing considerations for textile composites covered in this guide.

However, in some cases, current standards do not meet the needs for testing of the required properties.

This guide is intended to increase the user’s awareness of the special considerations necessary for the

testing of these materials. It also provides the user with recommended ASTM standards that are

applicable for evaluating textile composites. The specific properties for which current ASTM

standards might not apply are also highlighted in this guide.

1. Scope

1.1 This guide is applicable to the testing of textile composites fabricated using fabric preforms, such as weaves, braids, stitched

preforms, and so forth, as the reinforcement. The purpose of this guide is to:

1.1.1 Ensure that proper consideration is given to the unique characteristics of these materials in testing.

1.1.2 Assist the user in selecting the best currently available ASTM test method for the measurement of commonly evaluated

material properties for this class of materials.

1.2 Areas where current ASTM test methods do not meet the needs for testing of textile composites are indicated.

1

This guide is under the jurisdiction of ASTM Committee D30 on Composite Materials and is the direct responsibility of Subcommittee D30.04 on Lamina and Laminate

Test Methods.

Current edition approved Sept. 1, 2016Nov. 1, 2023. Published September 2016November 2023. Originally approved in 2003. Last previous edition approved in 20032016

ɛ1

as D6856-03(2008)D6856 – 03 (2016). . DOI: 10.1520/D6856_D6856M-03R16.10.1520/D6856_D6856M-23.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D6856/D6856M − 23

1.3 It is not the intent of this guide to cover all test methods which could possibly be used for textile composites. Only the most

commonly used and most applicable standards are included.

1.4 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system may not beare not necessarily exact equivalents; therefore, to ensure conformance with the standard, each system shall be

used independently of the other. Combiningother, and values from the two systems may result in non-conformance with the

standard.shall not be combined.

1.4.1 Within the text the inch-pound units are shown in brackets.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and healthsafe

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.