ASTM F2094/F2094M-08

(Specification)Standard Specification for Silicon Nitride Bearing Balls

Standard Specification for Silicon Nitride Bearing Balls

ABSTRACT

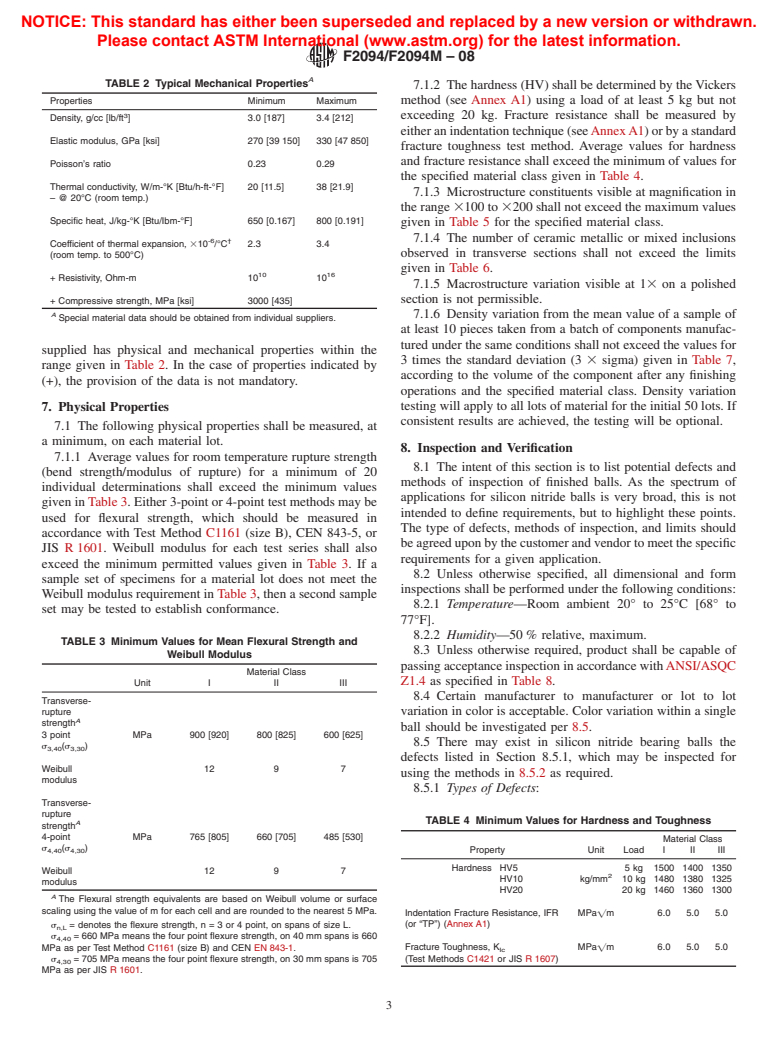

This specification covers the establishment of the basic quality, physical/mechanical property, and test requirements for silicon nitride balls Classes I, II, and III to be used for ball bearings and specialty ball applications. Silicon nitride balls should be produced from either silicon nitride powder having the compositional limits from silicon metal powder.

SCOPE

1.1 This specification covers the establishment of the basic quality, physical/mechanical property, and test requirements for silicon nitride balls Classes I, II, and III to be used for ball bearings and specialty ball applications.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with the specification.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

Designation: F2094/F2094M – 08

Standard Specification for

1

Silicon Nitride Bearing Balls

ThisstandardisissuedunderthefixeddesignationF2094/F2094M;thenumberimmediatelyfollowingthedesignationindicatestheyear

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope B 46.1 Surface Texture (Surface Roughness, Waviness, and

5

Lay)

1.1 This specification covers the establishment of the basic

2.6 ISO Standards:

quality, physical/mechanical property, and test requirements

4505 Hardmetals—Metallographic Determination of Poros-

for silicon nitride balls Classes I, II, and III to be used for ball

3

ity and Uncombined Carbon

bearings and specialty ball applications.

2.7 JIS Standards:

1.2 The values stated in either SI units or inch-pound units

R 1601 Testing Method for Flexural Strength (Modulus of

are to be regarded separately as standard. The values stated in

6

Rupture) of High Performance Ceramics

each system are not exact equivalents; therefore, each system

R 1607 Testing Method for Fracture Toughness of High

must be used independently of the other. Combining values

6

Performance Ceramics

from the two systems may result in nonconformance with the

2.8 CEN Standards:

specification.

EN 843-1 Advanced Technical Ceramics—Monolithic

2. Referenced Documents

Ceramics—Mechanical Properties at Room Temperature,

7

Part 1. Determination of Flexural Strength

2.1 Order of Precedence:

ENV 843-5 Advanced Technical Ceramics—Monolithic

2.1.1 In the event of a conflict between the test of this

Ceramics—Mechanical Properties at Room Temperature,

document and the references herein, the text of this document

7

Part 5, Statistical Analysis

takes precedence. Nothing in this document, however, super-

sedes applicable laws and regulations unless a specific exemp-

3. Terminology

tion has been obtained.

2

3.1 Definitions of Terms Specific to This Standard:

2.2 ASTM Standards:

3.1.1 ball diameter variation (Vdws)—ball diameter varia-

C1161 Test Method for Flexural Strength of Advanced

tion is the difference between the largest and smallest diameter

Ceramics at Ambient Temperature

measured on the same ball.

C1421 Test Methods for Determination of Fracture Tough-

3.1.2 ball gage (S)—prescribed small amount by which the

ness of Advanced Ceramics at Ambient Temperature

lot mean diameter should differ from nominal diameter, this

2.3 ANSI Standard:

amount being one of an established series of amounts. A ball

ANSI/ASQC Z1.4 Sampling Procedures and Tables for

3

gage, in combination with the ball grade and nominal ball

Inspection by Attributes

diameter, should be considered as the most exact ball size

2.4 ABMA Standards:

4

specification to be used by a customer for ordering purposes.

STD 10 Metal Balls

3.1.3 ball gage deviation (DS)—difference between the lot

2.5 ASME Standard:

mean diameter and the sum of the nominal diameter and the

ball gage.

1

ThisspecificationisunderthejurisdictionofASTMCommitteeF34onRolling

3.1.4 ball grade (G)—specific combination of dimensional

Element Bearings and is the direct responsibility of Subcommittee F34.01 on

form and surface roughness tolerances. A ball grade is desig-

Rolling Element.

nated by a grade number followed by the letter “C” indicating

Current edition approved Nov. 15, 2008. Published January 2009. Originally

´1

Silicon Nitride Ceramic.

approved in 2001. Last previous edition approved in 2006 as F2094–06 . DOI:

10.1520/F2094_F2094M-08.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

5

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Application for copies should be addressed to the American Society of

Standards volume information, refer to the standard’s Document Summary page on Mechanical Engineers (ASME), ASME International Headquarters, Three Park

the ASTM website. Ave., New York, NY 10016-5990, http://www.asme.org.

3 6

ApplicationforcopiesshouldbeaddressedtotheAmericanNationalStandards Application for copies should be addressed to the Japanese Standards Organi-

Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://

zation (JSA), 4-1-24 Akasaka Minato-Ku, Tokyo, 107-8440, Japan, http://

www.ansi.org. www.jsa.or.jp.

4 7

Application for copies should be addressed to theAmerican Bearing Manufac- Application for copies should be addressed to the British Standards Institute

turer’sAssociation, 1200 19th Street NW, Suite 300, Washington, DC 20036-2401. (BSI), 389 Chiswick High Rd., LondonW4 4AL, U.K., http://www.bsi-global.com.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ---------------------

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation:F2094–06 Designation: F 2094/F 2094M – 08

Standard Specification for

1

Silicon Nitride Bearing Balls

This standard is issued under the fixed designation F2094/F2094M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

1

reapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval. ´ NOTE—Table2waseditorially

corrected in June 2007.

1. Scope

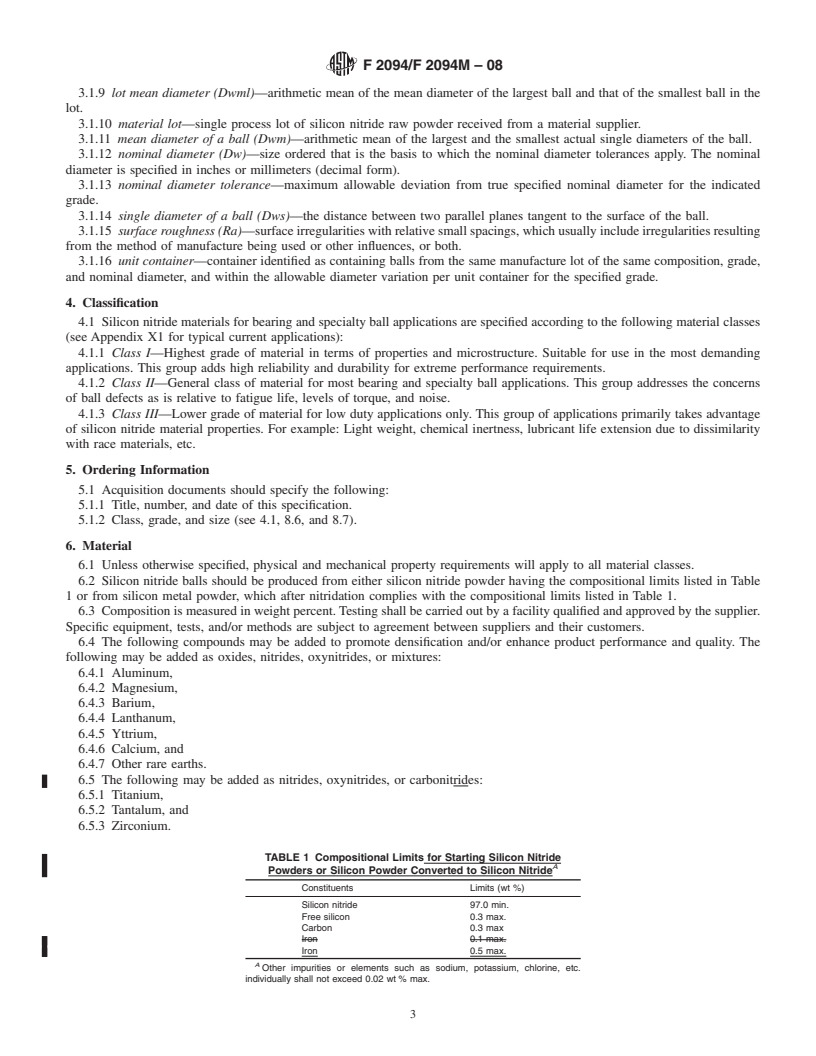

1.1 This specification covers the establishment of the basic quality, physical/mechanical property, and test requirements for

silicon nitride balls Classes I, II, and III to be used for ball bearings and specialty ball applications.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard.The values stated in each

system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two

systems may result in nonconformance with the specification.

2. Referenced Documents

2.1 Order of Precedence:

2.1.1 In the event of a conflict between the test of this document and the references herein, the text of this document takes

precedence. Nothing in this document, however, supersedes applicable laws and regulations unless a specific exemption has been

obtained.

2

2.2 ASTM Standards:

C373Test Method for Water Absorption, Bulk Density, Apparent Porosity, and Apparent Specific Gravity of Fired Whiteware

Products

C1161 Test Method for Flexural Strength of Advanced Ceramics at Ambient Temperature

C1198Test Method for Dynamic Young’s Modulus, Shear Modulus, and Poisson’s Ratio for Advanced Ceramics by Sonic

Resonance

C1239Practice for Reporting Uniaxial Strength Data and Estimating Weibull Distribution Parameters for Advanced Ceramics

C1327Test Method for Vickers Indentation Hardness of Advanced Ceramics

C1421 Test Methods for Determination of Fracture Toughness of Advanced Ceramics at Ambient Temperature

E165Test Method for Liquid Penetrant Examination

E384Test Method for Microindentation Hardness of Materials

E831Test Method for Linear Thermal Expansion of Solid Materials by Thermomechanical Analysis

E1417Practice for Liquid Penetrant Testing Test Methods for Determination of Fracture Toughness of Advanced Ceramics at

Ambient Temperature

2.3 ANSI Standard:

3

ANSI/ASQC Z1.4 Sampling Procedures and Tables for Inspection by Attributes

2.4 ABMA Standards:

STD 1Terminology for Anti-Friction Ball and Roller Bearings and Parts

4

STD 10 Metal Balls

2.5 ASME Standard:

5

B 46.1 Surface Texture (Surface Roughness, Waviness, and Lay)

2.6 DIN Standards:

1

This specification is under the jurisdiction of ASTM Committee F34 on Rolling Element Bearings and is the direct responsibility of Subcommittee F34.01 on Rolling

Element.

Current edition approved Nov. 1, 2006. Published December 2006. Originally approved in 2001. Last previous edition approved in 2003 as F2094–03a.

´1

Current edition approved Nov. 15, 2008. Published January 2009. Originally approved in 2001. Last previous edition approved in 2006 as F2094–06 .

2

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Application for copies should be addressed to the American National Standards Institute (ANSI), 25 WestW. 43rd Street,St., 4th Floor, New York, NY 10036,

http://www.ansi.org.

4

Application for copies should be addressed to the American Bearing Manufacturer’s Association, 1200 19th Street NW, Suite 300, Washington, DC 20036-2401.

5

Application for copies should be addressed to the American Society of Mechanical Engineers, 345 East Street, New York, NY 10017.

5

Application for copies should be addressed to theAmerican Society of Mechanical Engineers (ASME),ASME International Headquarters, Three ParkAve., NewYork,

NY 10016-5990, http://www.asme.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

F 2094/F 2094M – 08

5401Rolling Bearings; Balls of Through-Hardening Rolling Bearing Steel, Part 1

5401Rolling Bearings; Balls of Through-Hardening Rolling Bearing Steel, Part 2

2.7 ISO Standards:

3

3290Rolling Bearings, Bearing Parts, Balls for Rolling Bearings

3

4505 Hardmetals—Metallographic Determination of Porosity and Uncombined

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.