ASTM C1196-92(1997)

(Test Method)Standard Test Method for In Situ Compressive Stress Within Solid Unit Masonry Estimated Using Flatjack Measurements

Standard Test Method for In Situ Compressive Stress Within Solid Unit Masonry Estimated Using Flatjack Measurements

SCOPE

1.1 This test method covers the determination of the average compressive stress in existing unreinforced solid-unit masonry. This test method concerns the measurement of in-situ compressive stress in existing masonry by use of thin, bladder-like flatjack devices that are installed in saw cut mortar joints in the masonry wall. This test method provides a relatively non-destructive means of determining masonry properties in place.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact

ASTM International (www.astm.org) for the latest information.

Designation: C 1196 – 92 (Reapproved 1997)

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Test Method for

In Situ Compressive Stress Within Solid Unit Masonry

Estimated Using Flatjack Measurements

This standard is issued under the fixed designation C 1196; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Significance and Use

1.1 This test method covers the determination of the 4.1 Stress is applied as pressure over the area of the flatjack.

average compressive stress in existing unreinforced solid-unit In the case of multi-wythe masonry, stress is estimated only in

masonry. This test method concerns the measurement of in-situ the wythe in which the flatjack is inserted. Stress in other

compressive stress in existing masonry by use of thin, bladder- wythes may be different.

like flatjack devices that are installed in saw cut mortar joints

5. Apparatus

in the masonry wall. This test method provides a relatively

5.1 Flatjack:

non-destructive means of determining masonry properties in

5.1.1 A flatjack is a thin envelope-like bladder with inlet and

place.

1.2 The values stated in inch-pound units are to be regarded outlet ports which may be pressurized with hydraulic oil.

Flatjacks may be of any shape in plan, and are designed to be

as the standard. The values given in parentheses are for

information only. compatible with the masonry being tested. Typically configu-

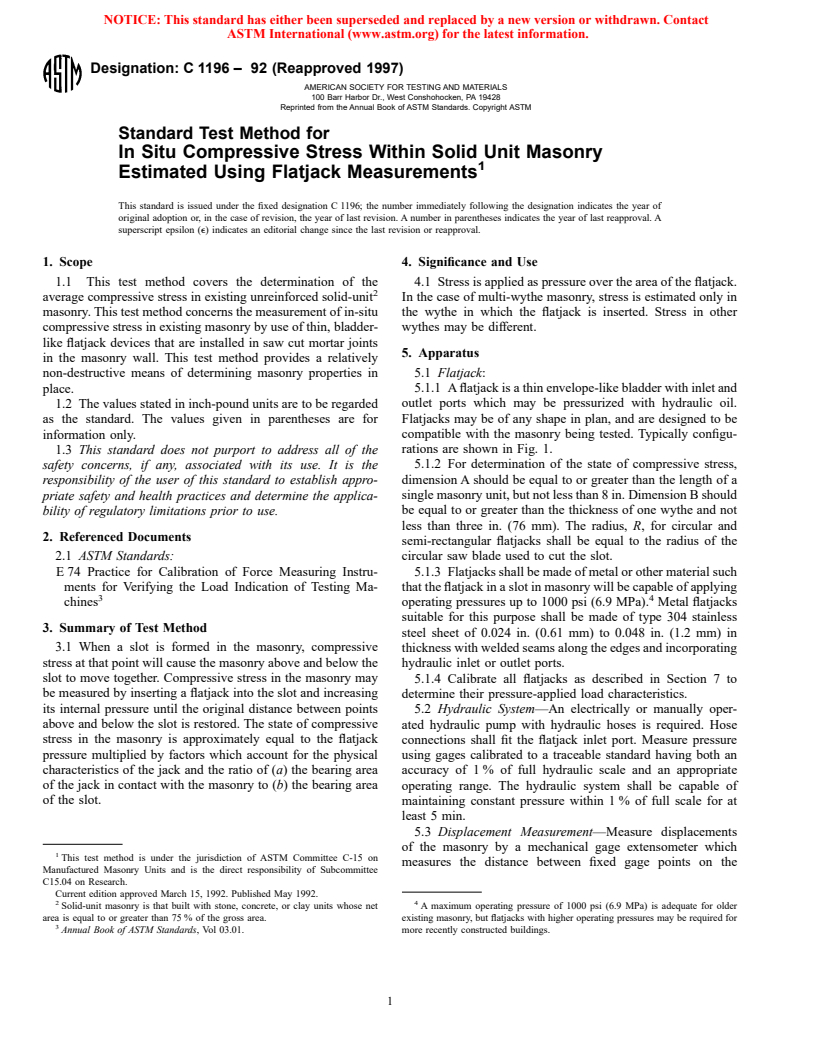

rations are shown in Fig. 1.

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the 5.1.2 For determination of the state of compressive stress,

dimension A should be equal to or greater than the length of a

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica- single masonry unit, but not less than 8 in. Dimension B should

be equal to or greater than the thickness of one wythe and not

bility of regulatory limitations prior to use.

less than three in. (76 mm). The radius, R, for circular and

2. Referenced Documents

semi-rectangular flatjacks shall be equal to the radius of the

2.1 ASTM Standards: circular saw blade used to cut the slot.

E 74 Practice for Calibration of Force Measuring Instru- 5.1.3 Flatjacks shall be made of metal or other material such

ments for Verifying the Load Indication of Testing Ma- that the flatjack in a slot in masonry will be capable of applying

3 4

chines operating pressures up to 1000 psi (6.9 MPa). Metal flatjacks

suitable for this purpose shall be made of type 304 stainless

3. Summary of Test Method

steel sheet of 0.024 in. (0.61 mm) to 0.048 in. (1.2 mm) in

3.1 When a slot is formed in the masonry, compressive

thickness with welded seams along the edges and incorporating

stress at that point will cause the masonry above and below the hydraulic inlet or outlet ports.

slot to move together. Compressive stress in the masonry may

5.1.4 Calibrate all flatjacks as described in Section 7 to

be measured by inserting a flatjack into the slot and increasing

determine their pressure-applied load characteristics.

its internal pressure until the original distance between points 5.2 Hydraulic System—An electrically or manually oper-

above and below the slot is restored. The state of compressive

ated hydraulic pump with hydraulic hoses is required. Hose

stress in the masonry is approximately equal to the flatjack connections shall fit the flatjack inlet port. Measure pressure

pressure multiplied by factors which account for the physical

using gages calibrated to a traceable standard having both an

characteristics of the jack and the ratio of (a) the bearing area accuracy of 1 % of full hydraulic scale and an appropriate

of the jack in contact with the masonry to (b) the bearing area

operating range. The hydraulic system shall be capable of

of the slot. maintaining constant pressure within 1 % of full scale for at

least 5 min.

5.3 Displacement Measurement—Measure displacements

of the masonry by a mechanical gage extensometer which

This test method is under the jurisdiction of ASTM Committee C-15 on

measures the distance between fixed gage points on the

Manufactured Masonry Units and is the direct responsibility of Subcommittee

C15.04 on Research.

Current edition approved March 15, 1992. Published May 1992.

2 4

Solid-unit masonry is that built with stone, concrete, or clay units whose net A maximum operating pressure of 1000 psi (6.9 MPa) is adequate for older

area is equal to or greater than 75 % of the gross area. existing masonry, but flatjacks with higher operating pressures may be required for

Annual Book of ASTM Standards, Vol 03.01. more recently constructed buildings.

NOTICE:¬This¬standard¬has¬either¬been¬superceded¬and¬replaced¬by¬a¬new¬version¬or¬discontinued.¬

Contact¬ASTM¬International¬(www.astm.org)¬for¬the¬latest¬information.¬

C 1196

6.3 Slots:

6.3.1 Rectangular slots into which rectangular flatjacks are

to be inserted may be formed by drilling adjacent or overlap-

ping holes (stitch drilling) and subsequently using a drill, bar,

or tool to remove mortar and produce a slot of desired

dimensions with smooth upper and lower surfaces.

6.3.2 Cut slots for circular and semi-rectangular flatjacks

using circular saws of sufficient radius to provide the depth

required (Fig. 1, dimension B). Use carbide or diamond tipped

blades to remove all mortar from the slot.

7. Calibration

7.1 A flatjack has an inherent stiffness which resists expan-

sion when the jack is pressurized. Therefore, the fluid pressure

in the flatjack is greater than the stress the flatjack applies to

masonry. A flatjack must be calibrated to provide a conversion

factor, K , to relate internal fluid pressure to stress applied.

m

7.2 Calibrate flatjacks in a compression machine of at least

100 kip capacity which has been calibrated according to

Practice E 74.

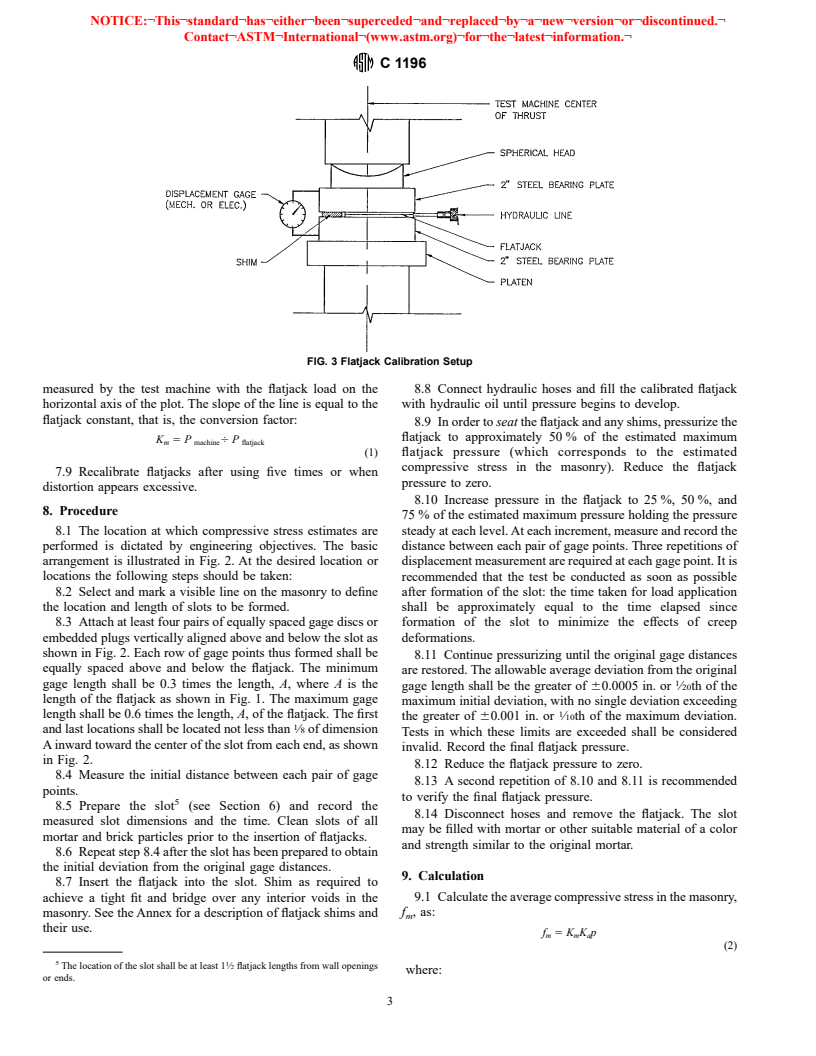

7.3 Place a 2 in. (50 mm) thick steel bearing plate on the

lower platen of the compression machine. The bearing plate

shall be of sufficient size to completely cover the flatjack being

FIG. 1 Flatjack Configurations

calibrated. Place the flatjack on the lower bearing plate such

that the edge of the flatjack with the inlet/outlet ports is

masonry as shown in Fig. 2. The method or device used to

coincident with the edge of the bearing plate. Place steel

measure deformations shall be capable of deformation mea-

spacers around the other edges of the flatjack. The thickness of

surements up to ⁄16 in. (5 mm). Deformation measurements

the spacers shall be equal to approximately 1 ⁄3 times the

shall have an accuracy of at least 60.005 % of gage length.

combined thickness of the two steel sheets used in fabrication.

5.4 Gage Points—Use adhered metal discs or embedded

Place the upper 2 in. (50 mm) thick bearing plate on top of the

metal inserts as gage points during the measurement process.

shims and flatjack, and align it to be directly above the lower

Attach gage points securely to the masonry (using a rigid

bearing plate. Position the bearing plate/flatjack/shim assembly

adhesive for discs or cementitious grout for plugs) which will

on the lower platen such that the centroid of the area of the

prevent movement and ensure the required measurement accu-

flatjack is within ⁄4 in. (6 mm) of the axis of thrust of the test

racy. The gage points shall have a conical depression at their

machine. The calibration setup is illustrated in Fig. 3.

center, compatible with the pointed elements of the extensom-

7.4 Raise the moveable platen such that the non-moveable

eter. The angles of the depression of the cone and the

platen is in contact with the top bearing plate. Apply a pre-load

extensometer points shall be the same.

sufficient to provide full contact between the bearing plates and

the spacers, equivalent to 10 psi over the gross area of the

6. Preparation of Slots

flatjack.

6.1 Slots in masonry are normally prepared by removing the

7.5 The distance between platens must be held constant

mortar from masonry bed joints to avoid disfiguring the

during the calibration procedure. Fix the displacement of the

masonry. Remove all mortar in the bed joint, so that pressure

test machine at this point if using a displacement controllable

exerted by a flatjack shall be directly against the cleaned

machine. If not, attach displacement gages (mechanical or

surfaces of the masonry units.

electrical) such that the distance between platens established by

6.2 The plan geometry of the slot shall be similar to that of

the procedures of paragraph 7.4 can be held constant when

the flatjack being used. Plan dimensions of the prepared slot

using a force-control test machine.

shall not exceed those of the flatjack by more than ⁄2 in. (12

7.6 Pressurize and depressurize the flatjack three cycles

mm).

with the maximum pressure in the flatjack not to exceed 1000

psi (2.069 MN/m ) nor the stress applied to the flatjack by the

compression machine to exceed 1000 psi (2.069 MN/m ) based

on the gross area of the flatjack.

7.7 Increase the pressure in the flatjack in 50 to 100 psi

(344.8 to 689.5 KN/m ) increments up to 1000 psi 6 50 psi

2 2

(6.895 MN/m 6 344.8 KN/m ) while holding the distance

between platens constant. At each increment, record flatjack

hydraulic pressure and force measured by the test machine.

7.8 Calculate the load applied by the flatjack as internal

FIG. 2 Flatjack Test Setup for In Situ Stress Measurement pressure times gross flatjack area. Plot flatjack load versus load

NOTICE:¬This¬standard¬has¬either¬been¬superceded¬and¬replaced¬by¬a¬new¬version¬or¬discontinued.¬

Contact¬ASTM¬International¬(www.astm.org)¬for¬the¬latest¬information.¬

C 1196

FIG. 3 Flatjack

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.