ASTM E96/E96M-14

(Test Method)Standard Test Methods for Water Vapor Transmission of Materials

Standard Test Methods for Water Vapor Transmission of Materials

SIGNIFICANCE AND USE

5.1 The purpose of these tests is to obtain, by means of simple apparatus, reliable values of water vapor transfer through permeable and semipermeable materials, expressed in suitable units. These values are for use in design, manufacture, and marketing. A permeance value obtained under one set of test conditions may not indicate the value under a different set of conditions. For this reason, the test conditions should be selected that most closely approach the conditions of use. While any set of conditions may be used and those conditions reported, standard conditions that have been useful are shown in Appendix X1.

SCOPE

1.1 These test methods cover the determination of water vapor transmission (WVT) of materials through which the passage of water vapor may be of importance, such as paper, plastic films, other sheet materials, fiberboards, gypsum and plaster products, wood products, and plastics. The test methods are limited to specimens not over 11/4 in. [32 mm] in thickness except as provided in Section 9. Two basic methods, the Desiccant Method and the Water Method, are provided for the measurement of permeance, and two variations include service conditions with one side wetted and service conditions with low humidity on one side and high humidity on the other. Agreement should not be expected between results obtained by different methods. The method should be selected that more nearly approaches the conditions of use.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard. However, derived results can be converted from one system to the other using appropriate conversion factors (see Table 1). (A) These units are used in the construction trade. Other units may be used in other standards.(B) All conversions of mm Hg to Pa are made at a temperature of 0°C.

1.3 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

- Status

- Historical

- Publication Date

- 14-Oct-2014

- Technical Committee

- C16 - Thermal Insulation

- Drafting Committee

- C16.33 - Insulation Finishes and Moisture

- Current Stage

Relations

- Effective Date

- 15-Oct-2014

- Effective Date

- 01-May-2015

- Effective Date

- 15-Oct-2014

- Effective Date

- 15-Oct-2014

- Effective Date

- 15-Oct-2014

- Effective Date

- 15-Oct-2014

- Effective Date

- 15-Oct-2014

- Effective Date

- 15-Oct-2014

- Effective Date

- 15-Oct-2014

- Effective Date

- 15-Oct-2014

- Referred By

ASTM D5456-21e1 - Standard Specification for Evaluation of Structural Composite Lumber Products - Effective Date

- 15-Oct-2014

- Effective Date

- 15-Oct-2014

- Effective Date

- 15-Oct-2014

- Effective Date

- 15-Oct-2014

- Referred By

ASTM C755-20 - Standard Practice for Selection of Water Vapor Retarders for Thermal Insulation - Effective Date

- 15-Oct-2014

ASTM E96/E96M-14 - Standard Test Methods for Water Vapor Transmission of Materials

REDLINE ASTM E96/E96M-14 - Standard Test Methods for Water Vapor Transmission of Materials

Frequently Asked Questions

ASTM E96/E96M-14 is a standard published by ASTM International. Its full title is "Standard Test Methods for Water Vapor Transmission of Materials". This standard covers: SIGNIFICANCE AND USE 5.1 The purpose of these tests is to obtain, by means of simple apparatus, reliable values of water vapor transfer through permeable and semipermeable materials, expressed in suitable units. These values are for use in design, manufacture, and marketing. A permeance value obtained under one set of test conditions may not indicate the value under a different set of conditions. For this reason, the test conditions should be selected that most closely approach the conditions of use. While any set of conditions may be used and those conditions reported, standard conditions that have been useful are shown in Appendix X1. SCOPE 1.1 These test methods cover the determination of water vapor transmission (WVT) of materials through which the passage of water vapor may be of importance, such as paper, plastic films, other sheet materials, fiberboards, gypsum and plaster products, wood products, and plastics. The test methods are limited to specimens not over 11/4 in. [32 mm] in thickness except as provided in Section 9. Two basic methods, the Desiccant Method and the Water Method, are provided for the measurement of permeance, and two variations include service conditions with one side wetted and service conditions with low humidity on one side and high humidity on the other. Agreement should not be expected between results obtained by different methods. The method should be selected that more nearly approaches the conditions of use. 1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard. However, derived results can be converted from one system to the other using appropriate conversion factors (see Table 1). (A) These units are used in the construction trade. Other units may be used in other standards.(B) All conversions of mm Hg to Pa are made at a temperature of 0°C. 1.3 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

SIGNIFICANCE AND USE 5.1 The purpose of these tests is to obtain, by means of simple apparatus, reliable values of water vapor transfer through permeable and semipermeable materials, expressed in suitable units. These values are for use in design, manufacture, and marketing. A permeance value obtained under one set of test conditions may not indicate the value under a different set of conditions. For this reason, the test conditions should be selected that most closely approach the conditions of use. While any set of conditions may be used and those conditions reported, standard conditions that have been useful are shown in Appendix X1. SCOPE 1.1 These test methods cover the determination of water vapor transmission (WVT) of materials through which the passage of water vapor may be of importance, such as paper, plastic films, other sheet materials, fiberboards, gypsum and plaster products, wood products, and plastics. The test methods are limited to specimens not over 11/4 in. [32 mm] in thickness except as provided in Section 9. Two basic methods, the Desiccant Method and the Water Method, are provided for the measurement of permeance, and two variations include service conditions with one side wetted and service conditions with low humidity on one side and high humidity on the other. Agreement should not be expected between results obtained by different methods. The method should be selected that more nearly approaches the conditions of use. 1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard. However, derived results can be converted from one system to the other using appropriate conversion factors (see Table 1). (A) These units are used in the construction trade. Other units may be used in other standards.(B) All conversions of mm Hg to Pa are made at a temperature of 0°C. 1.3 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

ASTM E96/E96M-14 is classified under the following ICS (International Classification for Standards) categories: 77.040.99 - Other methods of testing of metals. The ICS classification helps identify the subject area and facilitates finding related standards.

ASTM E96/E96M-14 has the following relationships with other standards: It is inter standard links to ASTM E96/E96M-13, ASTM E96/E96M-15, ASTM E2556/E2556M-10(2022), ASTM F3510-21, ASTM E2321-03(2019), ASTM F2733-21, ASTM F3299-18(2023), ASTM C1290-16(2021), ASTM C1668-20, ASTM C1126-19, ASTM D5456-21e1, ASTM D3833/D3833M-96(2019), ASTM C1396/C1396M-17, ASTM C727-19, ASTM C755-20. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ASTM E96/E96M-14 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E96/E96M − 14

StandardTest Methods for

Water Vapor Transmission of Materials

This standard is issued under the fixed designation E96/E96M; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope E177Practice for Use of the Terms Precision and Bias in

ASTM Test Methods

1.1 These test methods cover the determination of water

D449Specification for Asphalt Used in Dampproofing and

vapor transmission (WVT) of materials through which the

Waterproofing

passage of water vapor may be of importance, such as paper,

D2301Specification for Vinyl Chloride Plastic Pressure-

plastic films, other sheet materials, fiberboards, gypsum and

Sensitive Electrical Insulating Tape

plasterproducts,woodproducts,andplastics.Thetestmethods

E691Practice for Conducting an Interlaboratory Study to

are limited to specimens not over 1 ⁄4 in. [32 mm] in thickness

except as provided in Section 9. Two basic methods, the Determine the Precision of a Test Method

Desiccant Method and the Water Method, are provided for the

measurementofpermeance,andtwovariationsincludeservice

3. Terminology

conditions with one side wetted and service conditions with

3.1 Definitions of terms used in this standard will be found

low humidity on one side and high humidity on the other.

in Terminology C168, from which the following is quoted:

Agreementshouldnotbeexpectedbetweenresultsobtainedby

“water vapor permeability—the time rate of water vapor

different methods. The method should be selected that more

transmissionthroughunitareaofflatmaterialofunitthickness

nearly approaches the conditions of use.

inducedbyunitvaporpressuredifferencebetweentwospecific

1.2 The values stated in either SI units or inch-pound units

surfaces, under specified temperature and humidity conditions.

are to be regarded separately as standard. The values stated in

Discussion—Permeabilityisapropertyofamaterial,butthe

each system may not be exact equivalents; therefore, each

permeability of a body that performs like a material may be

system shall be used independently of the other. Combining

used. Permeability is the arithmetic product of permeance and

values from the two systems may result in non-conformance

with the standard. However, derived results can be converted thickness.

from one system to the other using appropriate conversion

water vapor permeance—the time rate of water vapor

factors (see Table 1).

transmission through unit area of flat material or construction

1.3 This standard does not purport to address all of the inducedbyunitvaporpressuredifferencebetweentwospecific

safety problems, if any, associated with its use. It is the

surfaces, under specified temperature and humidity conditions.

responsibility of the user of this standard to establish appro-

Discussion—Permeanceisaperformanceevaluationandnot

priate safety and health practices and determine the applica-

a property of a material.

bility of regulatory limitations prior to use.

3.2 water vapor transmission rate—the steady water vapor

2. Referenced Documents

flowinunittimethroughunitareaofabody,normaltospecific

2.1 ASTM Standards: parallel surfaces, under specific conditions of temperature and

C168Terminology Relating to Thermal Insulation

humidity at each surface.”

These test methods are under the jurisdiction of ASTM Committee C16 on

4. Summary of Test Methods

Thermal Insulation and are the direct responsibility of Subcommittee C16.33 on

Insulation Finishes and Moisture.

4.1 In the Desiccant Method the test specimen is sealed to

Current edition approved Oct. 15, 2014. Published January 2015. Originally

the open mouth of a test dish containing a desiccant, and the

approved in 1953. Last previous edition approved in 2013 as E96–13. DOI:

assembly placed in a controlled atmosphere. Periodic weigh-

10.1520/E0096_E0096M-14.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

ings determine the rate of water vapor movement through the

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

specimen into the desiccant.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E96/E96M − 14

A,B

TABLE 1 Metric Units and Conversion Factors

limited to about 10 to 12%. For a thick specimen the ledge

To Obtain (for the

should not exceed ⁄4 in. [19 mm] for a 10-in. [254-mm] or

Multiply by

same test condition)

larger mouth (square or circular) or ⁄8 in. [3 mm] for a 5-in.

WVT

[127-mm] mouth (square or circular). For a 3-in. [76-mm]

2 2

g/h·m 1.43 grains/h·ft

2 2

mouth (square or circular) the ledge should not exceed 0.11 in.

grains/h·ft 0.697 g/h·m

Permeance

[2.8 mm] wide. An allowable ledge may be interpolated for

2 7

g/Pa·s·m 1.75 × 10 1 Perm (inch-pound)

intermediate sizes or calculated according to Joy and Wil-

−8 2

1 Perm (inch-pound) 5.72 × 10 g/Pa·s·m

son.(1)Arim around the ledge (Fig. X2.1) may be useful. If a

Permeability

g/Pa·s·m 6.88 × 10 1 Perm inch

rim is provided, it shall be not more than ⁄4 in. [6 mm] higher

−9

1 Perm inch 1.45 × 10 g/Pa·s·m

than the specimen as attached. Different depths may be used

A

These units are used in the construction trade. Other units may be used in other 3

for the Desiccant Method and Water Method, but a ⁄4-in.

standards.

B

[19-mm] depth (below the mouth) is satisfactory for either

All conversions of mm Hg to Pa are made at a temperature of 0°C.

method.

6.2 Test Chamber—The room or cabinet where the as-

4.2 In the Water Method, the dish contains distilled water, sembled test dishes are to be placed shall have a controlled

temperature (see Note 1) and relative humidity. Some standard

and the weighings determine the rate of vapor movement

through the specimen from the water to the controlled atmo- testconditionsthathavebeenusefularegiveninAppendixX1.

The temperature chosen shall be determined according to the

sphere.The vapor pressure difference is nominally the same in

both methods except in the variation, with extremes of humid- desired application of the material to be tested (see Appendix

X1). The relative humidity shall be maintained at 50 62%,

ity on opposite sides.

except where extremes of humidities are desired, when the

5. Significance and Use

conditions shall be 100 6 1.8°F [38 6 1°C] and 90 6 2%

relativehumidity.Bothtemperatureandrelativehumidityshall

5.1 The purpose of these tests is to obtain, by means of

be measured frequently or preferably recorded continuously.

simple apparatus, reliable values of water vapor transfer

Air shall be continuously circulated throughout the chamber,

through permeable and semipermeable materials, expressed in

with a velocity sufficient to maintain uniform conditions at all

suitable units.These values are for use in design, manufacture,

test locations. The air velocity over the specimen shall be

and marketing. A permeance value obtained under one set of

-1

between 0.066 and 1 ft/s [0.02 and 0.3 m·s ]. Suitable racks

test conditions may not indicate the value under a different set

shall be provided on which to place the test dishes within the

of conditions. For this reason, the test conditions should be

test chamber.

selected that most closely approach the conditions of use.

While any set of conditions may be used and those conditions

NOTE 1—Simple temperature control by heating alone is usually made

reported, standard conditions that have been useful are shown

possible at 90°F [32°C]. However, it is very desirable to enter the

in Appendix X1. controlled space, and a comfortable temperature is more satisfactory for

thatarrangement.Temperaturesof73.4°F[23°C]and80°F[26.7°C]arein

use and are satisfactory for this purpose. With cyclic control, the average

6. Apparatus

test temperature may be obtained from a sensitive thermometer in a mass

6.1 Test Dish—The test dish shall be of any noncorroding

ofdrysand.Thetemperatureofthechamberwallsfacingaspecimenover

material, impermeable to water or water vapor. It may be of watershouldnotbecoolerthanthewatertoavoidcondensationonthetest

specimen.

any shape. Light weight is desirable. A large, shallow dish is

preferred,butitssizeandweightarelimitedwhenananalytical

6.3 Balance and Weights—The balance shall be sensitive to

balanceischosentodetectsmallweightchanges.Themouthof

a change smaller than 1% of the weight change during the

thedishshallbeaslargeaspracticalandatleast4.65in. [3000

period when a steady state is considered to exist. The weights

mm ]. The desiccant or water area shall be not less than the

used shall be accurate to 1% of the weight change during the

mouth area except if a grid is used, as provided in 12.1, its

steady-state period (Note 2). A light wire sling may be

effective area shall not exceed 10% of the mouth area. An

substituted for the usual pan to accommodate a larger and

external flange or ledge around the mouth, to which the

heavier load.

specimenmaybeattached,isusefulwhenshrinkingorwarping

6.4 Thickness-Measuring Gage—The nominal thickness of

occurs. When the specimen area is larger than the mouth area,

the specimen shall be determined using a thickness-measuring

this overlay upon the ledge is a source of error, particularly for

gage with an accuracy of 61% of the reading or 0.0001 in.

thick specimens. This overlay material should be masked as

[0.0025 mm], whichever is greater.

described in 10.1 so that the mouth area defines the test area.

-1 -1 -2

NOTE 2—For example: 1-perm [57 ng·Pa ·s ·m ] specimen 10 in.

The overlay material results in a positive error, indicating

[254 mm] square at 80°F [26.7°C] passes 8.6 grains or 0.56 g/day. In 18

excessivewatervaportransmission.Themagnitudeoftheerror days of steady state, the transfer is 10 g. For this usage, the balance must

haveasensitivityof1%of10gor0.1gandtheweightsmustbeaccurate

is a complex function of the thickness, ledge width, mouth

to 0.1 g. If, however, the balance has a sensitivity of 0.2 g or the weights

area, and possibly the permeability. This error is discussed by

are no better than 0.2 g, the requirements of this paragraph can be met by

Joy and Wilson (1) (see 13.4.3). This type of error should be

3 4

Theboldfacenumbersinparenthesesrefertothelistofreferencesattheendof The minimum acceptable is to perform this measurement each time the sample

this standard. is weighed.

E96/E96M − 14

continuingthesteadystatefor36days.Ananalyticalbalancethatismuch

maximum pit depths in both its faces, and its tested permeance

-2 -1 -1

more sensitive will permit more rapid results on specimens below 1 perm

shall be not greater than 5 perms [≈ 300 ng·m ·s ·Pa ].

-1 -1 -2

[57 ng·Pa ·s ·m ] when the assembled dish is not excessively heavy.

9.5 For homogeneous (not laminated) materials with thick-

7. Materials ness greater than ⁄2 in., the overall nominal thickness of each

specimen shall be measured with an accuracy of 61%ofthe

7.1 Desiccant and Water:

readingatthecenterofeachquadrantandtheresultsaveraged.

7.1.1 For the Desiccant Method, anhydrous calcium chlo-

ride in the form of small lumps that will pass a No. 8 9.6 When testing any material with a permeance less than

-2 -1 -1

[2.36-mm] sieve, and free of fines that will pass a No. 30 0.05perms[3ng·m ·s ·Pa ]orwhentestingalowpermeance

[600-µm] sieve, shall be used (Note 3). It shall be dried at material that may be expected to lose or gain weight through-

400°F [200°C] before use.

outthetest(becauseofevaporationoroxidation),itisstrongly

recommended that an additional specimen, or “dummy,” be

NOTE 3—If CaCl will react chemically on the specimen, an adsorbing

tested exactly like the others, except that no desiccant or water

desiccant such as silica gel, activated at 400°F [200°C], may be used; but

is put in the dish. Failure to use this dummy specimen to

the moisture gain by this desiccant during the test must be limited to 4%.

establish modified dish weights may significantly increase the

7.1.2 For the Water Method, distilled water shall be used in

time required to complete the test. Because time to reach

the test dish.

equilibrium of water permeance increases as the square of

7.2 Sealant—The sealant used for attaching the specimen to

thickness, thick, particularly hygroscopic, materials may take

thedish,inordertobesuitableforthispurpose,mustbehighly

as long as 60 days to reach equilibrium conditions.

resistant to the passage of water vapor (and water). It must not

lose weight to, or gain weight from, the atmosphere in an

10. Attachment of Specimen to Test Dish

amount, over the required period of time, that would affect the

10.1 Attach the specimen to the dish by sealing (and

test result by more than 2%. It must not affect the vapor

clamping if desired) in such a manner that the dish mouth

pressure in a water-filled dish. Molten asphalt or wax is

-2 defines the area of the specimen exposed to the vapor pressure

required for permeance tests below 4 perms [230 ng·m ·

-1 -1 in the dish. If necessary, mask the specimen top surface,

s ·Pa ]. Sealing methods are discussed in Appendix X2.

exposed to conditioned air so that its exposure duplicates the

mouth shape and size and is directly above it. A template is

8. Sampling

recommendedforlocatingthemask.Thoroughlysealtheedges

8.1 The material shall be sampled in accordance with

of the specimen to prevent the passage of vapor into, or out of,

standard methods of sampling applicable to the material under

oraroundthespecimenedgesoranyportionthereof.Thesame

test. The sample shall be of uniform thickness. If the material

assurancemustapplytoanypartofthespecimenfacesoutside

is of nonsymmetrical construction, the two faces shall be

their defined areas. Suggested methods of attachment are

designated by distinguishing marks (for example, on a one-

described in Appendix X2.

side-coated sample, “I” for the coated side and “II” for the

NOTE 4—In order to minimize the risk of condensation on the interior

uncoated side).

surface of the sample when it is placed in the chamber, the temperature of

the water prior to preparation of the test specimen should be within 62°F

9. Test Specimens

[61°C] of the test condition.

9.1 Test specimens shall be representative of the material

tested.Whenaproductisdesignedforuseinonlyoneposition, 11. Procedure for Desiccant Method

three specimens shall be tested by the same method with the

11.1 Fill the test dish with desiccant within ⁄4 in. [6 mm] of

vapor flow in the designated direction. When the sides of a

the specimen. Leave enough space so that shaking of the dish,

product are indistinguishable, three specimens shall be tested

which must be done at each weighing, will mix the desiccant.

by the same method. When the sides of a product are different

11.2 Attach the specimen to the dish (see 10.1) and place it

andeithersidemayfacethevaporsource,fourspecimensshall

in the controlled chamber, specimen up, weighing it at once.

be tested by the same method, two being tested with the vapor

(This weight may be helpful to an understanding of the initial

flow in each direction and so reported.

moisture in the specimen.)

9.2 A slab, produced and used as a laminate (such as a

11.3 Weigh the dish assembly periodically, often enough to

foamed plastic with natural “skins”) may be tested in the

provide eight or ten data points during the test.Adata point is

thickness of use. Alternatively, it may be sliced into two or

theweightataparticulartime.Thetimethattheweightismade

more sheets, each being separately tested and so reported as

should be recorded to a precision of approximately 1% of the

provided in 9.4, provided also, that the “overlay upon the cup

timespanbetweensuccessiveweighing.Thus,ifweighingsare

ledge” (6.1) of any laminate shall not exceed ⁄8 in. [3 mm].

made every hour, record the time to the nearest 30 s; if

9.3 When the material as used has a pitted or textured

recordings are made every day, a time to the nearest 15 min

surface, the tested thickness shall be that of use. When it is

wouldbeallowed.Atfirsttheweightmaychangerapidly;later

homogeneous, however, a thinner slice of the slab may be

a steady state will be reached where the rate of change is

tested as provided in 9.4.

substantially constant. Weighings should be accomplished

9.4 Ineithercase(9.2or9.3),thetestedoverallthickness,if without removal of the test dishes from the controlled

less than that of use, shall be at least five times the sum of the atmosphere,butifremovalisprescribednecessary,thetimethe

E96/E96M − 14

specimens are kept at different conditions, temperature or dummy specimen is strongly recommended. Such a dummy

relativehumidity,orboth,shouldbekepttoaminimum.When specimen should be attached to an empty cup in the normal

resultsofwatervaportransmissionareexpectedtobelessthan manner. The environment effects of temperature variation and

-2 -1 -1

0.05 perm [3 ng·m ·s ·Pa ], a dummy specimen is strongly buoyancyvariabilityduetobarometricpressurefluctuationcan

recommended. Such a dummy specimen should be attached to be arithmetically tared out of the weighing values. This

an empty cup in the normal manner.The environmental effects precaution permits earlier and more reliable achievement of

of temperature variation and buoyancy variability due to equilibrium conditions. Analyze the results as prescribed in

barometric pressure fluctuation can be arithmetically tared out 13.1.

of the weighing values. This precaution permits earlier and

12.4 Where water is expected to be in contact with the

more reliable achievement of equilibrium conditions. Analyze

barrierinservice,proceedasin11.3exceptplacethedishinan

the results as prescribed in 13.1.

inverted position. The dish must be sufficiently level so that

11.4 Terminate the test or change the desiccant before the water covers the inner surface of the specimen despite any

water added to the desiccant exceeds 10% of its starting distortion of the specimen due to the weight of the water.With

weight.Thislimitcannotbeexactlydeterminedandjudgement highlypermeablespecimensitisespeciallyimportanttolocate

is required. The desiccant gain may be more or less than the the test dish so that air circulates over the exposed surface at

dish weight-gain when the moisture content of the specimen

the specified velocity. The test dishes may be placed on the

has changed. balance in the upright position for weighing, but the period

duringwhichthewettedsurfaceofthespecimenisnotcovered

NOTE 5—The WVT of some materials (especially wood) may depend

with water must be kept to a minimum.

ontheambientrelativehumidityimmediatelybeforethetest.Anapparent

hysteresis results in higher WVT if the prior relative humidity was above

the test condition and vice versa. It is therefore recommended that

13. Calculation and Analysis of Results

specimens of wood and paper products be conditioned to constant weight

13.1 Theresultsoftherateofwatervaportransmissionmay

in a 50% relative humidity atmosphere before they are tested. Some

specimens may be advantageously preconditioned to minimize the mois-

be determined either graphically or numerically.

turethatthespecimenwillgiveuptothedesiccant.Thisapplieswhenthe

13.1.1 Dummy Specimen—If a dummy specimen has been

specimen is likely to have high moisture content or when it is coated on

used to compensate for variability in test conditions, due to

the top (vapor source) side.

temperature or barometric pressure, or both, the daily recorded

weightscanbeadjustedbycalculatingtheweightchangefrom

12. Procedure for Water Method

initial to time of weighing. This adjustment is made by

3 1

12.1 Fill the test dish with distilled water to a level ⁄4 6 ⁄4

reversingthedirectionofthedummy’sweightchange,relative

in.[19 66mm]fromthespecimen.Theairspacethusallowed

toitsinitialweight,andmodifyingalltheappropriatespecimen

has a small vapor resistance, but it is necessary in order to

weight(s) recorded at this time. This permits earlier achieve-

reduce the risk of water touching the specimen when the dish

ment of equilibrium conditions. An alternate procedure, par-

is handled. Such contact invalidates a test on some materials

ticular for tests of long duration and more than six weighings,

suchaspaper,wood,orotherhygroscopicmaterials.Thewater

is to subtract the arithmetic mean slope of the rate of weight

depthshallbenotlessthan ⁄8in.[3mm]toensurecoverageof

changeofthedummyspecimenfromthearithmeticmeanslope

the dish bottom throughout the test. However, if the dish is of

of each similar specimen to get an effective rate of weight

glass, its bottom must be visibly covered at all times but no

change. These procedures are also desirable if the specimen is

specific depth is required. Water surges may be reduced by

changing weight due to a curing process while under test.

placing a grid of light noncorroding material in the dish to

13.1.2 Graphic Analysis—Plot the weight, modified by the

breakthewatersurface.Thisgridshallbeatleast ⁄4in.[6mm]

dummy specimen when used, against elapsed time, and in-

below the specimen, and it shall not reduce the water surface

scribe a curve that tends to become straight. Judgment here is

by more than 10%.

required and numerous points are helpful.When a straight line

NOTE 6—For the Water Method, baking the empty dish and promptly

adequately fits the plot of at least six properly spaced points

coating its mouth with sealant before assembly is recommended. The

(periodic weight changes matching, or exceeding 20% of the

water may be added most conveniently after the specimen is attached,

multiple of 100 times the scale sensitivity), a nominally steady

through a small sealable hole in the dish above the water line.

state is assumed, and the slope of the straight line is the rate of

12.2 Attach the specimen to the dish (see 10.1). Some

water vapor transmission.

specimensarelikelytowarpandbreakthesealduringthetest.

13.1.3 Numerical Analysis—A mathematical least squares

The risk is reduced by preconditioning the specimen, and by

regression analysis of the weight, modified by the dummy

clamping it to the dish ledge (if one is provided).

specimen when used, as a function of time will give the rate of

12.3 Weigh the dish assembly and place it in the controlled watervaportransmission.Anuncertainty,orstandarddeviation

chamber on a true horizontal surface. Follow the procedure of this rate, can also be calculated to define the confidence

givenin11.3.Ifthetestspecimencannottoleratecondensation band. For very low permeability materials, this method can be

on the surface, the dish assembly shall not be exposed to a usedtodeterminetheresultsafter30to60dayswhenusingan

temperature that differs by more than 5°F [3°C] from the analytical balance, with a sensitivity of ≈1 mg, even if the

controlatmospheretominimizetheriskofcondensationonthe weight change does not meet the 100 times the sensitivity

specimen. When results of water vapor transmission are requirement of 6.3.These specimens must be clearly identified

-2 -1 -1

expected to be less than 0.05 perm [3 ng·m ·s ·Pa ], a in the report.

E96/E96M − 14

-1 -1 -2

13.2 Calculate the water vapor transmission, WVT, and value more than 2-perm [114 ng·Pa ·s ·m ]. Corrections for

-1

permeance as follows: materials with permeance value below 2-perm [114 ng·Pa ·

-1 -2

s ·m ] are insignificant and need not be done.The procedures

13.2.1 Water Vapor Transmission:

for making various corrections, as summarized below, are

WVT 5 G/tA 5 ~G/t!/A (1)

found in the literature. [2,3,4,5)

where:

13.4.1 Buoyancy Correction—The duration for one set of

In inch-pound units:

measurements can be many days or weeks. The atmospheric

pressure may significantly change during such periods. If the

G = weight change, grains (from the straight line),

t = time during which G occurred, h, testspecimenishighlyvaporresistant,thechangesinmassdue

G/t = slope of the straight line, grains/h,

to vapor transport may be overshadowed by the apparent

A = test area (cup mouth area), ft , and

gravimetric changes observed. In such cases, all gravimetric

WVT = rate of water vapor transmission, grains/h·ft .

data should be corrected to vacuum or any base line pressure.

The following equation (2) can be used for buoyancy correc-

In metric units:

tion.

G = weight change (from the straight line), g,

m ρ ρ 2 ρ

~ !

t = time, h,

2 a 1 2

511 (4)

G/t = slope of the straight line, g/h, m ρ ρ 2 ρ

~ !

1 1 2 a

A = test area (cup mouth area), m , and

where:

WVT = rate of water vapor transmission, g/h·m .

m = mass recorded by balance, kg,

13.2.2 Permeance:

m = mass after buoyancy correction, kg,

-3

ρ = density of air, kg m ,

Permeance 5WVT/∆p 5WVT/S R 2 R (2) a

~ !

1 2

-3

ρ = density of material of balance weights, kg m , and

-3

where:

ρ = bulk density of test assembly, kg m .

In inch-pound units:

13.4.1.1 The density of air can be calculated using the ideal

∆p = vapor pressure difference, in. Hg,

gas law for the measured atmospheric pressure and ambient

S = saturation vapor pressure at test temperature, in. Hg,

temperature.

R = relative humidity at the source expressed as a fraction

13.4.1.2 The buoyancy correction is important (6) when

(the test chamber for desiccant method; in the dish for

measured mass changes are in the range of 0 to 100 mg.

water method), and

13.4.2 Corrections for Resistance due to Still Air and

R = relative humidity at the vapor sink expressed as a

Specimen Surface—In general, if the material is highly

fraction.

permeable, these corrections are more significant.With known

In metric units:

thickness of the still air layer in the cup, the corresponding

∆p = vapor pressure difference, mm Hg (1.333×10 Pa), vapor resistance can be calculated using the following equa-

S = saturation vapor pressure at test temperature, mm Hg

tion(3) for permeability.

(1.333×10 Pa),

25 1.81

2.306 310 P T

o

R = relative humidity at the source expressed as a fraction δ 5 (5)

S D

a

R TP 273.15

v

(the test chamber for desiccant method; in the dish for

where:

water method), and

-1 -1 -1

R = relative humidity at the vapor sink expressed as a

2 δ = permeability of still air, kg·m ·s ·Pa ,

a

fraction.

T = temperature, K,

P = ambient pressure, Pa,

13.2.3 In the controlled chamber the relative humidity and

P = standard atmospheric pressure, that is, 101325 Pa, and

o

temperature are the average values actually measured during -1 -1

R = ideal gas constant for water, that is, 461.5 J·K ·kg .

v

thetestand(unlesscontinuouslyrecorded)thesemeasurements

13.4.2.1 In the absence of any measured data, the surface

shallbemadeasfrequentlyastheweightmeasurements.Inthe

resistances (that is, inside and outside surfaces of the speci-

dish the relative humidity is nominally 0% for the desiccant

men) may be approximated using Lewis’ relation.(4) For cup

and 100% for the water. These values are usually within 3%

methods that follow this standard, the total surface resistance

relative humidity of the actual relative humidity for specimens

7 2 -1

-1 -1 -2

(Hansen and Lund (5)) should be ≈4×10 Pa·s·m ·kg .

below 4 perms [230 ng·Pa ·s ·m ] when the required condi-

13.4.3 Edge Mask Correction—Thefollowingequation(Joy

tionsaremaintained(nomorethan10%moistureinCaCl and

and Wilson(1)) is to be used to correct the excess WVT effect

no more than 1 in. [25 mm] air space above water).

due to edge masking:

13.3 The calculation of permeability is optional and can be

400t 2

done only when the test specimen is homogeneous (not

PercentexcessWVT 5 log (6)

S D

e 2 2πb/t

~ !

1 πS 11e

laminated) and not less than ⁄2 in. [12.5 mm] thick, calculate 1

its average permeability as follows:

where:

Averagepermeability 5Permeance 3Thickness (3)

t = specimen thickness, m,

b = width of masked edge, m, and

13.4 Corrections—It is important that all applicable correc-

S = four times the test area divided by the perimeter, m.

tions be made to all measurements that result in permeance

E96/E96M − 14

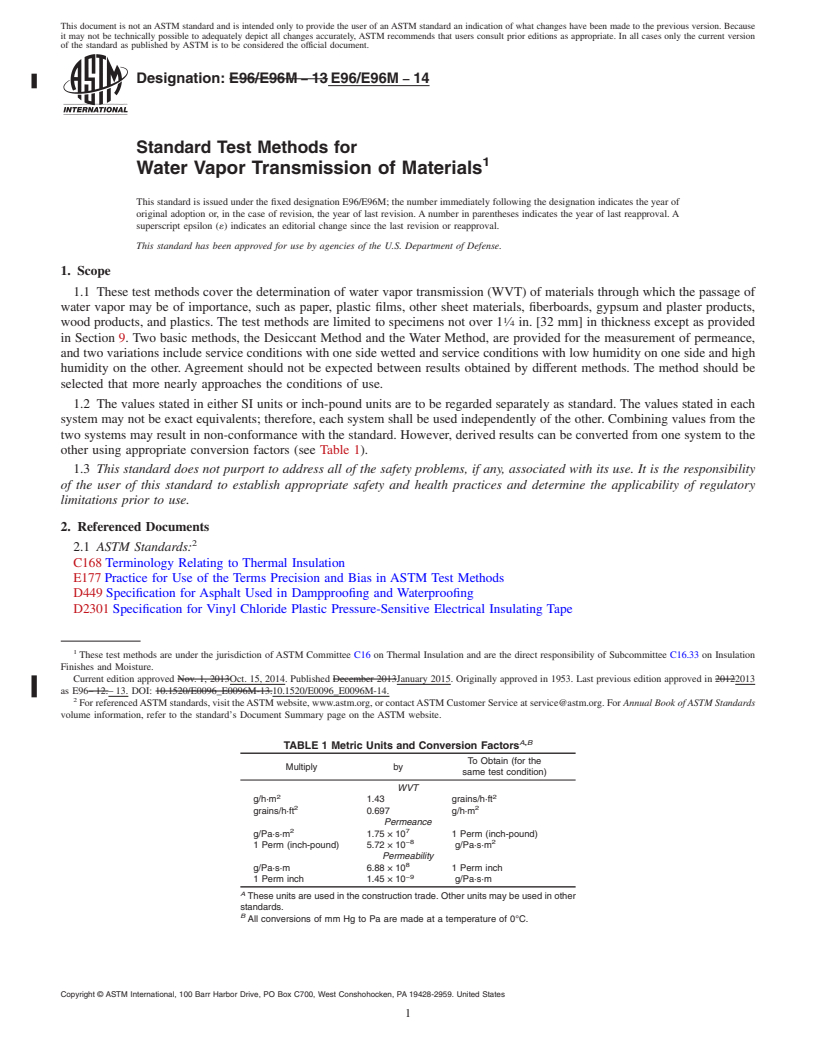

FIG. 1

13.4.3.1 Ifthecupassemblyincludesanyedgemaskingthis 13.6.2 Agraphic analysis of the data, according to 13.1.2 is

correction shall be made. shown in Fig. 1.

13.6.3 A linear least-squares analysis of the data according

13.5 MetricunitsandconversionfactoraregiveninTable1.

to 13.1.3 gives the slope of the straight line as 0.225 6 0.002

13.6 Example (in SI unit)—Inadesiccanttestonasampleof

-1

g·h , with a linear regression coefficient > 0.998.

medium density glass fiber insulation the following results

-1 2

WVT = 0.225 g·h ⁄ 0.01642 m

were recorded.

-1 -2 6 -2 -1

= 19.595 grains·h ·ft (' 3.81 × 10 ng·m ·s )

Thickness of the specimen = 25.81 mm S = 2775.6 Pa

Test area = 0.01642 m R = 0.523

Mass of the test specimen = 20.44 g R =0

6 -2 -1

Mass of the desiccant = 554.8 g Permeance = 3.81 × 10 ng·m ·s ⁄ (2775.6 Pa × 0.523)

-2 -1 -1

Initial mass of the test assembly = 1.257810 kg = 2630 ng·m ·s ·Pa

Thickness of air layer in the cup = 15 mm

13.6.4 Corrections for Resistance due to Still Air and

Mass of Barometric

Specimen Surface:

Elapsed Change Chamber Chamber

the Test Pressure

Time in Mass Temperature RH

Permeability of still air layer (Eq 5)

Assembly mm Hg

25 1.81

(h) (g) (°C) (% )

2.306310 3101325 22.791273.15

(g) (kPa)

5δ 5

S D

a

461.53s22.791273.15d399860 273.15

0.000 1257.810 0.000 22.83 52.60 744.7

(99.27) -1 -1 -1

= 198 ng·m ·s ·Pa

6.067 1259.469 1.659 22.84 52.6 741.11

Permeance of 15 mm still air layer

(98.79) -2 -1 -1

= (198) / (0.015) ng·m ·s ·Pa

26.633 1264.609 6.799 22.78 52.2 744.41 -2 -1 -1

= 13200 ng·m ·s ·Pa

(99.23)

Hence, the 15 mm air layer offers a vapor resistance

53.150 1271.062 13.252 22.82 52.1 743.21 2 -1 7 2 -1

= 1 / (13200) m ·s·Pa·ng ' 7.6×10 m ·s·Pa·kg

(99.07)

Surface resistances (see 13.4.2)

143.767 1290.773 32.963 22.74 52.2 757.69 7 2 -1

' 4.0×10 m ·s·Pa·kg

(101.00)

Total corrections for resistance due to still air and specimen surface

168.283 1296.389 38.579 22.78 52.1 749.81 7 7 2 -1

=(7.6×10 +4.0×10 )m ·s·Pa·kg

(99.95)

192.883 1301.953 44.143 22.78 52.1 758.44

13.6.5 Edge Mask Correction—Thetestassemblyuseddoes

(101.10)

not include any edge masking. However, for example, if it

13.6.1 Buoyancy Correction—As mentioned in 13.4.1, the

includes an edge mask of width 5 mm then the following

buoyancy effect will be insignificant for this set of readings as

correction is to be made (see 13.4.3).

recorded changes of mass are all above 100 mg. However, for

-3

t = specimen thickness, m =25.81 × 10 m

example, the corrected mass of the test assembly weight -3

b = width of masked edge, m=5×10 m

st 2

Test area = 0.01642 m

1257.810 g (1 reading) can be calculated using Eq 4.

Perimeter = 0.4541 m

-3

m = mass recorded by

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E96/E96M − 13 E96/E96M − 14

Standard Test Methods for

Water Vapor Transmission of Materials

This standard is issued under the fixed designation E96/E96M; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope

1.1 These test methods cover the determination of water vapor transmission (WVT) of materials through which the passage of

water vapor may be of importance, such as paper, plastic films, other sheet materials, fiberboards, gypsum and plaster products,

wood products, and plastics. The test methods are limited to specimens not over 1 ⁄4 in. [32 mm] in thickness except as provided

in Section 9. Two basic methods, the Desiccant Method and the Water Method, are provided for the measurement of permeance,

and two variations include service conditions with one side wetted and service conditions with low humidity on one side and high

humidity on the other. Agreement should not be expected between results obtained by different methods. The method should be

selected that more nearly approaches the conditions of use.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in non-conformance with the standard. However, derived results can be converted from one system to the

other using appropriate conversion factors (see Table 1).

1.3 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

C168 Terminology Relating to Thermal Insulation

E177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

D449 Specification for Asphalt Used in Dampproofing and Waterproofing

D2301 Specification for Vinyl Chloride Plastic Pressure-Sensitive Electrical Insulating Tape

These test methods are under the jurisdiction of ASTM Committee C16 on Thermal Insulation and are the direct responsibility of Subcommittee C16.33 on Insulation

Finishes and Moisture.

Current edition approved Nov. 1, 2013Oct. 15, 2014. Published December 2013January 2015. Originally approved in 1953. Last previous edition approved in 20122013

as E96– 12.– 13. DOI: 10.1520/E0096_E0096M-13.10.1520/E0096_E0096M-14.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

A,B

TABLE 1 Metric Units and Conversion Factors

To Obtain (for the

Multiply by

same test condition)

WVT

2 2

g/h·m 1.43 grains/h·ft

2 2

grains/h·ft 0.697 g/h·m

Permeance

2 7

g/Pa·s·m 1.75 × 10 1 Perm (inch-pound)

−8 2

1 Perm (inch-pound) 5.72 × 10 g/Pa·s·m

Permeability

g/Pa·s·m 6.88 × 10 1 Perm inch

−9

1 Perm inch 1.45 × 10 g/Pa·s·m

A

These units are used in the construction trade. Other units may be used in other

standards.

B

All conversions of mm Hg to Pa are made at a temperature of 0°C.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E96/E96M − 14

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

3. Terminology

3.1 Definitions of terms used in this standard will be found in Terminology C168, from which the following is quoted:

“water vapor permeability—the time rate of water vapor transmission through unit area of flat material of unit thickness induced

by unit vapor pressure difference between two specific surfaces, under specified temperature and humidity conditions.

Discussion—Permeability is a property of a material, but the permeability of a body that performs like a material may be used.

Permeability is the arithmetic product of permeance and thickness.

water vapor permeance—the time rate of water vapor transmission through unit area of flat material or construction induced by

unit vapor pressure difference between two specific surfaces, under specified temperature and humidity conditions.

Discussion—Permeance is a performance evaluation and not a property of a material.

3.2 water vapor transmission rate—the steady water vapor flow in unit time through unit area of a body, normal to specific

parallel surfaces, under specific conditions of temperature and humidity at each surface.”

4. Summary of Test Methods

4.1 In the Desiccant Method the test specimen is sealed to the open mouth of a test dish containing a desiccant, and the assembly

placed in a controlled atmosphere. Periodic weighings determine the rate of water vapor movement through the specimen into the

desiccant.

4.2 In the Water Method, the dish contains distilled water, and the weighings determine the rate of vapor movement through

the specimen from the water to the controlled atmosphere. The vapor pressure difference is nominally the same in both methods

except in the variation, with extremes of humidity on opposite sides.

5. Significance and Use

5.1 The purpose of these tests is to obtain, by means of simple apparatus, reliable values of water vapor transfer through

permeable and semipermeable materials, expressed in suitable units. These values are for use in design, manufacture, and

marketing. A permeance value obtained under one set of test conditions may not indicate the value under a different set of

conditions. For this reason, the test conditions should be selected that most closely approach the conditions of use. While any set

of conditions may be used and those conditions reported, standard conditions that have been useful are shown in Appendix X1.

6. Apparatus

6.1 Test Dish—The test dish shall be of any noncorroding material, impermeable to water or water vapor. It may be of any shape.

Light weight is desirable. A large, shallow dish is preferred, but its size and weight are limited when an analytical balance is chosen

2 2

to detect small weight changes. The mouth of the dish shall be as large as practical and at least 4.65 in. [3000 mm ]. The desiccant

or water area shall be not less than the mouth area except if a grid is used, as provided in 12.1, its effective area shall not exceed

10 % of the mouth area. An external flange or ledge around the mouth, to which the specimen may be attached, is useful when

shrinking or warping occurs. When the specimen area is larger than the mouth area, this overlay upon the ledge is a source of error,

particularly for thick specimens. This overlay material should be masked as described in 10.1 so that the mouth area defines the

test area. The overlay material results in a positive error, indicating excessive water vapor transmission. The magnitude of the error

is a complex function of the thickness, ledge width, mouth area, and possibly the permeability. This error is discussed by Joy and

Wilson (1) (see 13.4.3). This type of error should be limited to about 10 to 12 %. For a thick specimen the ledge should not exceed

3 1

⁄4 in. [19 mm] for a 10-in. [254-mm] or larger mouth (square or circular) or ⁄8 in. [3 mm] for a 5-in. [127-mm] mouth (square

or circular). For a 3-in. [76-mm] mouth (square or circular) the ledge should not exceed 0.11 in. [2.8 mm] wide. An allowable ledge

may be interpolated for intermediate sizes or calculated according to Joy and Wilson.(1) A rim around the ledge (Fig. X2.1) may

be useful. If a rim is provided, it shall be not more than ⁄4 in. [6 mm] higher than the specimen as attached. Different depths may

be used for the Desiccant Method and Water Method, but a ⁄4-in. [19-mm] depth (below the mouth) is satisfactory for either

method.

6.2 Test Chamber—The room or cabinet where the assembled test dishes are to be placed shall have a controlled temperature

(see Note 1) and relative humidity. Some standard test conditions that have been useful are given in Appendix X1. The temperature

chosen shall be determined according to the desired application of the material to be tested (see Appendix X1). The relative

humidity shall be maintained at 50 6 2 %, except where extremes of humidities are desired, when the conditions shall be 100 6

1.8°F [38 6 1°C] and 90 6 2 % relative humidity. Both temperature and relative humidity shall be measured frequently or

preferably recorded continuously. Air shall be continuously circulated throughout the chamber, with a velocity sufficient to

maintain uniform conditions at all test locations. The air velocity over the specimen shall be between 0.066 and 1 ft/s [0.02 and

-1

0.3 m·s ]. Suitable racks shall be provided on which to place the test dishes within the test chamber.

The boldface numbers in parentheses refer to the list of references at the end of this standard.

The minimum acceptable is to perform this measurement each time the sample is weighed.

E96/E96M − 14

NOTE 1—Simple temperature control by heating alone is usually made possible at 90°F [32°C]. However, it is very desirable to enter the controlled

space, and a comfortable temperature is more satisfactory for that arrangement. Temperatures of 73.4°F [23°C] and 80°F [26.7°C] are in use and are

satisfactory for this purpose. With cyclic control, the average test temperature may be obtained from a sensitive thermometer in a mass of dry sand. The

temperature of the chamber walls facing a specimen over water should not be cooler than the water to avoid condensation on the test specimen.

6.3 Balance and Weights—The balance shall be sensitive to a change smaller than 1 % of the weight change during the period

when a steady state is considered to exist. The weights used shall be accurate to 1 % of the weight change during the steady-state

period (Note 2). A light wire sling may be substituted for the usual pan to accommodate a larger and heavier load.

6.4 Thickness-Measuring Gage—The nominal thickness of the specimen shall be determined using a thickness-measuring gage

with an accuracy of 61 % of the reading or 0.0001 in. [0.0025 mm], whichever is greater.

-1 -1 -2

NOTE 2—For example: 1-perm [57 ng·Pa ·s ·m ] specimen 10 in. [254 mm] square at 80°F [26.7°C] passes 8.6 grains or 0.56 g/day. In 18 days of

steady state, the transfer is 10 g. For this usage, the balance must have a sensitivity of 1 % of 10 g or 0.1 g and the weights must be accurate to 0.1 g.

If, however, the balance has a sensitivity of 0.2 g or the weights are no better than 0.2 g, the requirements of this paragraph can be met by continuing

the steady state for 36 days. An analytical balance that is much more sensitive will permit more rapid results on specimens below 1 perm [57

-1 -1 -2

ng·Pa ·s ·m ] when the assembled dish is not excessively heavy.

7. Materials

7.1 Desiccant and Water:

7.1.1 For the Desiccant Method, anhydrous calcium chloride in the form of small lumps that will pass a No. 8 [2.36-mm] sieve,

and free of fines that will pass a No. 30 [600-μm] sieve, shall be used (Note 3). It shall be dried at 400°F [200°C] before use.

NOTE 3—If CaCl will react chemically on the specimen, an adsorbing desiccant such as silica gel, activated at 400°F [200°C], may be used; but the

moisture gain by this desiccant during the test must be limited to 4 %.

7.1.2 For the Water Method, distilled water shall be used in the test dish.

7.2 Sealant—The sealant used for attaching the specimen to the dish, in order to be suitable for this purpose, must be highly

resistant to the passage of water vapor (and water). It must not lose weight to, or gain weight from, the atmosphere in an amount,

over the required period of time, that would affect the test result by more than 2 %. It must not affect the vapor pressure in a

-2 -1 -1

water-filled dish. Molten asphalt or wax is required for permeance tests below 4 perms [230 ng·m · s ·Pa ]. Sealing methods are

discussed in Appendix X2.

8. Sampling

8.1 The material shall be sampled in accordance with standard methods of sampling applicable to the material under test. The

sample shall be of uniform thickness. If the material is of nonsymmetrical construction, the two faces shall be designated by

distinguishing marks (for example, on a one-side-coated sample, “I” for the coated side and “II” for the uncoated side).

9. Test Specimens

9.1 Test specimens shall be representative of the material tested. When a product is designed for use in only one position, three

specimens shall be tested by the same method with the vapor flow in the designated direction. When the sides of a product are

indistinguishable, three specimens shall be tested by the same method. When the sides of a product are different and either side

may face the vapor source, four specimens shall be tested by the same method, two being tested with the vapor flow in each

direction and so reported.

9.2 A slab, produced and used as a laminate (such as a foamed plastic with natural “skins”) may be tested in the thickness of

use. Alternatively, it may be sliced into two or more sheets, each being separately tested and so reported as provided in 9.4,

provided also, that the “overlay upon the cup ledge” (6.1) of any laminate shall not exceed ⁄8 in. [3 mm].

9.3 When the material as used has a pitted or textured surface, the tested thickness shall be that of use. When it is homogeneous,

however, a thinner slice of the slab may be tested as provided in 9.4.

9.4 In either case (9.2 or 9.3), the tested overall thickness, if less than that of use, shall be at least five times the sum of the

-2 -1 -1

maximum pit depths in both its faces, and its tested permeance shall be not greater than 5 perms [≈ 300 ng·m ·s ·Pa ].

9.5 For homogeneous (not laminated) materials with thickness greater than ⁄2 in., the overall nominal thickness of each

specimen shall be measured with an accuracy of 61 % of the reading at the center of each quadrant and the results averaged.

-2 -1 -1

9.6 When testing any material with a permeance less than 0.05 perms [3 ng·m ·s ·Pa ] or when testing a low permeance

material that may be expected to lose or gain weight throughout the test (because of evaporation or oxidation), it is strongly

recommended that an additional specimen, or “dummy,” be tested exactly like the others, except that no desiccant or water is put

in the dish. Failure to use this dummy specimen to establish modified dish weights may significantly increase the time required

to complete the test. Because time to reach equilibrium of water permeance increases as the square of thickness, thick, particularly

hygroscopic, materials may take as long as 60 days to reach equilibrium conditions.

E96/E96M − 14

10. Attachment of Specimen to Test Dish

10.1 Attach the specimen to the dish by sealing (and clamping if desired) in such a manner that the dish mouth defines the area

of the specimen exposed to the vapor pressure in the dish. If necessary, mask the specimen top surface, exposed to conditioned

air so that its exposure duplicates the mouth shape and size and is directly above it. A template is recommended for locating the

mask. Thoroughly seal the edges of the specimen to prevent the passage of vapor into, or out of, or around the specimen edges

or any portion thereof. The same assurance must apply to any part of the specimen faces outside their defined areas. Suggested

methods of attachment are described in Appendix X2.

NOTE 4—In order to minimize the risk of condensation on the interior surface of the sample when it is placed in the chamber, the temperature of the

water prior to preparation of the test specimen should be within 62°F [61°C] of the test condition.

11. Procedure for Desiccant Method

11.1 Fill the test dish with desiccant within ⁄4 in. [6 mm] of the specimen. Leave enough space so that shaking of the dish, which

must be done at each weighing, will mix the desiccant.

11.2 Attach the specimen to the dish (see 10.1) and place it in the controlled chamber, specimen up, weighing it at once. (This

weight may be helpful to an understanding of the initial moisture in the specimen.)

11.3 Weigh the dish assembly periodically, often enough to provide eight or ten data points during the test. A data point is the

weight at a particular time. The time that the weight is made should be recorded to a precision of approximately 1 % of the time

span between successive weighing. Thus, if weighings are made every hour, record the time to the nearest 30 s; if recordings are

made every day, a time to the nearest 15 min would be allowed. At first the weight may change rapidly; later a steady state will

be reached where the rate of change is substantially constant. Weighings should be accomplished without removal of the test dishes

from the controlled atmosphere, but if removal is prescribed necessary, the time the specimens are kept at different conditions,

temperature or relative humidity, or both, should be kept to a minimum. When results of water vapor transmission are expected

-2 -1 -1

to be less than 0.05 perm [3 ng·m ·s ·Pa ], a dummy specimen is strongly recommended. Such a dummy specimen should be

attached to an empty cup in the normal manner. The environmental effects of temperature variation and buoyancy variability due

to barometric pressure fluctuation can be arithmetically tared out of the weighing values. This precaution permits earlier and more

reliable achievement of equilibrium conditions. Analyze the results as prescribed in 13.1.

11.4 Terminate the test or change the desiccant before the water added to the desiccant exceeds 10 % of its starting weight. This

limit cannot be exactly determined and judgement is required. The desiccant gain may be more or less than the dish weight-gain

when the moisture content of the specimen has changed.

NOTE 5—The WVT of some materials (especially wood) may depend on the ambient relative humidity immediately before the test. An apparent

hysteresis results in higher WVT if the prior relative humidity was above the test condition and vice versa. It is therefore recommended that specimens

of wood and paper products be conditioned to constant weight in a 50 % relative humidity atmosphere before they are tested. Some specimens may be

advantageously preconditioned to minimize the moisture that the specimen will give up to the desiccant. This applies when the specimen is likely to have

high moisture content or when it is coated on the top (vapor source) side.

12. Procedure for Water Method

3 1

12.1 Fill the test dish with distilled water to a level ⁄4 6 ⁄4 in. [19 6 6 mm] from the specimen. The air space thus allowed

has a small vapor resistance, but it is necessary in order to reduce the risk of water touching the specimen when the dish is handled.

Such contact invalidates a test on some materials such as paper, wood, or other hygroscopic materials. The water depth shall be

not less than ⁄8 in. [3 mm] to ensure coverage of the dish bottom throughout the test. However, if the dish is of glass, its bottom

must be visibly covered at all times but no specific depth is required. Water surges may be reduced by placing a grid of light

noncorroding material in the dish to break the water surface. This grid shall be at least ⁄4 in. [6 mm] below the specimen, and it

shall not reduce the water surface by more than 10 %.

NOTE 6—For the Water Method, baking the empty dish and promptly coating its mouth with sealant before assembly is recommended. The water may

be added most conveniently after the specimen is attached, through a small sealable hole in the dish above the water line.

12.2 Attach the specimen to the dish (see 10.1). Some specimens are likely to warp and break the seal during the test. The risk

is reduced by preconditioning the specimen, and by clamping it to the dish ledge (if one is provided).

12.3 Weigh the dish assembly and place it in the controlled chamber on a true horizontal surface. Follow the procedure given

in 11.3. If the test specimen cannot tolerate condensation on the surface, the dish assembly shall not be exposed to a temperature

that differs by more than 5°F [3°C] from the control atmosphere to minimize the risk of condensation on the specimen. When

-2 -1 -1

results of water vapor transmission are expected to be less than 0.05 perm [3 ng·m ·s ·Pa ], a dummy specimen is strongly

recommended. Such a dummy specimen should be attached to an empty cup in the normal manner. The environment effects of

temperature variation and buoyancy variability due to barometric pressure fluctuation can be arithmetically tared out of the

weighing values. This precaution permits earlier and more reliable achievement of equilibrium conditions. Analyze the results as

prescribed in 13.1.

E96/E96M − 14

12.4 Where water is expected to be in contact with the barrier in service, proceed as in 11.3 except place the dish in an inverted

position. The dish must be sufficiently level so that water covers the inner surface of the specimen despite any distortion of the

specimen due to the weight of the water. With highly permeable specimens it is especially important to locate the test dish so that

air circulates over the exposed surface at the specified velocity. The test dishes may be placed on the balance in the upright position

for weighing, but the period during which the wetted surface of the specimen is not covered with water must be kept to a minimum.

13. Calculation and Analysis of Results

13.1 The results of the rate of water vapor transmission may be determined either graphically or numerically.

13.1.1 Dummy Specimen—If a dummy specimen has been used to compensate for variability in test conditions, due to

temperature or barometric pressure, or both, the daily recorded weights can be adjusted by calculating the weight change from

initial to time of weighing. This adjustment is made by reversing the direction of the dummy’s weight change, relative to its initial

weight, and modifying all the appropriate specimen weight(s) recorded at this time. This permits earlier achievement of

equilibrium conditions. An alternate procedure, particular for tests of long duration and more than six weighings, is to subtract the

arithmetic mean slope of the rate of weight change of the dummy specimen from the arithmetic mean slope of each similar

specimen to get an effective rate of weight change. These procedures are also desirable if the specimen is changing weight due

to a curing process while under test.

13.1.2 Graphic Analysis—Plot the weight, modified by the dummy specimen when used, against elapsed time, and inscribe a

curve that tends to become straight. Judgment here is required and numerous points are helpful. When a straight line adequately

fits the plot of at least six properly spaced points (periodic weight changes matching, or exceeding 20 % of the multiple of 100

times the scale sensitivity), a nominally steady state is assumed, and the slope of the straight line is the rate of water vapor

transmission.

13.1.3 Numerical Analysis—A mathematical least squares regression analysis of the weight, modified by the dummy specimen

when used, as a function of time will give the rate of water vapor transmission. An uncertainty, or standard deviation of this rate,

can also be calculated to define the confidence band. For very low permeability materials, this method can be used to determine

the results after 30 to 60 days when using an analytical balance, with a sensitivity of ≈1 mg, even if the weight change does not

meet the 100 times the sensitivity requirement of 6.3. These specimens must be clearly identified in the report.

13.2 Calculate the water vapor transmission, WVT, and permeance as follows:

13.2.1 Water Vapor Transmission:

WVT 5 G/tA 5 ~G/t!/A (1)

where:

In inch-pound units:

G = weight change, grains (from the straight line),

t = time during which G occurred, h,

G/t = slope of the straight line, grains/h,

A = test area (cup mouth area), ft , and

WVT = rate of water vapor transmission, grains/h·ft .

In metric units:

G = weight change (from the straight line), g,

t = time, h,

G/t = slope of the straight line, g/h,

A = test area (cup mouth area), m , and

WVT = rate of water vapor transmission, g/h·m .

13.2.2 Permeance:

Permeance 5 WVT/Δp 5 WVT/S~R 2 R ! (2)

1 2

where:

In inch-pound units:

Δp = vapor pressure difference, in. Hg,

S = saturation vapor pressure at test temperature, in. Hg,

R = relative humidity at the source expressed as a fraction (the test chamber for desiccant method; in the dish for water

method), and

R = relative humidity at the vapor sink expressed as a fraction.

In metric units:

Δp = vapor pressure difference, mm Hg (1.333 × 10 Pa),

S = saturation vapor pressure at test temperature, mm Hg (1.333 × 10 Pa),

E96/E96M − 14

R = relative humidity at the source expressed as a fraction (the test chamber for desiccant method; in the dish for water

method), and

R = relative humidity at the vapor sink expressed as a fraction.

13.2.3 In the controlled chamber the relative humidity and temperature are the average values actually measured during the test

and (unless continuously recorded) these measurements shall be made as frequently as the weight measurements. In the dish the

relative humidity is nominally 0 % for the desiccant and 100 % for the water. These values are usually within 3 % relative humidity

-1 -1 -2

of the actual relative humidity for specimens below 4 perms [230 ng·Pa ·s ·m ] when the required conditions are maintained (no

more than 10 % moisture in CaCl and no more than 1 in. [25 mm] air space above water).

13.3 The calculation of permeability is optional and can be done only when the test specimen is homogeneous (not laminated)

and not less than ⁄2 in. [12.5 mm] thick, calculate its average permeability as follows:

Average permeability 5 Permeance 3Thickness (3)

13.4 Corrections—It is important that all applicable corrections be made to all measurements that result in permeance value

-1 -1 -2 -1

more than 2-perm [114 ng·Pa ·s ·m ]. Corrections for materials with permeance value below 2-perm [114 ng·Pa ·

-1 -2

s ·m ] are insignificant and need not be done. The procedures for making various corrections, as summarized below, are found

in the literature. [2,3,4,5)

13.4.1 Buoyancy Correction—The duration for one set of measurements can be many days or weeks. The atmospheric pressure

may significantly change during such periods. If the test specimen is highly vapor resistant, the changes in mass due to vapor

transport may be overshadowed by the apparent gravimetric changes observed. In such cases, all gravimetric data should be

corrected to vacuum or any base line pressure. The following equation (2) can be used for buoyancy correction.

m ρ ρ 2 ρ

~ !

2 a 1 2

5 11 (4)

m ρ ~ρ 2 ρ !

1 1 2 a

where:

m = mass recorded by balance, kg,

m = mass after buoyancy correction, kg,

-3

ρ = density of air, kg m ,

a

-3

ρ = density of material of balance weights, kg m , and

-3

ρ = bulk density of test assembly, kg m .

13.4.1.1 The density of air can be calculated using the ideal gas law for the measured atmospheric pressure and ambient

temperature.

13.4.1.2 The buoyancy correction is important (6) when measured mass changes are in the range of 0 to 100 mg.

13.4.2 Corrections for Resistance due to Still Air and Specimen Surface—In general, if the material is highly permeable, these

corrections are more significant. With known thickness of the still air layer in the cup, the corresponding vapor resistance can be

calculated using the following equation(3) for permeability.

25 1.81

2.306 310 P T

o

δ 5 (5)

S D

a

R TP 273.15

v

where:

-1 -1 -1

δ = permeability of still air, kg·m ·s ·Pa ,

a

T = temperature, K,

P = ambient pressure, Pa,

P = standard atmospheric pressure, that is, 101325 Pa, and

o

-1 -1

R = ideal gas constant for water, that is, 461.5 J·K ·kg .

v

13.4.2.1 In the absence of any measured data, the surface resistances (that is, inside and outside surfaces of the specimen) may

be approximated using Lewis’ relation.(4) For cup methods that follow this standard, the total surface resistance (Hansen and Lund

7 2 -1

(5)) should be ≈ 4 × 10 Pa·s·m ·kg .

13.4.3 Edge Mask Correction—The following equation (Joy and Wilson(1)) is to be used to correct the excess WVT effect due

to edge masking:

400t 2

Percent excess WVT 5 log (6)

S D

e 2 2πb/t

~ !

πS 11e

where:

t = specimen thickness, m,

b = width of masked edge, m, and

S = four times the test area divided by the perimeter, m.

13.4.3.1 If the cup assembly includes any edge masking this correction shall be made.

E96/E96M − 14

FIG. 1

13.5 Metric units and conversion factor are given in Table 1.

13.6 Example (in SI unit)—In a desiccant test on a sample of medium density glass fiber insulation the following results were

recorded.

Thickness of the specimen = 25.81 mm

Test area = 0.01642 m

Mass of the test specimen = 20.44 g

Mass of the desiccant = 554.8 g

Initial mass of the test assembly = 1.257810 kg

Thickness of air layer in the cup = 15 mm

Mass of Barometric

Elapsed Change Chamber Chamber

the Test Pressure

Time in Mass Temperature RH

Assembly mm Hg

(h) (g) (°C) (% )

(g) (kPa)

0.000 1257.810 0.000 22.83 52.60 744.7

(99.27)

6.067 1259.469 1.659 22.84 52.6 741.11

(98.79)

26.633 1264.609 6.799 22.78 52.2 744.41

(99.23)

53.150 1271.062 13.252 22.82 52.1 743.21

(99.07)

143.767 1290.773 32.963 22.74 52.2 757.69

(101.00)

168.283 1296.389 38.579 22.78 52.1 749.81

(99.95)

192.883 1301.953 44.143 22.78 52.1 758.44

(101.10)

13.6.1 Buoyancy Correction—As mentioned in 13.4.1, the buoyancy effect will be insignificant for this set of readings as

recorded changes of mass are all above 100 mg. However, for example, the corrected mass of the test assembly weight 1257.810

st

g (1 reading) can be calculated using Eq 4.

-3

m = mass recorded by balance, kg = 1257.810 × 10 kg

P = Barometric pressure, Pa = 99.27 × 10 Pa

R = Gas constant for dry air = 287.055 J / (kg·K)

T = Chamber temperature = 22.83 + 273.15 = 295.98 K

-3 -3

ρ = density of air, kg m = P / (RT) = 1.1684 kg m

a

-3 -3

ρ = density of material of balance weights, kg m = 8000 kg m

-3

h = height of the test assembly, m = 44.7 × 10 m

-3

d = diameter of the test assembly, m = 168.0 × 10 m

-3

ρ = bulk density of test assembly, kg m

43m

5 51269.4 kg m

π3d 3h

1 1

-3

m = mass after buoyancy correction = 1258.78 × 10 kg

13.6.2 A graphic analysis of the data, according to 13.1.2 is shown in Fig. 1.

-1

13.6.3 A linear least-squares analysis of the data according to 13.1.3 gives the slope of the straight line as 0.225 6 0.002 g·h ,

with a linear regression coefficient > 0.998.

E96/E96M − 14

-1 2

WVT = 0.225 g·h ⁄ 0.01642 m

-1 -2 6 -2 -1

= 19.595 grains·h ·ft (' 3.81 × 10 ng·m ·s )

S = 2775.6 Pa

R = 0.523

R = 0

6 -2 -1

Permeance = 3.81 × 10 ng·m ·s ⁄ (2775.6 Pa × 0.523)

-2 -1 -1

= 2630 ng·m ·s ·Pa

13.6.4 Corrections for Resistance due to Still Air and Specimen Surface:

Permeability of still air layer (Eq 5)

25 1.81

2.306310 3101325 22.791273.15

5δ 5

S D

a

461.53 22.791273.15 399860 273.15

s d

-1 -1 -1

= 198 ng·m ·s

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...