ASTM D1301-91(2020)

(Test Method)Standard Test Methods for Chemical Analysis of White Lead Pigments

Standard Test Methods for Chemical Analysis of White Lead Pigments

SIGNIFICANCE AND USE

3.1 These test methods are suitable for determining the level of purity and for determining the levels of various impurities. They may be used to establish compliance with specification requirements.

SCOPE

1.1 These test methods cover procedures for the chemical analysis of basic carbonate white lead and basic sulfate white lead.

Note 1: If it is necessary to separate these pigments from others, refer to Practice D215.

1.2 The analytical procedures appear in the following order:

Section

Preparation of Sample

6

Basic Carbonate White Lead:

Small Amounts of Iron

7

Total Lead

8

Moisture and Other Volatile Matter

9

Carbon Dioxide (Evolution Method)

10

Carbon Dioxide and Combined Water (Combustion Method)

11

Lead Carbonate

12

Total Matter Insoluble in Acetic Acid

13

Total Matter Insoluble in Acid Ammonium Acetate

14

Total Impurities Other Than Moisture

15

Coarse Particles

16

Basic Sulfate White Lead:

Small Amounts of Iron

17

Total Lead

Moisture and Other Volatile Matter

19

Total Sulfate

20

Zinc Oxide

21

Basic Lead Oxide

22

Total Impurities

23

Coarse Particles

24

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

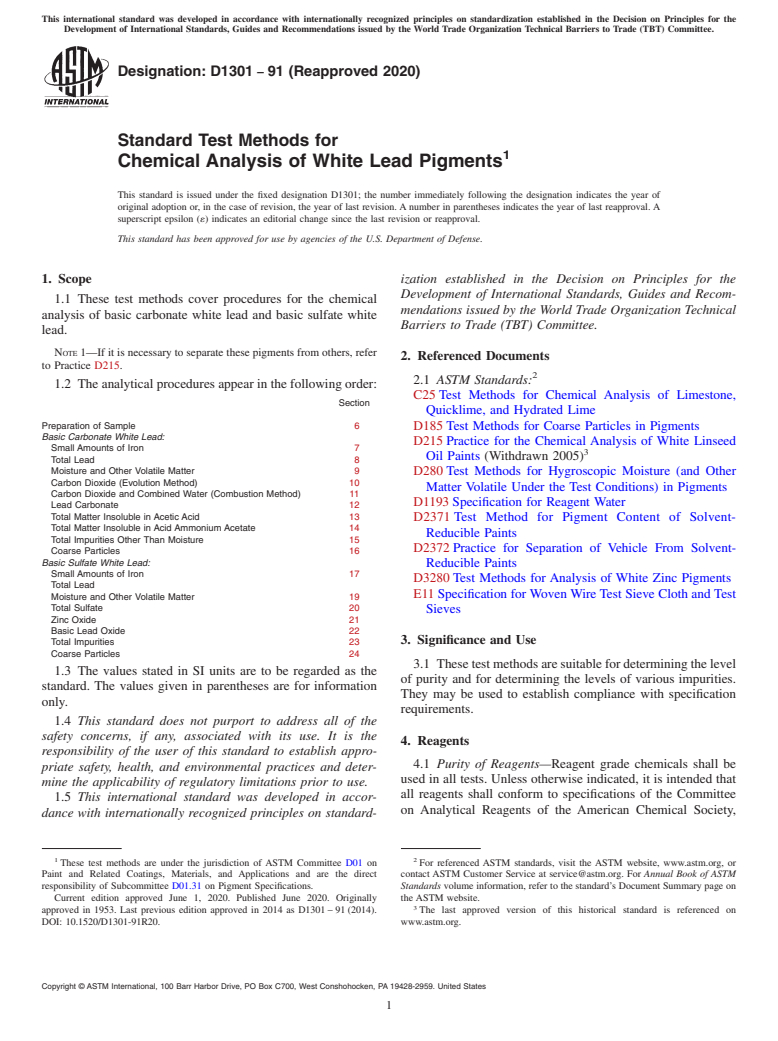

Designation: D1301 − 91 (Reapproved 2020)

Standard Test Methods for

Chemical Analysis of White Lead Pigments

This standard is issued under the fixed designation D1301; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

1.1 These test methods cover procedures for the chemical

mendations issued by the World Trade Organization Technical

analysis of basic carbonate white lead and basic sulfate white

Barriers to Trade (TBT) Committee.

lead.

NOTE 1—If it is necessary to separate these pigments from others, refer

2. Referenced Documents

to Practice D215.

2.1 ASTM Standards:

1.2 Theanalyticalproceduresappearinthefollowingorder:

C25Test Methods for Chemical Analysis of Limestone,

Section

Quicklime, and Hydrated Lime

Preparation of Sample 6

D185Test Methods for Coarse Particles in Pigments

Basic Carbonate White Lead:

D215Practice for the Chemical Analysis of White Linseed

Small Amounts of Iron 7

Oil Paints (Withdrawn 2005)

Total Lead 8

Moisture and Other Volatile Matter 9

D280Test Methods for Hygroscopic Moisture (and Other

Carbon Dioxide (Evolution Method) 10

Matter Volatile Under the Test Conditions) in Pigments

Carbon Dioxide and Combined Water (Combustion Method) 11

D1193Specification for Reagent Water

Lead Carbonate 12

Total Matter Insoluble in Acetic Acid 13

D2371 Test Method for Pigment Content of Solvent-

Total Matter Insoluble in Acid Ammonium Acetate 14

Reducible Paints

Total Impurities Other Than Moisture 15

D2372Practice for Separation of Vehicle From Solvent-

Coarse Particles 16

Basic Sulfate White Lead:

Reducible Paints

Small Amounts of Iron 17

D3280Test Methods for Analysis of White Zinc Pigments

Total Lead

E11Specification forWovenWireTest Sieve Cloth andTest

Moisture and Other Volatile Matter 19

Total Sulfate 20

Sieves

Zinc Oxide 21

Basic Lead Oxide 22

3. Significance and Use

Total Impurities 23

Coarse Particles 24

3.1 Thesetestmethodsaresuitablefordeterminingthelevel

1.3 The values stated in SI units are to be regarded as the

of purity and for determining the levels of various impurities.

standard. The values given in parentheses are for information

They may be used to establish compliance with specification

only.

requirements.

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

4. Reagents

responsibility of the user of this standard to establish appro-

4.1 Purity of Reagents—Reagent grade chemicals shall be

priate safety, health, and environmental practices and deter-

used in all tests. Unless otherwise indicated, it is intended that

mine the applicability of regulatory limitations prior to use.

all reagents shall conform to specifications of the Committee

1.5 This international standard was developed in accor-

on Analytical Reagents of the American Chemical Society,

dance with internationally recognized principles on standard-

1 2

These test methods are under the jurisdiction of ASTM Committee D01 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Paint and Related Coatings, Materials, and Applications and are the direct contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

responsibility of Subcommittee D01.31 on Pigment Specifications. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved June 1, 2020. Published June 2020. Originally the ASTM website.

approved in 1953. Last previous edition approved in 2014 as D1301–91(2014). The last approved version of this historical standard is referenced on

DOI: 10.1520/D1301-91R20. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D1301 − 91 (2020)

NOTE2—DetailedrequirementsforthissievearegiveninSpecification

where such specifications are available. Other grades may be

E11.

used, provided it is first ascertained that the reagent is of

sufficiently high purity to permit its use without lessening the 6.4 Preserve all samples in stoppered bottles or containers.

accuracy of the determination.

BASIC CARBONATE WHITE LEAD

4.2 Purity of Water—Unless otherwise indicated, references

towatershallbeunderstoodtomeanreagentwaterconforming

7. Small Amounts of Iron

to Type II of Specification D1193.

7.1 Reagents:

4.3 Concentration of Reagents:

7.1.1 Ammonium Hydroxide (sp gr 0.90). Warning—See

4.3.1 Concentrated Acids and Ammonium Hydroxide—

5.1.

When acids and ammonium hydroxide are specified by name

7.1.2 Hydrofluoric Acid (48%). Warning—See 5.1.

or chemical formula only, it shall be understood that concen-

7.1.3 Nitric Acid (sp gr 1.42). Warning—See 5.1.

trated reagents of the following specific gravities or concen-

7.1.4 Sulfuric Acid (sp gr 1.84). Warning—See 5.1.

trations are intended:

7.2 Procedure:

Acetic acid, CH COOH 99.5 %

7.2.1 Weigh to 10 mg about1gof specimen into a 400-mL

Hydrochloric acid, HCl sp gr 1.19

beaker.Treatthesamplewith10mLofHNO (1+1)anddilute

Hydrofluoric acid, HF 48 %

Nitric acid, HNO sp gr 1.42

3 to about 200 mL with water. If insoluble matter remains

Sulfuric acid, H SO sp gr 1.84

2 4

following treatment with HNO and dilution, filter and wash

Ammonium hydroxide, NH OH sp gr 0.90

the residue with hot water until lead free. Evaporate the filtrate

The desired specific gravities or concentrations of all other

and washings to about 200 mL. Add 20 mL of H SO (1+1)

2 4

concentrated acids are stated whenever they are specified.

to precipitate the bulk of the lead (it is unnecessary to

Warning—See Section 5.

evaporate down). Cool, filter, and wash with diluted H SO

2 4

4.3.2 Diluted Acids and Ammonium Hydroxide—

(1+99). Save the precipitate for determination of total lead

Concentrations of diluted acids and ammonium hydroxide,

(Section 8).

except when standardized, are specified as a ratio stating the

7.2.2 Ignite the HNO -insoluble matter and treat with HF

number of volumes of concentrated reagent to be diluted with

and H SO . Bring into solution, filter (any precipitate is

2 4

a given number of volumes of water, as in the following

probably BaSO ), and add to the PbSO filtrate.

4 4

example: HCl (1+99) means 1 volume of concentrated HCl

7.2.3 Colorimetrically determine iron in the combined fil-

(sp gr 1.19) diluted with 99 volumes of water.

trates by the thiocyanate method, using the same amounts of

reagents in preparing the reference standards. If copper is

5. Hazards

presentinthefiltrate,asshownbythecharacteristicblue-green

5.1 The concentrated acids bases and other reagents used in

or yellow color, remove it by precipitating the iron with

these test methods can be dangerous. Check their Material

NH OH,filtering,washing,redissolvingtheFe(OH) in10mL

4 3

Safety Data Sheets, (MSDS) before use.

of HNO (1+1), and diluting to about 200 mL before

proceeding with the thiocyanate method.

6. Preparation of Sample

8. Total Lead

6.1 Grind dry pigments, if lumpy or not finely ground, to a

fine powder for analysis. Large samples may be thoroughly

8.1 Apparatus:

mixed and a representative portion taken and powdered if

8.1.1 Gooch Crucible, prepared prior to use.

lumpy or not finely ground. Mix the sample in all cases

8.2 Reagents:

thoroughly and comminute before taking specimens for analy-

8.2.1 Acetic Acid (glacial)—Warning—See 5.1.

sis.

8.2.2 Ammonium Hydroxide (sp gr 0.90)—Warning—See

6.2 Incasesofpastesinoil,extracttheoilfromthepigment

5.1.

as described in Test Method D2371 or Practice D2372, but

8.2.3 Ethyl Alcohol (95 volume %)—Warning—See 5.1.

without straining.

8.2.4 Potassium Dichromate Solution (100 g K Cr O /L)—

2 2 7

Warning—See 5.1.

6.3 Drypigmentsseparatedfrompaintsorpastesinoilinan

oven at 95 to 98°C (203 to 210°F) for 2 h, grind to a fine

8.3 Procedure:

powder, pass through a No. 80 (180-µm) sieve (Note 2)to

8.3.1 IgnitethePbSO precipitateandfilterpaperfrom7.2.1

remove skins, and mix thoroughly. Such pigments, after

at or below 550°C (1020°F), and transfer the residue to a

weighing, should be moistened with a little ethyl alcohol

400-mL beaker. (If preferred, a new 1-g specimen of pigment

(95%) before adding reagents for analysis.

may be weighed to 10 mg into a 400-mL beaker. Proceed to

8.3.2.)

8.3.2 Moisten with water and add 5 mL of glacial acetic

ACS Reagent Chemicals, Specifications and Procedures for Reagents and

acid.Warmtodissolvethematerialanddilutetoabout200mL

Standard-Grade Reference Materials, American Chemical Society, Washington,

DC. For suggestions on the testing of reagents not listed by theAmerican Chemical

Society, see Analar Standards for Laboratory Chemicals, BDH Ltd., Poole, Dorset,

U.K., and the United States Pharmacopeia and National Formulary, U.S. Pharma- Described in Scott, Standard Methods of Chemical Analysis, Fifth Edition, D.

copeial Convention, Inc. (USPC), Rockville, MD. Van Nostrand Co., New York, NY, 1939, p. 486.

D1301 − 91 (2020)

withwater.NeutralizethesolutionwithNH OHandthenmake 550°C (840 to 1020°F), absorption bulb for water, and an

slightly acid with acetic acid, adding about 3 mLexcess. Filter absorption bulb for CO .

off any insoluble residue and wash thoroughly with hot water.

11.2 Procedure:

8.3.3 Unite the filtrate and washings, heat to boiling, and

11.2.1 Heat the furnace, without the combustion tube, from

add 15 mLof K Cr O solution. Stir and heat until the yellow

2 2 7

450 to 550°C (840 to 1022°F). Connect the combustion tube

precipitate assumes an orange col

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.