ASTM D2171-94

(Test Method)Standard Test Method for Viscosity of Asphalts by Vacuum Capillary Viscometer

Standard Test Method for Viscosity of Asphalts by Vacuum Capillary Viscometer

SCOPE

1.1 This test method covers procedures for the determination of viscosity of asphalt (bitumen) by vacuum capillary viscometers at 60°C (140°F). It is applicable to materials having viscosities in the range from 0.0036 to over 20 000 Pa.s (0.036 to over 200 000 P). Note 1—This test method is suitable for use at other temperatures, but the precision is based on determinations on asphalt cements at 60°C (140°F).

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 2171 – 94

Designation: 222/84 (89)

Standard Test Method for

Viscosity of Asphalts by Vacuum Capillary Viscometer

This standard is issued under the fixed designation D 2171; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

This test method has been approved by the sponsoring committees and accepted by the cooperating societies in accordance with

established procedures.

1. Scope liquid. It is commonly called the viscosity of the liquid. The

cgs unit of viscosity is 1 g/cm·s (1 dyne·s/cm ) and is called a

1.1 This test method covers procedures for the determina-

poise (P). The SI unit of viscosity is 1 Pa·s (1 N·s/m ) and is

tion of viscosity of asphalt (bitumen) by vacuum capillary

equivalent to 10 P.

viscometers at 140°F (60°C). It is applicable to materials

having viscosities in the range from 0.036 to over 200 000 P.

4. Summary of Test Method

NOTE 1—This test method is suitable for use at other temperatures, but

4.1 The time is measured for a fixed volume of the liquid to

the precision is based on determinations on asphalt cements at 140°F

be drawn up through a capillary tube by means of vacuum,

(60°C).

under closely controlled conditions of vacuum and tempera-

1.2 This standard does not purport to address all of the

ture. The viscosity in poises is calculated by multiplying the

safety concerns, if any, associated with its use. It is the

flow time in seconds by the viscometer calibration factor.

responsibility of the user of this standard to establish appro-

NOTE 2—The rate of shear decreases as the liquid moves up the tube,

priate safety and health practices and determine the applica-

or it can also be varied by the use of different vacuum or different size

bility of regulatory limitations prior to use.

viscometer. Thus, this method is suitable for the measurement of viscosi-

ties of Newtonian (simple) and non-Newtonian (complex) liquids.

2. Referenced Documents

2.1 ASTM Standards: 5. Significance and Use

E 1 Specification for ASTM Thermometers

5.1 The viscosity at 60°C (140°F) characterizes flow behav-

E 11 Specification for Wire-Cloth Sieves for Testing Pur-

ior and may be used for specification requirements for cutbacks

poses

and asphalt cements.

E 77 Test Method for Inspection and Verification of Liquid-

6. Apparatus

In-Glass Thermometers

6.1 Viscometers, capillary-type, made of borosilicate glass,

3. Terminology

annealed, suitable for this test are as follows:

3.1 Definitions:

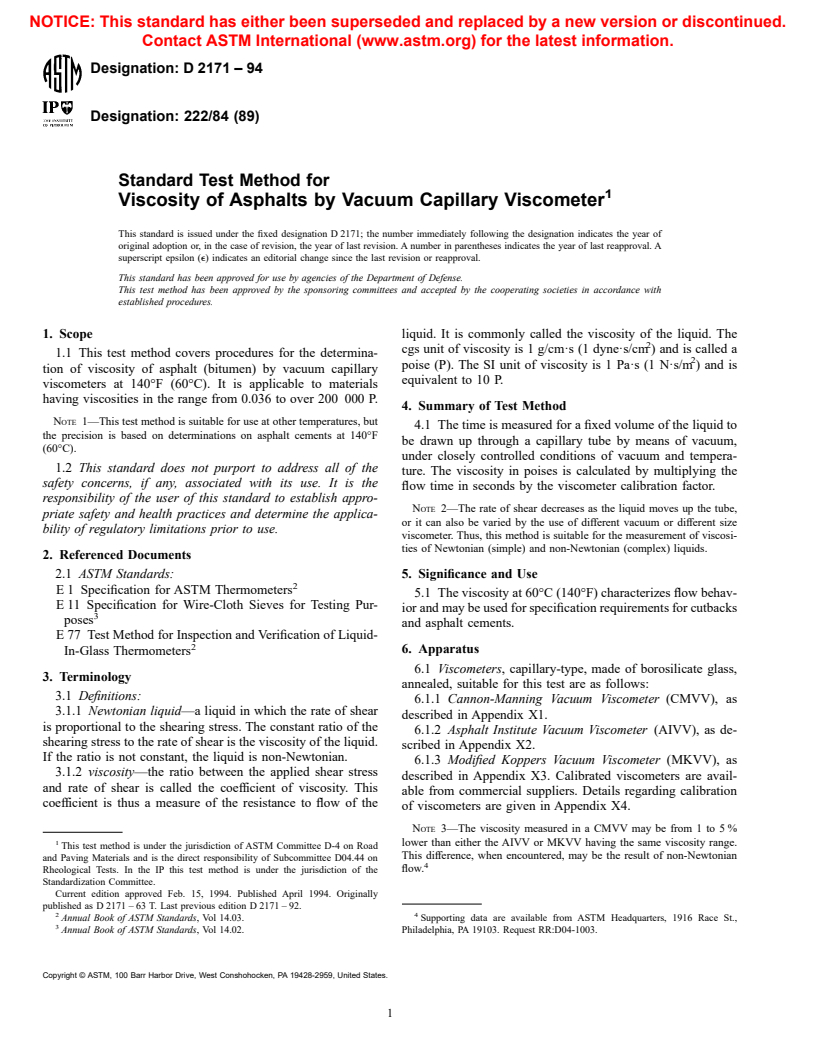

6.1.1 Cannon-Manning Vacuum Viscometer (CMVV), as

3.1.1 Newtonian liquid—a liquid in which the rate of shear

described in Appendix X1.

is proportional to the shearing stress. The constant ratio of the

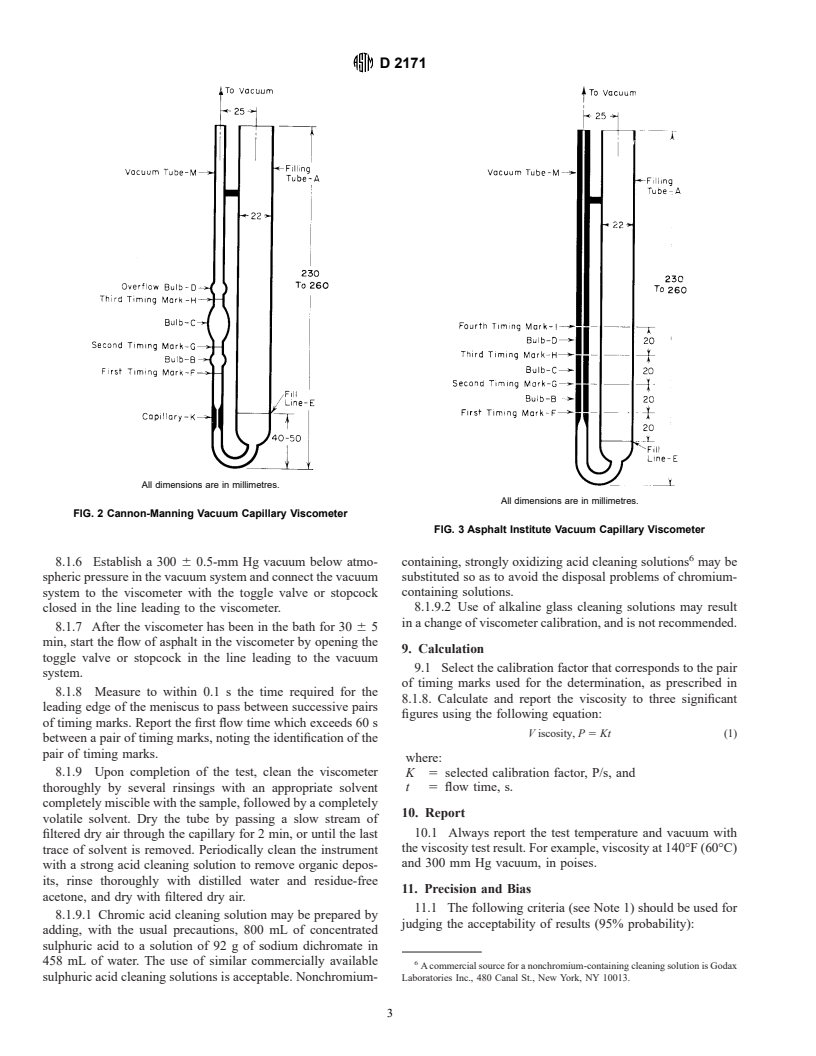

6.1.2 Asphalt Institute Vacuum Viscometer (AIVV), as de-

shearing stress to the rate of shear is the viscosity of the liquid.

scribed in Appendix X2.

If the ratio is not constant, the liquid is non-Newtonian.

6.1.3 Modified Koppers Vacuum Viscometer (MKVV), as

3.1.2 viscosity—the ratio between the applied shear stress

described in Appendix X3. Calibrated viscometers are avail-

and rate of shear is called the coefficient of viscosity. This

able from commercial suppliers. Details regarding calibration

coefficient is thus a measure of the resistance to flow of the

of viscometers are given in Appendix X4.

NOTE 3—The viscosity measured in a CMVV may be from 1 to 5 %

lower than either the AIVV or MKVV having the same viscosity range.

This test method is under the jurisdiction of ASTM Committee D-4 on Road

This difference, when encountered, may be the result of non-Newtonian

and Paving Materials and is the direct responsibility of Subcommittee D04.44 on

Rheological Tests. In the IP this test method is under the jurisdiction of the flow.

Standardization Committee.

Current edition approved Feb. 15, 1994. Published April 1994. Originally

published as D 2171 – 63 T. Last previous edition D 2171 – 92.

2 4

Annual Book of ASTM Standards, Vol 14.03. Supporting data are available from ASTM Headquarters, 1916 Race St.,

Annual Book of ASTM Standards, Vol 14.02. Philadelphia, PA 19103. Request RR:D04-1003.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

D 2171

6.2 Thermometers— Calibrated liquid-in-glass thermom-

eters (see Table X5.1) of an accuracy after correction of 0.04°F

(0.02°C) can be used or any other thermometric device of equal

accuracy. ASTM Kinematic Viscosity Thermometers 47F and

47C are suitable for the most commonly used temperature of

140°F (60°C).

6.2.1 The specified thermometers are standardized at“ total

immersion,” which means immersion to the top of the mercury

column with the remainder of the stem and the expansion

chamber at the top of the thermometer exposed to room

temperature. The practice of completely submerging the ther-

mometer is not recommended. When thermometers are com-

pletely submerged, corrections for each individual thermom-

eter based on calibration under conditions of complete

submergence must be determined and applied. If the thermom-

eter is completely submerged in the bath during use, the

pressure of the gas in the expansion chamber will be higher or

lower than during standardization, and may cause high or low

readings on the thermometer.

6.2.2 It is essential that liquid-in-glass thermometers be

calibrated periodically using the technique given in Test

Method E 77 (see Appendix X5).

6.3 Bath—A bath suitable for immersion of the viscometer

so that the liquid reservoir or the top of the capillary, whichever

is uppermost, is at least 20 mm below the upper surface of the

bath liquid and with provisions for visibility of the viscometer

FIG. 1 Suggested Vacuum System for Vacuum Capillary

and the thermometer. Firm supports for the viscometer shall be

Viscometers

provided. The efficiency of the stirring and the balance between

stirring the sample to aid heat transfer and to assure uniformity.

heat losses and heat input must be such that the temperature of

7.2 Transfer a minimum of 20 mL into a suitable container

the bath medium does not vary by more than 60.05°F

and heat to 275 6 10°F (135 6 5.5°C), stirring occasionally to

(60.03°C) over the length of the viscometer, or from viscom-

prevent local overheating and taking care to avoid the entrap-

eter to viscometer in the various bath positions.

ment of air.

6.4 Vacuum System— A vacuum system capable of main-

taining a vacuum to within 60.5 mm of the desired level up to

NOTE 4—If it is suspected that the sample may contain solid material,

and including 300 mm Hg. The essential system is shown strain the melted sample into the container through a No. 50 (300-μm)

sieve conforming to No. 50 Specification E 11.

schematically in Fig. 1. Glass tubing of 6.35-mm ( ⁄4-in.) inside

diameter should be used, and all glass joints should be airtight

8. Procedure

so that when the system is closed, no loss of vacuum is

8.1 The specific details of operation vary somewhat for the

indicated by the open-end mercury manometer having 1-mm

various types of viscometers. See the detailed descriptions of

graduations. A vacuum or aspirator pump is suitable for the

viscometers in Appendix X1-Appendix X3 for instructions for

vacuum source.

using the type of viscometer selected. In all cases, however,

6.5 Timer—A stop watch or other timing device graduated

follow the general procedure described in 8.1.1-8.1.9.

in divisions of 0.1 s or less and accurate to within 0.05 % when

8.1.1 Maintain the bath at the test temperature within6

tested over intervals of not less than 15 min.

0.05°F (60.03°C). Apply the necessary corrections, if any, to

6.6 Electrical Timing Devices may be used only on electri-

all thermometer readings.

cal circuits, the frequencies of which are controlled to an

8.1.2 Select a clean, dry viscometer that will give a flow

accuracy of 0.05 % or better.

time greater than 60 s, and preheat to 275 6 10°F (135 6

6.6.1 Alternating currents, the frequencies of which are

5.5°C).

intermittently and not continuously controlled, as provided by

8.1.3 Charge the viscometer by pouring the prepared

some public power systems, can cause large errors, particularly

sample to within 62 mm of fill line E (Fig. 2, Fig. 3, and Fig.

over short timing intervals, when used to actuate electrical

4).

timing devices.

8.1.4 Place the charged viscometer in an oven or bath

7. Sample Preparations

maintained at 275 6 10°F (135 6 5.5°C) for a period of 10 6

7.1 Heat the sample with care to prevent local overheating

2 min, to allow large air bubbles to escape.

until it has become sufficiently fluid to pour, occasionally

8.1.5 Remove the viscometer from the oven or bath and,

within 5 min, insert the viscometer in a holder, and position the

viscometer vertically in the bath so that the upper most timing

The vacuum control system marketed by Cannon Instrument Co., P. O. Box 16,

State College, PA 16801, has been found satisfactory for this purpose. mark is at least 20 mm below the surface of the bath liquid.

D 2171

All dimensions are in millimetres.

All dimensions are in millimetres.

FIG. 2 Cannon-Manning Vacuum Capillary Viscometer

FIG. 3 Asphalt Institute Vacuum Capillary Viscometer

8.1.6 Establish a 300 6 0.5-mm Hg vacuum below atmo- containing, strongly oxidizing acid cleaning solutions may be

spheric pressure in the vacuum system and connect the vacuum substituted so as to avoid the disposal problems of chromium-

system to the viscometer with the toggle valve or stopcock containing solutions.

8.1.9.2 Use of alkaline glass cleaning solutions may result

closed in the line leading to the viscometer.

in a change of viscometer calibration, and is not recommended.

8.1.7 After the viscometer has been in the bath for 30 6 5

min, start the flow of asphalt in the viscometer by opening the

9. Calculation

toggle valve or stopcock in the line leading to the vacuum

9.1 Select the calibration factor that corresponds to the pair

system.

of timing marks used for the determination, as prescribed in

8.1.8 Measure to within 0.1 s the time required for the

8.1.8. Calculate and report the viscosity to three significant

leading edge of the meniscus to pass between successive pairs

figures using the following equation:

of timing marks. Report the first flow time which exceeds 60 s

V iscosity, P 5 Kt (1)

between a pair of timing marks, noting the identification of the

pair of timing marks.

where:

8.1.9 Upon completion of the test, clean the viscometer K 5 selected calibration factor, P/s, and

thoroughly by several rinsings with an appropriate solvent t 5 flow time, s.

completely miscible with the sample, followed by a completely

10. Report

volatile solvent. Dry the tube by passing a slow stream of

10.1 Always report the test temperature and vacuum with

filtered dry air through the capillary for 2 min, or until the last

the viscosity test result. For example, viscosity at 140°F (60°C)

trace of solvent is removed. Periodically clean the instrument

and 300 mm Hg vacuum, in poises.

with a strong acid cleaning solution to remove organic depos-

its, rinse thoroughly with distilled water and residue-free

11. Precision and Bias

acetone, and dry with filtered dry air.

11.1 The following criteria (see Note 1) should be used for

8.1.9.1 Chromic acid cleaning solution may be prepared by

judging the acceptability of results (95% probability):

adding, with the usual precautions, 800 mL of concentrated

sulphuric acid to a solution of 92 g of sodium dichromate in

458 mL of water. The use of similar commercially available

A commercial source for a nonchromium-containing cleaning solution is Godax

sulphuric acid cleaning solutions is acceptable. Nonchromium- Laboratories Inc., 480 Canal St., New York, NY 10013.

D 2171

11.1.2 Reproducibility— The results submitted by each of

two laboratories should not be considered suspect unless the

two results differ by more than 10 % of their mean.

All dimensions are in millimetres.

FIG. 4 Modified Koppers Vacuum Capillary Viscometer

11.1.1 Repeatability— Duplicate results by the same opera-

tor using the same viscometer should not be considered suspect

unless they differ by more than 7 % of their mean.

APPENDIXES

(Nonmandatory Information)

X1. CANNON-MANNING VACUUM CAPILLARY VISCOMETER (CMVV)

TABLE X1.1 Standard Viscometer Sizes, Approximate Calibration

X1.1 Scope

Factors, K and Viscosity Ranges for Cannon-Manning Vacuum

X1.1.1 The Cannon-Manning vacuum capillary viscometer

Capillary Viscometers

,

7 8

(CMVV) is available in eleven sizes (Table X1.1) covering

A

Approximate Calibration Factor, K,

a range from 0.036 to 80 000 P. Sizes 10 through 14 are best Viscometer

B

300 mm Hg Vacuum, P/s

Viscosity Range, P

Size Number

suited to viscosity measurements of asphalt cements at 140°F

Bulb B Bulb C

(60°C).

4 0.002 0.0006 0.036 to 0.8

5 0.006 0.002 0.12 to 2.4

X1.2 Apparatus

6 0.02 0.006 0.36 to 8

7 0.06 0.02 1.2 to 24

X1.2.1 Details of the design and construction of Cannon-

8 0.2 0.06 3.6 to 80

Manning vacuum capillary viscometers are shown in Fig. 2. 9 0.6 0.2 12 to 240

10 2.0 0.6 36 to 800

11 6.0 2.0 120 to 2 400

12 20.0 6.0 360 to 8

Griffith, J. M. and Puzinauskas, P., “Relation of Empirical Tests to Fundamental

13 60.0 20.0 1 200 to 24 000

Viscosity of Asphalt Cement and the Relative Precision of Data Obtained by Various 14 200.0 60.0 3 600 to 80 000

Tests Methods,” Symposium on Fundamental Viscosity of Bituminous Materials,

A

Exact calibration factors must be determined with viscosity standards.

ASTM STP 328, Am. Soc. Testing Mats., ASTTA, 1962, pp. 20–44.

B

The viscosity ranges shown in this table correspond to a filling time of 60 to

Manning, R. E., “Comments on Vacuum Viscometers for Measuring the

400 s. Longer flow times (up to 1000 s) may be used.

Viscosity of Asphalt Cements,” Symposium on Fundamental Viscosity of Bituminous

Materials, ASTM STP No. 328, Am. Soc. Testing Mats., ASTTA, 1962, pp. 44–47.

D 2171

The size numbers, approximate bulb factors, K, and viscosity rubber stopper. The center-to-center distance between holes

ranges for the series of Cannon-Manning vacuum capillary should be 25 mm. Slit through the rubber stopper between

viscometers are given in Table X1.1.

holes and also between the 8-mm hole and edge of the stopper.

X1.2.2 For all viscometer sizes, the volume of measuring

When placed in a 2-in. (51-mm) diameter ho

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.