ASTM B907-05

(Specification)Standard Specification for Zinc, Tin and Cadmium Base Alloys Used as Solders

Standard Specification for Zinc, Tin and Cadmium Base Alloys Used as Solders

ABSTRACT

This specification covers solder metal alloys used as solders for the purpose of joining together two or more metals at temperatures below their melting points. The solder alloy shall conform to the required chemical compositions of cadmium, zinc, tin, lead, antimony, silver, copper, aluminum, bismuth, arsenic, iron, nickel and magnesium. The solder paste shall conform to the required smoothness of textures, powder mesh size, and viscosity.

SCOPE

1.1 This specification covers solder metal alloys (commonly known as soft solders), including zinc-aluminum, zinc-aluminum-copper, zinc-tin, zinc-tin-copper, zinc-cadmium-tin, zinc-cadmium, tin-zinc, cadmium-zinc, cadmium-zinc-silver, and cadmium-silver, used as solders for the purpose of joining together two or more metals at temperatures below their melting points.

1.1.1 Certain alloys specified in this standard are also used as Thermal Spray Wire in the electronics industry and are covered for this purpose in Specification B 943. Specification B 833 covers Zinc and Zinc Alloy Wire for Thermal Spraying (Metallizing) used primarily for the corrosion protection of steel (as noted in the Annex part of this specification).

1.1.2 Tin base alloys are included in this specification because their use in the electronics industry is different than the major use of the tin and lead solder compositions specified in Specification B 32.

1.1.3 These solders include alloys having a nominal liquidus temperature not exceeding 850°F (455°C).

1.1.4 This specification includes solder in the form of solid bars, ingots, wire, powder and special forms, and in the form of solder paste.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 Toxicity— Warning: Soluble and respirable forms of cadmium may be harmful to human health and the environment in certain forms and concentrations. Therefore, ingestion and inhalation of cadmium should be controlled under the appropriate regulations of the U.S. Occupational Safety and Health Administration (OSHA). Cadmium-containing alloys and coatings should not be used on articles that will contact food or beverages, or for dental and other equipment that is normally inserted in the mouth. Similarly, if articles using cadmium-containing alloys or coatings are welded, soldered, brazed, ground, flame-cut, or otherwise heated during fabrication, adequate ventilation must be provided to maintain occupational cadmium exposure below the OSHA Permissible Exposure Level (PEL).

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to become familiar with all hazards including those identified in the appropriate Material Safety Data Sheet (MSDS) for this product/material as provided by the manufacturer, to establish appropriate safety and health practices, and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B907 – 05

Standard Specification for

1

Zinc, Tin and Cadmium Base Alloys Used as Solders

This standard is issued under the fixed designation B907; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* adequateventilationmustbeprovidedtomaintainoccupational

cadmium exposure below the OSHA Permissible Exposure

1.1 Thisspecificationcoverssoldermetalalloys(commonly

Level (PEL).

known as soft solders), including zinc-aluminum, zinc-

1.4 This standard does not purport to address all of the

aluminum-copper, zinc-tin, zinc-tin-copper, zinc-cadmium-tin,

safety concerns, if any, associated with its use. It is the

zinc-cadmium, tin-zinc, cadmium-zinc, cadmium-zinc-silver,

responsibility of the user of this standard to become familiar

and cadmium-silver, used as solders for the purpose of joining

with all hazards including those identified in the appropriate

together two or more metals at temperatures below their

Material Safety Data Sheet (MSDS) for this product/material

melting points.

as provided by the manufacturer, to establish appropriate

1.1.1 Certain alloys specified in this standard are also used

safety and health practices, and determine the applicability of

as Thermal Spray Wire in the electronics industry and are

regulatory limitations prior to use.

covered for this purpose in Specification B943. Specification

B833 covers Zinc and Zinc Alloy Wire for Thermal Spraying

2. Referenced Documents

(Metallizing) used primarily for the corrosion protection of

2

2.1 ASTM Standards:

steel (as noted in the Annex part of this specification).

B32 Specification for Solder Metal

1.1.2 Tin base alloys are included in this specification

B833 Specification for Zinc and Zinc Alloy Wire for Ther-

becausetheiruseintheelectronicsindustryisdifferentthanthe

mal Spraying (Metallizing) for the Corrosion Protection of

major use of the tin and lead solder compositions specified in

Steel

Specification B32.

B899 Terminology Relating to Non-ferrous Metals and

1.1.3 These solders include alloys having a nominal liqui-

Alloys

dus temperature not exceeding 850°F (455°C).

B943 Specification for Zinc and Tin Alloy Wire Used in

1.1.4 This specification includes solder in the form of solid

Thermal Spraying for Electronic Applications

bars,ingots,wire,powderandspecialforms,andintheformof

E29 Practice for Using Significant Digits in Test Data to

solder paste.

Determine Conformance with Specifications

1.2 The values stated in inch-pound units are to be regarded

E46 Test Methods for Chemical Analysis of Lead and

as the standard. The values given in parentheses are for

3

Tin-Base Solder

information only.

E47 Test Methods for Chemical Analysis of Zinc Die-

1.3 Toxicity—Warning: Soluble and respirable forms of

3

Casting Alloys

cadmiummaybeharmfultohumanhealthandtheenvironment

E51 Method for Spectrographic Analysis of Tin Alloys by

in certain forms and concentrations. Therefore, ingestion and

3

the Powder Technique

inhalation of cadmium should be controlled under the appro-

E55 Practice for Sampling Wrought Nonferrous Metals and

priate regulations of the U.S. Occupational Safety and Health

Alloys for Determination of Chemical Composition

Administration (OSHA). Cadmium-containing alloys and coat-

E87 Methods for Chemical Analysis of Lead, Tin, Anti-

ings should not be used on articles that will contact food or

3

mony, and Their Alloys (Photometry Method)

beverages, or for dental and other equipment that is normally

E88 Practice for Sampling Nonferrous Metals andAlloys in

inserted in the mouth. Similarly, if articles using cadmium-

Cast Form for Determination of Chemical Composition

containing alloys or coatings are welded, soldered, brazed,

ground, flame-cut, or otherwise heated during fabrication,

1

This specification is under the jurisdiction of ASTM Committee B02 on

2

Nonferrous Metals and Alloys and is the direct responsibility of Subcommittee For referenced ASTM standards, visit the ASTM website, www.astm.org, or

B02.04 on Zinc and Cadmium. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Current edition approved Nov. 1, 2005. Published December 2005. Originally Standards volume information, refer to the standard’s Document Summary page on

approved in 2000. Last previous edition approved in 2004 as B907 – 04. DOI: the ASTM website.

3

10.1520/B0907-05. Withdrawn.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B907 – 05

TABL

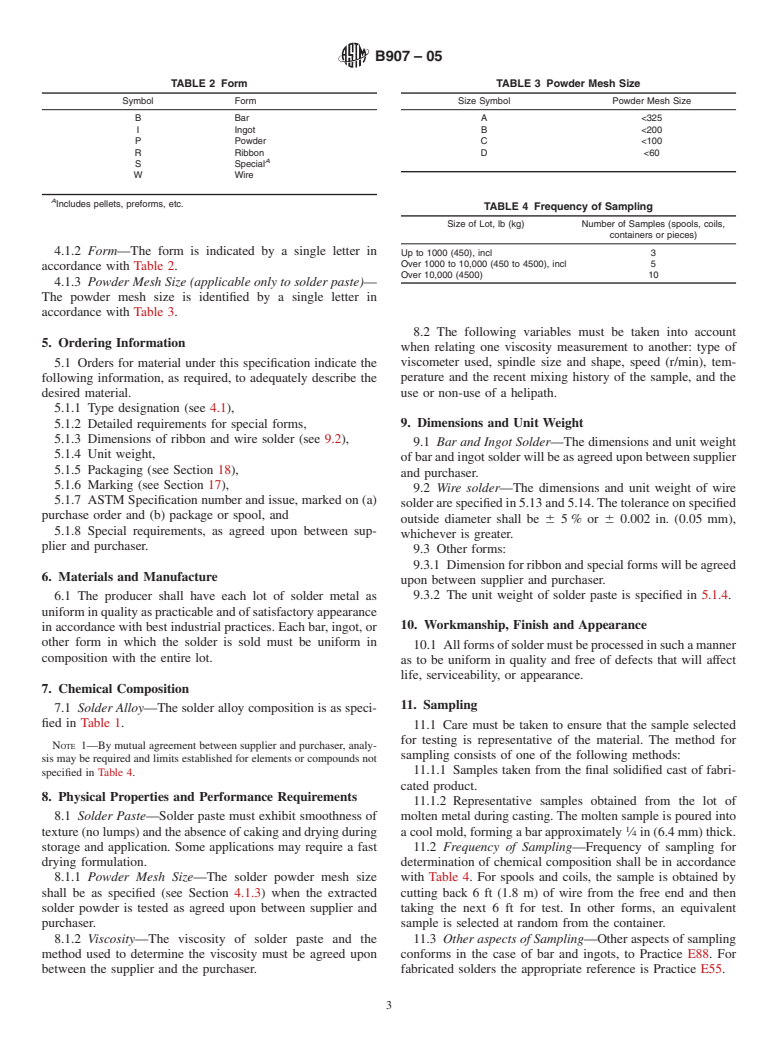

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.