ASTM A1071/A1071M-11

(Test Method)Standard Test Method for Evaluating Hygrothermal Corrosion Resistance of Permanent Magnet Alloys

Standard Test Method for Evaluating Hygrothermal Corrosion Resistance of Permanent Magnet Alloys

SIGNIFICANCE AND USE

This test method provides a controlled corrosive environment which can be utilized to produce relative corrosion resistance information for sintered permanent magnets.

Although prediction of performance in natural environments has seldom been statistically correlated with corrosion test results, sufficient empirical results are available to support the usefulness of this test in quantifying relative resistance to corrosion from moisture and heat.

The reproducibility of results in this test method is dependent on the type, size, and shape of specimens tested, and the control of the operating variables. In any testing program, sufficient replicates should be included to establish confidence limits. Replicates may be run simultaneously, in subsequent test runs, or in duplicate test chambers.

When multiple test chambers and operators are utilized, efforts shall be made to perform a suitable repeatability and reproducibility study for the equipment, operators, and test method.

SCOPE

1.1 This test method covers the equipment, procedures, and measurement of the resistance of permanent magnet alloys against corrosion in high temperature, high pressure water vapor environments. This test is also known as the Bulk Corrosion Test (BCT).

1.2 The values and equations stated in customary (cgs-emu and inch-pound) units or SI units are to be regarded separately as standard. Within this standard the SI units, when different from customary units, are shown in brackets, the values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A1071/A1071M − 11

StandardTest Method for

Evaluating Hygrothermal Corrosion Resistance of

Permanent Magnet Alloys

This standard is issued under the fixed designation A1071/A1071M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

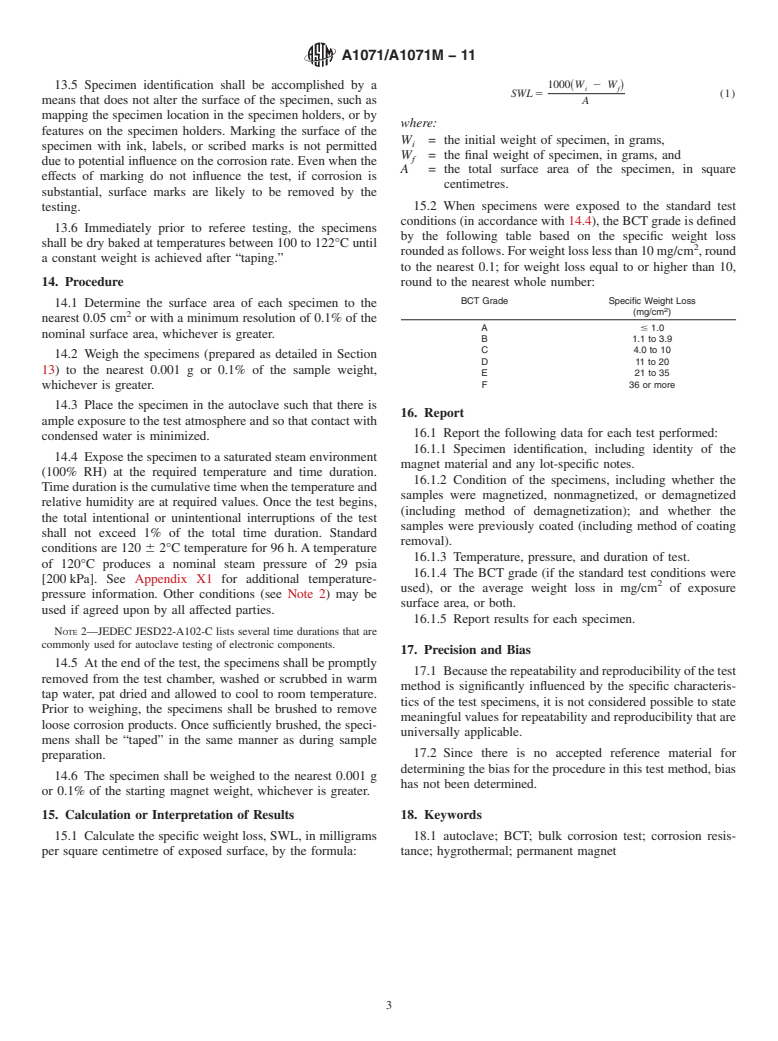

1. Scope 3.1.1 bulk corrosion test (BCT) grade, n—grade given to

ranges of specific weight loss to indicate the relative corrosion

1.1 This test method covers the equipment, procedures, and

resistance of a material. (The grades are listed in 15.2.)

measurement of the resistance of permanent magnet alloys

against corrosion in high temperature, high pressure water 3.1.2 specific weight loss, n—weight loss of the specimen

vapor environments. This test is also known as the Bulk per unit of exposed surface area, in units of milligrams per

Corrosion Test (BCT). square centimetre, due to corrosion and disintegration.

1.2 The values and equations stated in customary (cgs-emu

4. Summary of Test Method

and inch-pound) units or SI units are to be regarded separately

as standard. Within this standard the SI units, when different

4.1 Permanent magnet samples are exposed to pressurized

from customary units, are shown in brackets, the values stated

steam to determine the resistance of these materials, especially

in each system may not be exact equivalents; therefore, each

rare earth-type permanent magnets, to degradation by the

system shall be used independently of the other. Combining

combined action of heat and water vapor. The resulting weight

values from the two systems may result in nonconformance

loss (including removed loosely-attached material) is used to

with this standard.

rate the hygrothermal corrosion resistance of the magnet.

1.3 This standard does not purport to address all of the

5. Significance and Use

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

5.1 This test method provides a controlled corrosive envi-

priate safety and health practices and determine the applica-

ronment which can be utilized to produce relative corrosion

bility of regulatory limitations prior to use.

resistance information for sintered permanent magnets.

5.2 Although prediction of performance in natural environ-

2. Referenced Documents

ments has seldom been statistically correlated with corrosion

2.1 ASTM Standards:

test results, sufficient empirical results are available to support

D3330/D3330M TestMethodforPeelAdhesionofPressure-

the usefulness of this test in quantifying relative resistance to

Sensitive Tape

corrosion from moisture and heat.

2.2 JEDEC Standards:

5.3 The reproducibility of results in this test method is

JESD22-A102-C Accelerated Moisture Resistance – Unbi-

dependentonthetype,size,andshapeofspecimenstested,and

ased Autoclave

the control of the operating variables. In any testing program,

sufficient replicates should be included to establish confidence

3. Terminology

limits. Replicates may be run simultaneously, in subsequent

3.1 Definitions:

test runs, or in duplicate test chambers.

5.4 When multiple test chambers and operators are utilized,

efforts shall be made to perform a suitable repeatability and

This test method is under the jurisdiction of ASTM Committee A06 on

reproducibility study for the equipment, operators, and test

MagneticPropertiesandisthedirectresponsibilityofSubcommitteeA06.01onTest

method.

Methods.

Current edition approved May 1, 2011. Published May 2011. DOI:10.1520/

A1071_A1071M–11.

6. Interferences

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

6.1 This test method will not yield meaningful results if

Standards volume information, refer to the standard’s Document Summary page on

nonhomogeneous specimens such as assemblies or partially

the ASTM website.

coated magnets are tested because of the potential aggravating

Available from JEDEC Solid State Technology Association, 2500 Wilson

Boulevard, Arlington, VA 22201–3834. www.jedec.org effect of galvanic corrosion between dissimilar materials,

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

A1071/A1071M − 11

chemical reactivity with included materials, incompletely ex- relief valve) shall be employed to ensure that the pressure

posed surfaces, and difficulty in determining the amount of within the equipment does not exceed its design limit.

weight loss attributable to the magnet and coating.

9.2 This test method utilizes pressurized steam which has

6.2 Many cleansers contain bleach or chlorides which will the ability to cause severe burns. Suitable means should be

increase the corrosion rate of the samples being tested. Do not employed to ensure that personnel are protected from vented

use bleach- or chloride-containing cleansers to clean the steam during operation, and in particular when the chamber is

interior of the test chamber or sample racks. Nonmetallic opened at the conclusion of the test.

scrubbing pads and water rinsing have been found to be

9.3 This test method utilizes elevated temperature. Suitable

suitable for routine cleaning of chambers and racks.

means should be employed to prevent burns caused by the

equipment, vented steam, and the specimens.

7. Apparatus

10. Sampling, Test Specimens, and Test Units

7.1 Autoclave—Aheatedpressurechambercapableofmain-

taining pressurized steam at controlled temperature. The tem-

10.1 A minimum of three replicates should be tested.

perature shall be maintained within 62°C of the selected

10.2 Whenever possible the samples should be unmagne-

temperature for the duration of the exposure. The atmosphere

tized. Magnetized samples may be demagnetized electro-

during test shall be saturated steam (100% RH). This can be

magnetically or thermally, provided the thermal process does

achieved by venting the chamber as it reaches operating

not damage the sample or significantly change its metallurgical

temperature and pressure and resealing the chamber after

state. Magnetized samples may be used in the magnetized state

pressure has been reduced to 5 psi [34 kPa] through venting.

provided they are secured on the rack so that they do not

The escaping steam purges the chamber of air, leaving only

contact other samples. Care shall be taken to prevent magnetic

steam within the chamber. While commercial autoclaves are

particles from being attracted to and sticking to the test

available that have self-contained heaters and timers, a con-

samples, causing erroneous readings. Obtaining accurate

ventional pressure cooker with external heater may also be

weights of magnetic material is difficult on many balances. For

used, as long as temperature and pressure controls capable of

magnetized samples, equipment and techniques that yield

maintaining suitable control of these variables are present.

accurate weights shall be used, including spacing the magnet

7.2 Balance—With suitable holders capable of measuring

away from the mechanism of the balance.

the mass of magnetic material to within 60.001 g or 60.1% of

11. Preparation of Apparatus

the magnet’s nominal weight (whichever is greater).

11.1 All equipment and specimen holders shall be inspected

7.3 Specimen Holders or Racks—Suitable containers or

and cleaned as necessary prior to use to ensure that the test

racks which can keep specimens from touching each other or

chamber, support racks, and other components are free of

metallic parts of the autoclave chamber. They must be con-

debris and visible contamination.

structed of material that will not affect the corrosion rate of the

sample. Suitable materials of construction have been found to

12. Calibration and Standardization

be aluminum (see Note 1), borosilicate or laboratory glass, or

12.1 Verify calibration of balance and autoclave (tempera-

halogen-free polymers.

ture controller). Verify that autoclave test temperature is

NOTE 1—Aluminum readily develops an insulating film when exposed

operating within specified range (see 7.1).

to air or steam. Care should be exercised when using freshly prepared or

refinished aluminum surfaces as the oxide film may be thin enough to

13. Sample Preparation

allow galvanic corrosion with the magnet under test. Generally, after

13.1 Test

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.