ASTM F1667-11ae1

(Specification)Standard Specification for Driven Fasteners: Nails, Spikes, and Staples

Standard Specification for Driven Fasteners: Nails, Spikes, and Staples

ABSTRACT

This specification covers nails, spikes, staples, and other fasteners driven by hand tool, power tool, or mechanical device in single or multiple strikes and are positioned by hand, tool, or machine. The driven fasteners are classified as type I: nails (NL); type II: cut nails (CN); type III: spikes (SP); and type IV: staples (ST). Materials shall be tested and the individual types shall conform to the material requirements and physical properties, such as ductility, tensile strength. Protective coating and finishes are also detailed.

SCOPE

1.1 This specification covers nails, spikes, staples, and other driven fasteners, as listed in Table 1.

Note 1—Fastener ductility information is presented in Table 2 and dimensional information in Tables 3-67.

1.2 Fasteners described in this specification are driven by hand tool, power tool, or mechanical device in single or multiple strikes and are positioned by hand, tool, or machine.

1.3 The values stated in inch-pound units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 Fasteners in this specification are sold in bulk (loose) form and are collated for loading into the magazine of an application tool. Other than as covered in Section 9, Workmanship, cohering materials (including, but not limited to, plastic, adhesive bond, paper tape, plastic strip, plastic carrier, wire, etc.) and relative orientation of collated fasteners are not within the scope of this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

TABLE 1 Classification and Identification Index Type Style Style Identification Table INails (NL) 1. Brads BR 3 2. Barrel BL 4 3. Boat BTH/BTL 5 4. Box A BXA 6 Box B BXB 7 5. Broom BM 8 6. Casing CN 9 7. Cooler CL 10 8. Sinker SK 11 9. Corker CK 12 10. Common CMA 13 Common CMC 14 Common CMS 15 Common CMM 16 11. Concrete CTS/CTM 17 12. Double-headed DH 18 13. Fine FN 19 14. Finishing FH 20 15. Flooring FL 21 16. Lath LHF 22 Lath LHH 23 17. Masonry MR/MRH 24 18. Pallet PL 25 19. Gypsum wallboard GWS 26 Gypsum wallboard GWM 27 20. Roofing RFA 28 Roofing RFS 29 Roofing RFC 30 Roofing RFL 31 Roofing RFR 32 Roofing RFD 33 Roofing RFNS/RFND 34 21. Shingle SHAD/SHAS 35 Shingle SHSS/SHNSB 36 22. Siding SDF/SDC/SDK 37 23. Slating SLA/SLC/SLS 38 24. Rubber heel RH 39 25. Underlayment UL 40 26. Square-barbed SB 41 27. Masonry drive MD 42 28. Escutcheon ES 43 29. Glulam rivet GR 44 30.Post framePF45 IICut nails (CN) 1. Common CM 46 2. Basket BK 47 3. Clout CL 48 4. Trunk TR 49 5. Cobblers CB 50 6. Extra-iron clinching EC 51 7. Hob HB 52 IIISpikes (SP) 1. Common CM 53 2. Gutter GRF/GRO 54 3. Round RDC/RDF 55 4. Barge and boat BB 56 IVStaples (ST) 1. Fence FN 57 2. Poultry netting PN 58 3. Flat top crown FC 59 Flat top crown FCC 60 4. Round or V crown RC 61 5. Preformed PC 62 6. Electrical RE 63 7. Preformed hoop PH 64 8. CapSTC 65

TABLE 2 Bend Angles for Fasteners Using the Test Methods F680 Bend Test Fastener Material Bend Angle, ° 1. Steel wire: (low-carbon, medium-low

carbon, medium-carbon) (unhardened) 180 2. Stainless steel wire 180 3. Hardened steel fasteners 20 4. Sheet steel for cut nails, Type II,

and cut spikes, Type III 90 5. Copper (min 98 %) 180 6. Copper clad wire (min 20 %) 180 7. Aluminum alloy wire 90 8. Brass wire 180

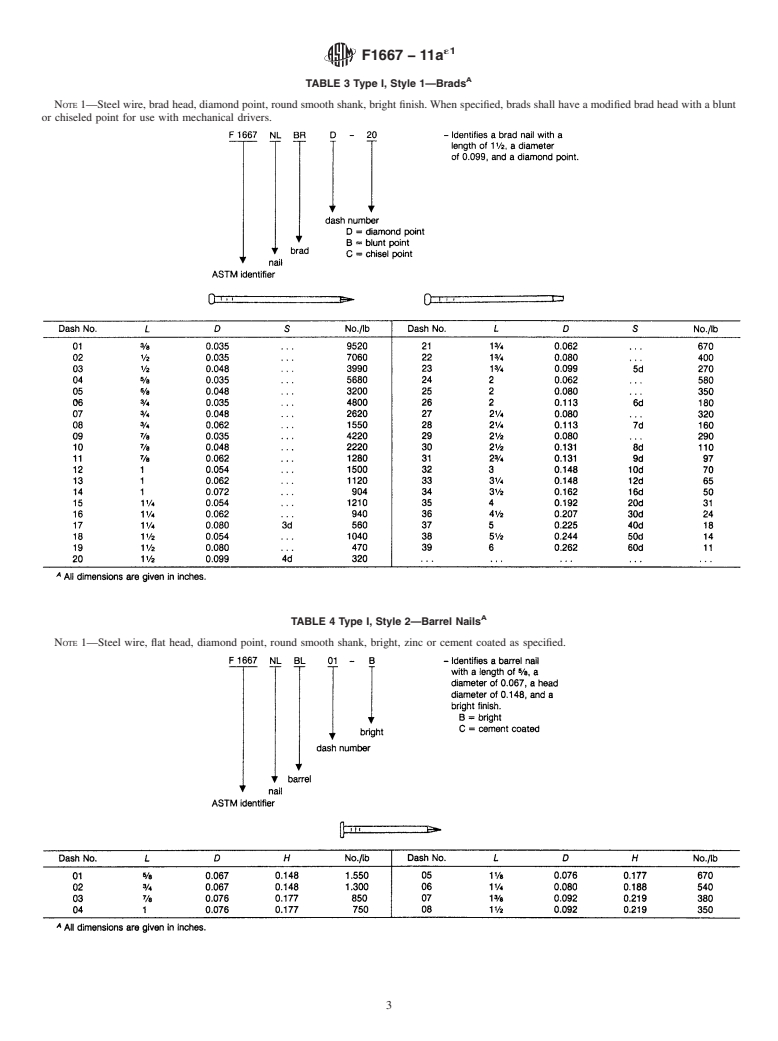

TABLE 3 Type I, Style 1BradsA

Note—Steel wire, brad head, diamond point, round smooth shank, bright finish. When specified, brads shall have a modified brad head with a blunt or chiseled point for use with mechanical drivers.

TABLE 4 Type I, Style 2Barrel Nail...

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation:F1667 −11a

StandardSpecification for

1

Driven Fasteners: Nails, Spikes, and Staples

This standard is issued under the fixed designation F1667; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

The Commercial and Government Entity (Cage) Code for ASTM: 81346.

1

´ NOTE—The fastener description on the first page of Table 33 was editorially updated in March 2012.

1. Scope* Rods and Coarse Round Wire, Carbon Steel (Metric)

A641/A641MSpecification for Zinc–Coated (Galvanized)

1.1 Thisspecificationcoversnails,spikes,staples,andother

Carbon Steel Wire

driven fasteners, as listed in Table 1.

B695Specification for Coatings of Zinc Mechanically De-

NOTE 1—Fastener ductility information is presented in Table 2 and

dimensional information in Tables 3-65. posited on Iron and Steel

F547Terminology of Nails for Use with Wood and Wood-

1.2 Fasteners described in this specification are driven by

Base Materials

hand tool, power tool, or mechanical device in single or

F592Terminology of Collated and Cohered Fasteners and

multiple strikes and are positioned by hand, tool, or machine.

Their Application Tools

1.3 Thevaluesstatedininch-poundunitsaretoberegarded

F680Test Methods for Nails

asstandard.Nootherunitsofmeasurementareincludedinthis

F1575TestMethodforDeterminingBendingYieldMoment

standard.

of Nails

1.4 Fasteners in this specification are sold in bulk (loose)

form and are collated for loading into the magazine of an

3. Terminology

application tool. Other than as covered in Section 9,

3.1 Definitions—The definitions used in this specification

Workmanship, cohering materials (including, but not limited

are those of common commercial acceptance and usage and

to, plastic, adhesive bond, paper tape, plastic strip, plastic

also appear in Terminologies F547 and F592.

carrier, wire, etc.) and relative orientation of collated fasteners

are not within the scope of this standard.

4. Classification

1.5 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

4.1 The fasteners and their Table 1 classification are iden-

responsibility of the user of this standard to establish appro-

tified as follows:

priate safety and health practices and determine the applica-

NOTE 2—The identification of fasteners, classified by style and type

bility of regulatory limitations prior to use.

(alpha indicators) followed by a dash number (numerical code) based on

Tables 3-65, identifies dimensions specifically and establishes a PIN (part

2. Referenced Documents

identifying number) system when preceded by the F1667 ASTM desig-

2

nator of this specification. For example:

2.1 ASTM Standards:

A153/A153MSpecification for Zinc Coating (Hot-Dip) on

Iron and Steel Hardware

A510MSpecification for General Requirements for Wire

1

This specification is under the jurisdiction of ASTM Committee F16 on

Fasteners and is the direct responsibility of Subcommittee F16.05 on Driven and

Other Fasteners.

Current edition approved Nov. 1, 2011. Published November 2011. Originally

approved in 1995. Last previous edition approved in 2011 as F1667–11. DOI:

10.1520/F1667-11AE01.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

4.2 Thetradedesignation, S,pennyweight,usedincommer-

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. cial practice is referenced in Tables 3-64 wherever it applies.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

´1

F1667−11a

TABLE 1 Classification and Identification Index TABLE 2 Bend Angles for Fasteners Using the Test Methods

F680 Bend Test

Type Style Style Identification Table

Fastener Material Bend

I—Nails (NL) 1. Brads BR 3

Angle, °

2. Barrel BL 4

3. Boat BTH/BTL 5

1. Steel wire: (low-carbon, medium-low 180

4. Box A BXA 6

carbon, medium-carbon) (unhardened)

Box B BXB 7 2. Stainless steel wire 180

5. Broom BM 8

3. Hardened steel fasteners 20

6. Casing CN 9 4. Sheet steel for cut nails, Type II, 90

7. Cooler CL 10

and cut spikes, Type III

8. Sinker SK 11

5. Copper (min 98 %) 180

9. Corker CK 12

6. Copper clad wire (min 20 %) 180

10. Common CMA 13

7. Aluminum alloy wire 90

Common CMC 14 8. Brass wire 180

Common CMS 15

Common CMM 16

11. Concrete CTS/CTM 17

5.1.3 Special material requirements

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.