ASTM D4226-00

(Test Method)Standard Test Methods for Impact Resistance of Rigid Poly(Vinyl Chloride) (PVC) Building Products

Standard Test Methods for Impact Resistance of Rigid Poly(Vinyl Chloride) (PVC) Building Products

SCOPE

1.1 These test methods cover the determination of the energy required to crack or break rigid poly(vinyl chloride) (PVC) plastic sheeting and profile flat sections used in building products, as well as extruded or molded test samples, under specified conditions of impact from a freefalling standard weight striking an impactor with either of two configurations in contact with the specimen.

1.2 Two test procedures are included:

1.2.1 Procedure A used to determine minimum impact energy required to cause failure (hole, crack, split, shatter, or tear).

1.2.2 Procedure B used to determine minimum impact energy required to cause brittle failure.

1.3 The values in inch-pound units are to be regarded as the standard.

Note 1--There is no similar or equivalent ISO standard.

1.4 The text of this standard references notes and footnotes which provide explanatory material. These notes and footnotes (excluding, those in tables in figures) shall not be considered as requirements of this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in Section 8.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: D 4226 – 00

Standard Test Methods for

Impact Resistance of Rigid Poly(Vinyl Chloride) (PVC)

Building Products

This standard is issued under the fixed designation D 4226; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope * Insulating Materials for Testing

D 883 Terminology Relating to Plastics

1.1 These test methods cover the determination of the

D 1898 Practice for Sampling of Plastics

energy required to crack or break rigid poly(vinyl chloride)

D 3679 Specification for Rigid Poly(Vinyl Chloride) (PVC)

(PVC) plastic sheeting and profile flat sections used in building

Siding

products, as well as extruded or molded test samples, under

E 178 Practice for Dealing with Outlying Observations

specified conditions of impact from a freefalling standard

weightstrikinganimpactorwitheitheroftwoconfigurationsin

3. Terminology

contact with the specimen.

3.1 Definitions— Definitions are in accordance with Termi-

1.2 Two test procedures are included:

nology D 883, unless otherwise indicated.

1.2.1 Procedure A, used to determine minimum impact

3.2 Definitions of Terms Specific to This Standard:

energy required to cause failure (hole, crack, split, shatter, or

3.2.1 failure (of test specimen)—signifiedbythepresenceof

tear).

a punched hole, crack, split, shatter, or tear that was created in

1.2.2 Procedure B, used to determine minimum impact

the target area by the impact of the falling weight and is clearly

energy required to cause brittle failure.

visible to the naked eye when the sample is held up to the light

1.3 The values in inch-pound units are to be regarded as the

(see Fig. 1).

standard.

3.2.2 brittle failure—a punched hole, split, or shatter where

NOTE 1—There is no similar or equivalent ISO standard.

a piece of the specimen separates from the main part of the

specimen or a crack that has a 0° angle at the tip as measured

1.4 The text of this standard references notes and footnotes

which provide explanatory material. These notes and footnotes by the naked eye (see Fig. 1).

(excluding,thoseintablesinfigures)shallnotbeconsideredas 3.2.3 mean failure height (Procedure A)—the height from

which the falling weight will cause 50 % of the specimens to

requirements of this standard.

1.5 This standard does not purport to address all of the fail.

3.2.4 mean failure energy (mean impact resistance), ( Pro-

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- cedure A)—energy required to produce 50 % failures; the

product of the weight and mean failure height.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. Specific precau- 3.2.5 normalized mean failure energy (normalized mean

impact resistance)—the mean failure energy per unit (average)

tionary statements are given in Section 8.

specimen thickness (Procedure A).

2. Referenced Documents

3.2.6 mean brittle failure height—the height from which the

2.1 ASTM Standards: falling weight will cause 50 % brittle failures in specimens

D 374 Test Methods for Thickness of Solid Electrical Insu- (Procedure B).

lation 3.2.7 mean brittle failure energy (mean energy of ductile-

D 618 Practice for Conditioning Plastics and Electrical to-brittle transition), (Procedure B)—energy required to pro-

duce 50 % brittle failures; the product of the weight and mean

brittle failure height.

These test methods are under the jurisdiction of ASTM Committee D20 on

Plastics and are the direct responsibility of Subcommittee D20.24 on Plastic

Building Products. Annual Book of ASTM Standards, Vol 08.01.

Current edition approved Dec. 10, 2000. Published February 2001. Originally Annual Book of ASTM Standards, Vol 03.06.

published as D 4226 - 83. Last previous edition D 4226 - 99.

Annual Book of ASTM Standards, Vol 08.04.

2 6

Annual Book of ASTM Standards, Vol 10.01. Annual Book of ASTM Standards, Vol 14.02.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 4226

FIG. 1 Types of Failures of the Specimen

3.2.8 normalized mean brittle failure energy (normalized a stand that has a 0.64-in. (16.3-mm) hole. The falling weight

mean energy of ductile-to-brittle transition), (Procedure B)— impacts on the impactor head tending to drive it through the

the mean brittle failure energy per unit (average) specimen specimen into the hole of the stand.

thickness. 4.5 The technique used to find 50 % failure level in both

3.2.9 outlier—an observation that appears to deviate mark- procedures is commonly called the Bruceton Staircase Method

edly from other members of the sample in which it occurs. or Up-and-Down Method. Testing is concentrated near the

mean, reducing the number of specimens required to obtain a

4. Summary of Test Method

reasonably precise estimate.

4.1 The building product profile is cut apart, if necessary, to

5. Significance and Use

obtain a flat specimen at least 0.75 in. (19 mm) wide.

4.2 Procedure A establishes the height from which a stan- 5.1 The impact strength values obtained on the flat sections

dard falling 8-lb (3.6-kg) weight will cause 50 % of the of a building product profile are relevant only to the flat section

specimens to fail. thathasbeentestedandthesevaluesdonotnecessarilyindicate

4.3 Procedure B establishes the height from which a stan- theimpactresistanceofthewholeproduct,whichisaffectedby

dard falling 8-lb (3.6-kg) weight will cause 50 % of the the configuration of the profile (that is, corners, ribs, etc).

specimens to fail in a brittle mode. 5.2 Constant weight and variable height, employed in these

4.4 Both procedures employ either of two configurations of test methods, allow the velocity of impact to vary and,

impactor heads resting on the specimen. The specimen lays on therefore, by Procedure B, can determine the energy of

D 4226

ductile-to-brittle transition, which cannot be determined if a 6. Interferences

variable weight is dropped from a constant height.

6.1 The results obtained are greatly influenced by the

5.3 These test procedures have been found to be useful

qualityofthetestspecimens.Cracksusuallystartatthesurface

elements in rigid poly(vinyl chloride) (PVC) building product

in tension; the surface opposite the one that is struck by the

characterization. Compound qualification, finished product

impactor head. The composition of this surface layer and the

quality control, environmental and weatherability research and

degree of orientation introduced during the formation of the

development studies, and fabrication tolerance prediction con-

specimen are very important variables. Flaws in this surface

stitute useful applications.

will also affect results. Because of these factors, sometimes

5.4 Choice of the specific impactor head configuration used

additional information about the sample is achieved by testing

is related to a variety of product attributes, such as specimen

the sample from a variety of locations in a product or testing

thickness and product toughness as well as abstract factors,

from both sides of a flat section.

suchastheanticipatedmodeoffailureinaspecificapplication.

The geometric uniqueness of the impactor head configurations

7. Apparatus

prevents any comparison or correlation of testing results on

samples tested with differing impactor head configurations. In

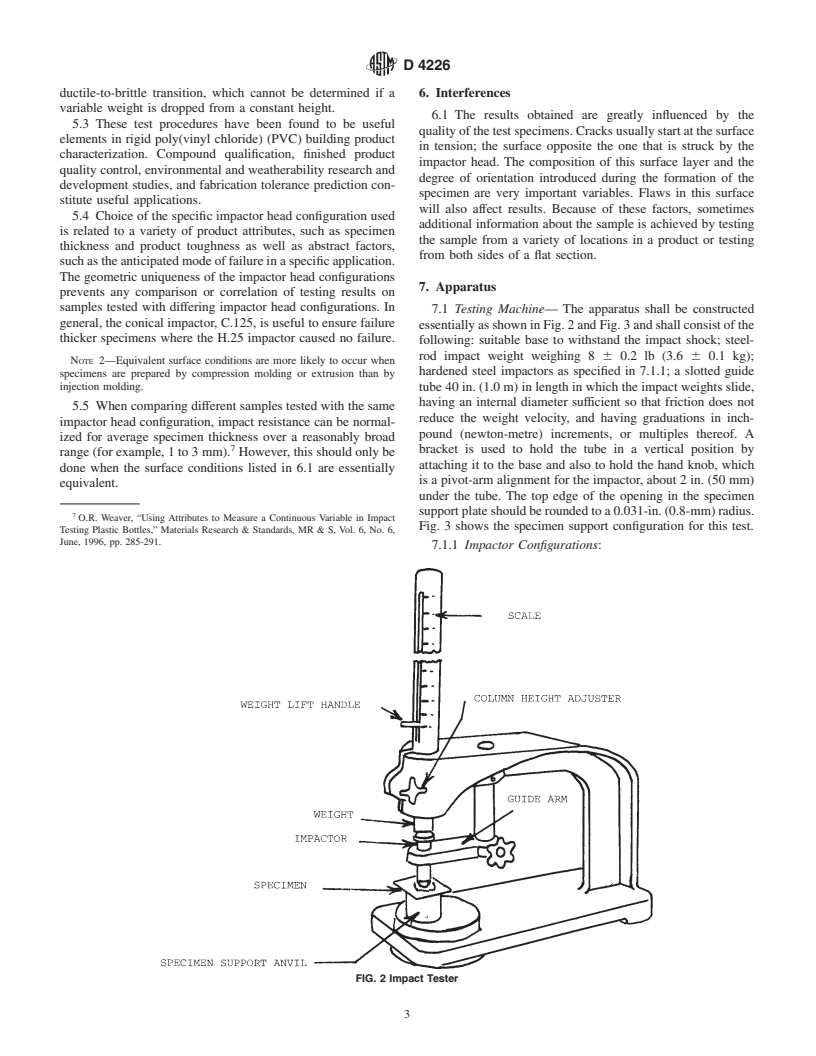

7.1 Testing Machine— The apparatus shall be constructed

general, the conical impactor, C.125, is useful to ensure failure

essentiallyasshowninFig.2andFig.3andshallconsistofthe

thicker specimens where the H.25 impactor caused no failure.

following: suitable base to withstand the impact shock; steel-

rod impact weight weighing 8 6 0.2 lb (3.6 6 0.1 kg);

NOTE 2—Equivalent surface conditions are more likely to occur when

hardened steel impactors as specified in 7.1.1; a slotted guide

specimens are prepared by compression molding or extrusion than by

injection molding.

tube 40 in. (1.0 m) in length in which the impact weights slide,

having an internal diameter sufficient so that friction does not

5.5 When comparing different samples tested with the same

reduce the weight velocity, and having graduations in inch-

impactor head configuration, impact resistance can be normal-

pound (newton-metre) increments, or multiples thereof. A

ized for average specimen thickness over a reasonably broad

bracket is used to hold the tube in a vertical position by

range (for example, 1 to 3 mm). However, this should only be

attaching it to the base and also to hold the hand knob, which

done when the surface conditions listed in 6.1 are essentially

is a pivot-arm alignment for the impactor, about 2 in. (50 mm)

equivalent.

under the tube. The top edge of the opening in the specimen

supportplateshouldberoundedtoa0.031-in.(0.8-mm)radius.

O.R. Weaver, “Using Attributes to Measure a Continuous Variable in Impact

Fig. 3 shows the specimen support configuration for this test.

Testing Plastic Bottles,” Materials Research & Standards, MR & S, Vol. 6, No. 6,

June, 1996, pp. 285-291.

7.1.1 Impactor Configurations:

FIG. 2 Impact Tester

D 4226

FIG. 3 Impactor Head Configuration H.25 Specimen Support Detail

7.1.1.1 Impactor C.125 shall be constructed, as is shown in cotterpin to prevent rebound. The cotterpin must be located

Fig. 4, of tough, hardened (Rockwell C 50-55), scratch well above the penetration depth of the impactor head.

resistantsteel.Itshouldhaveaconical(40-°)configurationand

0.125-in. (3.18-mm) radius hemispherical tip. 9. Sampling

7.1.1.2 Impactor H.25 shall be constructed, as is shown in

9.1 Select samples in accordance with Practice D 1898. The

Fig. 3, of tough, hardened (Rockwell C 50-55) scratch resistant

samples shall be representative of the lot under study.

steel. It should have a 0.25-in. (6.35-mm) radius hemispherical

tip (see Fig. 3andFig. 4 ).

10. Test Specimen

7.1.1.3 The surface of the impactor head shall be polished

10.1 Flat test specimens at least 0.75-in. (19-mm) wide can

free of nicks, scratches, or other surface irregularities.

betested.Thespecimensshallbefreeofobviousimperfections

7.2 Supporting Base—In order to minimize the energy

unless they constitute variables under study.

absorption, compression, and deflection of the support the

10.2 When the approximate mean failure height for a given

tester shall be firmly fixed to a dense, solid, block or base.

sample is known, 20 specimens usually yield sufficiently

7.2.1 The main body of said block or base shall have

precise results. If the mean failure height cannot be approxi-

maximum dimensions of 16 in. (h) 3 30 in. (w) 3 30 in. (d)

mated, six or more specimens should be used to determine the

and shall have a minimum weight of 400 lbs. This block shall

appropriate starting point of the test.

be placed at a height that facilitates equipment usage. It is not

NOTE 4—Specimen quantity, as small as five, often yields sufficiently

necessary to bolt blocks or bases of this weight to the floor.

reliable estimates of the mean failure height. However, the estimated

NOTE 3—The required block weight and dimensions conform to com-

standard deviation will be relatively large.

mercially available butcher block type tables.

11. Conditioning

7.2.2 Alternative supporting bases or those lighter than 400

11.1 Unless otherwise specified, condition the test speci-

lbs should be bolted to a concrete floor. Mean failure energy

mens at 73.4 6 3.6°F (23 6 2°C) and 50 6 5 % relative

comparisons shall be made between these alternative supports

humidity for not less than 40 h prior to test in accordance with

and one where the tester is bolted directly to the concrete floor.

Procedure A of Methods D 618. In cases of disagreement, the

If mean failure energy differences between the concrete floor

tolerance shall be 61.8°F (61°C) and 62 % relative humidity.

and the alternative support are found statistically nonsignifi-

11.2 Quality Control Tests—Condition the test specimens at

cant, use of the lighter support shall be allowed.

73.4 6 3.6°F (23 6 2°C) for4hinair.

7.2.3 Use of rubber mats either under the tester or the

supporting base is prohibited.

12. Procedure

7.3 Micrometer, for measurement of specimen thickness. It

should be accurate to1%ofthe average thickness of

12.1 Procedure A:

specimensused.SeeTestMethodsD374forsuitablemicrome-

12.1.1 Measure and record the thickness of each specimen

ters.

at the anticipated area of impact. Average the values for all

8. Safety Precautions

8.1 Shieldingdevicesshallbeprovidedtoprotectpersonnel.

Brownless, K. A., Hodges J. L., Jr., and Rosenblatt, Murray, “The Up-and-

8.2 Atube can contain the impactor head if it rebounds after

Down Method with Small Samples,” American Statistical Association Journal,

striking a specimen, or the impactor head may be drilled for a JSTNA, Vol. 48, 1953, pp. 262-277.

D 4226

FIG. 4 Impactor Head Configuration C.125

specimens in a sample and use this average thickness in 12.1.6 Raise the weight in the tube to the approximate

calculating normalized mean failure energy. failure energy value for the specific sample and release it so

that the weight drops on the impactor. If the approximate

NOTE 5—When using a large specimen, such as PVC sliding, measure

failure energy value for the sample is unknown, run about six

the thickness at five points uniformly across the width of the specimen.

Use the average of these five values as the average thickness to calculate impact tests at varying energy levels to bracket the approxi-

the normalized mean failure energy.

mate failure energy level before initiating the test series of

12.1.2 Choose a specimen at random from the sample. impacts.

Determine the order of testing by using a set of random

12.1.7 Remove the specimen and examine it to determine

numbers.

whether it has failed. See 3.2.1 for criteria of failure.

12.1.3 Selecttheproperimpactor-headconfiguration(C.125

12.1.8 If the first impact of the specimen results in failure,

or H.25) specified for the test and install on the apparatus.

decrease the drop height one increment. If the first impact of

Adjust the guide arm so that each impactor head is visually

the specimen does not cause failure, increase the drop height

centeredandachievestheproperdepthofpenetration.Depthof

one increment. Then test a second specimen or

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.