ASTM A231/A231M-96(2002)

(Specification)Standard Specification for Chromium-Vanadium Alloy Steel Spring Wire

Standard Specification for Chromium-Vanadium Alloy Steel Spring Wire

SCOPE

1.1 This specification covers round chromium-vanadium alloy steel spring wire having properties and quality intended for the manufacture of springs used at moderately elevated temperatures. This wire shall be either in the annealed and cold-drawn or oil-tempered condition as specified by the purchaser.

1.2 The values stated in either SI (metric) units or inch-pound units are to be regarded separately as standard. The values stated in each system are not exact equivalents; therefore, each system must be used independent of the other.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

Designation: A 231/A231M – 96 (Reapproved 2002)

Standard Specification for

Chromium-Vanadium Alloy Steel Spring Wire

This standard is issued under the fixed designationA231/A231M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 2.5 AIAG Standard:

AIAGB-5 02.00 Primary Metals Identification TagApplica-

1.1 This specification covers round chromium-vanadium

tion Standard

alloy steel spring wire having properties and quality intended

for the manufacture of springs used at moderately elevated

3. Ordering Information

temperatures. This wire shall be either in the annealed and

3.1 Orders for material under this specification should

cold-drawn or oil-tempered condition as specified by the

include the following information for each ordered item:

purchaser.

3.1.1 Quantity (mass),

1.2 The values stated in either SI (metric) units or inch-

3.1.2 Name of material (chromium-vanadium alloy steel

pound units are to be regarded separately as standard. The

wire),

values stated in each system are not exact equivalents; there-

3.1.3 Wire diameter (Table 1 and Table 2),

fore, each system must be used independent of the other.

3.1.4 Packaging (Section 14),

2. Referenced Documents 3.1.5 Cast or heat analysis report (if requested) (5.2),

3.1.6 Certification or test report, or both, if specified (Sec-

2.1 ASTM Standards:

tion 13), and

A 370 Test Methods and Definitions for MechanicalTesting

3.1.7 ASTM designation and date of issue.

of Steel Products

A 700 Practices for Packaging, Marking, and Loading

NOTE 1—A typical ordering description is as follows: 20 000 kg

Methods for Steel Products for Domestic Shipment oil-tempered chromium-vanadium alloy steel wire, size 6.00 mm in

150-kg coils to ASTM A 231M dated_______ , or for inch-pound units,

A 751 Test Methods, Practices, and Terminology for

40 000 lb oil-tempered chromium-vanadium alloy steel spring wire, size

Chemical Analysis of Steel Products

0.250 in. in 350-lb coils to ASTM A 231 dated_______.

A 752 Specification for General Requirements for Wire

Rods and Coarse Round Wire, Alloy Steel

4. Materials and Manufacture

E 29 Practice for Using Significant Digits in Test Data to

4.1 The steel may be made by any commercially accepted

Determine Conformance with Specifications

steel–making process. The steel may be either ingot cast or

2.2 ANSI Standard:

strand cast.

B 32.4M Preferred Metric Sizes for Round, Square, Rect-

4.2 The finished wire shall be free from detrimental pipe

angle, and Hexagon Metal Products

and undue segregation.

2.3 Military Standard:

MIL-STD-163 Steel Mill Products, Preparation for Ship-

5. Chemical Composition

ment and Storage

5.1 The steel shall conform to the requirements as to

2.4 Federal Standard:

chemical composition specified in Table 3.

Fed. Std. No. 123 Marking for Shipment (Civil Agencies)

5.2 Cast or Heat Analysis—Each cast or heat of steel shall

beanalyzedbythemanufacturertodeterminethepercentageof

1 elements prescribed in Table 3. This analysis shall be made

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

Stainless Steel, and RelatedAlloys and is the direct responsibility of Subcommittee fromatestspecimenpreferablytakenduringthepouringofthe

A01.03 on Steel Rod and Wire.

cast or heat. When requested, this shall be reported to the

Current edition approved March 10, 1996. Published May 1996. Originally

purchaser and shall conform to the requirements of Table 3.

published as A 230 – 39 T. Last previous edition A 231/A 231M – 93.

5.3 Product Analysis ( formerly Check Analysis)—An

Annual Book of ASTM Standards, Vol 01.03.

Annual Book of ASTM Standards, Vol 01.05.

analysis may be made by the purchaser from finished wire

Annual Book of ASTM Standards, Vol 14.02.

Available from American National Standards Institute, 11 West 42nd Street,

13th Floor, New York, NY 10036.

6 7

AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700 Available from the Automotive Industry Action Group, 26200 Lahser, Suite

Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS. 200, Southfield, MI 48034.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

A 231/A231M – 96 (2002)

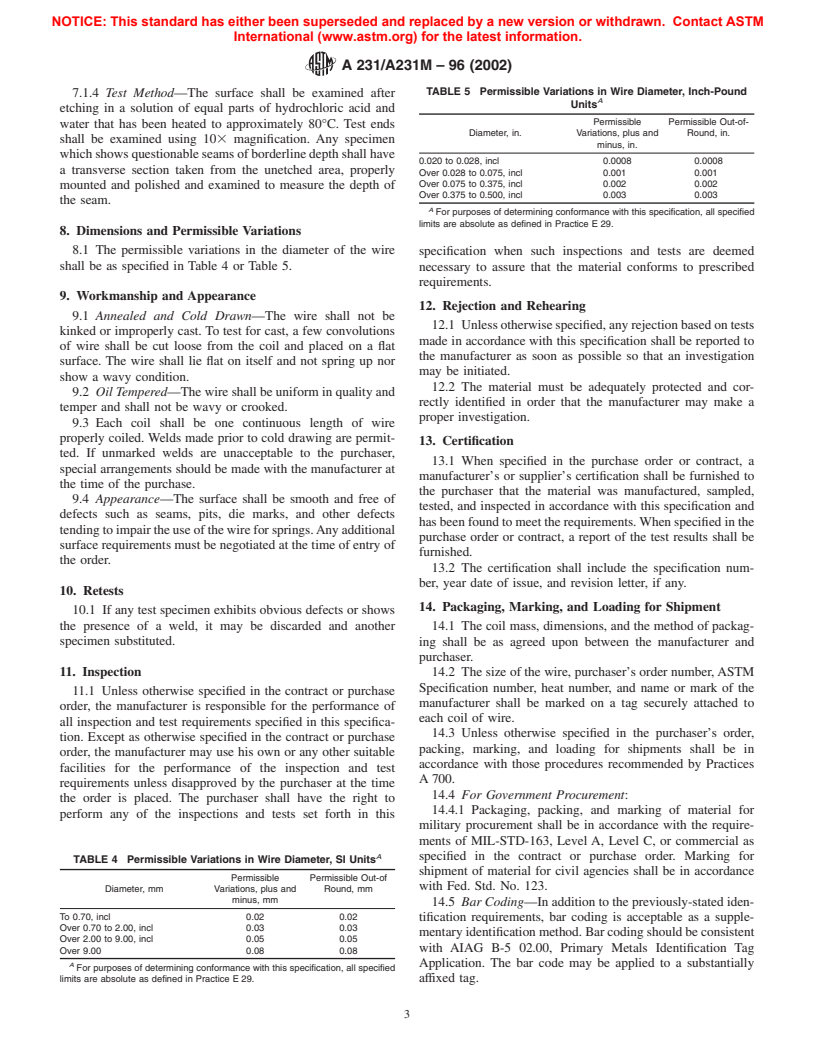

A

TABLE 1 Tensile Requirements, SI Units TABLE 3 Chemical Requirements

Tensile Strength, MPa Reduction of Areas, Element Analysis, %

B

Diameter, mm

min, %

Carbon 0.48–0.53

min max

Manganese 0.70–0.90

C

0.50 2060 2260

Phosphorus 0.040 max

C

0.55 2050 2240

Sulfur 0.040 max

C

0.60 2030 2220

Silicon 0.15–0.35

C

0.65 2010 2200

Chromium 0.80–1.10

C

0.70 2000 2160

Vanadium 0.15 min

C

0.80 1980 2140

C

0.90 1960 2120

C

1.00 1940 2100

C

1.10 1920 2080

C

1.20 1900 2060

6. Mechanical Properties

C

1.40 1860 2020

C

1.60 1820 1980

6.1 Annealed and Cold Drawn—When purchased in the

C

1.80 1800 1960

annealed and cold-drawn condition, the wire shall have been

C

2.00 1780 1930

C

given a sufficient amount of cold working to meet the purchas-

2.20 1750 1900

2.50 1720 1860 45

er’s coiling requirements and shall be in a suitable condition to

2.80 1680 1830 45

respond properly to heat treatment. In special cases the

3.00 1660 1800 45

3.50 1620 1760 45 hardness, if desired, shall be stated in the purchase order.

4.00 1580 1720 40

6.2 Oil Tempered—When purchased in the oil-tempered

4.50 1560 1680 40

condition, the tensile strength and minimum percent reduction

5.00 1520 1640 40

of area, sizes 2.50 mm or 0.105 in. and coarser, of the wire

5.50 1480 1620 40

6.00 1460 1600 40

shall conform to the requirements as shown inTable 1 orTable

6.50 1440 1580 40

2.

7.00 1420 1560 40

8.00 1400 1540 40 6.2.1 NumberofTests—Onetestspecimenshallbetakenfor

9.00 1380 1520 40

each ten coils, or fraction thereof, in a lot. Each cast or heat in

10.00 1360 1500 40

a given lot shall be tested.

11.00 1340 1480 40

12.00 1320 1460 40 6.2.2 LocationofTests—Test specimens shall be taken from

A

either end of the coil.

Tensile strength values for intermediate diameters may be interpolated.

B

Preferred sizes. For a complete list, refer to ANSI B 32.4M, Preferred Metric

6.2.3 Test Method—The tension test shall be made in

Sizes for Round, Square, Rectangle, and Hexagon Metal Products.

C accordance with Test Methods and Definitions A 370.

The reduction of area test is not applicable to wire diameters under 2.34 mm.

6.3 Wrap Test:

6.3.1 Oil tempered or cold drawn wire 4.00 mm or 0.162 in.

A

and smaller in diameter shall wind on itself as an arbor without

TABLE 2 Tensile Requirements, Inch-Pound Units

breakage.Largerdiameterwireuptoandincluding8.00mmor

Tensile Strength, ksi Reduction of Area,

B

Diameter, in.

min, %

0.312in.indiametershallwrapwithoutbreakageonamandrel

min max

twice the wire diameter.The wrap test is not applicable to wire

C

0.020 300 325

C

over 8.00 mm or 0.312 in. in diameter.

0.032 290 315

C

0.041 280 305

6.3.2 NumberofTests—Onetestspecimenshallbetakenfor

C

0.054 270 295

each ten coils, or fraction thereof, in a lot. Each cast or heat in

C

0.062 265 290

C

a given lot shall be tested.

0.080 255 275

0.105 245 265 45

6.3.3 Location of Test—Test specimens shall be taken from

0.135 235 255 45

either end of the coil.

0.162 225 245 40

6.3.4 Test Method—The wrap test shall be made in accor-

0.192 220 240 40

0.244 210 230 40

dance with Supplement IV of Test Methods and Definitions

0.283 205 225 40

A 370.

0.312 203 223 40

0.375 200 220 40

0.438 195 215 40

7. Metallurgical Properties

0.500 190 210 40

7.1 Surface Condition:

A

Tensile strength values for intermediate diameters m

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.