ASTM A876-09e1

(Specification)Standard Specification for Flat-Rolled, Grain-Oriented, Silicon-Iron, Electrical Steel, Fully Processed Types

Standard Specification for Flat-Rolled, Grain-Oriented, Silicon-Iron, Electrical Steel, Fully Processed Types

ABSTRACT

This specification covers the detailed requirements for specified grades of flat-rolled, grain-oriented, fully processed low-carbon silicon-iron electrical steels, whose low core loss and high permeability in the direction of rolling have been achieved by appropriate metallurgical processing. These steels are primarily used in transformer cores operating at moderate to high magnetic flux densities at commercial power frequencies. The ASTM core-loss type designations for the electrical steels covered here are 18G041, 23G045, 27G051, 30G058, 35G066, 23H070, 27H074, 30H083, 35H094, 23P060, 27P066, 23Q054, and 27Q057. Steels may be acquired in any of four conditions, classified according to a combination of material form and surface type or treatment as desired for the expected end use. Materials shall conform to specified values of magnetic properties (core loss, permeability, and magnetic aging), physical dimensions (thickness, length, and width), and mechanical properties (lamination factor and ductility).

SCOPE

1.1 This specification covers the detailed requirements to which the specified grades of flat-rolled, grain-oriented, fully processed electrical steels shall conform. These steels are used primarily in transformer cores operating at moderate to high magnetic flux densities at commercial power frequencies (50 and 60 Hz).

1.2 These grain-oriented electrical steels are low-carbon, silicon-iron alloys with a silicon content of approximately 3.2 % in which low core loss and high permeability in the direction of rolling have been achieved by appropriate metallurgical processing.

1.3 The electrical-steel grades described in this specification include (1) conventional grain-oriented electrical steel tested at 15 kG (1.5 T) in accordance with Test Method A343/A343M, (2) conventional grain-oriented electrical steel tested at 17 kG (1.7 T) in accordance with Test Method A343/A343M, (3) high-permeability grain-oriented electrical steel tested at 17 kG (1.7 T) in accordance with Test Method A343/A343M, and (4) laser-scribed high-permeability grain-oriented electrical steel tested at 17 kG (1.7 T) in accordance with Test Methods A804/A804M.

1.4 The values stated in customary (cgs-emu and inch-pound) units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units, which are provided for information only and are not considered standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation:A876 −09

StandardSpecification for

Flat-Rolled, Grain-Oriented, Silicon-Iron, Electrical Steel,

1

Fully Processed Types

This standard is issued under the fixed designation A876; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

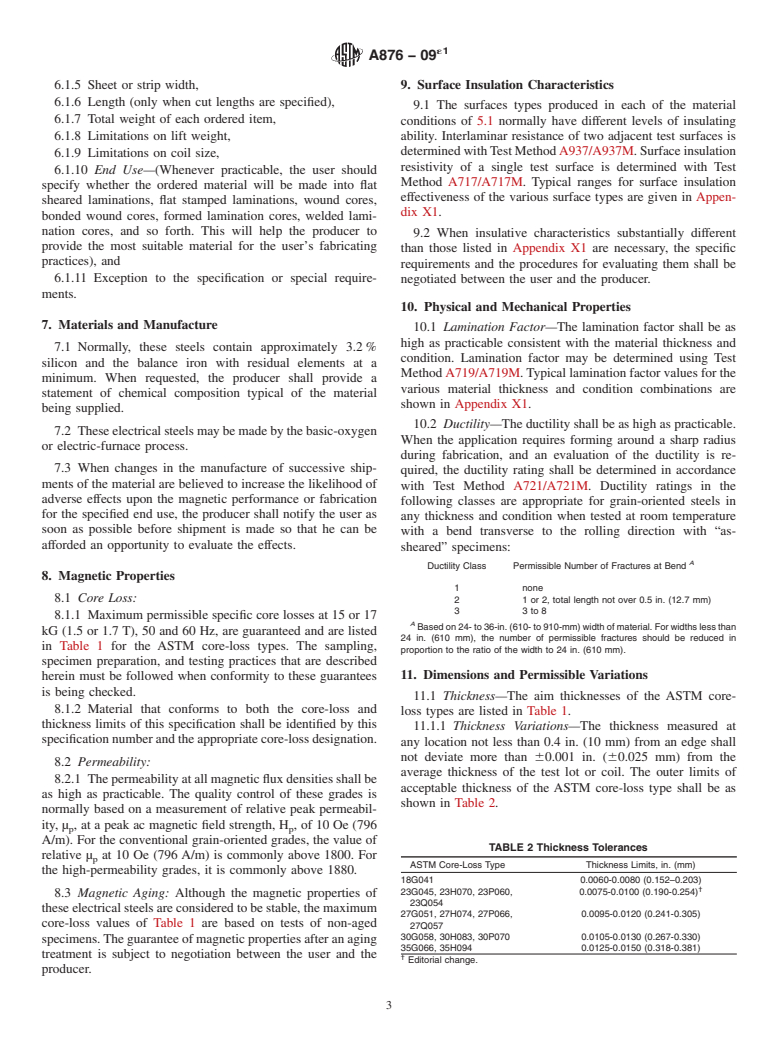

´ NOTE—Corrected conversion in Table 2 editorially in March 2012.

1. Scope 2. Referenced Documents

2

1.1 This specification covers the detailed requirements to 2.1 ASTM Standards:

which the specified grades of flat-rolled, grain-oriented, fully A34/A34MPractice for Sampling and Procurement Testing

processed electrical steels shall conform.These steels are used of Magnetic Materials

primarily in transformer cores operating at moderate to high A340Terminology of Symbols and Definitions Relating to

magnetic flux densities at commercial power frequencies (50 Magnetic Testing

and 60 Hz). A343/A343MTest Method for Alternating-Current Mag-

netic Properties of Materials at Power Frequencies Using

1.2 These grain-oriented electrical steels are low-carbon,

Wattmeter-Ammeter-Voltmeter Method and 25-cm Ep-

silicon-iron alloys with a silicon content of approximately

stein Test Frame

3.2% in which low core loss and high permeability in the

A345Specification for Flat-Rolled Electrical Steels for

direction of rolling have been achieved by appropriate metal-

Magnetic Applications

lurgical processing.

A664Practice for Identification of Standard Electrical Steel

1.3 Theelectrical-steelgradesdescribedinthisspecification

Grades in ASTM Specifications

include(1)conventionalgrain-orientedelectricalsteeltestedat

A700Practices for Packaging, Marking, and Loading Meth-

15 kG (1.5 T) in accordance with Test Method A343/A343M,

ods for Steel Products for Shipment

(2) conventional grain-oriented electrical steel tested at 17 kG

A717/A717MTestMethodforSurfaceInsulationResistivity

(1.7 T) in accordance with Test Method A343/A343M,(3)

of Single-Strip Specimens

high-permeabilitygrain-orientedelectricalsteeltestedat17kG

A719/A719MTest Method for Lamination Factor of Mag-

(1.7T) in accordance withTest Method A343/A343M, and (4)

netic Materials

laser-scribed high-permeability grain-oriented electrical steel

A721/A721MTest Method for Ductility of Oriented Electri-

tested at 17 kG (1.7 T) in accordance with Test Methods

cal Steel

A804/A804M.

A804/A804MTest Methods for Alternating-Current Mag-

1.4 The values stated in customary (cgs-emu and inch- netic Properties of Materials at Power Frequencies Using

Sheet-Type Test Specimens

pound) units are to be regarded as standard. The values given

inparenthesesaremathematicalconversionstoSIunits,which A937/A937MTest Method for Determining Interlaminar

Resistance of Insulating Coatings Using Two Adjacent

are provided for information only and are not considered

standard. Test Surfaces

A976Classification of Insulating Coatings for Electrical

Steels by Composition, Relative Insulating Ability and

1

This specification is under the jurisdiction of ASTM Committee A06 on

Application

Magnetic Properties and is the direct responsibility of Subcommittee A06.02 on

Material Specifications.

2

This specification replaces A665, A725, and A843. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved May 1, 2009. Published June 2009. Originally contactASTM Customer Service at service@astm.org. ForAnnual Book ofASTM

approved in 1987. Last previous edition approved in 2003 as A876–03. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/A0876-09. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

´1

A876−09

3. Terminology 5.1.3 Condition F5—Thermally flattened sheet or coiled

strip having an inorganic surface coating, Type C-2, plus an

3.1 The terms and symbols used in this specification are

inorganic coating, Type C-5, applied over the inherent C-2

defined in Terminology A340.

coating to provide extra surface insulation resistance. The

principal application is in flat sheared laminations for cores of

4. Classification

power transformers.

4.1 The ASTM core-loss type designations, formulated in

5.1.4 Condition PQ—Thermally flattened sheet or coiled

accordance with Practice A664, for grain-oriented electrical

strip (sometimes called “punching quality”) with the inherent

steels covered by this specification are listed in Table 1.

C-2 coating removed and an inorganic coating, Type C-5,

applied for insulative purposes. The principal application is in

5. Condition

flat stamped laminations

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.