ASTM C128-97

(Test Method)Standard Test Method for Density, Relative Density (Specific Gravity), and Absorption of Fine Aggregate

Standard Test Method for Density, Relative Density (Specific Gravity), and Absorption of Fine Aggregate

SCOPE

1.1 This test method covers the determination of the average density of a quantity of fine aggregate particles (not including the volume of voids between the particles), the relative density (specific gravity), and the absorption of the fine aggregate. Depending on the procedure used, the density, in kg/m3 (lb/ft3) is expressed as oven-dry (OD), saturated-surface-dry (SSD), or as apparent density. Likewise, relative density (specific gravity), a dimensionless quality, is expressed as OD, SSD, or as apparent relative density (apparent specific gravity). The OD density and OD relative density are determined after drying the aggregate. The SSD density, SSD relative density, and absorption are determined after soaking the aggregate in water for a prescribed duration.

1.2 This test method is used to determine the density of the essentially solid portion of a large number of aggregate particles and provides an average value representing the sample. Distinction is made between the density of aggregate particles as determined by this test method, and the bulk density of aggregates as determined by Test Method C 29/C 29M, which includes the volume of voids between the particles of aggregates.

1.3 This test method is not intended to be used for lightweight aggregates.

1.4 The values stated in SI units are to be regarded as the standard for conducting the tests. The test results for density shall be reported in either SI units or inch-pound units, as appropriate for the use to be made of the results.

1.5 The text of this test method references notes and footnotes which provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of this test method.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: C 128 – 97

Standard Test Method for

Specific Gravity and Absorption of Fine Aggregate

This standard is issued under the fixed designation C 128; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope D 75 Practice for Sampling Aggregates

E 12 Terminology Relating to Density and Specific Gravity

1.1 This test method covers the determination of bulk and

of Solids, Liquids, and Gases

apparent specific gravity, 23/23°C (73.4/73.4°F), and absorp-

E 380 Practice for Use of the International System of Units

tion of fine aggregate.

(SI) (the Modernized Metric System)

1.2 This test method determines (after 24 h in water) the

2.2 AASHTO Standard:

bulk specific gravity and the apparent specific gravity as

AASHTO No. T 84 Specific Gravity and Absorption of Fine

defined in Terminology E 12, the bulk specific gravity on the

Aggregates

basis of weight of saturated surface-dry aggregate, and the

absorption as defined in Definitions C 125.

3. Significance and Use

NOTE 1—The subcommittee is considering revising Test Methods

3.1 Bulk specific gravity is the characteristic generally used

C 127 and C 128 to use the term “density” instead of “specific gravity” for

for calculation of the volume occupied by the aggregate in

coarse and fine aggregate, respectively.

various mixtures containing aggregate including portland ce-

1.3 The values stated in SI units are to be regarded as the

ment concrete, bituminous concrete, and other mixtures that

standard.

are proportioned or analyzed on an absolute volume basis.

1.4 This standard does not purport to address all of the

Bulk specific gravity is also used in the computation of voids

safety concerns, if any, associated with its use. It is the

in aggregate in Test Method C 29 and the determination of

responsibility of the user of this standard to establish appro-

moisture in aggregate by displacement in water in Test Method

priate safety and health practices and determine the applica-

C 70. Bulk specific gravity determined on the saturated

bility of regulatory limitations prior to use.

surface-dry basis is used if the aggregate is wet, that is, if its

absorption has been satisfied. Conversely, the bulk specific

2. Referenced Documents

gravity determined on the oven-dry basis is used for compu-

2.1 ASTM Standards:

tations when the aggregate is dry or assumed to be dry.

C 29/C 29M Test Method for Unit Weight and Voids in

3.2 Apparent specific gravity pertains to the relative density

Aggregate

of the solid material making up the constituent particles not

C 70 Test Method for Surface Moisture in Fine Aggregate

including the pore space within the particles that is accessible

C 125 Terminology Relating to Concrete and Concrete

to water. This value is not widely used in construction

Aggregates

aggregate technology.

C 127 Test Method for Specific Gravity and Absorption of

3.3 Absorption values are used to calculate the change in the

Coarse Aggregate

weight of an aggregate due to water absorbed in the pore

C 188 Test Method for Density of Hydraulic Cement

spaces within the constituent particles, compared to the dry

C 566 Test Method for Total Moisture Content of Aggregate

condition, when it is deemed that the aggregate has been in

by Drying

contact with water long enough to satisfy most of the absorp-

C 670 Practice for Preparing Precision and Bias Statements

tion potential. The laboratory standard for absorption is that

for Test Methods for Construction Materials

obtained after submerging dry aggregate for approximately 24

C 702 Practice for Reducing Samples of Aggregate to

h in water. Aggregates mined from below the water table may

Testing Size

have a higher absorption when used, if not allowed to dry.

Conversely, some aggregates when used may contain an

amount of absorbed moisture less than the 24 h-soaked

This test method is under the jurisdiction of ASTM Committee C-9 on Concrete

and Concrete Aggregates and is the direct responsibility of Subcommittee C09.20 on

Normal Weight Aggregates. Annual Book of ASTM Standards, Vol 04.03.

Current edition approved Nov. 10, 1997. Published October 1998. Originally Annual Book of ASTM Standards, Vol 15.05.

published as C 128 – 36. Last previous edition C 128 – 93. Annual Book of ASTM Standards, Vol 14.02. Excerpts in all volumes.

2 7

Annual Book of ASTM Standards, Vol 04.02. Available from American Association of State Highway and Transportation

Annual Book of ASTM Standards, Vol 04.01. Officials, 444 North Capitol St. N.W., Suite 225, Washington, DC 20001.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

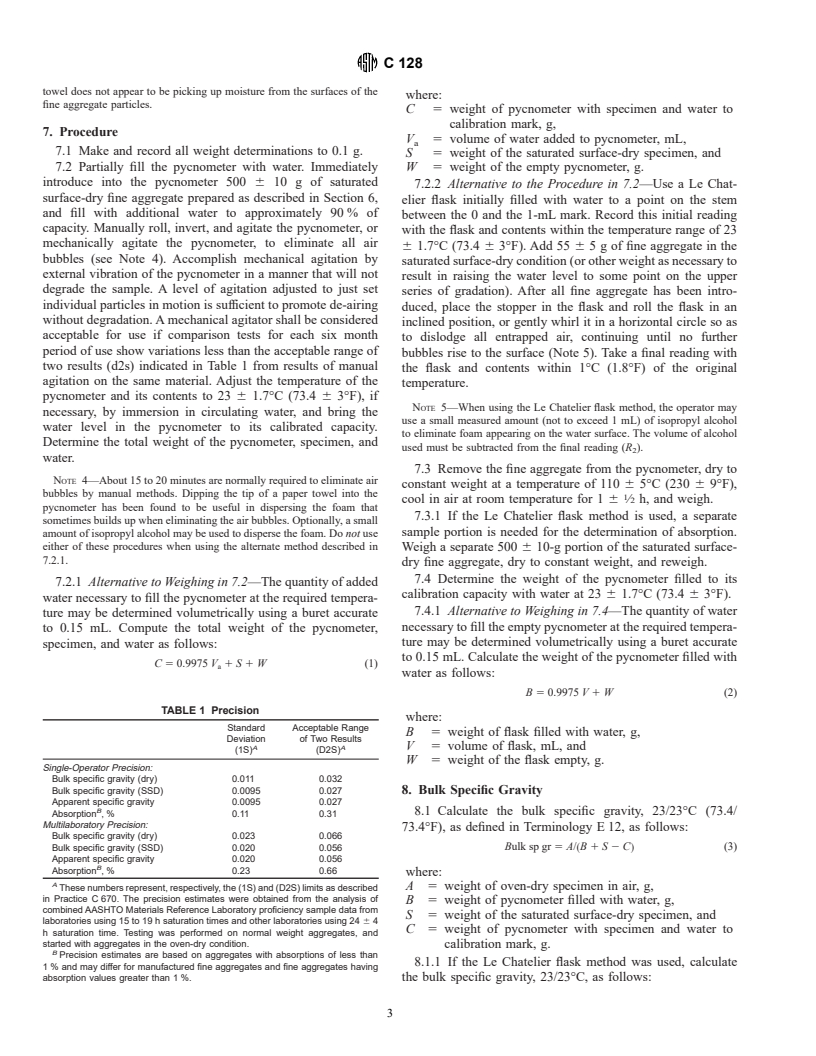

C 128

condition. For an aggregate that has been in contact with water saturated surface-dry condition. Continue this operation until

and that has free moisture on the particle surfaces, the the test specimen approaches a free-flowing condition. Follow

percentage of free moisture can be determined by deducting the

the procedure in 6.2.1 to determine whether or not surface

absorption from the total moisture content determined by Test moisture is present on the constituent fine aggregate particles.

Method C 566 by drying.

It is intended that the first trial of the cone test will be made

with some surface water in the specimen. Continue drying with

4. Apparatus

constant stirring and test at frequent intervals until the test

4.1 Balance—A balance or scale having a capacity of 1 kg

indicates that the specimen has reached a surface-dry condi-

or more, sensitive to 0.1 g or less, and accurate within 0.1 % of

tion. If the first trial of the surface moisture test indicates that

the test load at any point within the range of use for this test.

moisture is not present on the surface, it has been dried past the

Within any 100-g range of test load, a difference between

saturated surface-dry condition. In this case thoroughly mix a

readings shall be accurate within 0.1 g.

few millilitres of water with the fine aggregate and permit the

4.2 Pycnometer—A flask or other suitable container into

specimen to stand in a covered container for 30 min. Then

which the fine aggregate test sample can be readily introduced

resume the process of drying and testing at frequent intervals

and in which the volume content can be reproduced within

for the onset of the surface-dry condition.

60.1 cm . The volume of the container filled to mark shall be

6.2.1 Cone Test for Surface Moisture—Hold the mold firmly

at least 50 % greater than the space required to accommodate

on a smooth nonabsorbent surface with the large diameter

the test sample. A volumetric flask of 500 cm capacity or a

down. Place a portion of the partially dried fine aggregate

fruit jar fitted with a pycnometer top is satisfactory for a 500-g

loosely in the mold by filling it to overflowing and heaping

test sample of most fine aggregates. A Le Chatelier flask as

additional material above the top of the mold by holding it with

described in Test Method C 188 is satisfactory for an approxi-

the cupped fingers of the hand holding the mold. Lightly tamp

mately 55-g test sample.

the fine aggregate into the mold with 25 light drops of the

4.3 Mold—A metal mold in the form of a frustum of a cone

tamper. Each drop should start about 5 mm (0.2 in.) above the

with dimensions as follows: 40 6 3 mm inside diameter at the

top surface of the fine aggregate. Permit the tamper to fall

top, 90 6 3 mm inside diameter at the bottom, and 75 6 3mm

freely under gravitational attraction on each drop. Adjust the

in height, with the metal having a minimum thickness of 0.8

starting height to the new surface elevation after each drop and

mm.

distribute the drops over the surface. Remove loose sand from

4.4 Tamper—A metal tamper weighing 3406 15 g and

the base and lift the mold vertically. If surface moisture is still

having a flat circular tamping face 25 6 3 mm in diameter.

present, the fine aggregate will retain the molded shape. When

the fine aggregate slumps slightly it indicates that it has

5. Sampling

reached a surface-dry condition. Some angular fine aggregate

5.1 Sampling shall be accomplished in general accordance

or material with a high proportion of fines may not slump in the

with Practice D 75.

cone test upon reaching a surface-dry condition. This may be

6. Preparation of Test Specimen the case if fines become airborne upon dropping a handful of

the sand from the cone test 100 to 150 mm onto a surface. For

6.1 Obtain approximately 1 kg of the fine aggregate from

these materials the saturated surface-dry condition should be

the sample using the applicable procedures described in

considered as the point that one side of the fine aggregate

Practice C 702.

slumps slightly upon removing the mold.

6.1.1 Dry the test specimen in a suitable pan or vessel to

constant weight at a temperature of 110 6 5°C (230 6 9°F).

NOTE 3—The following criteria have also been used on materials that

Allow it to cool to comfortable handling temperature, cover

do not readily slump:

with water, either by immersion or by the addition of at least

(1) Provisional Cone Test—Fill the cone mold as described in 6.2.1

6 % moisture to the fine aggregate, and permit to stand for 24

except only use 10 drops of the tamper. Add more fine aggregate and use

6 4h.

10 drops of the tamper again. Then add material two more times using 3

and 2 drops of the tamper, respectively. Level off the material even with

6.1.2 As an alternative to 6.1.1, where the absorption and

the top of the mold, remove loose material from the base; and lift the mold

specific gravity values are to be used in proportioning concrete

vertically.

mixtures with aggregates used in their naturally moist condi-

(2) Provisional Surface Test—If airborne fines are noted when the fine

tion, the requirement for initial drying to constant weight may

aggregate is such that it will not slump when it is at a moisture condition,

be eliminated and, if the surfaces of the particles have been

add more moisture to the sand, and at the onset of the surface-dry

kept wet, the 24-h soaking may also be eliminated.

condition, with the hand lightly pat approximately 100 g of the material on

a flat, dry, clean, dark or dull nonabsorbent surface such as a sheet of

NOTE 2—Values for absorption and for specific gravity in the saturated

rubber, a worn oxidized, galvanized, or steel surface, or a black-painted

surface-dry condition may be significantly higher for aggregate not oven

metal surface. After 1 to 3 s remove the fine aggregate. If noticeable

dried before soaking than for the same aggregate treated in accordance

moisture shows on the test

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.