ASTM A194/A194M-14a

(Specification)Standard Specification for Carbon and Alloy Steel Nuts for Bolts for High Pressure or High Temperature Service, or Both

Standard Specification for Carbon and Alloy Steel Nuts for Bolts for High Pressure or High Temperature Service, or Both

ABSTRACT

This specification covers a variety of carbon, alloy, and martensitic and austenitic stainless steel nuts. These nuts are intended for high-pressure or high-temperature service, or both. Bars from which the nuts are made shall be hot-wrought. The material may be further processed by centerless grinding or by cold drawing. Austenitic stainless steel may be solution annealed or annealed and strain-hardened. Each alloy shall conform to the chemical composition requirements prescribed. Hardness tests, proof of load tests, and cone proof load tests shall be made to all nuts to meet the requirements specified.

SCOPE

1.1 This specification2 covers a variety of carbon, alloy, and martensitic stainless steel nuts in the size range 1/4 through 4 in. and metric M6 through M100 nominal. It also covers austenitic stainless steel nuts in the size range 1/4 in. and M6 nominal and above. These nuts are intended for high-pressure or high-temperature service, or both. Grade substitutions without the purchaser's permission are not allowed.

1.2 Bars from which the nuts are made shall be hot-wrought. The material may be further processed by centerless grinding or by cold drawing. Austenitic stainless steel may be solution annealed or annealed and strain-hardened. When annealed and strain hardened austenitic stainless steel is ordered in accordance with Supplementary Requirement S1, the purchaser should take special care to ensure that 8.2.2, Supplementary Requirement S1, and Appendix X1 are thoroughly understood.

1.3 Supplementary requirements of an optional nature are provided. These shall apply only when specified in the inquiry, contract, and order.

1.4 This specification is expressed in both inch-pound units and in SI units. However, unless the order specifies the applicable“ M” specification designation (SI units), the material shall be furnished to inch-pound units.

1.5 The values stated in either inch-pound units or SI units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard. Within the text, the SI units are shown in brackets.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:A194/A194M −14a Endorsedby

Manufacturers Standardization Society

of the Valve and Fittings Industry

Used in USNRC-RDT Standards

Standard Specification for

Carbon and Alloy Steel Nuts for Bolts for High Pressure or

High Temperature Service, or Both

This standard is issued under the fixed designationA194/A194M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* 2. Referenced Documents

1.1 This specification covers a variety of carbon, alloy, and 2.1 ASTM Standards:

martensiticstainlesssteelnutsinthesizerange ⁄4 through4in.

A153/A153M Specification for Zinc Coating (Hot-Dip) on

andmetricM6throughM100nominal.Italsocoversaustenitic Iron and Steel Hardware

stainless steel nuts in the size range ⁄4 in. and M6 nominal and

A276 Specification for Stainless Steel Bars and Shapes

above. These nuts are intended for high-pressure or high- A320/A320M Specification for Alloy-Steel and Stainless

temperature service, or both. Grade substitutions without the

Steel Bolting for Low-Temperature Service

purchaser’s permission are not allowed.

A370 Test Methods and Definitions for Mechanical Testing

of Steel Products

1.2 Barsfromwhichthenutsaremadeshallbehot-wrought.

A962/A962M Specification for Common Requirements for

The material may be further processed by centerless grinding

Bolting Intended for Use at Any Temperature from Cryo-

or by cold drawing. Austenitic stainless steel may be solution

genic to the Creep Range

annealed or annealed and strain-hardened. When annealed and

B633 Specification for Electrodeposited Coatings of Zinc on

strain hardened austenitic stainless steel is ordered in accor-

Iron and Steel

dance with Supplementary Requirement S1, the purchaser

B695 Specification for Coatings of Zinc Mechanically De-

should take special care to ensure that 8.2.2, Supplementary

posited on Iron and Steel

Requirement S1, and Appendix X1 are thoroughly understood.

B696 Specification for Coatings of Cadmium Mechanically

1.3 Supplementary requirements of an optional nature are

Deposited

provided. These shall apply only when specified in the inquiry,

B766 Specification for Electrodeposited Coatings of Cad-

contract, and order.

mium

1.4 This specification is expressed in both inch-pound units

E112 Test Methods for Determining Average Grain Size

and in SI units. However, unless the order specifies the

E566 PracticeforElectromagnetic(EddyCurrent)Sortingof

applicable“ M” specification designation (SI units), the mate-

Ferrous Metals

rial shall be furnished to inch-pound units.

F606 Test Methods for Determining the Mechanical Proper-

ties of Externally and Internally Threaded Fasteners,

1.5 The values stated in either inch-pound units or SI units

are to be regarded separately as standard. The values stated in Washers, Direct Tension Indicators, and Rivets

F1940 Test Method for Process Control Verification to

each system may not be exact equivalents; therefore, each

system shall be used independently of the other. Combining Prevent Hydrogen Embrittlement in Plated or Coated

Fasteners

values from the two systems may result in non-conformance

with the standard. Within the text, the SI units are shown in F1941 Specification for Electrodeposited Coatings on

brackets. Threaded Fasteners (Unified Inch Screw Threads (UN/

UNR))

This specification is under the jurisdiction ofASTM Committee A01 on Steel, F2329 Specification for Zinc Coating, Hot-Dip, Require-

Stainless Steel and Related Alloysand is the direct responsibility of Subcommittee

ments for Application to Carbon and Alloy Steel Bolts,

A01.22 on Steel Forgings andWrought Fittings for PipingApplications and Bolting

Materials for Piping and Special Purpose Applications.

Current edition approved Nov. 1, 2014. Published November 2014. Originally

approved in 1936. Last previous edition approved in 2013 as A194/A194M–14. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

DOI: 10.1520/A0194_A0194M-14A. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

For ASME Boiler and Pressure Vessel Code applications see related Specifi- Standards volume information, refer to the standard’s Document Summary page on

cation SA-194 in Section II of that code. the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

A194/A194M−14a

Screws, Washers, Nuts, and Special Threaded Fasteners 4.1.3 Dimensions (see Section 9),

2.2 ASME Standards: 4.1.4 Options in accordance with 8.2.2.1, 9.1, 9.2, 10.3, and

12, and

B 1.1 Unified Screw Threads

B 1.2 Gages and Gaging for Unified Inch Screw Threads 4.1.5 Supplementary Requirements, if any.

B 1.13M Metric Screw Threads

4.2 Coatings—Coatings are prohibited unless specified by

B 18.2.2 Square and Hex Nuts

the purchaser (see Supplementary Requirements S7 and S8).

B 18.2.4.6M Metric Heavy Hex Nuts

When coated nuts are ordered, the purchaser should take

2.3 ISO Standards:

special care to ensure that Appendix X2 is thoroughly under-

4033 Hexagon High Nuts (Style 2) – Product A and B

stood.

3. Terminology 4.3 See Supplementary Requirement S3 for nuts to be used

in low temperature applications (Specification A320/A320M).

3.1 Definitions of Terms Specific to This Standard:

3.1.1 Austenitic Grades—All grades with a prefix of “8” or 4.4 Proof Load Testing—See Supplementary Requirement

S9 for proof load testing of nuts manufactured to dimensions

“9.”

and configurations other than those covered in Tables 3 and 4.

3.1.2 Ferritic Grades—Grades 1, 2, 2H, 2HM, 3, 4, 6, 6F, 7,

7M, and 16.

5. Common Requirements

3.1.3 Lot—Unless otherwise specified (see Discussion

5.1 Materialandfastenerssuppliedtothisspecificationshall

below),alotisthequantityofnutsofasinglenominalsizeand

conform to the requirements of Specification A962/A962M.

grade produced by the same manufacturing process.

These requirements include test methods, finish, thread

3.1.3.1 Discussion—When Supplementary Requirement S5

dimensions, marking, certification, optional supplementary

is invoked on the purchase order, the following definitions of a

requirements, and others. Failure to comply with the require-

lot shall apply:

ments of Specification A962/A962M constitutes nonconfor-

3.1.3.2 For Grade 8 Nuts—The quantity of all the nuts of a

mance with this specification. In case of conflict between the

single nominal diameter and grade made from the same heat of

requirements of this specification and Specification A962/

steel and made by the same manufacturing process.

A962M, this specification shall prevail.

3.1.3.3 For All Other Grade Nuts—(see 8.2 and

8.1.2.1)—All the nuts of a single nominal diameter and grade 6. Manufacture (Process)

made from the same heat number and heat treated in the same

6.1 Stainless steels for all types of Grade 6 and 8 nuts shall

batch if batch-type heat treating equipment is used or heat

be made by one of the following processes:

treated in the same continuous run of not more than 8 h under

6.1.1 Electric-furnace (with separate degassing and refining

the same conditions if continuous-type heat treating equipment

optional),

is used.

6.1.2 Vacuum induction furnace, or

3.1.4 Type:

6.1.3 Either of the above followed by electroslag remelting,

3.1.4.1 For Grade 8 Nuts—Variations within the grade

or consumable-arc remelting.

designated by a letter and differentiated by chemistry and by

6.2 The steel producer shall exercise adequate control to

manufacturing process.

eliminate excessive unhomogeneity, nonmetallics, pipe,

3.1.4.2 For Grade 6 Nuts—Variations within the grade

porosity, and other defects.

designated by the letter F as differentiated by chemical addi-

6.3 Grades 1 and 2 nuts shall be hot or cold forged, or shall

tions made for machineability.

be machined from hot-forged, hot-rolled, or cold-drawn bars.

3.1.5 Series—The dimensional relationship and geometry of

6.3.1 All Grade 1 and 2 nuts shall be stress-relief annealed

the nuts as described inASME B 18.2.2 for inch nuts and ISO

at a temperature of at least 1000 °F [538 °C] after forming or

4033 for metric nuts sizes M6 through M10 and ASME B

machining from bar with the following exceptions:

18.2.4.6M for nuts sizes M12 through M100.

6.3.1.1 Nuts made by hot forging.

6.3.1.2 Nuts machined from hot-forged or hot-rolled bar.

4. Ordering Information

6.3.1.3 Nuts machined from hot-forged/hot-rolled and cold-

4.1 The inquiry and order for material under this specifica-

finished (max 10 % reduction in area) bar.

tion shall include the following as required to describe the

6.3.1.4 Nuts machined from cold-drawn and annealed (min

material adequately:

1000 °F [538 °C]) bar.

4.1.1 Specification designation, year date, and grade, issue

6.3.2 Grade 1 and 2 nuts made by hot forging or by

date and revision letter,

machiningfromhot-forgedorhot-rolledbarsneednotbegiven

4.1.2 Quantity, number of pieces,

any stress relief annealing treatment.

6.4 Grades 2H, 2HM, 3, 4, 6, 6F, 7, 7M, and 16 nuts shall

Available from American Society of Mechanical Engineers (ASME), ASME

be hot- or cold-forged or shall be machined from hot-forged,

International Headquarters, Two Park Ave., New York, NY 10016-5990, http://

hot-rolled, or cold-drawn bars and shall be heat treated to meet

www.asme.org.

the required mechanical properties. These grades shall be

Available from International Organization for Standardization (ISO), 1, ch. de

la Voie-Creuse, CP 56, CH-1211 Geneva 20, Switzerland, http://www.iso.org. uniformly reheated to the proper austenitizing temperature (a

A194/A194M−14a

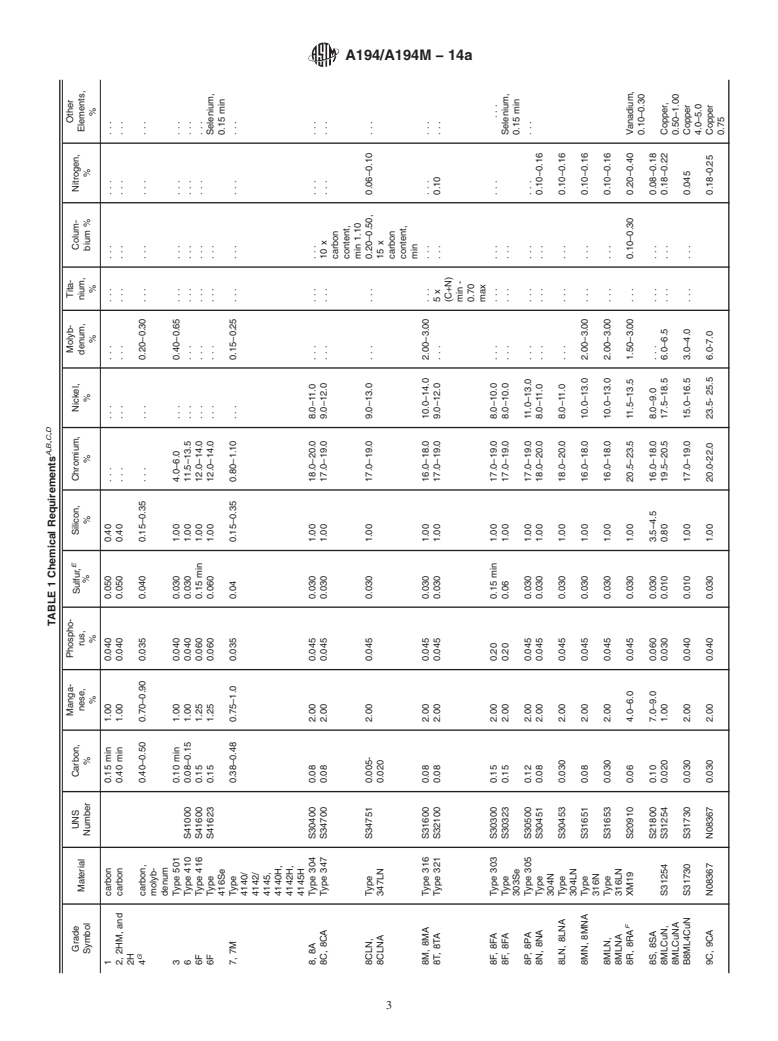

A,B,C,D

TABLE 1 Chemical Requirements

Manga- Phospho- Molyb- Tita- Other

E

Grade UNS Carbon, Silicon, Chromium, Nickel, Colum- Nitrogen,

Sulfur,

Material nese, rus, denum, nium, Elements,

%

Symbol Number % % % % bium % %

% % % % %

1 carbon 0.15 min 1.00 0.040 0.050 0.40 . . . . . . . . . . . . . . . . . . . . .

2, 2HM, and carbon 0.40 min 1.00 0.040 0.050 0.40 . . . . . . . . . . . . . . . . . . . . .

2H

G

4 carbon, 0.40–0.50 0.70–0.90 0.035 0.040 0.15–0.35 . . . . . . 0.20–0.30 . . . . . . . . . . . .

molyb-

denum

3 Type 501 0.10 min 1.00 0.040 0.030 1.00 4.0–6.0 . . . 0.40–0.65 . . . . . . . . . . . .

6 Type 410 S41000 0.08–0.15 1.00 0.040 0.030 1.00 11.5–13.5 . . . . . . . . . . . . . . . . . .

6F Type 416 S41600 0.15 1.25 0.060 0.15 min 1.00 12.0–14.0 . . . . . . . . . . . . . . . . . .

6F Type S41623 0.15 1.25 0.060 0.060 1.00 12.0–14.0 . . . . . . . . . . . . Selenium,

416Se 0.15 min

7, 7M Type 0.38–0.48 0.75–1.0 0.035 0.04 0.15–0.35 0.80–1.10 . . . 0.15–0.25 . . . . . . . . . . . .

4140/

4142/

4145,

4140H,

4142H,

4145H

8, 8A Type 304 S30400 0.08 2.00 0.045 0.030 1.00 18.0–20.0 8.0–11.0 . . . . . . . . . . . . . . .

8C, 8CA Type 347 S34700 0.08 2.00 0.045 0.030 1.00 17.0–19.0 9.0–12.0 . . . . . . 10 x . .

carbon

content,

min 1.10

8CLN, Type S34751 0.005- 2.00 0.045 0.030 1.00 17.0–19.0 9.0–13.0 . . . . . . 0.20–0.50, 0.06–0.10 . . .

8CLNA 347LN 0.020 15 x

carbon

content,

min

8M, 8MA Type 316 S31600 0.08 2.00 0.045 0.030 1.00 16.0–18.0 10.0–14.0 2.00–3.00 . . . . . . . . . . . .

8T, 8TA Type 321 S32100 0.08 2.00 0.045 0.030 1.00 17.0–19.0 9.0–12.0 . . . 5 x . 0.10 .

(C+N)

min -

0.70

max

8F, 8FA Type 303 S30300 0.15 2.00 0.20 0.15 min 1.00 17.0–19.0 8.0–10.0 . . . . . . . . . . . . . . .

8F, 8FA Type S30323 0.15 2.00 0.20 0.06 1.00 17.0–19.0 8.0–10.0 . . . . . . . . . Selenium,

303Se 0.15 min

8P, 8PA Type 305 S30500 0.12 2.00 0.045 0.030 1.00 17.0–19.0 11.0–13.0 . . . . . . . . . . . . . . .

8N, 8NA Type S30451 0.08 2.00 0.045 0.030 1.00 18.0–20.0 8.0–11.0 . . . . . . . . . 0.10–0.16

304N

8LN, 8LNA Type S30453 0.030 2.00 0.045 0.030 1.00 18.0–20.0 8.0–11.0 . . . . . . . . . 0.10–0.16

304LN

8MN, 8MNA Type S31651 0.08 2.00 0.045 0.030 1.00 16.0–18.0 10.0–13.0 2.00–3.00 . . . . . . 0.10–0.16

316N

8MLN, Type S31653 0.030 2.00 0.045 0.030 1.00 16.0–18.0 10.0–13.0 2.00–3.00 . . . . . . 0.10–0.16

8MLNA 316LN

F

8R, 8RA XM19 S20910 0.06 4.0–6.0 0.045 0.030 1.00 20.5–23.5 11.5–13.5 1.50–3.00 . . . 0.10–0.30 0.20–0.40 Vanadium,

0.10–0.30

8S, 8SA S21800 0.10 7.0–9.0 0.060 0.030 3.5–4.5 16.0–18.0 8.0–9.0 . . . . . . . . . 0.08–0.18

8MLCuN, S31254 S31254 0.020 1.00 0.030 0.010 0.80 19.5–20.5 17.5–18.5 6.0–6.5 . . . . . . 0.18–0.22 Copper,

8MLCuNA 0.50–1.00

B8ML4CuN S31730 S31730 0.030 2.00 0.040 0.010 1.00 17.0–19.0 15.0–16.5 3.0–4.0 . . . . . . 0.045 Copper

4.0–5.0

9C, 9CA N08367 N08367 0.030 2.00 0.040 0.030 1.00 20.0-22.0 23.5- 25.5 6.0-7.0 0.18-0.25 Copper

0.75

A194/A194M−14a

TABLE1 Continued

Manga- Phospho- Molyb- Tita- Other

E

Grade UNS Carbon, Silicon, Chromium, Nickel, Colum- Nitrogen,

Sulfur,

Material nese, rus, denum, nium, Elements,

%

Symbol Number % % % % bium % %

% % % % %

16 Chromium 0.36–0.47 0.45–0.70 0.035 0.040 0.15–0.35 0.80–1.15 . . . 0.50–0.65 . . . . . . . . . Vanadium,

Molyb- 0.25–0.35

B

denum Aluminum

0.015

Vanadium

A

The intentional addition of Bi, Se, Te, and Pb is not permitted except for Grades 6F, 8F, and 8FA, in which Se is specified and required.

B

Total aluminum, soluble and insoluble.

C

Maximum, unless minimum or range is indicated.

D

Where ellipses ({) appear in this table there is no requirement and the element need not be determined or reported.

E

Because of the degree to which sulfur segregates, product analysis for sulfur over 0.060 % max is not technologically appropriate.

F

As described in Specification A276.

G

Grade 4 is expected to be withdrawn within approximately 2 years. Grade 7 is an acceptable substitute for Grade 4. See 7.2.

A194/A194M−14a

A

TABLE 2 Hardness Requirements

Completed Nuts Sample Nut after Treatment as in 8.1.5

Brinell Rockwell Hardness Brinell Rockwell

Grade and Type

Hardness Hardness, Hardness B

C Scale B Scale

min Scale, min

1 121 min . 70 min 121 70

2 159 to 352 . 84 min 159 84

2H to 1 ⁄2 in. or M36, incl 248 to 327 24 to 35 . 179 89

2H over 1 ⁄2 in. or M36 212 to 327 35 max 95 min 147 79

2HM and 7M 159 to 235 . 84 to 99 159 84

3, 4, 7, and 16 248 to 327 24 to 35 . 201 94

6 and 6F 228 to 271 20 to 28 . . .

8, 8C, 8CLN, 8M, 8T, 8F, 8P, 126 to 300 32 max 60 min . .

8N,

8MN, 8LN, 8MLN,

8MLCuN, 8ML4CuN,

and 9C

8A, 8CA, 8CLNA, 8MA, 8TA, 126 to 192 . 60 to 90 . .

8FA, 8PA, 8NA, 8MNA,

8LNA, 8MLNA,

8MLCuNA,

8ML4CuNA,

and 9CA

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: A194/A194M − 14 A194/A194M − 14a Endorsed by

Manufacturers Standardization Society

of the Valve and Fittings Industry

Used in USNRC-RDT Standards

Standard Specification for

Carbon and Alloy Steel Nuts for Bolts for High Pressure or

High Temperature Service, or Both

This standard is issued under the fixed designation A194/A194M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope*

1.1 This specification covers a variety of carbon, alloy, and martensitic stainless steel nuts in the size range ⁄4 through 4 in.

and metric M6 through M100 nominal. It also covers austenitic stainless steel nuts in the size range ⁄4 in. and M6 nominal and

above. These nuts are intended for high-pressure or high-temperature service, or both. Grade substitutions without the purchaser’s

permission are not allowed.

1.2 Bars from which the nuts are made shall be hot-wrought. The material may be further processed by centerless grinding or

by cold drawing. Austenitic stainless steel may be solution annealed or annealed and strain-hardened. When annealed and strain

hardened austenitic stainless steel is ordered in accordance with Supplementary Requirement S1, the purchaser should take special

care to ensure that 8.2.2, Supplementary Requirement S1, and Appendix X1 are thoroughly understood.

1.3 Supplementary requirements of an optional nature are provided. These shall apply only when specified in the inquiry,

contract, and order.

1.4 This specification is expressed in both inch-pound units and in SI units. However, unless the order specifies the applicable“

M” specification designation (SI units), the material shall be furnished to inch-pound units.

1.5 The values stated in either inch-pound units or SI units are to be regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in non-conformance with the standard. Within the text, the SI units are shown in brackets.

2. Referenced Documents

2.1 ASTM Standards:

A153/A153M Specification for Zinc Coating (Hot-Dip) on Iron and Steel Hardware

A276 Specification for Stainless Steel Bars and Shapes

A320/A320M Specification for Alloy-Steel and Stainless Steel Bolting for Low-Temperature Service

A370 Test Methods and Definitions for Mechanical Testing of Steel Products

A962/A962M Specification for Common Requirements for Bolting Intended for Use at Any Temperature from Cryogenic to the

Creep Range

B633 Specification for Electrodeposited Coatings of Zinc on Iron and Steel

B695 Specification for Coatings of Zinc Mechanically Deposited on Iron and Steel

B696 Specification for Coatings of Cadmium Mechanically Deposited

B766 Specification for Electrodeposited Coatings of Cadmium

E112 Test Methods for Determining Average Grain Size

E566 Practice for Electromagnetic (Eddy Current) Sorting of Ferrous Metals

This specification is under the jurisdiction of ASTM Committee A01 on Steel, Stainless Steel and Related Alloysand is the direct responsibility of Subcommittee A01.22

on Steel Forgings and Wrought Fittings for Piping Applications and Bolting Materials for Piping and Special Purpose Applications.

Current edition approved May 1, 2014Nov. 1, 2014. Published June 2014November 2014. Originally approved in 1936. Last previous edition approved in 2013 as

A194/A194M–13.–14. DOI: 10.1520/A0194_A0194M-14.10.1520/A0194_A0194M-14A.

For ASME Boiler and Pressure Vessel Code applications see related Specification SA-194 in Section II of that code.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

A194/A194M − 14a

F606 Test Methods for Determining the Mechanical Properties of Externally and Internally Threaded Fasteners, Washers, Direct

Tension Indicators, and Rivets

F1940 Test Method for Process Control Verification to Prevent Hydrogen Embrittlement in Plated or Coated Fasteners

F1941 Specification for Electrodeposited Coatings on Threaded Fasteners (Unified Inch Screw Threads (UN/UNR))

F2329 Specification for Zinc Coating, Hot-Dip, Requirements for Application to Carbon and Alloy Steel Bolts, Screws, Washers,

Nuts, and Special Threaded Fasteners

2.2 ASME Standards:

B 1.1 Unified Screw Threads

B 1.2 Gages and Gaging for Unified Inch Screw Threads

B 1.13M Metric Screw Threads

B 18.2.2 Square and Hex Nuts

B 18.2.4.6M Metric Heavy Hex Nuts

2.3 ISO Standards:

4033 Hexagon High Nuts (Style 2) – Product A and B

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 Austenitic Grades—All grades with a prefix of “8” or “9.”

3.1.2 Ferritic Grades—Grades 1, 2, 2H, 2HM, 3, 4, 6, 6F, 7, 7M, and 16.

3.1.3 Lot—Unless otherwise specified (see Discussion below), a lot is the quantity of nuts of a single nominal size and grade

produced by the same manufacturing process.

Available from American Society of Mechanical Engineers (ASME), ASME International Headquarters, Two Park Ave., New York, NY 10016-5990, http://

www.asme.org.

Available from International Organization for Standardization (ISO), 1, ch. de la Voie-Creuse, CP 56, CH-1211 Geneva 20, Switzerland, http://www.iso.org.

3.1.3.1 Discussion—

When Supplementary Requirement S5 is invoked on the purchase order, the following definitions of a lot shall apply:

3.1.3.2 For Grade 8 Nuts—The quantity of all the nuts of a single nominal diameter and grade made from the same heat of steel

and made by the same manufacturing process.

3.1.3.3 For All Other Grade Nuts—(see 8.2 and 8.1.2.1)—All the nuts of a single nominal diameter and grade made from the

same heat number and heat treated in the same batch if batch-type heat treating equipment is used or heat treated in the same

continuous run of not more than 8 h under the same conditions if continuous-type heat treating equipment is used.

3.1.4 Type:

3.1.4.1 For Grade 8 Nuts—Variations within the grade designated by a letter and differentiated by chemistry and by

manufacturing process.

3.1.4.2 For Grade 6 Nuts—Variations within the grade designated by the letter F as differentiated by chemical additions made

for machineability.

3.1.5 Series—The dimensional relationship and geometry of the nuts as described in ASME B 18.2.2 or B 18.2.4.6M.for inch

nuts and ISO 4033 for metric nuts sizes M6 through M10 and ASME B 18.2.4.6M for nuts sizes M12 through M100.

4. Ordering Information

4.1 The inquiry and order for material under this specification shall include the following as required to describe the material

adequately:

4.1.1 Specification designation, year date, and grade, issue date and revision letter,

4.1.2 Quantity, number of pieces,

4.1.3 Dimensions (see Section 9),

4.1.4 Options in accordance with 8.2.2.1, 9.1, 9.2, 10.3, and 12, and

4.1.5 Supplementary Requirements, if any.

4.2 Coatings—Coatings are prohibited unless specified by the purchaser (see Supplementary Requirements S7 and S8). When

coated nuts are ordered, the purchaser should take special care to ensure that Appendix X2 is thoroughly understood.

4.3 See Supplementary Requirement S3 for nuts to be used in low temperature applications (Specification A320/A320M).

4.4 Proof Load Testing—See Supplementary Requirement S9 for proof load testing of nuts manufactured to dimensions and

configurations other than those covered in Tables 3 and 4.

A194/A194M − 14a

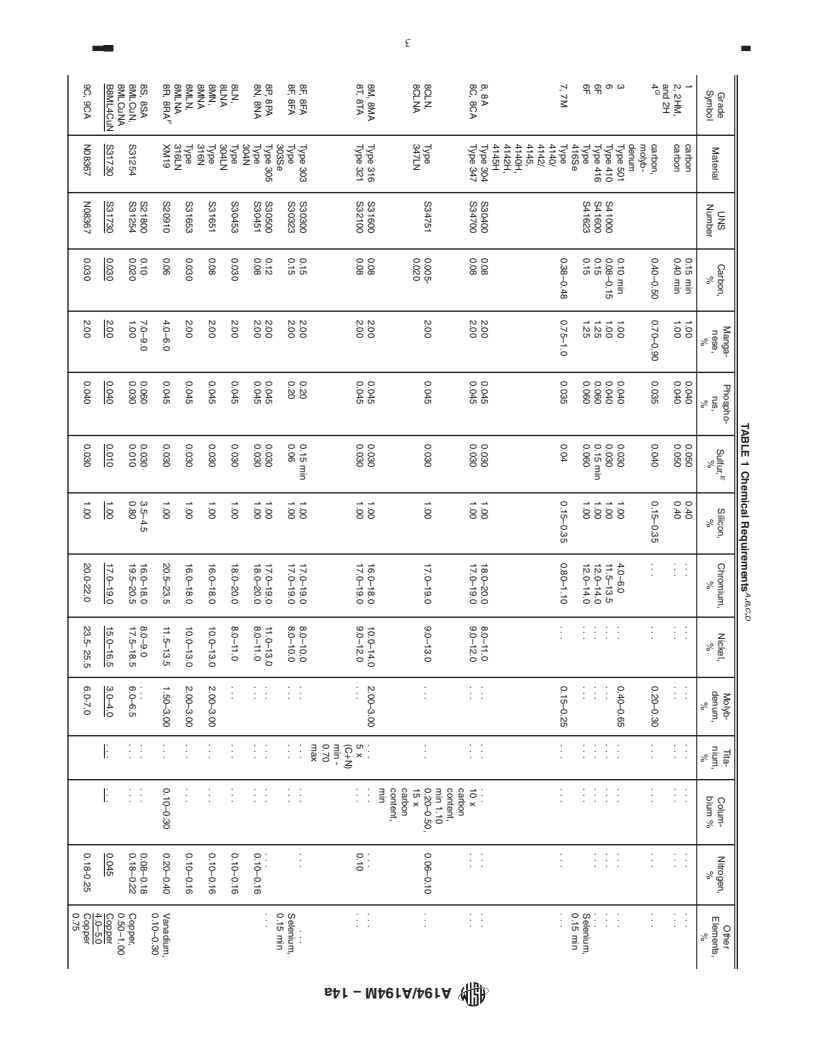

A,B,C,D

TABLE 1 Chemical Requirements

Manga- Phospho- Molyb- Tita- Other

E

Grade UNS Carbon, Silicon, Chromium, Nickel, Colum- Nitrogen,

Sulfur,

Material nese, rus, denum, nium, Elements,

Symbol Number % % % % % bium % %

% % % % %

1 carbon 0.15 min 1.00 0.040 0.050 0.40 . . . . . . . . . . . . . . . . . . . . .

2, 2HM, carbon 0.40 min 1.00 0.040 0.050 0.40 . . . . . . . . . . . . . . . . . . . . .

and 2H

G

4 carbon, 0.40–0.50 0.70–0.90 0.035 0.040 0.15–0.35 . . . . . . 0.20–0.30 . . . . . . . . . . . .

molyb-

denum

3 Type 501 0.10 min 1.00 0.040 0.030 1.00 4.0–6.0 . . . 0.40–0.65 . . . . . . . . . . . .

6 Type 410 S41000 0.08–0.15 1.00 0.040 0.030 1.00 11.5–13.5 . . . . . . . . . . . . . . . . . .

6F Type 416 S41600 0.15 1.25 0.060 0.15 min 1.00 12.0–14.0 . . . . . . . . . . . . . . . . . .

6F Type S41623 0.15 1.25 0.060 0.060 1.00 12.0–14.0 . . . . . . . . . . . . Selenium,

416Se 0.15 min

7, 7M Type 0.38–0.48 0.75–1.0 0.035 0.04 0.15–0.35 0.80–1.10 . . . 0.15–0.25 . . . . . . . . . . . .

4140/

4142/

4145,

4140H,

4142H,

4145H

8, 8A Type 304 S30400 0.08 2.00 0.045 0.030 1.00 18.0–20.0 8.0–11.0 . . . . . . . . . . . . . . .

8C, 8CA Type 347 S34700 0.08 2.00 0.045 0.030 1.00 17.0–19.0 9.0–12.0 . . . . . . 10 x . . . . . .

carbon

content,

min 1.10

8CLN, Type S34751 0.005- 2.00 0.045 0.030 1.00 17.0–19.0 9.0–13.0 . . . . . . 0.20–0.50, 0.06–0.10 . . .

8CLNA 347LN 0.020 15 x

carbon

content,

min

8M, 8MA Type 316 S31600 0.08 2.00 0.045 0.030 1.00 16.0–18.0 10.0–14.0 2.00–3.00 . . . . . . . . . . . .

8T, 8TA Type 321 S32100 0.08 2.00 0.045 0.030 1.00 17.0–19.0 9.0–12.0 . . . 5 x . . . 0.10 . . .

(C+N)

min -

0.70

max

8F, 8FA Type 303 S30300 0.15 2.00 0.20 0.15 min 1.00 17.0–19.0 8.0–10.0 . . . . . . . . . . . . . . .

8F, 8FA Type S30323 0.15 2.00 0.20 0.06 1.00 17.0–19.0 8.0–10.0 . . . . . . . . . Selenium,

303Se 0.15 min

8P, 8PA Type 305 S30500 0.12 2.00 0.045 0.030 1.00 17.0–19.0 11.0–13.0 . . . . . . . . . . . . . . .

8N, 8NA Type S30451 0.08 2.00 0.045 0.030 1.00 18.0–20.0 8.0–11.0 . . . . . . . . . 0.10–0.16

304N

8LN, Type S30453 0.030 2.00 0.045 0.030 1.00 18.0–20.0 8.0–11.0 . . . . . . . . . 0.10–0.16

8LNA 304LN

8MN, Type S31651 0.08 2.00 0.045 0.030 1.00 16.0–18.0 10.0–13.0 2.00–3.00 . . . . . . 0.10–0.16

8MNA 316N

8MLN, Type S31653 0.030 2.00 0.045 0.030 1.00 16.0–18.0 10.0–13.0 2.00–3.00 . . . . . . 0.10–0.16

8MLNA 316LN

F

8R, 8RA XM19 S20910 0.06 4.0–6.0 0.045 0.030 1.00 20.5–23.5 11.5–13.5 1.50–3.00 . . . 0.10–0.30 0.20–0.40 Vanadium,

0.10–0.30

8S, 8SA S21800 0.10 7.0–9.0 0.060 0.030 3.5–4.5 16.0–18.0 8.0–9.0 . . . . . . . . . 0.08–0.18

8MLCuN, S31254 S31254 0.020 1.00 0.030 0.010 0.80 19.5–20.5 17.5–18.5 6.0–6.5 . . . . . . 0.18–0.22 Copper,

8MLCuNA 0.50–1.00

B8ML4CuN S31730 S31730 0.030 2.00 0.040 0.010 1.00 17.0–19.0 15.0–16.5 3.0–4.0 . . . . . . 0.045 Copper

4.0–5.0

9C, 9CA N08367 N08367 0.030 2.00 0.040 0.030 1.00 20.0-22.0 23.5- 25.5 6.0-7.0 0.18-0.25 Copper

0.75

A194/A194M − 14a

TABLE 1 Continued

Manga- Phospho- Molyb- Tita- Other

E

Grade UNS Carbon, Silicon, Chromium, Nickel, Colum- Nitrogen,

Sulfur,

Material nese, rus, denum, nium, Elements,

%

Symbol Number % % % % bium % %

% % % % %

16 Chromium 0.36–0.47 0.45–0.70 0.035 0.040 0.15–0.35 0.80–1.15 . . . 0.50–0.65 . . . . . . . . . Vanadium,

Molyb- 0.25–0.35

B

denum Aluminum

0.015

Vanadium

A

The intentional addition of Bi, Se, Te, and Pb is not permitted except for Grades 6F, 8F, and 8FA, in which Se is specified and required.

B

Total aluminum, soluble and insoluble.

C

Maximum, unless minimum or range is indicated.

D

Where ellipses ({) appear in this table there is no requirement.requirement and the element need not be determined or reported.

E

Because of the degree to which sulfur segregates, product analysis for sulfur over 0.060 % max is not technologically appropriate.

F

As described in Specification A276.

G

Grade 4 is expected to be withdrawn within approximately 2 years. Grade 7 is an acceptable substitute for Grade 4. See 7.2.

A194/A194M − 14a

A

TABLE 2 Hardness Requirements

Completed Nuts Sample Nut after Treatment as in 8.1.5

Brinell Rockwell Hardness Brinell Rockwell

Grade and Type

Hardness Hardness, Hardness B

C Scale B Scale

min Scale, min

1 121 min . 70 min 121 70

2 159 to 352 . 84 min 159 84

2H to 1 ⁄2 in. or M36, incl 248 to 327 24 to 35 . 179 89

2H over 1 ⁄2 in. or M36 212 to 327 35 max 95 min 147 79

2HM and 7M 159 to 235 . 84 to 99 159 84

3, 4, 7, and 16 248 to 327 24 to 35 . 201 94

6 and 6F 228 to 271 20 to 28 . . .

8, 8C, 8CLN, 8M, 8T, 8F, 8P, 126 to 300 32 max 60 min . .

8N,

8MN, 8LN, 8MLN,

8MLCuN, and

9C

8, 8C, 8CLN, 8M, 8T, 8F, 8P, 126 to 300 32 max 60 min . .

8N,

8MN, 8LN, 8MLN,

8MLCuN, 8ML4CuN,

and 9C

8A, 8CA, 8CLNA, 8MA, 8TA, 126 to 192 . 60 to 90 . .

8FA, 8PA, 8NA, 8MNA,

8LNA, 8MLNA,

8MLCuNA,

and 9CA

8A, 8CA, 8CLNA, 8MA, 8TA, 126 to 192 . 60 to 90 . .

8FA, 8PA, 8NA, 8MNA,

8LNA, 8MLNA,

8MLCuNA,

8ML4CuNA,

and 9CA

8R, 8RA, 8S, and 8SA 183 to 271 25 max 88 min . .

A

Where ellipses ({) appear in this table there is no requirement.

5. Common Requirements

5.1 Material and fasteners supplied to this specification shall conform to the requirements of Specification A962/A962M. These

requirements include test methods, finish, thread dimensions, marking, certification, optional supplementary requirements, and

others. Failure to comply with the requirements of Specification A962/A962M constitutes nonconformance with this specification.

In case of conflict between the requirements of this specification and Specification A962/A962M, this specification shall prevail.

6. Manufacture (Process)

6.1 Stainless steels for all types of Grade 6 and 8 nuts shall be made by one of the following processes:

6.1.1 Electric-furnace (with separate degassing and refining optional),

6.1.2 Vacuum induction furnace, or

6.1.3 Either of the above followed by electroslag remelting, or consumable-arc remelting.

6.2 The steel producer shall exercise adequate control to eliminate excessive unhomogeneity, nonmetallics, pipe, porosity, and

other defects.

6.3 Grades 1 and 2 nuts shall be hot or cold forged, or shall be machined from hot-forged, hot-rolled, or cold-drawn bars.

6.3.1 All Grade 1 and 2 nuts shall be stress-relief annealed at a temperature of at least 1000 °F [538 °C] after forming or

machining from bar wi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.