ASTM D4772-97

(Test Method)Standard Test Method for Surface Water Absorption of Terry Fabrics (Water Flow)

Standard Test Method for Surface Water Absorption of Terry Fabrics (Water Flow)

SCOPE

1.1 This test method determines the ability of a terry fabric to rapidly absorb and retain liquid water from surfaces such as human skin, dishes, and furniture.

1.2 This test method is not applicable to non-terry fabrics such as huck towels, honeycomb towels, crash towels, flour-sack towels, and nonwoven wipes. The steep angle of the specimen on the apparatus may cause a large amount of water to runoff these non-pile fabrics, or the lightweight/ open structure of these fabrics may allow a large amount of water to completely pass through the specimen; thus the test result may not be a valid measure of a non-terry fabric's ability to absorb water.

1.3 This test method is not applicable to decorative terry fabrics that will not be used to absorb water from surfaces.

1.4 This test method is written in SI units. The inch-pound units that are provided are not necessarily exact equivalents of the SI units. Either system of units may be used in this test method. In case of referee decisions the SI units will prevail.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 4772 – 97

Standard Test Method for

Surface Water Absorption of Terry Fabrics (Water Flow)

This standard is issued under the fixed designation D 4772; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope sumer Textile and Leather Products Other Than Carpets

and Upholstery

1.1 This test method determines the ability of a terry fabric

D 5433 Performance Specification for Towel Products for

to rapidly absorb and retain liquid water from surfaces such as

Institutional and Household Use

human skin, dishes, and furniture.

2.2 AATCC Standard:

1.2 This test method is not applicable to non-terry fabrics

Test Method 135 Dimensional Changes in Automatic Home

such as huck towels, waffle-weave towels, crash towels,

Laundering of Woven and Knit Fabrics

flour-sack towels, and nonwoven wipes. The steep angle of the

specimen on the apparatus may cause a large amount of water

3. Terminology

to runoff these non-pile fabrics, or the lightweight/open struc-

3.1 Definitions:

ture of these fabrics may allow a large amount of water to

3.1.1 absorption, n—a process in which one material (the

completely pass through the specimen; thus the test result may

absorbent) takes in or absorbs another (the absorbate); as the

not be a valid measure of a non-terry fabric’s ability to absorb

absorption of moisture by fibers.

water.

3.1.2 pile, n—in pile fabric, the raised loops or tufts (cut

1.3 This test method is not applicable to decorative terry

loops) that form all or part of the surface.

fabrics that will not be used to absorb water from surfaces.

3.1.3 surface water absorption, n—by a fabric, the process

1.4 This test method is written in SI units. The inch-pound

of removing liquid water from a surface such as human skin,

units that are provided are not necessarily exact equivalents of

dishes, or furniture.

the SI units. Either system of units may be used in this test

3.1.4 terry fabric, n—a material with a woven warp pile or

method. In case of referee decisions the SI units will prevail.

a knitted pile, with uncut loops on a single side or uncut loops

1.5 This standard does not purport to address all of the

on both sides, and which is used for such products as toweling,

safety concerns, if any, associated with its use. It is the

beachwear, and bathrobes.

responsibility of the user of this standard to establish appro-

3.1.5 For definitions of other textile terms used in this test

priate safety and health practices and determine the applica-

method, refer to Terminologies D 123 and D 3136.

bility of regulatory limitations prior to use.

4. Summary of Test Method

2. Referenced Documents

4.1 A terry fabric product with hems or with both hems and

2.1 ASTM Standards:

2 selvages (such as a bath towel), or a terry fabric without hems

D 123 Terminology Relating to Textiles

2 or without both hems and selvages (such as a terry fabric cut

D 1776 Practice for Conditioning Textiles for Testing

from a roll) is prepared for testing by preconditioning and

D 2904 Practice for Interlaboratory Testing of a Textile Test

2 conditioning. Specimens are placed one at a time in an

Method that Produces Normally Distributed Data

embroidery hoop and then the hoop/specimen assembly is

D 2906 Practice for Statements on Precision and Bias for

2 placed at an angle on the base of the apparatus. After water

Textiles

flows down the surface of each specimen, the amount of water

D 3136 Terminology for Permanent Care Labels for Con-

retained by each specimen is measured. Six specimens are

tested, three on the face of the fabric and three on the back of

the fabric. The six observations are averaged to determine the

This test method is under the jurisdiction of ASTM Committee D-13 on Textiles surface water absorption of the fabric.

and is the direct responsibility of Subcommittee D13.59 on Fabric Test Methods,

General.

Current edition approved Jan. 10, 1997. Published June 1997. Originally Annual Book of ASTM Standards, Vol 07.02.

published as D 4772-88. Last previous editioin D 4772 – 88. Available from American Association of Textile Chemists and Colorists, P.O.

Annual Book of ASTM Standards, Vol 07.01. Box 12215, Research Triangle Park, NC 27709.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 4772

5. Significance and Use

5.1 This test method may be used to test the surface water

absorption of terry fabrics for bath towels, bath sheets, hand

towels, kitchen towels, dishcloths, washcloths, beachwear,

bathrobes, and the like. Different specifications may be needed

for each of these fabrics because of different applications.

5.2 It is recognized that surface water absorption is only one

of the characteristics that the ultimate consumer may use in

determining which terry fabric is acceptable. Consult Specifi-

cation D 5433 for other characteristics that may be applicable

to terry fabrics.

5.3 This test method is recommended for quality control

testing of terry fabrics during manufacturing and product

comparisons of different terry fabrics by manufacturers, retail-

ers, and users.

5.4 This test method may be used for the acceptance testing

of commercial shipments of terry fabrics, but caution is

advised since interlaboratory precision is known to be poor.

Comparative tests as directed in 5.4.1 may be advisable.

5.4.1 In case of a dispute arising from differences in

reported test results when using this test method for acceptance

testing of commercial shipments, the purchaser and the sup-

plier should conduct comparative tests to determine if there is

a statistical bias between their laboratories. Competent statis-

tical assistance is recommended for the investigation of bias.

As a minimum, the two parties should take a group of

laboratory sampling units (such as towels) that are as homo-

A = Hoop,

geneous as possible and that are from a lot of material of the

B = Base,

C = Funnel,

type in question. The laboratory sampling units should then be

D = Valve,

randomly assigned in equal numbers to each laboratory for

E = Graduate,

testing. The average results from the two laboratories should be

F = Pour Spout,

G = Pan, and

compared using appropriate statistical analysis for unpaired

H = Adjustment Screw.

data and an acceptable probability level chosen by the two

FIG. 1 Schematic Diagram of a Typical Water Flow Tester

parties before the testing is begun. If a bias is found, either its

cause must be found and corrected or the purchaser and

supplier must agree to interpret future test results with consid-

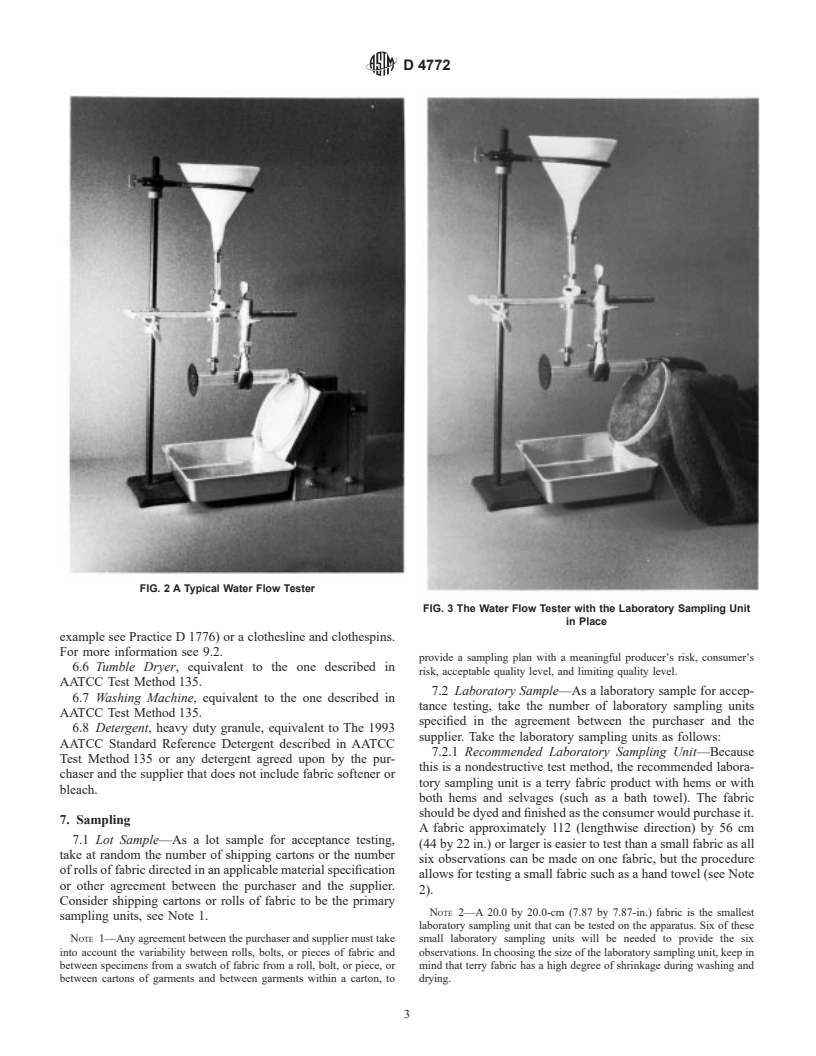

and 0.6 6 0.4 cm (0.24 6 0.16 in.) away from the hoop/

eration of the known bias.

specimen assembly (see Fig. 1 and Fig. 3).

6.1.3 The funnel, valve, fittings, tubing, and graduate

6. Apparatus and Materials

mounted on the apparatus (see Fig. 2) must not restrict the flow

6.1 Water Flow Tester—This tester is not commercially

of water. The time between the opening of the valve and the

available, but it is not difficult or expensive to build. The tester

time the water has exited the graduate (except for a few drops)

shown in Figs. 1-3 can be made from the parts and the series

must be less than 8.0 s. (The tester shown in Figs. 2 and 3 has

of steps described in Annex A1; however, there are other

a mean of 5.7 s and a standard deviation of 0.5 s).

acceptable ways to build the tester. Sections 6.1.1-6.1.4 indi-

6.1.4 The hoop/specimen assembly must be mounted on the

cate the critical factors which must be incorporated into the

base in a manner to direct all water not absorbed by the

design of the tester.

specimen toward the pan (see Figs. 1-3). It is especially

6.1.1 The hoop/specimen assembly must be at 1.1 rad (60°)

important that any water that passes completely through the

to the table top (see Fig. 1 and Fig. 3).

specimen is directed toward the pan and is not allowed to be

6.1.2 The 50-mL graduate mounted on the apparatus must

absorbed by the lower portion of the specimen, or the edge of

be parallel to the table top (see Figs. 1 and 2). The pour spout

the laboratory sampling unit, or held where the hoop contacts

on this graduate must be 3.0 6 0.2 cm (1.18 6 0.08 in.) down

the base.

from where the adjustment screw bracket joints the outer hoop

6.2 Embroidery Hoop, 15.3-cm (6-in.) outer diameter of

inner hoop. If the hoop is made of wood, it must have a

water-resistant finish (such as a marine varnish).

The relationship between water and textiles is complex. For information on the

6.3 Graduate, Polymethylpentene (PMP) 50 mL.

different forms of interaction between water and textiles see: Zeronian, S. H.

6.4 Distilled or Deionized Water,at21 6 1°C (70 6 2°F).

“Analysis of the Interaction Between Water and Textiles,” pages 117–128 in

6.5 Laboratory Sampling Unit Conditioning Equipment,

Analytical Methods for a Textile Laboratory, American Association of Textile

Chemists and Colorists, third edition, 1984, edited by J. W. Weaver. facilities such as a multiple shelf/rod conditioning rack (for

D 4772

FIG. 2 A Typical Water Flow Tester

FIG. 3 The Water Flow Tester with the Laboratory Sampling Unit

in Place

example see Practice D 1776) or a clothesline and clothespins.

For more information see 9.2.

provide a sampling plan with a meaningful producer’s risk, consumer’s

6.6 Tumble Dryer, equivalent to the one described in

risk, acceptable quality level, and limiting quality level.

AATCC Test Method 135.

7.2 Laboratory Sample—As a laboratory sample for accep-

6.7 Washing Machine, equivalent to the one described in

tance testing, take the number of laboratory sampling units

AATCC Test Method 135.

specified in the agreement between the purchaser and the

6.8 Detergent, heavy duty granule, equivalent to The 1993

supplier. Take the laboratory sampling units as follows:

AATCC Standard Reference Detergent described in AATCC

7.2.1 Recommended Laboratory Sampling Unit—Because

Test Method 135 or any detergent agreed upon by the pur-

this is a nondestructive test method, the recommended labora-

chaser and the supplier that does not include fabric softener or

tory sampling unit is a terry fabric product with hems or with

bleach.

both hems and selvages (such as a bath towel). The fabric

should be dyed and finished as the consumer would purchase it.

7. Sampling

A fabric approximately 112 (lengthwise direction) by 56 cm

7.1 Lot Sample—As a lot sample for acceptance testing,

(44 by 22 in.) or larger is easier to test than a small fabric as all

take at random the number of shipping cartons or the number

six observations can be made on one fabric, but the procedure

of rolls of fabric directed in an applicable material specification

allows for testing a small fabric such as a hand towel (see Note

or other agreement between the purchaser and the supplier.

2).

Consider shipping cartons or rolls of fabric to be the primary

NOTE 2—A 20.0 by 20.0-cm (7.87 by 7.87-in.) fabric is the smallest

sampling units, see Note 1.

laboratory sampling unit that can be tested on the apparatus. Six of these

NOTE 1—Any agreement between the purchaser and supplier must take small laboratory sampling units will be needed to provide the six

into account the variability between rolls, bolts, or pieces of fabric and observations. In choosing the size of the laboratory sampling unit, keep in

between specimens from a swatch of fabric from a roll, bolt, or piece, or mind that terry fabric has a high degree of shrinkage during washing and

between cartons of garments and between garments within a carton, to drying.

D 4772

7.2.2 Alternate Laboratory Sampling Unit—As an alterna-

tive to the procedure described in 7.2.1, a terry fabric without

hems or without both hems and selvages can be used (such as

a terry fabric cut from a roll). The fabric should be dyed and

finished as the consumer would purchase it. A fabric approxi-

mately 112 (lengthwise direction) by 56 cm (44 by 22 in.) or

larger is easier to test than a small fabric as all six observations

can be made on one fabric, but the procedure allows for testing

a small fabric (see Note 2).

7.3 Specimens—After the laboratory sampling unit(s) has

been prepared as directed in Section 8 and conditioned as

directed in Section 9, take six specimens (the area inside the

hoop) by locating the hoop on the laboratory sampling unit(s)

as follows:

7.3.1 For a laboratory sampling unit(s) that is approximately

112 (lengthwise direction) by 56 cm (44 by 22 in.) or larger,

locate the hoop as shown in Fig. 4.

7.3.2 For a laboratory sampling unit(s) that is not large

enough to locate the hoop so that all six specimens are on one

laboratory sampling unit, alternate the hoop from face to back

using as many laboratory sampling units as needed to obtain

the six specimens.

8. Preparation of the Laboratory Sampling Unit

8.1 Recommended Preparation of the Laboratory Sampling

Unit—The recommended preparation of the laboratory sam-

FIG. 4 Location of the Hoop for a Large Laboratory Sampling

pling unit uses a dryer to precondition the laboratory sampling

Unit Such as a Bath Towel

unit and raise the pile so it is not matted down. See 6.6 for a

description of the dryer. The procedure is as follows:

8.1.1 If fabric softener has recently been used in the dryer,

purchaser and the supplier, however, must agree on the number

dry a 3.6-kg (8-lb) dummy load of desized unsoftened fabrics

of washing and drying cycles. This procedure may cause more

which will not be tested, and then repeat this procedure with a

variation in the test result than the procedure described in 8.1

different dummy load of 3.6 kg (8 lb) of desized unsoftened

and it is not recommended for acceptance testing unless there

fabrics.

has been an agreement between the purchaser and the supplier.

8.1.2 Clean the lint filter.

This procedure uses the equipment and the supplies described

8.1.3 Load the dryer with laboratory sampling units that

in 6.6-6.8. The procedure is as follows:

comprise a homogeneous load (for example, same manufac-

8.2.1 If fabric softener has recently been used in the washer

turer, same line, same finishing, and same previous care). It is

or dryer, wash or dry or both a 3.6-kg (8-lb) dummy load of

not necessary to have a full load in the dryer, so it is acceptable

desized unsoftened fabrics which will not be tested, and then

to load only one laboratory sampling unit into the dryer.

repeat this procedure with a different dummy load of 3.6 kg (8

8.1.4 Select normal cycle, medium t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.