ASTM G146-96

(Practice)Standard Practice for Evaluation of Disbonding of Bimetallic Stainless Alloy/Steel Plate for Use in High-Pressure, High-Temperature Refinery Hydrogen Service

Standard Practice for Evaluation of Disbonding of Bimetallic Stainless Alloy/Steel Plate for Use in High-Pressure, High-Temperature Refinery Hydrogen Service

SCOPE

1.1 This practice describes a procedure for the evaluation of disbonding of bimetallic stainless alloy/steel plate for use in refinery high-pressure/high-temperature (HP/HT) gaseous hydrogen service. It includes procedures to (a) produce suitable laboratory test specimens (b) obtain hydrogen charging conditions in the laboratory that are similar to those found in refinery HP/HT hydrogen gas service for evaluation of bimetallic specimens exposed to these environments, and (c) perform analysis of the test data. The purpose of this practice is to allow for comparison of data among test laboratories on the resistance of bimetallic stainless alloy/steels to hydrogen-induced disbonding (HID).

1.2 This practice applies primarily to bimetallic products fabricated by weld overlay of stainless alloy onto a steel substrate. Most of the information developed using this practice has been obtained for such materials. The procedures described herein, may also be appropriate for evaluation of hot roll bonded, explosive bonded, or other suitable processes for applying stainless alloys on steel substrates. However, due to the broad range of possible materials, test conditions, and variations in test peocedures, it is up to the user of this practice to determine the suitability and applicability of these procedures for evaluation of such materials.

1.3 This practice is intended to be applicable for evaluation of materials for service conditions involving severe hydrogen charging which may produce HID as shown in Fig. 1 for stainless steel weld overlay on steel equipment (see Refs1 and 2 and Appendix X1). However, it should be noted that this practice may not be appropriate for forms of bimetallic construction or service conditions which have not been observed to cause HID in service.

1.4 Additional information regarding the evaluation of bimetallic stainless alloy/steel plate for HID, test methodologies, and the effects of test conditions, materials, and welding variables, and inspection techniques is given in Appendix X1.

1.5 The values stated in SI units are to be regarded as the standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: G 146 – 96

Standard Practice for

Evaluation of Disbonding of Bimetallic Stainless Alloy/Steel

Plate for Use in High-Pressure, High-Temperature Refinery

Hydrogen Service

This standard is issued under the fixed designation G 146; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This practice describes a procedure for the evaluation of

disbonding of bimetallic stainless alloy/steel plate for use in

refinery high-pressure/high-temperature (HP/HT) gaseous hy-

drogen service. It includes procedures to (a) produce suitable

laboratory test specimens, (b) obtain hydrogen charging con-

ditions in the laboratory that are similar to those found in

refinery HP/HT hydrogen gas service for evaluation of bime-

tallic specimens exposed to these environments, and (c) per-

form analysis of the test data. The purpose of this practice is to

allow for comparison of data among test laboratories on the

resistance of bimetallic stainless alloy/steels to hydrogen-

induced disbonding (HID).

1.2 This practice applies primarily to bimetallic products

fabricated by weld overlay of stainless alloy onto a steel

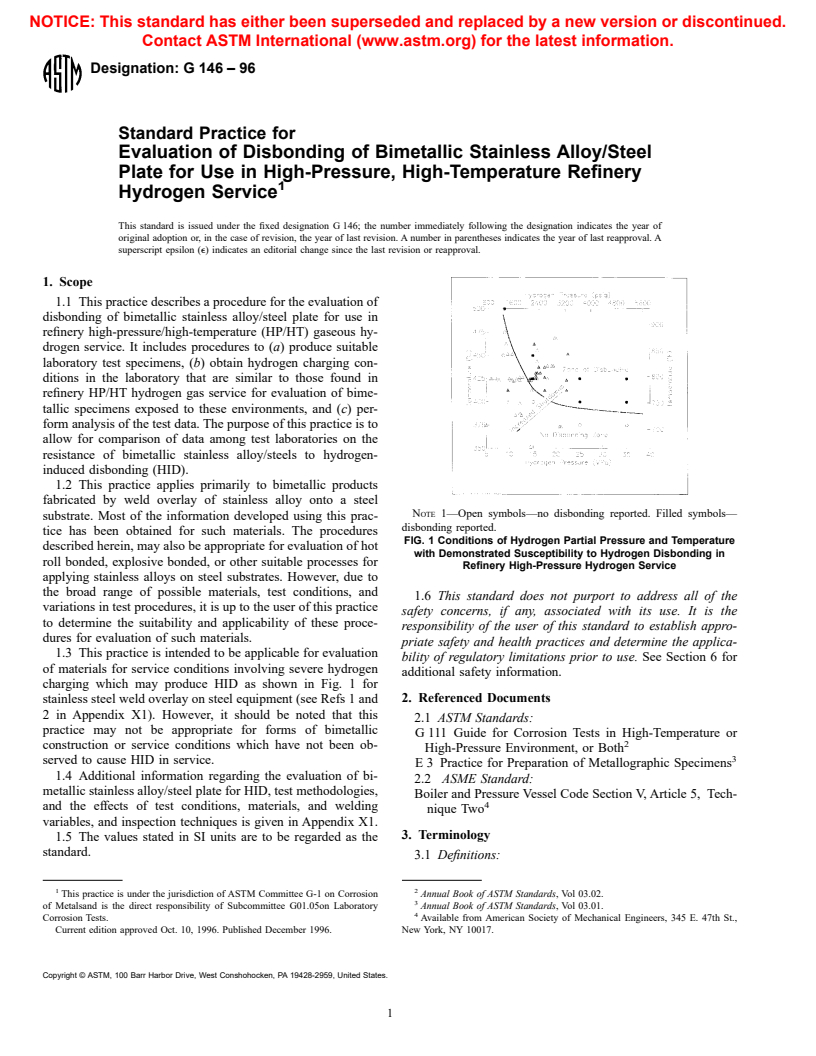

NOTE 1—Open symbols—no disbonding reported. Filled symbols—

substrate. Most of the information developed using this prac-

disbonding reported.

tice has been obtained for such materials. The procedures

FIG. 1 Conditions of Hydrogen Partial Pressure and Temperature

described herein, may also be appropriate for evaluation of hot

with Demonstrated Susceptibility to Hydrogen Disbonding in

roll bonded, explosive bonded, or other suitable processes for

Refinery High-Pressure Hydrogen Service

applying stainless alloys on steel substrates. However, due to

the broad range of possible materials, test conditions, and

1.6 This standard does not purport to address all of the

variations in test procedures, it is up to the user of this practice

safety concerns, if any, associated with its use. It is the

to determine the suitability and applicability of these proce-

responsibility of the user of this standard to establish appro-

dures for evaluation of such materials.

priate safety and health practices and determine the applica-

1.3 This practice is intended to be applicable for evaluation

bility of regulatory limitations prior to use. See Section 6 for

of materials for service conditions involving severe hydrogen

additional safety information.

charging which may produce HID as shown in Fig. 1 for

2. Referenced Documents

stainless steel weld overlay on steel equipment (see Refs 1 and

2 in Appendix X1). However, it should be noted that this

2.1 ASTM Standards:

practice may not be appropriate for forms of bimetallic

G 111 Guide for Corrosion Tests in High-Temperature or

construction or service conditions which have not been ob-

High-Pressure Environment, or Both

served to cause HID in service.

E 3 Practice for Preparation of Metallographic Specimens

1.4 Additional information regarding the evaluation of bi-

2.2 ASME Standard:

metallic stainless alloy/steel plate for HID, test methodologies,

Boiler and Pressure Vessel Code Section V, Article 5, Tech-

and the effects of test conditions, materials, and welding

nique Two

variables, and inspection techniques is given in Appendix X1.

3. Terminology

1.5 The values stated in SI units are to be regarded as the

standard.

3.1 Definitions:

1 2

This practice is under the jurisdiction of ASTM Committee G-1 on Corrosion Annual Book of ASTM Standards, Vol 03.02.

of Metalsand is the direct responsibility of Subcommittee G01.05on Laboratory Annual Book of ASTM Standards, Vol 03.01.

Corrosion Tests. Available from American Society of Mechanical Engineers, 345 E. 47th St.,

Current edition approved Oct. 10, 1996. Published December 1996. New York, NY 10017.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

G 146

3.1.1 HID—a delamination of a stainless alloy surface layer 6.2 There are many types of test cell configurations which

from its steel substrate produced by exposure of the material to can be used to conduct evaluations of HID. This practice does

a hydrogen environment. not recommend or endorse any particular test cell design. Fig.

3.1.2 Discussion—This phenomenon can occur in internally 2 shows a schematic representation of a typical test cell

stainless alloy lined steel equipment by the accumulation of designed to conduct HID tests in HP/HT gaseous hydrogen

molecular hydrogen in the region of the metallurgical bond at environments. Other designs may also provide acceptable

the interface between the steel and stainless alloy surface layer performance. However, the typical components should include

produced by exposure to service conditions involving HP/HT the following:

hydrogen in the refinery hydroprocessing. 6.2.1 Metal Test Cell—The test cell should be constructed

from materials which have been proven to have high resistance

4. Summary of Practice

to hydrogen embrittlement and high-temperature hydrogen

4.1 Stainless alloy/steel specimens are exposed to a gaseous

attack under the anticipated test conditions. Materials with low

hydrogen containing environment at HP/HT conditions for resistance to these phenomena should be avoided. Typical test

sufficient time to produce hydrogen charging in the material.

cells for high-pressure hydrogen testing are constructed from

Following exposure, the specimens are cooled to ambient stainless steel (UNS S31600 or S34700) or nickel alloys (UNS

temperature at a controlled rate. The specimens are then held at

N10276 or N06625) in the solution annealed condition. Steel

room temperature for a designated period to allow for the vessels with stainless alloy exposed surfaces may also be

development of HID between the stainless alloy surface layer

suitable.

and the steel. Following the hold period, the specimens are 6.2.2 Closure and Seal—To facilitate operation of the test

evaluated for HID at this interface using straight beam ultra- cell, the closure should provide for rapid opening and closing

sonic methods with metallographic examination to confirm any

of the test cell while retaining reliable sealing capabilities for

HID found. The size and distribution of the disbonded re- hydrogen. This can include either metallic or nonmetallic

gion(s) are then characterized by this practice. Single or

materials with high resistance to thermal degradation and

multiple hydrogen exposure/cooling cycles can be conducted hydrogen attack.

and varying exposure conditions and cooling rates can be

6.2.3 Gas Port(s)—The gas port should be designed to

incorporated into this evaluation to provide assessment of the promote flow and circulation of the gaseous test environments,

disbonding characteristics of materials and service condition

inert gas purging, and evacuation as required to produce the

used for refinery process equipment containing HP/HT hydro- intended test environment. Usually two ports are used so that

gen containing environments.

separate flow-through capabilities are attained to facilitate

these functions.

5. Significance and Use

6.2.4 Electrical Feed-Throughs—High-temperature condi-

5.1 This practice provides an indication of the resistance or

tions are required in this practice. It is usually advantageous to

susceptibility, or both, to HID of a metallurgically bonded

stainless alloy surface layer on a steel substrate due to exposure

to hydrogen-containing gaseous environments under HP/HT

conditions. This practice is applicable over a broad range of

pressures, temperatures, cooling rates, and gaseous hydrogen

environments where HID could be a significant problem. These

procedures can be used to assess the effects of material

composition, processing methods, fabrication techniques, and

heat treatment as well as the effects of hydrogen partial

pressure, service temperature, and cooling rate. The HID

produced by these procedures may not correlate directly with

service experience for particular applications. Additionally, this

practice does not address the evaluation of high-temperature

hydrogen attack in the steel substrate. Typically, longer expo-

sure times at the test conditions must be utilized to allow for

the resistance to decarburization, internal blistering or crack-

ing, or both, to be evaluated.

6. Apparatus

6.1 Because this practice is intended to be conducted at high

pressures and high temperatures, the apparatus must be con-

structed to safely contain the test environment while being

resistant to the cumulative embrittling effects of hydrogen.

Secondly, the test apparatus must be capable of allowing (a)

introduction of the test gas, (b) removal of air from the test cell,

(c) uniform heating of the test specimens, and (d) cooling of

the specimens at controlled rates. FIG. 2 Typical Test Cell

G 146

utilize an internal heater to heat just the test specimens and the 9. Sampling

gaseous environment in the immediate vicinity of the speci-

9.1 The procedure for sampling stainless alloy bimetallic

men. Therefore, feed-throughs are usually needed to make

products should be sufficient to provide specimens that are

electrical contact with an internal resistance or induction

representative of the plate from which they are taken. The

heater. These feed-throughs must also provide (a) electrical

details of this procedure should be covered in product or

isolation from the test cell and internal fixtures and (b)

purchase specifications and are not covered in this practice.

maintain a seal to prevent leakage of the test environment. If

9.2 Sampling of the test environment is recommended to

external heaters are used, no electric feed-throughs are re-

confirm that the test procedure is in conformance with this

quired.

practice and attains the intended test conditions. The frequency

6.2.5 Electric Resistance or Induction Heater(s)—Either

of environmental sampling should be covered in applicable

internal or external heaters can be used to obtain elevated

product, purchase, or testing specifications, or both. As a

temperature. For lower temperatures (<300°C), external heat-

minimum requirement to be in compliance with this practice,

ing of the test cell is typically more convenient but may limit

sampling of the test environment shall be conducted at the start

cooling rates since they heat the entire vessel. For high

of testing in a particular apparatus and when any element of the

temperatures (>300°C), an internal heater is commonly used to

test procedure or test system has been changed or modified.

heat only the test specimen and the gaseous environment in the

10. Test Specimens

vicinity of the test specimens to limit power requirements and

problems with high-temperature sealing and pressure contain-

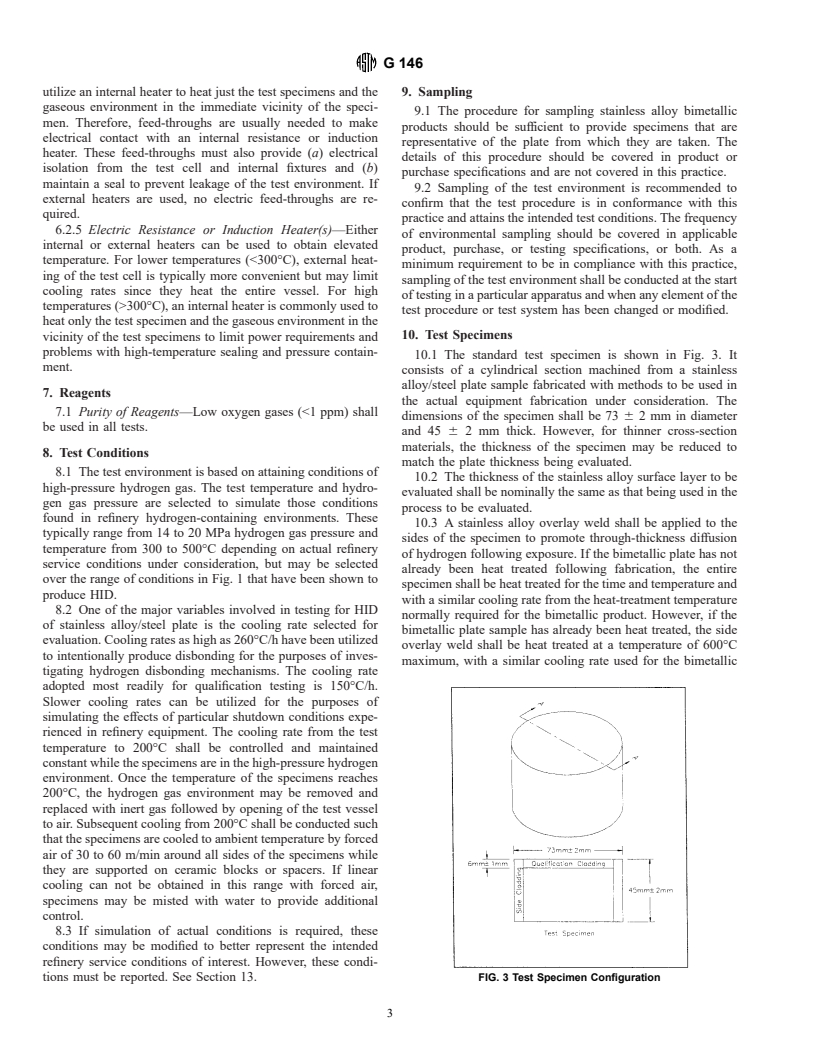

10.1 The standard test specimen is shown in Fig. 3. It

ment.

consists of a cylindrical section machined from a stainless

alloy/steel plate sample fabricated with methods to be used in

7. Reagents

the actual equipment fabrication under consideration. The

7.1 Purity of Reagents—Low oxygen gases (<1 ppm) shall

dimensions of the specimen shall be 73 6 2 mm in diameter

be used in all tests.

and 45 6 2 mm thick. However, for thinner cross-section

materials, the thickness of the specimen may be reduced to

8. Test Conditions

match the plate thickness being evaluated.

8.1 The test environment is based on attaining conditions of

10.2 The thickness of the stainless alloy surface layer to be

high-pressure hydrogen gas. The test temperature and hydro-

evaluated shall be nominally the same as that being used in the

gen gas pressure are selected to simulate those conditions

process to be evaluated.

found in refinery hydrogen-containing environments. These

10.3 A stainless alloy overlay weld shall be applied to the

typically range from 14 to 20 MPa hydrogen gas pressure and

sides of the specimen to promote through-thickness diffusion

temperature from 300 to 500°C depending on actual refinery

of hydrogen following exposure. If the bimetallic plate has not

service conditions under consideration, but may be selected

already been heat treated following fabrication, the entire

over the range of conditions in Fig. 1 that have been shown to

specimen shall be heat treated for the time and temperature and

produce HID.

with a similar cooling rate from the heat-treatment temperature

8.2 One of the major variables involved in testing for HID

normally required for the bimetallic product. However, if the

of stainless alloy/steel plate is the cooling rate selected for

bimetallic plate sample has already been heat treated, the side

evaluation. Cooling rates as high as 260°C/h have been utilized

overlay weld shall be heat treated at a temperature of 600°C

to intentionally produce disbonding for the purposes of inves-

maximum, with a similar cooling rate used for the bimetallic

tigating hydrogen disbonding mechanisms. The cooling rate

adopted most readily for qualification testing is 150°C/h.

Slower cooling rates can be utilized for the purposes of

simulating the effects of particular shutdown conditions expe-

rienced in refinery equipment. The cooling rate from the test

temperature to 200°C shall be controlled and maintained

constant while the specimens are in the high-pressure hydrogen

environment. Once the temperature of the specimens reaches

200°C, the hydrogen gas environment may be removed and

replaced with inert gas followed by opening of the test vessel

to air. Subsequent cooling from 200°C shall be conducted such

that the specimens are cooled to ambient temperature by forced

air of 30 to 60 m/min around all sides of the specimens while

they are supported on ceramic blocks or spacers. If linear

cooling can not be obtained in this range with forced air,

specimens may be misted with water to provide additional

control.

8.3 If simulation of actual conditions is required, these

conditions may be modified to better represent the intended

refinery service conditions of interest. However, these condi-

tions must be reported. See Section 13. FIG. 3 Test Specimen Configuration

G 146

product prior to testing.

10.4 The only steel surface on the specimen is the one

opposite the alloy surface being evaluated in the test. The

purpose of the side overlay is to limit diffusion of hydrogen in

the radial direction during and after cooling of the specimen to

ambient conditions. The side overlay weld produces conditions

for diffusion of hydrogen from the test specimen in which

diffusion occurs primarily in th

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.