ASTM B760-07(2013)

(Specification)Standard Specification for Tungsten Plate, Sheet, and Foil

Standard Specification for Tungsten Plate, Sheet, and Foil

ABSTRACT

This specification covers wrought unalloyed tungsten plate, sheet, and foil. The various tungsten flat products covered by this specification shall be formed with the conventional rolling, forging, or extrusion equipment, normally found in primary ferrous and nonferrous plants. The ingot metal shall be consolidated employing either the powder metallurgy or vacuum-arc-casting process. The materials shall conform to the required chemical composition for carbon, oxygen, nitrogen, iron, nickel, and silicon. Plate, sheet, and foil shall be furnished in the following metallurgical condition: hot-rolled, stress relieved, and cold-rolled. The materials shall also conform to the required permissible variations in physical dimensions such as thickness, width, length, and flatness.

SCOPE

1.1 This specification covers wrought unalloyed tungsten plate, sheet, and foil.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 The following precautionary caveat pertains only to the test method portions of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:B760 −07 (Reapproved 2013)

Standard Specification for

Tungsten Plate, Sheet, and Foil

This standard is issued under the fixed designation B760; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope pressed and sintered powder metallurgy shapes, or a single

ingot in the case of products manufactured from ingot.

1.1 This specification covers wrought unalloyed tungsten

3.2 Product Forms:

plate, sheet, and foil.

3.2.1 foil, n—a flat product less than 0.005 in. (0.13 mm) in

1.2 The values stated in inch-pound units are to be regarded

thickness.

as standard. The values given in parentheses are mathematical

3.2.2 plate, n—aflatproduct0.188in.(4.75mm)ormorein

conversions to SI units that are provided for information only

thickness.

and are not considered standard.

3.2.3 sheet, n—a flat product from .005 in. (0.13 mm) to

1.3 The following precautionary caveat pertains only to the

0.187 in. (4.75 mm) in thickness.

test method portions of this specification: This standard does

not purport to address all of the safety concerns, if any,

4. Ordering Information

associated with its use. It is the responsibility of the user of this

4.1 Ordersformaterialunderthisspecificationshallinclude

standard to establish appropriate safety and health practices

the following information:

and determine the applicability of regulatory limitations prior

4.1.1 Material identification and metallurigical condition

to use.

(Section 7),

4.1.2 Product form (Section 3),

2. Referenced Documents

2 4.1.3 Chemical requirements (Table 1),

2.1 ASTM Standards:

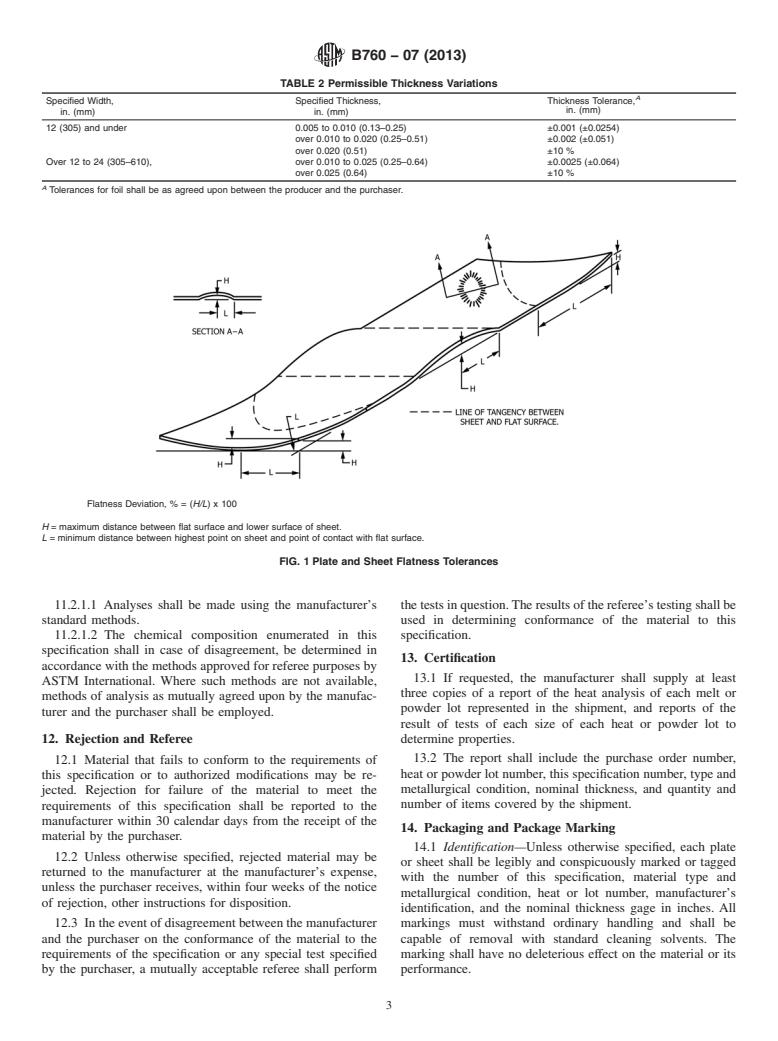

4.1.4 Tolerances (Section 9, Table 2, and Fig. 1),

E29Practice for Using Significant Digits in Test Data to

4.1.5 Workmanship and quality level requirements (Section

Determine Conformance with Specifications

10),

4.1.6 Packaging (Section 14),

3. Terminology

4.1.7 Marking (Section 14),

3.1 Lot Definitions:

4.1.8 Certification and reports (Section 13), and

3.1.1 ingot, n—no definition required.

4.1.9 Disposition of rejected material (Section 12).

3.1.2 A manufacturing lot shall consist of a material of the

5. Materials and Manufacture

samesize,shape,condition,andfinishproducedfromtheingot

orpowderblendbythesamerollingreductionscheduleandthe

5.1 The various tungsten flat products covered by this

same heat treatment parameters. Unless otherwise agreed

specification shall be formed with the conventional rolling,

between manufacturer and purchaser, a lot shall be limited to

forging, or extrusion equipment, normally found in primary

the product of an 8 h period for final continuous anneal, or to

ferrous and nonferrous plants.

a single furnace load for final batch anneal.

5.2 The ingot metal is consolidated employing either the

3.1.3 A chemical analysis lot shall consist of a single

powder metallurgy or vacuum-arc-casting process.

powder blend in the case of products manufactured from

6. Chemical Composition

6.1 The tungsten ingots or billets for conversion to finished

This specification is under the jurisdiction of ASTM Committee B10 on

products covered by this specification shall conform to the

Reactive and Refractory Metals and Alloys and is the direct responsibility of

Subcommittee B10.04 on Molybdenum and Tungsten.

requirements of the chemical composition prescribed in Table

Current edition approved May 1, 2013. Published May 2013. Originally

1.

approved in 1986. Last previous edition approved in 2007 as B760 – 07. DOI:

10.1520/B0760-07R13.

6.2 Heat Analysis:

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

6.2.1 Heat analysis is an analysis made by the manufacturer

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

ofthemetalonarepresentativesampleofpowderfromasingle

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. powder blend in the case of material made from pressed and

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

B760−07 (2013)

TABLE 1 Chemical Composition/Check Analysis

9. Permissible Variations in Dimensions

Composition, Permissible Variations in

Element 9.1 The thickness tolerances on tungsten products covered

max, % Check Analysis, %

by this specification shall be as specified in Table 2.

C 0.010 ±0.002

A

O 0.010 + 10 % relative

9.2 The width tolerances shall be as agreed upon between

N 0.010 + 0.0005

the manufacturer and the purchaser. In general, shearing

Fe 0.010 + 0.001

Ni 0.010 + 0.001 tolerancewillbe 6 ⁄16in.(61.6mm)andslittingtolerancewill

Si 0.010 + 0.001 1

be 6 ⁄32 in. (60.8 mm).

A

If chemical analysis is performed on a sample from the powder blend used to

9.3 The length and camber tolerances shall be as agreed

make the finished product, oxygen will be reported for information only.

upon between the manufacturer and the purchaser. In general,

length and camber tolerances will show a maximum deviation

of + ⁄16 in., − 0/ft (1.6 mm/m) of length.

sintered powder billets, or on a representative sample of a cast

ingot or intermediate product from that ingot in the case of

9.4 Flatness tolerances on tungsten flat products shall be as

material made from cast ingot.

follows:

6.2.2 Chemical lot analysis shall be as specified in Table 1,

Thickness, in.(mm) Flatness Deviation,

with the exception of oxygen which shall be reported for max,%

0.005–0.187 (0.13–4.75) 4

information only, and not be required to meet the requirements

0.188–0.625 (4.75–15.9) 5

of Table 1.

9.4.1 Determine flatness deviation (Fig. 1) as follows:

6.3 Check Analysis:

Flatnessdeviation, % 5 H/L 3100

~ !

6.3.1 Checkanalysisisananalysismadebythepurchaseror

the manufacturer of the metal after it has been processed into

where:

finished mill forms, and is either for the purpose of verifying

H = maximum vertical distance between a flat reference

the composition of a heat or lot, or to determine variations in

surface and the lower surface of the flat product, and

the composition within a heat or lot.

L = minimum horizontal distance between the highest point

6.3.2 Checkanalysistolerancesdonotbroadenthespecified

of the flat product where H is determined, and the point

heat analysis requirements but cover variations between labo-

of contact of the lower surface of the flat product with

ratories in the measurement of chemical content.

a flat reference surface.

6.3.3 Check analysis limits shall be as specified in Table 1.

6.3.4 The manufacturer shall not ship material that is

10. Workmanship, Finish, and Appearance

outside the limits specified in Table 1.

10.1 Cracks, seams, slivers, blisters, burrs, and other inju-

7. Metallurgical Condition rious imperfections shall not exceed standards of acceptability

agreed upon by the manufacturer and the purchaser.

7.1 Plate, sheet and foil shall be furnished in one of the

following conditions as designated on the purchase order:

10.2 Tungstenplate,sheet,andfoilshallbefreeofinjurious

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.