ASTM F16-67(2000)

(Test Method)Standard Test Methods for Measuring Diameter or Thickness of Wire and Ribbon for Electronic Devices and Lamps

Standard Test Methods for Measuring Diameter or Thickness of Wire and Ribbon for Electronic Devices and Lamps

SCOPE

1.1 These test methods cover procedures for measuring the diameter or thickness of round and flat wire (ribbon) 0.060 in. (1.52 mm) maximum used in electronic devices and lamps. They are intended primarily for referee use, for laboratory measuring, and for certifying size of standard samples used for checking other measuring equipment that may be agreed upon between the supplier and the purchaser.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F 16–67(Reapproved2000)

Standard Test Methods for

Measuring Diameter or Thickness of Wire and Ribbon for

Electronic Devices and Lamps

ThisstandardisissuedunderthefixeddesignationF16;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (e) indicates an editorial change since the last revision or reapproval.

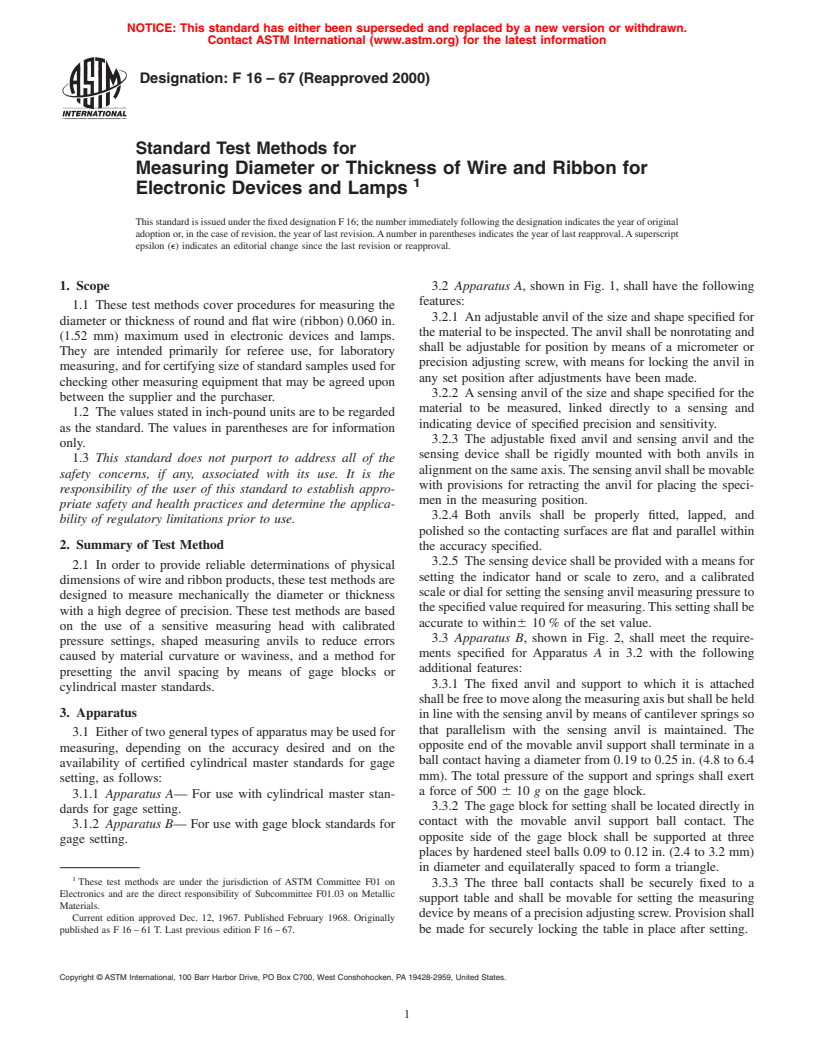

1. Scope 3.2 Apparatus A, shown in Fig. 1, shall have the following

features:

1.1 These test methods cover procedures for measuring the

3.2.1 An adjustable anvil of the size and shape specified for

diameter or thickness of round and flat wire (ribbon) 0.060 in.

the material to be inspected. The anvil shall be nonrotating and

(1.52 mm) maximum used in electronic devices and lamps.

shall be adjustable for position by means of a micrometer or

They are intended primarily for referee use, for laboratory

precision adjusting screw, with means for locking the anvil in

measuring, and for certifying size of standard samples used for

any set position after adjustments have been made.

checking other measuring equipment that may be agreed upon

3.2.2 Asensing anvil of the size and shape specified for the

between the supplier and the purchaser.

material to be measured, linked directly to a sensing and

1.2 The values stated in inch-pound units are to be regarded

indicating device of specified precision and sensitivity.

as the standard. The values in parentheses are for information

3.2.3 The adjustable fixed anvil and sensing anvil and the

only.

sensing device shall be rigidly mounted with both anvils in

1.3 This standard does not purport to address all of the

alignmentonthesameaxis.Thesensinganvilshallbemovable

safety concerns, if any, associated with its use. It is the

with provisions for retracting the anvil for placing the speci-

responsibility of the user of this standard to establish appro-

men in the measuring position.

priate safety and health practices and determine the applica-

3.2.4 Both anvils shall be properly fitted, lapped, and

bility of regulatory limitations prior to use.

polished so the contacting surfaces are flat and parallel within

2. Summary of Test Method the accuracy specified.

3.2.5 The sensing device shall be provided with a means for

2.1 In order to provide reliable determinations of physical

setting the indicator hand or scale to zero, and a calibrated

dimensions of wire and ribbon products, these test methods are

scale or dial for setting the sensing anvil measuring pressure to

designed to measure mechanically the diameter or thickness

thespecifiedvaluerequiredformeasuring.Thissettingshallbe

with a high degree of precision. These test methods are based

accurate to within6 10 % of the set value.

on the use of a sensitive measuring head with calibrated

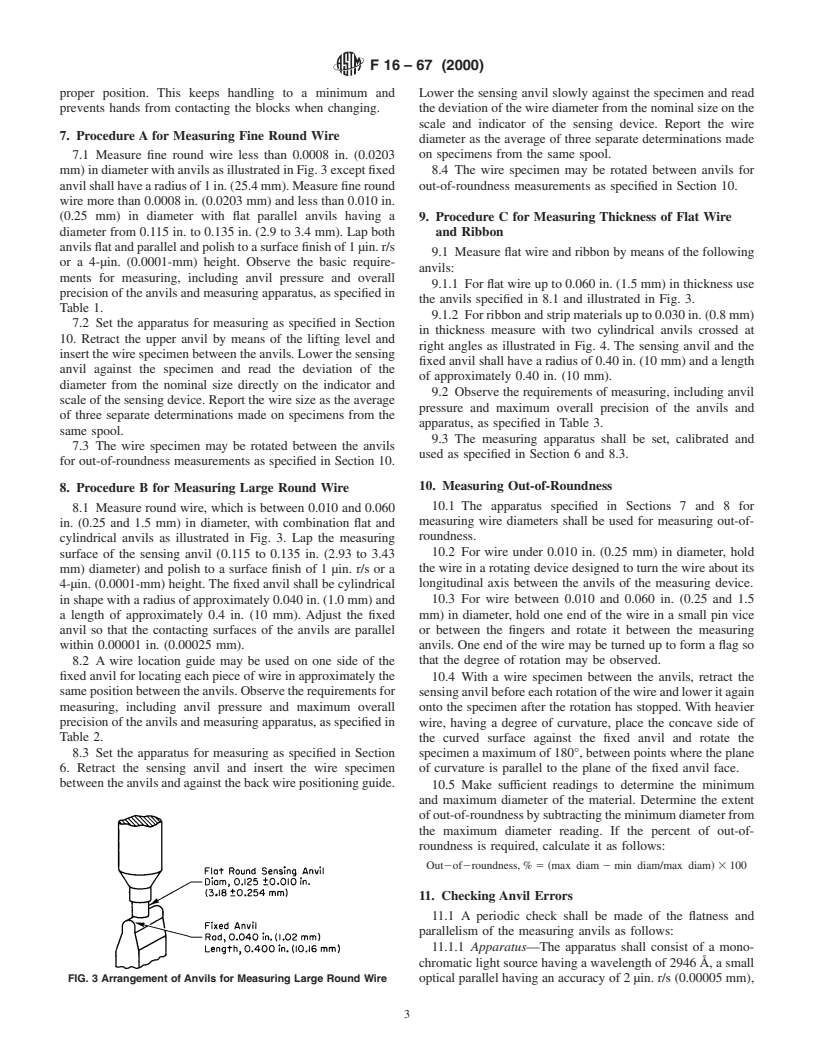

3.3 Apparatus B, shown in Fig. 2, shall meet the require-

pressure settings, shaped measuring anvils to reduce errors

ments specified for Apparatus A in 3.2 with the following

caused by material curvature or waviness, and a method for

additional features:

presetting the anvil spacing by means of gage blocks or

3.3.1 The fixed anvil and support to which it is attached

cylindrical master standards.

shallbefreetomovealongthemeasuringaxisbutshallbeheld

3. Apparatus

in line with the sensing anvil by means of cantilever springs so

that parallelism with the sensing anvil is maintained. The

3.1 Eitheroftwogeneraltypesofapparatusmaybeusedfor

opposite end of the movable anvil support shall terminate in a

measuring, depending on the accuracy desired and on the

ball contact having a diameter from 0.19 to 0.25 in. (4.8 to 6.4

availability of certified cylindrical master standards for gage

mm). The total pressure of the support and springs shall exert

setting, as follows:

a force of 500 6 10 g on the gage block.

3.1.1 Apparatus A— For use with cylindrical master stan-

3.3.2 The gage block for setting shall be located directly in

dards for gage setting.

contact with the movable anvil support ball contact. The

3.1.2 Apparatus B— For use with gage block standards for

opposite side of the gage block shall be supported at three

gage setting.

places by hardened steel balls 0.09 to 0.12 in. (2.4 to 3.2 mm)

in diameter and equilaterally spaced to form a triangle.

These test methods are under the jurisdiction of ASTM Committee F01 on

3.3.3 The three ball contacts shall be securely fixed to a

Electronics and are the direct responsibility of Subcommittee F01.03 on Metallic

support table and shall be movable for setting the measuring

Materials.

device by means of a precision adjusting screw. Provision shall

Current edition approved Dec. 12, 1967. Published February 1968. Originally

published as F 16 – 61 T. Last previous edition F 16 – 67. be made for securely locking the table in place after setting.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F 16–67 (2000)

causes (see 5.1) of inaccurate measurements. The measuring

devices shall be used in a small gage laboratory with tempera-

ture variations kept to within6 5°C. The equipment shall be

laid out on a clean surface with tools and gage blocks on foam

rubber pads. All equipment used for measuring, and the

material samples, shall be stabilized by leaving them together

in the gage room for at least 1 h. Gage blocks shall be handled

with tongs to prevent temperature variations.

5.3 Gage blocks shall be recalibrated at least once every

year, using the block calibration size for the calibration setting.

Blocks must be carefully cleaned and handled to prevent

uneven wear with consequent introduction of errors into the

gage setting.

5.4 The device shall be cleaned, calibrated, and set for

measuring by means of certified gage blocks or cylindrical

master standards as specified in Section 10.

6. Setting MeasuringApparatus

6.1 Set the measuring apparatus by means of standards so

FIG. 1 Measuring Apparatus A for Use with Cylindrical Master

that the indicator hand or scale of the sensing device is at zero

Standards for Gage Setting

when adjusted for the nominal size of the material to be

measured. This shall be done by means of certified cylindrical

master standards for Apparatus A and by means of certified

gage blocks for Apparatus B.

6.2 Cylindrical master standards shall be certified for diam-

eter, roundness, and surface finish by a metrology laboratory.

The master cylinders of wire shall be made of hardened steel

having a Rockwell hardness of C63 to C65, and lapped to a

finish of 1 µin. rms or a 4-µin. height (0.0001 mm).

6.3 Gage blocks shall be certified for length, flatness,

parallelism, and surface finish by a metrology laboratory. The

exact thickness of the blocks shall be reported to the nearest

microinch (0.000025 mm) as measured near the center of each

block. The surface finish shall be equivalent to 1 µin. rms or a

4-µin. (0.0001-mm) height or better.

6.4 Set Apparatus A for the nominal material size to be

measured by placing a cylindrical master standard between the

two anvils and adjusting the fixed anvil adjusting screw to get

FIG. 2 Measuring Apparatus B for Use with Gage Block

a zero reading on the sensing device. Raise and lower the

Standards for Gage Setting

sensing anvil against the standard several times and readjust

4. Test Specimens

the screw until three consecutive zero readings are obtained.

6.5 Set Apparatus B for nominal material size to be mea-

4.1 Test specimens shall be selected at least 3 ft (0.9 m)

sured by means of gage blocks. Select two blocks with a

from the end of a spool or coil of material and shall be straight

difference equal to the nominal size of the material. Use the

and free from kinks, dents, or other damage that would

exact length of the blocks as taken from the last certification.

interfere with measuring accuracy.

Place the longer block between the three-ball support table and

4.2 Wire or fine ribbon shall be drawn from the spool under

the ball end of the anvil support block, and carefully seat near

uniformly low tension to prevent elongation. If the material is

the center of the block. Turn the adjusting screw until the

obviously contaminated with oil, dirt, or other foreign matter,

indicator on the sensing device is on zero. Raise the ball end of

it shall be drawn gently through a lint-free cloth, wet with a

the anvil support block, remove the longer gage block, and

suitable solvent.

replace it with the shorter block in the same position. This in

5. Test Conditions

effect lowers the fixed measuring anvil from the first zero

5.1 The measuring device shall be used in a location that is setting by an amount equal to the nominal size of the material

clean and free of dust and lint. Vibration, drafts, direct heat to be measured. Leave this gage block in place while measure-

from lamps, and temperature variations shall be minimized. ments are being made.

The equipment shall be kept clean and covered when not in 6.6 To keep the effect of temperature variations to a mini-

use. mum, handle each block with insulated tongs when placed into

5.2 For fine wire, smaller than 0.0008 in. (0.02 mm) in position. Both blocks may also be inserted and interchanged by

diameter, extra precautions shall be taken to avoid all possible means of a shifting device for moving either block into the

F 16–67 (2000)

proper position. This keeps handling to a minimum and Lower the sensing anvil slowly against the specimen and read

prevents hands from contacting the blocks when changing. the deviation of the wire diameter from the nominal size on the

scale and indicator of the sensing device. Report the wire

7. ProcedureAfor Measuring Fine Round Wire

diameter as the average of three separate determinations made

on specimens from the same spool.

7.1 Measure fine round wire less than 0.0008 in. (0.0203

mm)indiameterwithanvilsasillustratedinFig.3exceptfixed 8.4 The wire specimen may be rotated between anvils for

anvilshallhavearadiusof1in.(25.4mm).Measurefineround out-of-roundness measurements as specified in Section 10.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.