ASTM F2080-01

(Specification)Standard Specification for Cold-Expansion Fittings With Metal Compression-Sleeves for Cross-Linked Polyethylene (PEX) Pipe

Standard Specification for Cold-Expansion Fittings With Metal Compression-Sleeves for Cross-Linked Polyethylene (PEX) Pipe

SCOPE

1.1 This specification covers metal cold-expansion fittings using metal compression-sleeves for use with cross-linked polyethylene (PEX) plastic pipe in ½-in., ¾-in., and 1-in. nominal diameters, whereby the PEX pipe is cold-expanded before fitting assembly. These cold-expansion fittings and metal compression-sleeves are intended for use in residential and commercial, hot and cold, potable water distribution systems, as well as sealed central heating, including under-floor heating systems, with continuous operation at pressures up to and including 100 psi (690 kPa), and at temperatures up to and including 180oF (82oC).

1.2 Included in this specification are the requirements for materials, workmanship, dimensions, burst pressure and sustained pressure, excessive temperature and pressure, and thermocycling tests, and markings to be used on the fittings and compression-sleeves.

1.3 The values stated in inch-pound units are to be regarded as the standard. The SI values stated in parentheses are provided for information purposes only.

1.4 The following precautionary caveat pertains only to the test method portion, Section 10, of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: F 2080 – 01

Standard Specification for

Cold-Expansion Fittings With Metal Compression-Sleeves

for Cross-Linked Polyethylene (PEX) Pipe

This standard is issued under the fixed designation F 2080; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope B 283 Specification for Copper and Copper-Alloy Die Forg-

ings (Hot-Pressed)

1.1 This specification covers metal cold-expansion fittings

B 689 Specification for Electroplated Engineering Nickel

using metal compression-sleeves for use with cross-linked

1 3 Coatings

polyethylene (PEX) plastic pipe in ⁄2-in., ⁄4-in., and 1-in.

B 851 Specification for Automated Controlled Shot Peening

nominal diameters, whereby the PEX pipe is cold-expanded

of Metallic Articles Prior to Nickel, Autocatalytic Nickel,

before fitting assembly. These cold-expansion fittings and

or Chromium Plating, or As a Final Finish

metal compression-sleeves are intended for use in residential

D 618 Practice for Conditioning Plastics and Electrical

and commercial, hot and cold, potable water distribution

Insulating Materials for Testing

systems, as well as sealed central heating, including under-

D 792 Test Methods for Density and Specific Gravity (Rela-

floor heating systems, with continuous operation at pressures

tive Density) of Plastics by Displacement

up to and including 100 psi (690 kPa), and at temperatures up

D 1505 Test Method for Density of Plastics by the Density-

to and including 180°F (82°C).

Gradient Technique

1.2 Included in this specification are the requirements for

D 1598 Test Method for Time-to-Failure of Plastic Pipe

materials, workmanship, dimensions, burst pressure and sus-

Under Constant Internal Pressure

tained pressure, excessive temperature and pressure, and ther-

D 1599 Test Method for Short-Time, Hydraulic Failure

mocycling tests, and markings to be used on the fittings and

Pressure of Plastic Pipe, Tubing, and Fittings

compression-sleeves.

D 1600 Terminology for Abbreviated Terms Relating to

1.3 The values stated in inch-pound units are to be regarded

Plastics

as the standard. The SI values stated in parentheses are

D 2122 Test Method for Determining Dimensions of Ther-

provided for information purposes only.

moplastic Pipe and Fittings

1.4 The following precautionary caveat pertains only to the

D 2765 Test Methods for Determination of Gel Content and

test method portion, Section 10, of this specification. This

Swell Ratio of Cross-Linked Ethylene Plastics

standard does not purport to address all of the safety concerns,

D 3045 Practice for Heat Aging of Plastics Without Load

if any, associated with its use. It is the responsibility of the user

F 412 Terminology Relating to Plastic Piping Systems

of this standard to establish appropriate safety and health

F 876 Specification for Crosslinked Polyethylene (PEX)

practices and determine the applicability of regulatory limita-

Tubing

tions prior to use.

F 877 Specification for Crosslinked Polyethylene (PEX)

2. Referenced Documents

Plastic Hot- and Cold-Water Distribution Systems

2.2 Canadian Standards Association:

2.1 ASTM Standards:

CAN/CSA B137.5 – M99

A 582/A 582M Specification for Free-Machining Stainless

2.3 ANSI Standards:

and Heat Resisting Steel Bars

B1.20.1 Pipe Threads General Purpose (Inch)

B 16/B 16M Specification for Free-Cutting Brass Rod, Bar,

B16.18 Cast Copper Alloy Solder Joint Pressure Fittings

and Shapes for Use in Screw Machines

(Inch)

B 140/B 140M Specification for Copper-Zinc-Lead

(Leaded Red Brass or Hardware Bronze) Rod, Bar and

Shapes

Annual Book of ASTM Standards, Vol 02.05.

Annual Book of ASTM Standards, Vol 08.01.

Annual Book of ASTM Standards, Vol 08.04.

1 7

This specification is under the jurisdiction of ASTM Committee F17 on Plastic Annual Book of ASTM Standards, Vol 08.02.

Piping Systems and is the direct responsibility of Subcommittee F17.61 on Water. Available from the Canadian Standards Association, 178 Rexdale Blvd.,

Current edition approved Jan. 10, 2001. Published April 2001. Rexdale (Toronto), Canada M9W 1R3

2 9 nd

Annual Book of ASTM Standards, Vol 01.03. Available from the American National Standards Institute, 11 West 42 St.,

3 th

Annual Book of ASTM Standards, Vol 02.01. 13 Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

F2080–01

B16.22 Wrought Copper Alloy Solder Joint Pressure Fit- 5.2.1 Machined Brass—Machined brass compression-

tings (Inch)

sleeves shall be made from material meeting the requirements

2.4 NSF Standards:

of Specification B 16/B 16M copper-alloy UNS C36000.

Standard No. 14 for Plastic Piping Components and Related

5.2.2 Machined Stainless Steel—Machined stainless steel

Materials

compression-sleeves shall be made from material meeting the

Standard No. 61 for Drinking Water System Components –

requirements of Specification A 582/A 582M, stainless steel

Health Effects

alloy 304L.

2.5 MSS Standards:

5.3 Plating—Plating of either fitting component with nickel

SP-104 Wrought Copper Solder Joint Pressure Fittings

or chrome, or both, is optional and must fall within the

dimensional tolerances of this specification.

3. Terminology

5.3.1 Nickel Plating—Application of electroplated nickel

3.1 Definitions—Definitions of terms used in this specifica-

coating shall meet the requirements of Specifications B 689

tion are in accordance with Terminology F 412, and abbrevia-

and B 851.

tions are in accordance with Terminology D 1600, unless

5.3.2 Chrome Plating—Application of electroplated chrome

otherwise indicated.

coating shall meet the requirements of Specification B 851.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 cross-linked polyethylene, n—plastics prepared by

6. Performance Requirements

cross-linking (curing) polyethylene compounds (PEX).

3.2.2 fitting assembly, n—comprised of a metal cold-

6.1 General—All performance tests shall be conducted on

expansion fitting and a metal compression-sleeve, whereby the

assemblies of fittings (cold-expansion fittings and

PEX pipe is cold-expanded before fitting insertion, and the

compression-sleeves) and PEX pipe. Fittings shall meet the

compression-sleeve is pulled over the PEX pipe.

material and dimensional requirements of this specification.

PEX pipe shall meet the requirements of Specifications F 876

4. Classification

and F 877. Assembly of test specimens shall be in accordance

4.1 This specification covers one class of metal cold-

with 9.3. Each assembly shall contain at least two joints. Use

expansion fittings with metal compression-sleeves suitable for

separate sets of assemblies for each performance test require-

use with PEX pipe that meets the requirements of Specifica-

ment.

tions F 876 and F 877.

6.2 Hydrostatic-Burst—Assemblies shall meet the mini-

mum hydrostatic burst requirements, shown in Table 1, when

5. Materials and Manufacture

tested in accordance with 10.5.

5.1 Fittings—Cold-expansion fittings shall be made from

6.3 Hydrostatic Sustained Pressure Strength—Assemblies

one of the following materials:

shall meet the hydrostatic, sustained-pressure requirements

5.1.1 Machined Brass—Machined brass cold-expansion fit-

shown in Table 2, when tested in accordance with 10.6.

tings shall be made from material meeting the requirements of

6.4 Thermocycling—Assemblies shall not leak or separate

Specification B 16/B 16M, copper-alloy UNS C36000, or

when thermocycled 1000 cycles between the temperatures of

Specification B 140, copper alloy UNS C31400, or Specifica-

60°F (16°C) and 180°F (82°C) when tested in accordance with

tion B 283, copper-alloy UNS C89844.

10.7.

5.1.2 Machined Stainless Steel—Machined stainless steel

6.5 Excessive Temperature Hydrostatic Sustained Pressure:

cold-expansion fittings shall be made from material meeting

the requirements of Specification A 582, stainless steel alloy 6.5.1 General—Assemblies shall have the ability to accom-

304L.

modate the short-term test conditions: 30 days of 210°F (99°C)

5.1.3 Forged Brass—Forged brass cold-expansion fittings

and 150 psi (1034 kPa).

shall be made from material meeting the requirements of

6.5.2 Excessive Temperature Hydrostatic Sustained

Specification B 283, copper-alloy UNS C37700 or UNS

Pressure—Assemblies shall have the ability to accommodate

C89844.

the short-term conditions shown in Table 3 when tested in

5.1.4 Cast Copper Alloys—Cast copper alloy cold-

accordance with 10.8.

expansion fittings shall be made from material meeting the

requirements of Specification B 62 copper alloy UNS C83600,

or Specification B 584, copper-alloy UNS C83800, C84400 or

TABLE 1 Minimum, Hydrostatic Burst Strength Requirements for

A

C89844.

Cold-Expansion Fittings and PEX Piping Assemblies

5.2 Compression-Sleeves—Metal compression-sleeves shall

Nominal Minimum Burst Pressure

be made from one of the following materials: Piping Size at Different Temperatures

In. mm psi @ 73.4°F (kPa @ 23°C) psi @ 180°F (kPa @ 82.2°C)

⁄2 13 480 (3309) 215 (1482)

⁄8 + 16+ 475 (3275) 210 (1448)

A

Available from NSF International, P.O. Box 130140, Ann Arbor, MI

The fiber stress used to derive this test pressure is:

48113–0140.

At 74.3°F (23°C) 1900 psi (13.10 MPa)

Available from Manufacturer’s Standardization Society of the Valve and At 180°F (82.2°C) 850 psi (5.86 MPa)

Fittings Industry, 5203 Leesburg Pike, Suite 502, Falls Church, VA 22041.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

F2080–01

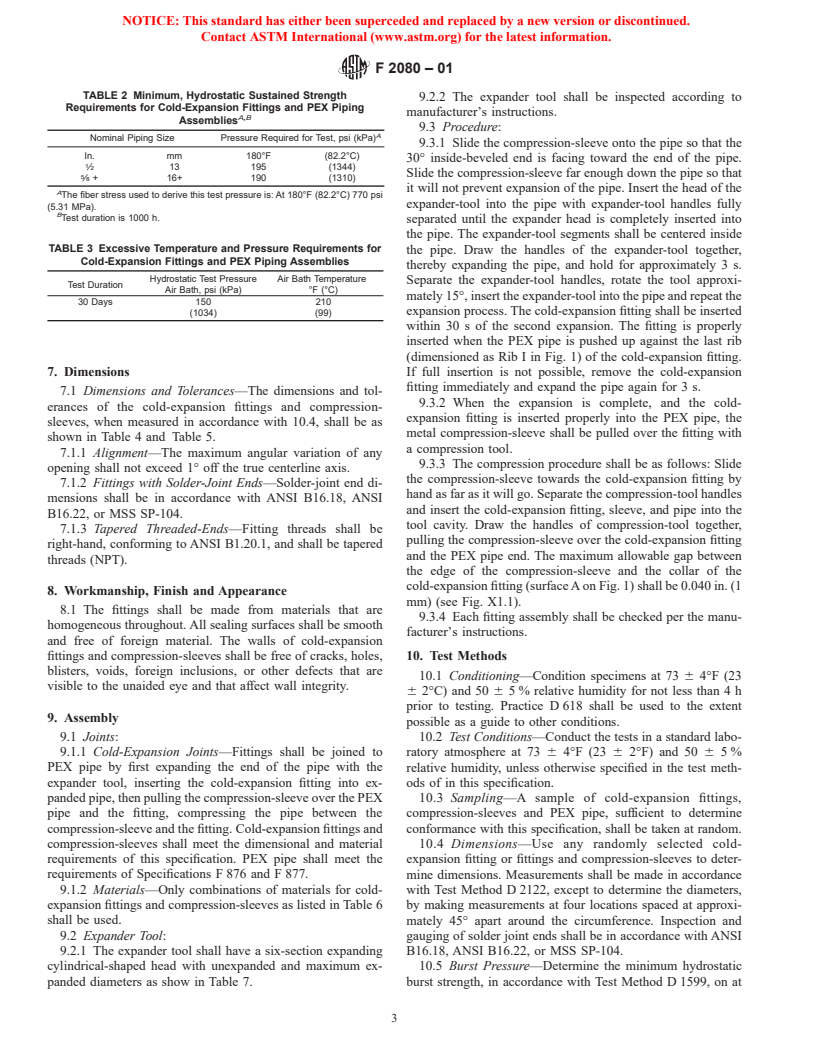

TABLE 2 Minimum, Hydrostatic Sustained Strength

9.2.2 The expander tool shall be inspected according to

Requirements for Cold-Expansion Fittings and PEX Piping

manufacturer’s instructions.

A,B

Assemblies

9.3 Procedure:

A

Nominal Piping Size Pressure Required for Test, psi (kPa)

9.3.1 Slide the compression-sleeve onto the pipe so that the

In. mm 180°F (82.2°C)

30° inside-beveled end is facing toward the end of the pipe.

⁄2 13 195 (1344)

Slide the compression-sleeve far enough down the pipe so that

⁄8 + 16+ 190 (1310)

it will not prevent expansion of the pipe. Insert the head of the

A

The fiber stress used to derive this test pressure is: At 180°F (82.2°C) 770 psi

expander-tool into the pipe with expander-tool handles fully

(5.31 MPa).

B

Test duration is 1000 h.

separated until the expander head is completely inserted into

the pipe. The expander-tool segments shall be centered inside

TABLE 3 Excessive Temperature and Pressure Requirements for

the pipe. Draw the handles of the expander-tool together,

Cold-Expansion Fittings and PEX Piping Assemblies

thereby expanding the pipe, and hold for approximately 3 s.

Hydrostatic Test Pressure Air Bath Temperature

Separate the expander-tool handles, rotate the tool approxi-

Test Duration

Air Bath, psi (kPa) °F (°C)

mately 15°, insert the expander-tool into the pipe and repeat the

30 Days 150 210

expansion process. The cold-expansion fitting shall be inserted

(1034) (99)

within 30 s of the second expansion. The fitting is properly

inserted when the PEX pipe is pushed up against the last rib

(dimensioned as Rib I in Fig. 1) of the cold-expansion fitting.

7. Dimensions If full insertion is not possible, remove the cold-expansion

fitting immediately and expand the pipe again for 3 s.

7.1 Dimensions and Tolerances—The dimensions and tol-

9.3.2 When the expansion is complete, and the cold-

erances of the cold-expansion fittings and compression-

expansion fitting is inserted properly into the PEX pipe, the

sleeves, when measured in accordance with 10.4, shall be as

metal compression-sleeve shall be pulled over the fitting with

shown in Table 4 and Table 5.

a compression tool.

7.1.1 Alignment—The maximum angular variation of any

9.3.3 The compression procedure shall be as follows: Slide

opening shall not exceed 1° off the true centerline axis.

the compression-sleeve towards the cold-expansion fitting by

7.1.2 Fittings with Solder-Joint Ends—Solder-joint end di-

hand as far as it will go. Separate the compression-tool handles

mensions shall be in accordance with ANSI B16.18, ANSI

and insert the cold-expansion fitting, sleeve, and pipe into the

B16.22, or MSS SP-104.

tool cavity. Draw the handles of compression-tool together,

7.1.3 Tapered Threaded-Ends—Fitting threads shall be

pulling the compression-sleeve over the cold-expansion fitting

right-hand, conforming to ANSI B1.20.1, and shall be tapered

and the PEX pipe end. The maximum allowable gap between

threads (NPT).

the edge of the compression-sleeve and the collar of the

cold-expansion fitting (surface A on Fig. 1) shall be 0.040 in. (1

8. Workmanship, Finish and Appearance

mm) (see Fig. X1.1).

8.1 The fittings shall be made from materials that are

9.3.4 Each fitting assembly shall be checked per the manu-

homogeneous throughout. All sealing surfaces shall be smooth

facturer’s instructions.

and free of foreign material. The walls of cold-expansion

fittings and compression-sleeves shall be free of cracks, holes,

10. Test Methods

blisters, voids, foreign inclusions, or other defects that are

10.1 Conditioning—Condition specimens at 73 6 4°F (23

visible to the unaided eye and that affect wall integrity.

6 2°C) and 50 6 5 % relative humidity for not less than 4 h

prior to testing. Practice D 618 shall be used to the extent

9. Assembly

possible as a guide to other conditions.

9.1 Joints: 10.2 Test Conditions—Conduct the tests in a standard labo-

9.1.1 Cold-Expansion Joints—Fittings shall be joined to ratory atmosphere at 73 6 4°F (23 6 2°F) and 50 6 5%

PEX pipe by first expanding the end of the pipe with the relative humidity, unless otherwise specified in the test meth-

expander tool, inserting the cold-expansion fitting into ex- ods of in this specification.

panded pipe, then pulling the compression-sleeve over the PEX 10.3 Sampling—A sample of cold-expansion fittings,

pipe and the fitting, compressing the pipe between the

compression-sleeves and PEX pipe, sufficient to determine

compression-sleeve and the fitting. Cold-expansion fittings and conformance with this specification, shall be taken at random.

compression-sleeves shall meet the dimensional and material

10.4 Dimensions—Use any randomly selected cold-

requirements of this specification. PEX pipe shall meet the expansion fitting or fittings and c

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.