ASTM A961-00b

(Specification)Standard Specification for Common Requirements for Steel Flanges, Forged Fittings, Valves, and Parts for Piping Applications

Standard Specification for Common Requirements for Steel Flanges, Forged Fittings, Valves, and Parts for Piping Applications

SCOPE

1.1 This specification covers a group of common requirements that shall apply to steel flanges, forged fittings, valves, and parts for piping applications under any of the following individual product specifications:

Title of Specification ASTM DesignationForgings, Carbon Steel, for Piping Components A105/A105MForgings, Carbon Steel, for General-Purpose Piping A181/A181MForged or Rolled Alloy-Steel Pipe Flanges, Forged A182/A182M Fittings, and Valves and Parts for High Temperature ServiceForgings, Carbon and Low Alloy Steel, Requiring Notch A350/A350MToughness Testing for Piping Components Forged or Rolled 8 and 9% Nickel AlloyA522/A522MSteel Flanges, Fittings, Valves, and Partsfor Low-Temperature ServiceForgings, Carbon and Alloy Steel, for Pipe Flanges, A694/A694MFittings, Valves, and Parts for High-Pressure Transmission Service Flanges, Forged, Carbon and Alloy Steel for Low A707/A707MTemperature Service Forgings, Carbon Steel, for Piping Components with A727/A727MInherent Notch Toughness Forgings, Titanium-Stabilized Carbon Steel, for A836/A836MGlass-Lined Piping and Pressure Vessel Service

1.2 In case of conflict between a requirement of the individual product specification and a requirement of this general requirement specification, the requirements of the individual product specification shall prevail over those of this specification.

1.2 By mutual agreement between the purchaser and the supplier, additional requirements may be specified (see section 4.1.2). The acceptance of any such additional requirements shall be dependent on negotiations with the supplier and must be included in the order as agreed upon between the purchaser and supplier.

1.3 The values stated in either inch-pound units or SI units (metric) are to be regarded separately as standard. Within the text and the tables, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore each system must be used independently of the other. Combining values from the two systems may result in nonconformance with the specification. The inch-pound units shall apply unless the "M" designation (SI) of the product specification is specified in the order.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: A 961 – 00b An American National Standard

Standard Specification for

Common Requirements for Steel Flanges, Forged Fittings,

Valves, and Parts for Piping Applications

This standard is issued under the fixed designation A 961; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope Combining values from the two systems may result in noncon-

formance with the specification. The inch-pound units shall

1.1 This specification covers a group of common require-

apply unless the “M” designation (SI) of the product specifi-

ments that shall apply to steel flanges, forged fittings, valves,

cation is specified in the order.

and parts for piping applications under any of the following

individual product specifications:

2. Referenced Documents

Title of Specification ASTM Designation

2.1 ASTM Standards:

Forgings, Carbon Steel, for Piping Components A 105/A 105M

A 105/A 105M Specification for Carbon Steel Forgings for

Forgings, Carbon Steel, for General-Purpose Piping A 181/A 181M

Piping Applications

Forged or Rolled Alloy-Steel Pipe Flanges, Forged A 182/A 182M

A 181/A 181M Specification for Carbon Steel Forgings for

Fittings, and Valves and Parts for High Temperature

Service

General-Purpose Piping

Forgings, Carbon and Low Alloy Steel, Requiring Notch A 350/A 350M

A 182/A 182M Specification for Forged or Rolled Alloy-

Toughness Testing for Piping Components

Steel Pipe Flanges, Forged Fittings, and Valves and Parts

Forged or Rolled 8 and 9 % Nickel Alloy A 522/A 522M

Steel Flanges, Fittings, Valves, and Parts

for High-Temperature Service

for Low-Temperature Service

A 275/A 275M Test Method for Magnetic Particle Exami-

Forgings, Carbon and Alloy Steel, for Pipe Flanges, A 694/A 694M

nation of Steel Forgings

Fittings, Valves, and Parts for High-Pressure Trans-

mission Service

A 350/A 350M Specification for Carbon and Low-Alloy

Flanges, Forged, Carbon and Alloy Steel for Low A 707/A 707M

Steel Forgings, Requiring Notch Toughness Testing for

Temperature Service

Piping Components

Forgings, Carbon Steel, for Piping Components with A 727/A 727M

Inherent Notch Toughness

A 370 Test Methods and Definitions for Mechanical Testing

Forgings, Titanium-Stabilized Carbon Steel, for A 836/A 836M

of Steel Products

Glass-Lined Piping and Pressure Vessel Service

A 522/A 522M Specification for Forged or Rolled 8 and

1.2 In case of conflict between a requirement of the indi-

9 % Nickel Alloy Steel Flanges, Fittings, Valves, and Parts

vidual product specification and a requirement of this general 2

for Low-Temperature Service

requirement specification, the requirements of the individual

A 694/A 694M Specification for Carbon and Alloy Steel

product specification shall prevail over those of this specifica-

Forgings for Pipe Flanges, Fittings, Valves, and Parts for

tion. 2

High-Pressure Transmission Service

1.3 By mutual agreement between the purchaser and the

A 700 Practices for Packaging, Marking, and Loading

supplier, additional requirements may be specified (see section 3

Methods for Steel Products for Domestic Shipment

4.1.2). The acceptance of any such additional requirements

A 707/A 707M Specification for Forged Carbon and Alloy

shall be dependent on negotiations with the supplier and must 2

Steel Flanges for Low-Temperature Service

be included in the order as agreed upon between the purchaser

A 727/A 727M Specification for Carbon Steel Forgings, for

and supplier. 2

Piping Components with Inherent Notch Toughness

1.4 The values stated in either inch-pound units or SI units

A 751 Test Methods, Practices, and Terminology for

(metric) are to be regarded separately as standard. Within the 4

Chemical Analysis of Steel Products

text and the tables, the SI units are shown in brackets. The

A 836/A 836M Specification for Titanium-Stabilized Car-

values stated in each system are not exact equivalents; there-

bon Steel Forgings for Glass-Lined Piping and Pressure

fore each system must be used independently of the other.

Vessel Service

A 941 Terminology Relating to Steel, Stainless Steel, Re-

lated Alloys, and Ferroalloys

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

Stainless Steel, and Related Alloys and is the direct responsibility of Subcommittee

A01.22 on Steel Forgings and Wrought Fittings for Piping Applications and Bolting

Materials for Piping and Special Purpose Applications. Annual Book of ASTM Standards, Vol 01.01.

Current edition approved Sept. 10, 2000. Published November 2000. Originally Annual Book of ASTM Standards, Vol 01.05.

published as A 961– 96. Last previous edition A 961– 00a. Annual Book of ASTM Standards, Vol 01.03.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

A 961

A 967 Specification for Chemical Passivation Treatments the needed material. Examples of such information include, but

for Stainless Steel Parts are not limited to, the following:

A 991/A 991M Test Method for Conducting Temperature 4.1.1 Quantity.

Uniformity Surveys of Furnaces Used to Heat Treat Steel 4.1.2 Size and pressure class or dimensions. (Tolerances and

Products surface finishes should be included.)

E 165 Test Method for Liquid Penetrant Examination 4.1.3 Specification number with grade or class, or both, as

E 381 Method of Macroetch Testing Steel Bars, Billets, applicable, and year/date.

Blooms, and Forgings 4.1.4 Supplementary requirements.

E 709 Guide for Magnetic Particle Examination 4.1.5 Additional requirements.

E 1916 Guide for Identification and/or Mixed Lots of Met-

7 5. Melting Process

als

5.1 Unless otherwise specified in the individual Product

2.2 ASME Standard:

ASME Boiler and Pressure Vessel Code–Section IX Specification, the steel shall be fully killed.

5.2 If a specific type of melting is required by the purchaser,

2.3 Military Standard:

MIL-STD-163 Steel Mill Products, Preparation for Ship- it shall be stated on the purchase order.

5.3 The primary melting may incorporate separate degas-

ment and Storage

2.4 Manufacturer’s Standardization Society Standard: sing or refining and may be followed by secondary melting,

such as electroslag remelting or vacuum remelting. If second-

SP 25 Standard Marking System of Valves, Fittings,

Flanges and Unions ary melting is employed, the heat shall be defined as all of the

ingot remelted from a single primary heat.

3. Terminology

5.4 Steel may be cast in ingots or may be strand cast. When

3.1 Definitions of Terms Specific to This Standard and steel of different grades is sequentially strand cast, identifica-

Related Individual Product Specifications: tion of the resultant transition material is required. The steel

3.1.1 bar, n—a solid rolled or forged section that is long in producer shall remove the transition material by an established

relationship to its cross sectional dimensions, with a relatively procedure that positively separates the grades.

constant cross section throughout its length. A wrought micro- 5.5 A sufficient discard shall be made from the source

structure is required. material to secure freedom from injurious porosity and shrink-

3.1.2 certifying organization, n—the company or associa- age, and undue segregation.

tion responsible for the conformance of, and marking of, the

6. Manufacture

product to the specification requirements.

3.1.3 fitting, n—a component for non-bolted joints in piping 6.1 The finished part shall be manufactured from a forging

that is as close as practicable to the finished size or shape.

systems.

3.1.4 flange, n—a component for bolted joints used in Alternative starting materials may be used, but with the

following exceptions and requirements.

piping systems.

3.1.5 forging, n—the product of a substantially compressive 6.1.1 Bar—Flanges, elbows, return bends, tees, and header

tees shall not be machined directly from bar. Other hollow

hot or cold plastic working operation that consolidates the

cylindrical shaped parts up to, and including, NPS 4 can be

material and produces the required shape. The plastic working

machined from bar provided that the axial length of the part is

must be performed by a forging machine, such as a hammer,

approximately parallel to the metal flow lines of the starting

press, or ring rolling machine, and must deform the material to

produce a wrought structure throughout the material cross stock.

6.1.2 Seamless Tubing—Flanges shall not be machined

section.

3.1.6 seamless tubing, n—a tubular product made without a directly from seamless tubing. Other hollow cylindrical shaped

parts up to, and including, NPS 4 can be machined from

welded seam. It is manufactured usually by hot working the

material, and if necessary, by subsequently cold finishing the seamless tubing provided that the axial length of the part is

approximately parallel to the metal flow lines of the starting

hot worked tubular product to produce the desired shape,

dimensions and properties. stock.

7. Heat Treatment

4. Ordering Information

4.1 It is the purchaser’s responsibility to specify in the 7.1 Material requiring heat treatment shall be treated as

specified in the individual product specification using the

purchase order all ordering information necessary to purchase

following procedures that are defined in more detail in Termi-

nology A 941.

Annual Book of ASTM Standards, Vol 03.03.

7.1.1 Full Annealing—Material shall be uniformly reheated

Annual Book of ASTM Standards, Vol 03.01.

7 to a temperature above the transformation range and, after

Annual Book of ASTM Standards, Vol 03.06.

holding for a sufficient time at this temperature, cooled slowly

Available from the American Society of Mechanical Engineers, Three Park

Avenue, New York, NY 10016–5990.

to a temperature below the transformation range.

Available from Standardization Documents Order Desk, Bldg. 4, Section D,

7.1.2 Solution Annealing—Material shall be heated to a

700 Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

temperature that causes the chrome carbides to go into solu-

Available from the Manufacturer’s Standardization Society of the Valve and

Fittings Industry, 1815 N. Fort Myer Dr., Arlington, VA 22209. tion, and then, quenched in water or rapidly cooled by other

A 961

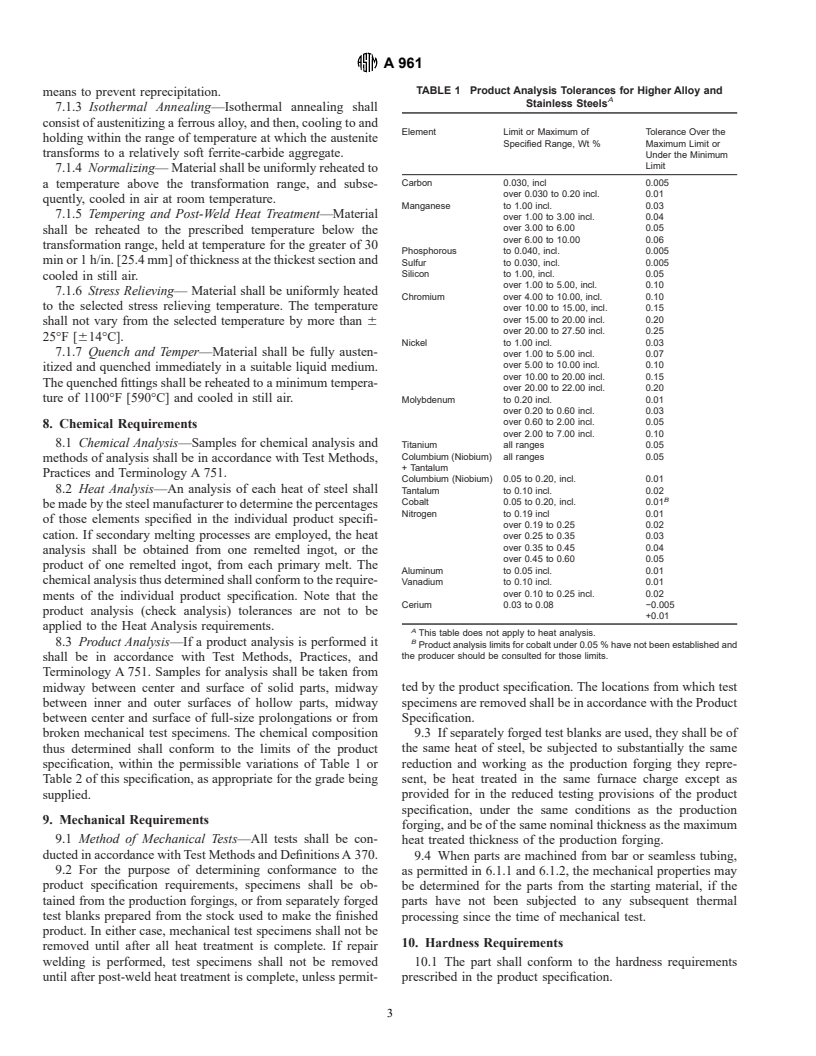

TABLE 1 Product Analysis Tolerances for Higher Alloy and

means to prevent reprecipitation.

A

Stainless Steels

7.1.3 Isothermal Annealing—Isothermal annealing shall

consist of austenitizing a ferrous alloy, and then, cooling to and

Element Limit or Maximum of Tolerance Over the

holding within the range of temperature at which the austenite

Specified Range, Wt % Maximum Limit or

transforms to a relatively soft ferrite-carbide aggregate.

Under the Minimum

Limit

7.1.4 Normalizing— Material shall be uniformly reheated to

Carbon 0.030, incl 0.005

a temperature above the transformation range, and subse-

over 0.030 to 0.20 incl. 0.01

quently, cooled in air at room temperature.

Manganese to 1.00 incl. 0.03

7.1.5 Tempering and Post-Weld Heat Treatment—Material

over 1.00 to 3.00 incl. 0.04

over 3.00 to 6.00 0.05

shall be reheated to the prescribed temperature below the

over 6.00 to 10.00 0.06

transformation range, held at temperature for the greater of 30

Phosphorous to 0.040, incl. 0.005

min or 1 h/in. [25.4 mm] of thickness at the thickest section and

Sulfur to 0.030, incl. 0.005

Silicon to 1.00, incl. 0.05

cooled in still air.

over 1.00 to 5.00, incl. 0.10

7.1.6 Stress Relieving— Material shall be uniformly heated

Chromium over 4.00 to 10.00, incl. 0.10

to the selected stress relieving temperature. The temperature

over 10.00 to 15.00, incl. 0.15

over 15.00 to 20.00 incl. 0.20

shall not vary from the selected temperature by more than 6

over 20.00 to 27.50 incl. 0.25

25°F [614°C].

Nickel to 1.00 incl. 0.03

7.1.7 Quench and Temper—Material shall be fully austen- over 1.00 to 5.00 incl. 0.07

over 5.00 to 10.00 incl. 0.10

itized and quenched immediately in a suitable liquid medium.

over 10.00 to 20.00 incl. 0.15

The quenched fittings shall be reheated to a minimum tempera-

over 20.00 to 22.00 incl. 0.20

ture of 1100°F [590°C] and cooled in still air. Molybdenum to 0.20 incl. 0.01

over 0.20 to 0.60 incl. 0.03

over 0.60 to 2.00 incl. 0.05

8. Chemical Requirements

over 2.00 to 7.00 incl. 0.10

8.1 Chemical Analysis—Samples for chemical analysis and

Titanium all ranges 0.05

Columbium (Niobium) all ranges 0.05

methods of analysis shall be in accordance with Test Methods,

+ Tantalum

Practices and Terminology A 751.

Columbium (Niobium) 0.05 to 0.20, incl. 0.01

8.2 Heat Analysis—An analysis of each heat of steel shall

Tantalum to 0.10 incl. 0.02

B

Cobalt 0.05 to 0.20, incl. 0.01

be made by the steel manufacturer to determine the percentages

Nitrogen to 0.19 incl 0.01

of those elements specified in the individual product specifi-

over 0.19 to 0.25 0.02

cation. If secondary melting processes are employed, the heat

over 0.25 to 0.35 0.03

over 0.35 to 0.45 0.04

analysis shall be obtained from one remelted ingot, or the

over 0.45 to 0.60 0.05

product of one remelted ingot, from each primary melt. The

Aluminum to 0.05 incl. 0.01

chemical analysis thus determined shall conform to the require- Vanadium to 0.10 incl. 0.01

over 0.10 to 0.25 incl. 0.02

ments of the individual product specification. Note that the

Cerium 0.03 to 0.08 −0.005

product analysis (check analysis) tolerances are not to be

+0.01

applied to the Heat Analysis requirements.

A

This table does not apply to heat analysis.

B

8.3 Product Analysis—If a product analysis is performed it

Product analysis limits for cobalt under 0.05 % have not been established and

the producer should be consulted for those limits.

shall be in accordance with Test Methods, Practices, and

Terminology A 751. Samples for analysis shall be taken from

midway between center and surface of solid parts, midway ted by the product specification. The locations from which test

specimens are removed shall be in accordance with the Product

between inner and outer surfaces of hollow parts, midway

between center and surface of full-size prolongations or from Specification.

9.3 If separately forged test blanks are used, they shall be of

broken mechanical test specimens. The chemical composition

thus determined shall conform to the limits of the product the same heat of steel, be subjected to substantially the same

reduction and working as the production forging they repre-

specification, within the permissible variations of Table 1 or

Table 2 of this specification, as appropriate for the grade being sent, be heat treated in the sam

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.