ASTM A228/A228M-07

(Specification)Standard Specification for Steel Wire, Music Spring Quality

Standard Specification for Steel Wire, Music Spring Quality

ABSTRACT

This specification covers high quality, round, cold-drawn steel music spring quality wire for the manufacture of springs subject to high stresses or requiring good fatigue properties. The steel shall either be ingot cast or strand cast. Heat and product analysis shall be performed wherein steel materials shall conform to required chemical compositions of carbon, manganese, phosphorus, sulfur, and silicon. Steel specimens shall also undergo tension test, wrap test, and torsion tests. Final products shall be marked by a tag.

SCOPE

1.1 This specification covers a high quality, round, cold-drawn steel music spring quality wire, uniform in mechanical properties, intended especially for the manufacture of springs subject to high stresses or requiring good fatigue properties.

1.2 The values stated in either SI (metric) units or inch-pound units are to be regarded separately as standard. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:A228/A228M −07

StandardSpecification for

1

Steel Wire, Music Spring Quality

This standard is issued under the fixed designationA228/A228M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 2.2 Military Standard:

MIL-STD-163 Steel Mill Products, Preparation for Ship-

1.1 This specification covers a high quality, round, cold-

3

ment and Storage

drawn steel music spring quality wire, uniform in mechanical

2.3 Federal Standard:

properties, intended especially for the manufacture of springs

3

Fed. Std. No. 123,Marking for Shipment (Civil Agencies)

subject to high stresses or requiring good fatigue properties.

4

2.4 American National Standard:

1.2 The values stated in either SI (metric) units or inch-

B32.4Preferred Metric Sizes for Round, Square, Rectangle,

pound units are to be regarded separately as standard. The

and Hexagon Metal Products

values stated in each system are not exact equivalents; 5

2.5 AIAG Standard:

therefore,eachsystemmustbeusedindependentlyoftheother.

AIAG B-502.00 Primary Metals IdentificationTagApplica-

tion Standard

2. Referenced Documents

2

3. Terminology

2.1 ASTM Standards:

A370Test Methods and Definitions for Mechanical Testing

3.1 Definitions—For definitions of terms used in this

of Steel Products

specification, refer to Terminology A941.

A510SpecificationforGeneralRequirementsforWireRods

4. Ordering Information

and Coarse Round Wire, Carbon Steel

A510MSpecification for General Requirements for Wire

4.1 It shall be the responsibility of the purchaser to specify

Rods and Coarse Round Wire, Carbon Steel (Metric)

all requirements that are necessary for material under this

A700Practices for Packaging, Marking, and Loading Meth-

specification. Such requirements may include, but are not

ods for Steel Products for Shipment

limited to, the following information:

A751Test Methods, Practices, and Terminology for Chemi-

4.1.1 Quantity (mass),

cal Analysis of Steel Products

4.1.2 Name of material (music steel spring wire),

A938Test Method for Torsion Testing of Wire

4.1.3 Dimensions (Table 1 and Section 9),

A941TerminologyRelatingtoSteel,StainlessSteel,Related

4.1.4 Finish (see 10.2),

Alloys, and Ferroalloys

4.1.5 Packaging (Section 15),

E29Practice for Using Significant Digits in Test Data to

4.1.6 Heat analysis report, if requested (see 6.2),

Determine Conformance with Specifications

4.1.7 Certification or test report, or both, if specified (Sec-

E1077Test Methods for Estimating the Depth of Decarbur-

tion 14), and

ization of Steel Specimens

4.1.8 ASTM designation and year of issue.

NOTE 1—A typical metric ordering description is as follows: 2500 kg

1

This specification is under the jurisdiction ofASTM Committee A01 on Steel,

Music SpringWire, 1.40 mm diameter, phosphate coated in 25 kg coils to

Stainless Steel and RelatedAlloys and is the direct responsibility of Subcommittee

A01.03 on Steel Rod and Wire.

3

Current edition approved Dec. 1, 2007. Published January 2008. Originally Available from Standardization Documents Order Desk, DODSSP, Bldg. 4,

approved in 1939. Last previous edition approved in 2002 as A228/A228M–02. Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098, http://

DOI: 10.1520/A0228_A0228M-07. www.dodssp.daps.mil.

2 4

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM 4th Floor, New York, NY 10036, http://www.ansi.org.

5

Standards volume information, refer to the standard’s Document Summary page on Available fromAutomotive IndustryAction Group (AIAG), 26200 Lahser Rd.,

the ASTM website. Suite 200, Southfield, MI 48033, http://www.aiag.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A228/A228M−07

TABLE 1 Tensile Requirements

furnished to this specification shall be in accordance with

SI Units

Specification A510 or A510M.

5.2 The finished wire shall be free from detrimental pipe

Diameter, Tensile Strength, MPa Diameter, Tensile Strength, MPa

A,B A,B

mm min max mm min max

and undue segregation.

0.10 3000 3300 0.90 2200 2450

5.3 The wire shall be cold drawn to produce the desired

0.11 2950 3250 1.00 2150 2400

mechanical properties.

0.12 2900 3200 1.1 2120 2380

0.14 2850 3150 1.2 2100 2350

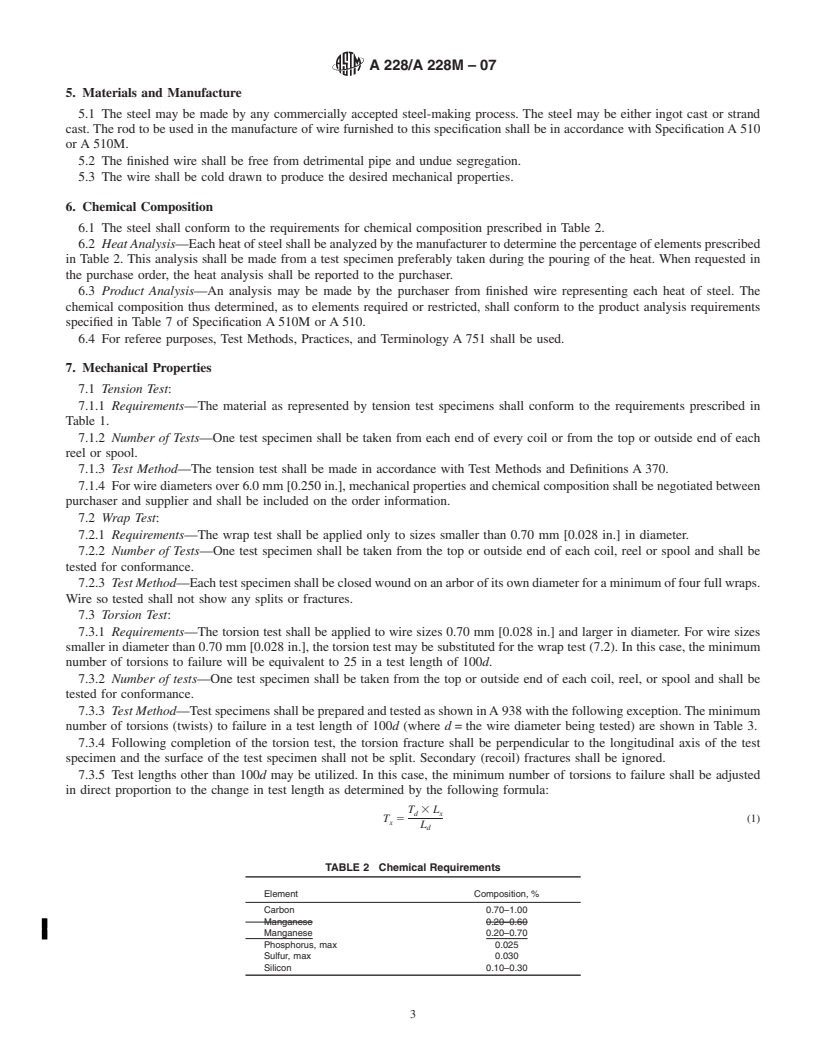

6. Chemical Composition

0.16 2800 3100 1.4 2050 2300

0.18 2750 3050 1.6 2000 2250

6.1 Thesteelshallcon

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:A228/A228M–02 Designation: A 228/A 228M – 07

Standard Specification for

1

Steel Wire, Music Spring Quality

This standard is issued under the fixed designationA 228/A 228M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope

1.1 This specification covers a high quality, round, cold-drawn steel music spring quality wire, uniform in mechanical

properties, intended especially for the manufacture of springs subject to high stresses or requiring good fatigue properties.

1.2 The values stated in either SI (metric) units or inch-pound units are to be regarded separately as standard. The values stated

in each system are not exact equivalents; therefore, each system must be used independently of the other.

2. Referenced Documents

2

2.1 ASTM Standards:

A 370 Test Methods and Definitions for Mechanical Testing of Steel Products

A 510 Specification for General Requirements for Wire Rods and Coarse Round Wire, Carbon Steel

A 510M Specification for General Requirements for Wire Rods and Coarse Round Wire, Carbon Steel [Metric]

A 700 Practices for Packaging, Marking, and Loading Methods for Steel Products for Domestic Shipment

A 751 Test Methods, Practices, and Terminology for Chemical Analysis of Steel Products

A 938Standard Test Test Method for Torsion Testing of Wire

A 941 Terminology Relating to Steel, Stainless Steel, Related Alloys, and Ferroalloys

E 29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

E 1077 Test Methods for Estimating the Depth of Decarburization of Steel Specimens

2.2 Military Standard:

3

MIL-STD-163 Steel Mill Products, Preparation for Shipment and Storage

2.3 Federal Standard:

3

Fed. Std. No. 123, Marking for Shipment (Civil Agencies)

4

2.4 American National Standard: American National Standard:

B32.4 Preferred Metric Sizes for Round, Square, Rectangle, and Hexagon Metal Products

5

2.5 AIAG Standard:

AIAG B-5 02.00 Primary Metals Identification Tag Application Standard

3. Terminology

3.1 Definitions— For definitions of terms used in this specification, refer to Terminology A 941.

4. Ordering Information

4.1 It shall be the responsibility of the purchaser to specify all requirements that are necessary for material under this

specification. Such requirements may include, but are not limited to, the following information:

4.1.1 Quantity (mass),

1

This specification is under the jurisdiction ofASTM CommitteeA01 on Steel, Stainless Steel,Steel and RelatedAlloys and is the direct responsibility of Subcommittee

A01.03 on Steel Rod and Wire.

Current edition approved March 10, 2002.Dec. 1, 2007. Published April 2002.January 2008. Originally published as A228–39T.approved in 1939. Last previous edition

approved in 2002 as A 228/A 228M – 002.

2

Annual Book of ASTM Standards, Vol 01.03.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Annual Book of ASTM Standards, Vol 01.05.

3

Available from Standardization Documents Order Desk, DODSSP, Bldg. 4, Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098, http://www.dodssp.daps.mil.

4

Annual Book of ASTM Standards, Vol 01.01.

4

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

5

Annual Book of ASTM Standards, Vol 14.02.

5

Available from Automotive Industry Action Group (AIAG), 26200 Lahser Rd., Suite 200, Southfield, MI 48033, http://www.aiag.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

A 228/A 228M – 07

4.1.2 Name of material (music steel spring wire),

4.1.3 Dimensions (Table 1 and Section 9),

4.1.4 Finish (see 10.2),

4.1.5 Packaging (Section 15),

4.1.6 Heat analysis report, if requested (see 6.2),

4.1.7 Certification or test report, or both, if specified (Section 14), and

4.1.8 ASTM designation and year of issue.

NOTE 1—Atypical metric ordering description is as follows: 2500 kg Music SpringWire, 1.40 mm diameter, phosphate coated in 25 kg coils

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.