ASTM F2754/F2754M-21

(Test Method)Standard Test Method for Measurement of Camber, Cast, Helix, and Direction of Helix of Coiled Wire

Standard Test Method for Measurement of Camber, Cast, Helix, and Direction of Helix of Coiled Wire

SIGNIFICANCE AND USE

4.1 The process of coiling wire causes the wire to take on a curvature from the process of being mechanically deformed into a coiled geometry. The curvature in the wire is permanent unless the wire is straightened. It will affect how the coiled wire will react when it is subjected to additional wire forming operations. In addition, residual stresses induced from the coiling operation can cause elastic recoil or spring back in subsequent wire forming operations unless the material is straightened and stress relieved prior to forming. These residual stresses can create wide variations in the dimensions of components and/or parts that have been built using the coiled wire (cast).

4.2 The direction that the wire has been coiled affects how the wire will be taken off of the coil for subsequent wire forming operations (helix direction).

4.3 Lift or spacing between adjacent coils also affects how the wire will be taken off of the coil and can also affect the dimensions of components and/or parts that have been built using the coiled wire due to residual stresses (helix).

SCOPE

1.1 This test method covers the various standard methods that are used for measuring camber, cast, helix, and helix direction. The wire may be coiled with or without a spool.

1.2 This test method applies to round wire that has a diameter between 0.0127 to 4.78 mm [0.0005 to 0.188 in.]. It also applies to flat or shaped wire.

1.3 This test method does not apply to superelastic nitinol wire. It does apply to the as-drawn condition of nitinol wire.

1.4 This test method does not apply to the measurement of the straightness of straightened to length wire and tubing.

1.5 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F2754/F2754M −21

Standard Test Method for

Measurement of Camber, Cast, Helix, and Direction of Helix

1

of Coiled Wire

This standard is issued under the fixed designation F2754/F2754M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 2.2.1 camber—the deflection in the width direction of a flat

or shaped wire, Fig. 1(e).

1.1 This test method covers the various standard methods

2.2.2 cast—the maximum diameter of coiled wire when one

that are used for measuring camber, cast, helix, and helix

complete circumference rests completely on a flat surface such

direction. The wire may be coiled with or without a spool.

as a table, workbench, or floor, Fig. 1(a).

1.2 This test method applies to round wire that has a

2.2.3 helix—there are two common methods for measuring

diameter between 0.0127 to 4.78 mm [0.0005 to 0.188 in.]. It

helix—free end lift and hanging helix. These definitions are

also applies to flat or shaped wire.

defined by Fig. 1(b) and Fig. 1(c), respectively.

1.3 This test method does not apply to superelastic nitinol

2.2.3.1 helix (free end lift)—the maximum lift of the free

wire. It does apply to the as-drawn condition of nitinol wire.

end of the wire when laid on a flat surface, Fig. 1(b).

1.4 This test method does not apply to the measurement of

2.2.3.2 helix (hanging helix)—the maximum distance be-

the straightness of straightened to length wire and tubing.

tween two adjacent coils of wire, Fig. 1(c).Ahanging helix can

1.5 The values stated in either SI units or inch-pound units

also be measured by suspending the coils.

are to be regarded separately as standard. The values stated in

2.2.4 helix direction—can be left or right-handed depending

each system may not be exact equivalents; therefore, each

upon how the wire was coiled, Fig. 1(d).

system shall be used independently of the other. Combining

2.2.4.1 left-handed helix—the wire is coiled in a counter-

values from the two systems may result in nonconformance

clockwise direction, Fig. 2(a).

with the standard.

2.2.4.2 right-handed helix—the wire is coiled in a clockwise

1.6 This standard does not purport to address all of the

direction, Fig. 2(b).

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

3. Summary of Test Method

priate safety, health, and environmental practices and deter-

3.1 The maximum diameter of at least one complete cir-

mine the applicability of regulatory limitations prior to use.

cumference is measured using a linear scale while it is resting

1.7 This international standard was developed in accor-

completely flat on a flat surface such as a table, workbench, or

dance with internationally recognized principles on standard-

floor (cast measurement). The maximum lift of the free end of

ization established in the Decision on Principles for the

the wire when laid on a flat surface is the free end lift helix and

Development of International Standards, Guides and Recom-

is measured using a linear scale. A hanging helix can be

mendations issued by the World Trade Organization Technical

measuredusingalinearscalewhilethewireisbeingsuspended

Barriers to Trade (TBT) Committee.

(hanging helix free end lift). Camber is the offset in the width

dimension of a flat or shaped wire and can also be measured

2. Terminology

using a linear scale while the wire is resting on a flat surface.

2.1 Fig. 1(a) through Fig. 1(e) illustrate the physical mean-

Alternatively, a coordinate measurement machine or optical

ing of cast, helix, direction of helix, and camber.

comparator may be used. Helix direction is the direction in

2.2 Definitions:

which the wire has been coiled.

4. Significance and Use

1

4.1 The process of coiling wire causes the wire to take on a

This test method is under the jurisdiction ofASTM Committee F04 on Medical

and Surgical Materials and Devices and is the direct responsibility of Subcommittee

curvature from the process of being mechanically deformed

F04.15 on Material Test Methods.

into a coiled geometry. The curvature in the wire is permanent

Current edition approved Oct. 1, 2021. Published October 2021. Originally

unless the wire is straightened. It will affect how the coiled

approved in 2009. Last previous edition approved in 2013 as F2754/F2754M – 09

(2013). DOI: 10.1520/F2754_F2754M-21. wire will react when it is subjected to additional wire forming

*A Summary of Changes section appears at th

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F2754/F2754M − 09 (Reapproved 2013) F2754/F2754M − 21

Standard Test Method for

Measurement of Camber, Cast, Helix, and Direction of Helix

1

of Coiled Wire

This standard is issued under the fixed designation F2754/F2754M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Scope*

1.1 This test method covers the various standard methods that are used for measuring camber, cast, helix, and helix direction. The

wire may be coiled with or without a spool.

1.2 This test method applies to round wire that has a diameter between 0.0127 to 4.78 mm (0.0005[0.0005 to 0.188 in.).in.]. It

also applies to flat or shaped wire.

1.3 This test method does not apply to superelastic nitinol wire. It does apply to the as-drawn condition of nitinol wire.

1.4 This test method does not apply to the measurement of the straightness of straightened to length wire and tubing.

1.5 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in non-conformancenonconformance with the standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of

the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Terminology

2.1 Fig. 1(a) through Fig. 1(e) illustrate the physical meaning of cast, helix, direction of helix, and camber.

2.2 Definitions:

1

This test method is under the jurisdiction of ASTM Committee F04 on Medical and Surgical Materials and Devices and is the direct responsibility of Subcommittee

F04.15 on Material Test Methods.

Current edition approved Oct. 1, 2013Oct. 1, 2021. Published October 2013October 2021. Originally approved in 2009. Last previous edition approved in 20092013 as

F2754/F2754M – 09. 09 (2013). DOI: 10.1520/F2754_F2754M-09R13.10.1520/F2754_F2754M-21.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F2754/F2754M − 21

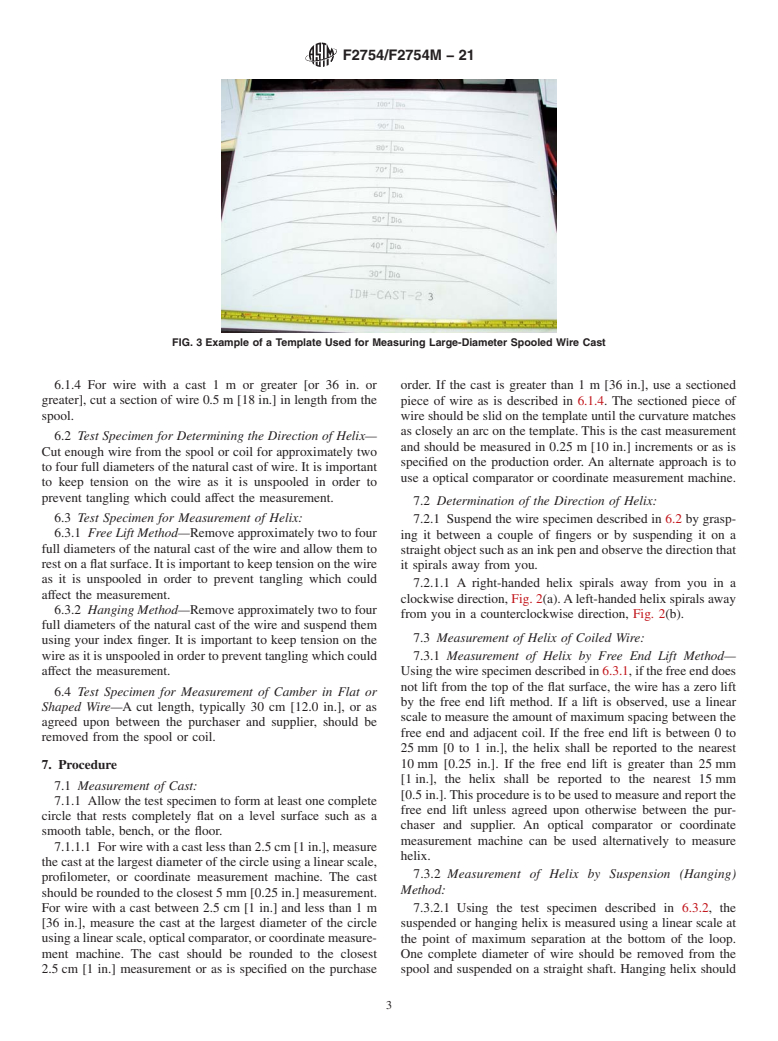

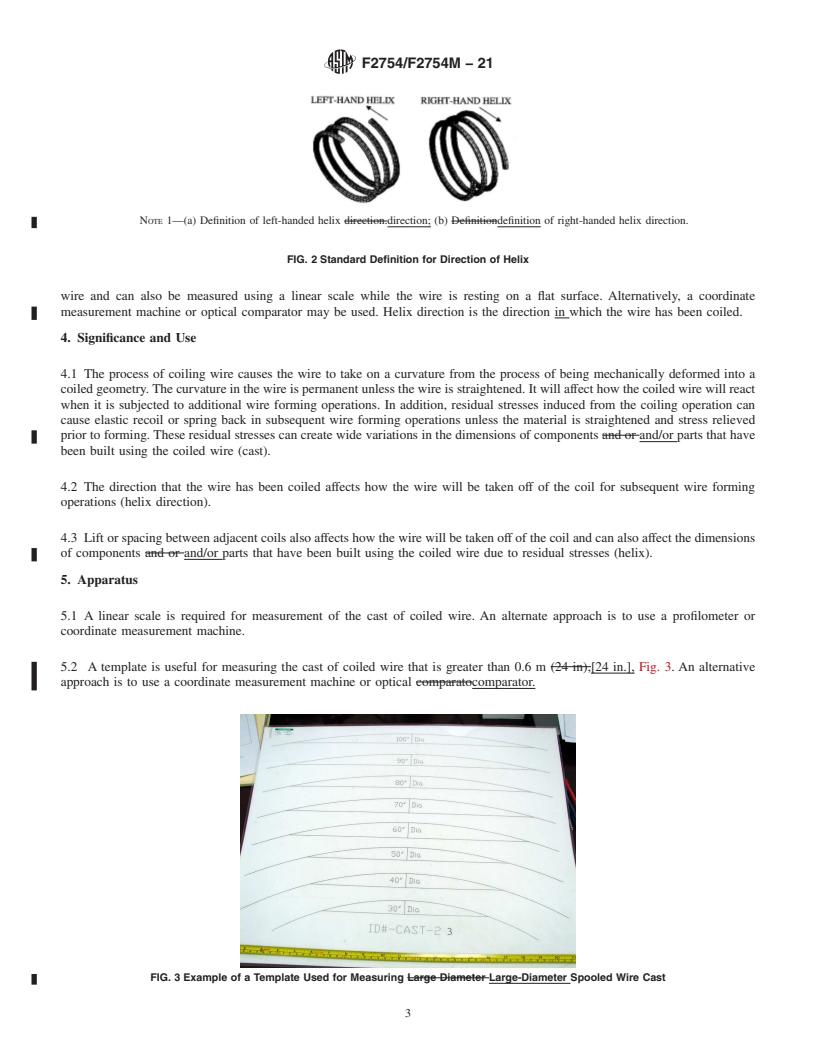

NOTE 1—(a) Definition of cast.cast; (b) Definitiondefinition of helix as measured by lift method.method; (c) Definitiondefinition of helix as measured

by hanging method.method; (d) Definitiondefinition of helix direction.direction; (e) Definitiondefinition of camber.

FIG. 1 Standard Definitions for Cast, Helix, and Camber of Spooled Wire

2.2.1 camber—the deflection in the width direction of a flat or shaped wire, Fig. 1(e).

2.2.2 cast—the maximum diameter of coiled wire when one complete circumference rests completely on a flat surface such as a

table, workbench, or floor.floor, Fig. 1(a).

2.2.3 helix—there are two common methods for measuring helix—free end lift and hanging helix. These definitions are defined

by Fig. 1(b) and Fig. 1(c), respectively.

2.2.3.1 helix (free end lift)—the maximum lift of the free end of the wire when laid on a flat surface, Fig. 1(b).

2.2.3.2 helix (hanging helix)—the maximum distance between two adjacent coils of wire, Fig. 1(c). A hanging helix can also

be measured by suspending the coils.

2.2.4 helix direction—can be left—left or right-handed depending upon how the wire was coiled, Fig. 1(d)(d).

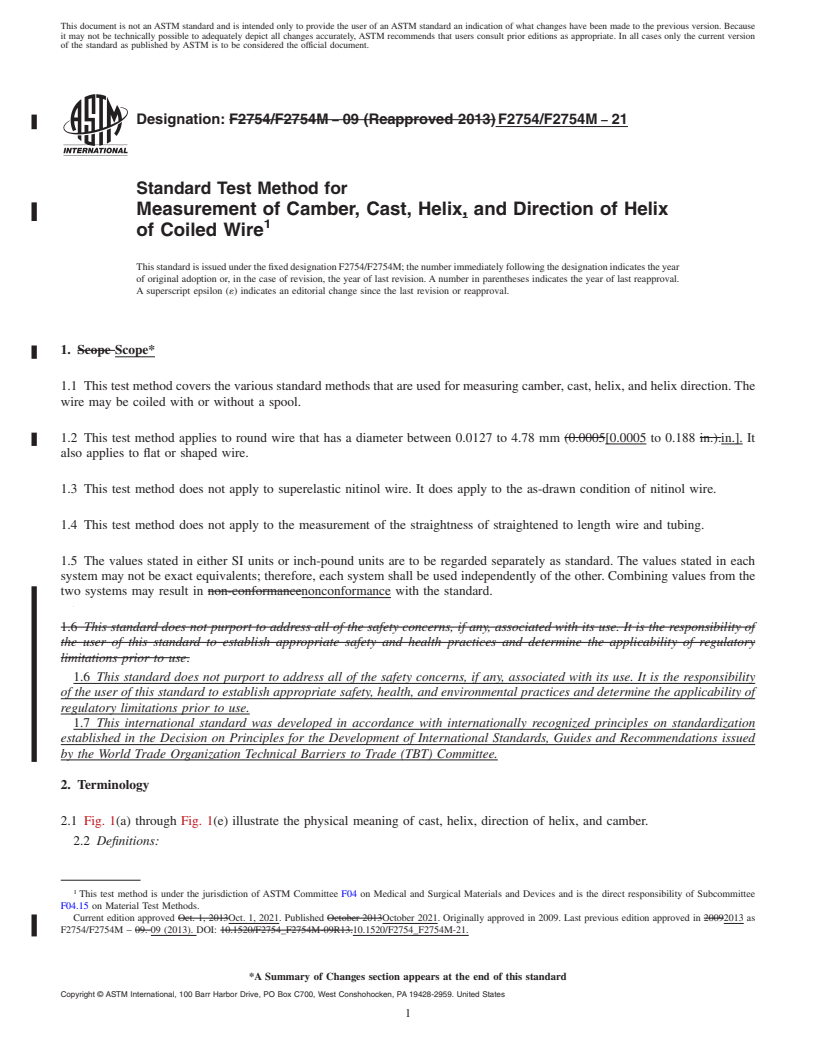

2.2.4.1 left-handed helix—the wire is coiled in a counterclockwise direction, Fig. 2(a).

2.2.4.2 right-handed helix—the wire is coiled in a clockwise direction, Fig. 2(b).

2.2.4 camber—the deflection in the w

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.