ASTM F2154-01

(Specification)Standard Specification for Sound-Absorbing Board, Fibrous Glass, Perforated Fibrous Glass Cloth Faced

Standard Specification for Sound-Absorbing Board, Fibrous Glass, Perforated Fibrous Glass Cloth Faced

SCOPE

1.1 This specification covers fibrous glass sound-absorbing board with a perforated fibrous glass cloth facing for sound reduction in ship spaces with high noise levels. This specification is primarily for materials used on ships. Additional requirements, testing, and certification are required for use of this material aboard U.S. Coast Guard inspected vessels in the United States.

1.2 This standard measures and describes the response of materials, products, or assemblies to heat and flame under controlled conditions, but does not by itself incorporate all factors required for fire hazard or fire risk assessment of materials, products, or assemblies under actual fire conditions.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory requirements prior to use.

General Information

Relations

Standards Content (Sample)

Designation: F 2154 – 01

Standard Specification for

Sound-Absorbing Board, Fibrous Glass, Perforated Fibrous

1

Glass Cloth Faced

This standard is issued under the fixed designation F 2154; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 46 CFR 164.012 Code of Federal Regulations—Interior

6

Finishes for Merchant Vessels

1.1 This specification covers fibrous glass sound-absorbing

7

Navigation and Vessel Inspection Circular (NVIC) 9-97

board with a perforated fibrous glass cloth facing for sound

reduction in ship spaces with high noise levels. This specifi-

3. Terminology

cation is primarily for materials used on ships. Additional

3.1 For definitions of terms used in this specification, see

requirements, testing, and certification are required for use of

Terminology C 634.

this material aboard U.S. Coast Guard inspected vessels in the

United States.

4. Ordering Information

1.2 This standard measures and describes the response of

4.1 Title, number, and date of this specification.

materials, products, or assemblies to heat and flame under

4.2 First article sample, when required (see 7.1).

controlled conditions, but does not by itself incorporate all

4.3 Width and length required, if other than 24- by 36-in.

factors required for fire hazard or fire risk assessment of

(609.6- by 914.4-mm) board (see 8.1).

materials, products, or assemblies under actual fire conditions.

4.4 Thickness required (see 8.2).

1.3 This standard does not purport to address all of the

4.5 Density of waffle board (see 10.1).

safety concerns, if any, associated with its use. It is the

4.6 Conformance inspection reports required (see 11.1).

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

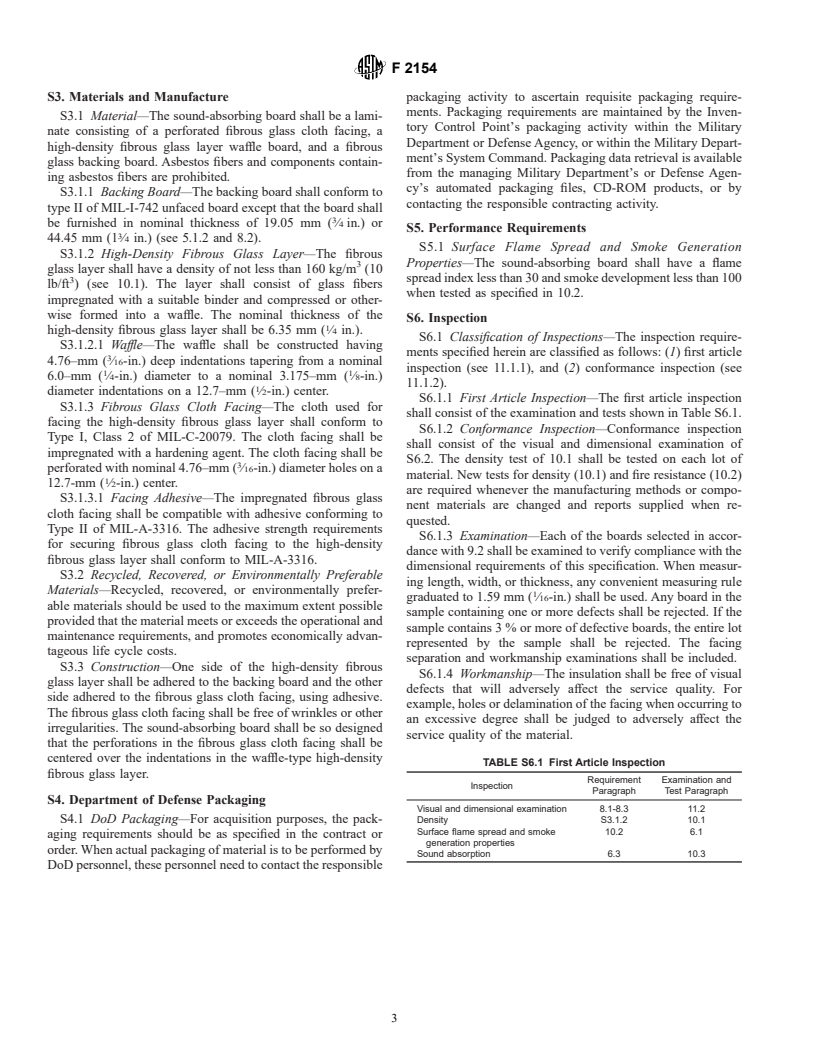

5. Materials and Manufacture

bility of regulatory requirements prior to use.

5.1 See typical construction details located in Supplemen-

tary Requirements Section S3.

2. Referenced Documents

2.1 ASTM Standards:

6. Performance Requirements

C 423 Test Method for Sound Absorption and Sound Ab-

6.1 Surface Flame Spread and Smoke Generation

2

sorption Coefficients by the Reverberation Room Method

2 Properties—The sound-absorbing board shall meet the re-

C 634 Terminology Relating to Environmental Acoustics

quirements for surface flame spread and smoke generation

3

D 3951 Practice for Commercial Packaging

properties for an U.S. Coast Guard Approved Interior Finish in

E 84 Test Method for Surface Burning Characteristics of

accordance with 46 CFR 164.012 or NVIC Circular 9-97.

4

Building Materials

6.2 Facing Separation—When the sound-absorbing board

2.2 ANSI Standard:

is cut or sawed, the threads of the fibrous glass cloth facing

ANSI/ASQC Z1.4 Sampling Procedures and Tables for

across which the cut is made shall not be separated from the

5

Inspection by Attributes

1

face over a distance of more than 3.0 mm ( ⁄8 in.). In case the

2.3 Other Documents:

fibrous glass cloth facing does not cover the entire surface of

the board, the uncovered portion of the board shall not extend

1

further than 3.175 mm ( ⁄8 in.) from any edge. The fibrous glass

1

This specification is under the jurisdiction of ASTM Committee F25 on Ships

cloth facing shall not extend over the edge of the board.

and Marine Technology and is the direct responsibility of Subcommittee F25.02 on

Insulation/Processes. 6.3 Sound-Absorption—When tested as specified in 10.3,

Current edition approved November 10, 2001. Published February 2002.

2

Annual Book of ASTM Standards, Vol 04.06.

3 6

Annual Book of ASTM Standards, Vol 15.09. Available from United States Government Printing Office, Washington, DC

4

Annual Book of ASTM Standards, Vol 04.07. 20593.

5 7

Available from American National Standards Institute, 25W. 3rd St., 4th Floor, Available from Superintendent of Documents, P.O. Box 371954, Pittsburgh, PA

New York, NY 10036. 15250–7954.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

F 2154

the sound-absorbing board shall have coefficients of absorption 9.3.1 Sampling for Density Test—Sample boards shall be

that are equal to or greater than those shown in Table 1. selected in accordance with ANSI Z1.4 at Inspection Level S-4

for the density test of 10.1. No defects shall be allowed.

7. Other Requirements

9.3.2 Sampling for Surface Flame Spread and Smoke Gen-

7.1 First Article—When specified (see Section 4), the con-

eration Properties—A sufficient number of boards shall be

tractor shall furnish sample unit(s) for first article inspection

randomly selected and joined end-to-end to form a specimen

and approval (see 11.1).

50.8 cm (20 in.) wide by 50.8 mm (2 in.) thick by 73

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.