ASTM F2155-01

(Specification)Standard Specification for Performance of Hasps and Other Attachment Devices for Padlocks or Seals

Standard Specification for Performance of Hasps and Other Attachment Devices for Padlocks or Seals

ABSTRACT

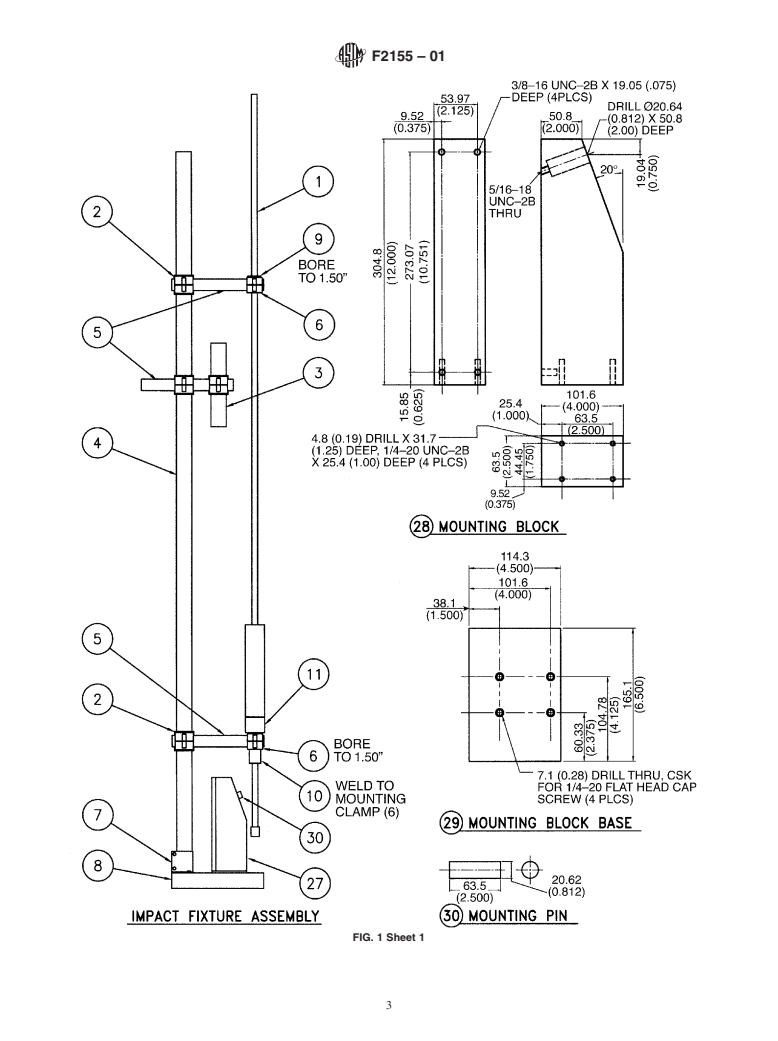

This specification describes and grades various levels of performance to provide standard criteria upon which to select suitable hasps and other attachment devices for padlocks and seals. Specially made hasps used by the Department of Defense or other highly sensitive applications are not covered by this specification. The tests specified are laboratory tests, and although they simulate field conditions as to attacks, they do not duplicate these conditions. Hasps that have special attributes not related to security may be used. Test specimen of each size and model shall be selected at random. Four hasps shall be selected for the forcing tests. Test apparatus preparation for the tensile loading device, shock impactor, and torque test fixture are detailed. Forcing tests includes the following: (1) staple axial load test, (2) hasp staple impact test, (3) hasp staple cutting test, and (4) hasp staple torque test. The test value requirements for the forcing tests are specified for the following grades: Grade 1, Grade 2, Grade 3, Grade 4, Grade 5, and Grade 6. The impact fixture assembly including the mounting block, anvil assembly, and weight assembly; assemble torque fixture; staple axial load test fixture; and staple cutting fixture are illustrated in detail.

SCOPE

1.1 This specification describes and grades various levels of performance to provide users of the standard with criteria upon which to select suitable hasps and other attachment devices. No effort has been made to include criteria for specially made hasps used by the Department of Defense or other highly sensitive applications.

1.2 The tests described are laboratory tests, and although they simulate field conditions as to attacks, they do not duplicate these conditions. Tests described are repeatable in the laboratory.

1.3 Some users of this standard may wish to use hasps that have special attributes not related to security.

1.4 The values stated in SI units are to be regarded as the standard. The inch-pound units given in parentheses are provided for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory requirements prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation: F2155 – 01

Standard Specification for

Performance of Hasps and Other Attachment Devices for

1

Padlocks or Seals

This standard is issued under the fixed designation F2155; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 3.1.2 fixed hasp, n—a combination of elements that, when

aligned, provide holes though which a padlock shackle or seal

1.1 This specification describes and grades various levels of

may pass to secure the elements.

performance to provide users of the standard with criteria upon

3.1.3 hasp, n—an attachment device having a hinged or

whichtoselectsuitablehaspsandotherattachmentdevices.No

fixed strap that engages a hasp staple to provide for the

effort has been made to include criteria for specially made

attachment of a padlock or seal.

hasps used by the Department of Defense or other highly

3.1.4 hasp staple, n—an eye- or U-shaped element that is

sensitive applications.

engaged by the slotted strap of a hasp and provides for the

1.2 The tests described are laboratory tests, and although

attachment of a padlock or seal.

they simulate field conditions as to attacks, they do not

3.1.5 hasp staple pad, n—a component of a hasp staple that

duplicatetheseconditions.Testsdescribedarerepeatableinthe

provides a fastening medium for attachment of the hasp staple

laboratory.

to the mounting surface.

1.3 Some users of this standard may wish to use hasps that

3.1.6 hasp strap, n—a component of a hasp that engages a

have special attributes not related to security.

hasp staple.

1.4 The values stated in SI units are to be regarded as the

3.1.7 hasp strap pad, n—a component of a hasp strap that

standard. The inch-pound units given in parentheses are

provides a fastening medium for attachment of the hasp to the

provided for information only.

mounting surface.

1.5 This standard does not purport to address all of the

3.1.8 hinged hasp, n—a hasp that includes a hasp strap, a

safety concerns, if any, associated with its use. It is the

hasp strap pad, a hasp staple, and a hasp staple pad in

responsibility of the user of this standard to establish appro-

combination such that the hasp strap, when closed, engages the

priate safety and health practices and determine the applica-

hasp staple, providing for the attachment of a padlock or seal

bility of regulatory requirements prior to use.

to cause the assembly to be latched and locked or sealed into

2. Referenced Documents a secure system.

2

3.1.9 latch, n—an item consisting of any number of mem-

2.1 ASTM Standards:

bers that act in combination to fasten separate elements into a

F883 Performance Specification for Padlocks

connected whole, and provides for the unfastening of this

3. Terminology

whole.

3.1.10 latching attachment device, n—an attachment device

3.1 Definitions of Terms Specific to This Standard:

that includes a latching feature that permits the assembly to

3.1.1 attachment device, n—an item consisting of any

remain engaged without the use of a padlock or seal.

number of members that act in combination with a padlock or

3.1.11 latching hasp, n—a hasp that includes a latching

seal to provide a locking security system.

feature that permits the strap to remain engaged with the hasp

staple without the use of a padlock or seal.

3.1.12 rotating hasp staple, n—a hasp staple that is free to

1

This specification is under the jurisdiction of ASTM Committee F12 on

turn in its pad, generally to provide a latching function by

Security Systems and Equipment and is the direct responsibility of Subcommittee

engaging the hasp strap, or to resist a torsional attack.

F12.50 on Locking Devices.

Current edition approved Dec. 10, 2001. Published March 2002. DOI: 10.1520/

4. General Requirements

F2155-01.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

4.1 Tolerances:

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

4.1.1 Fixture Tolerances—All tolerances shall follow stan-

Standards volume information, refer to the standard’s Document Summary page on

dard machining practices unless otherwise specified.

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

F2155 – 01

4.1.2 Test Setup Tolerances: a complete hasp, which has been mounted to the test sample

plate.Testthehaspinboththeverticalandhorizontalmounting

4.1.2.1 Force—61 % of working range.

configurations.

4.1.2.2 Height—63 mm (0.12 in.).

7

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.