ASTM C557-99

(Specification)Standard Specification for Adhesives for Fastening Gypsum Wallboard to Wood Framing

Standard Specification for Adhesives for Fastening Gypsum Wallboard to Wood Framing

SCOPE

1.1 This specification covers minimum standards for adhesives intended for bonding the back surface of gypsum wallboard to wood framing members.

1.2 This specification also covers test requirements and test methods for the adhesive used for the application of all thicknesses of gypsum wallboard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: C 557 – 99

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Specification for

Adhesives for Fastening Gypsum Wallboard to Wood

Framing

This standard is issued under the fixed designation C 557; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope of the specimen, not necessarily the true maximum stress in the

material.

1.1 This specification covers minimum standards for adhe-

3.1.3 tensile strength, n—in an adhesive joint, the maxi-

sives intended for bonding the back surface of gypsum

mum average stress when a force is applied perpendicular to

wallboard to wood framing members.

the joint.

1.2 This specification also covers test requirements and test

3.1.3.1 Discussion—In most adhesive test methods, the

methods for the adhesive used for the application of all

tensile strength is actually the maximum average stress at

thicknesses of gypsum wallboard.

failure of the specimen, not necessarily the true maximum

2. Referenced Documents stress in the material.

3.2 Definitions of Terms Specific to This Standard:

2.1 ASTM Standards:

3.2.1 lot, n—material from the same batch or blending

C 36 Specification for Gypsum Wallboard

operation that was processed in accordance with standard

D 828 Test Method for Tensile Properties of Paper and

manufacturing conditions.

Paperboard Using Constant-Rate-of-Elongation Appara-

tus

4. Significance and Use

D 907 Terminology of Adhesives

4.1 The specification applies to organic adhesives for bond-

D 1779 Specification for Adhesive for Acoustical Materi-

ing the back surface of gypsum wallboard of any thickness to

als

wood-framing members.

D 4338 Test Method for Flexibility Determination of Sup-

4 4.2 This specification provides a basis for ensuring the

ported Adhesive Films by Mandrel Bend Test Method

quality of the adhesives.

3. Terminology 4.3 Although the bonds rendered by these adhesives shall

have enough strength by themselves to maintain the bond

3.1 Definitions—Many terms in this specification are de-

between adherends, they are not intended as a substitute for the

fined in Terminology D 907.

common practice of using mechanical fasteners to maximize

3.1.1 gap-filling adhesive, n—an adhesive capable of form-

integrity of drywall-wood-framing structures.

ing and maintaining a bond between surfaces that are not

close-fitting.

5. Adhesive Physical Property Requirements

3.1.1.1 Discussion—Close-fitting is relative to a given ma-

5.1 Adhesives—The adhesives shall be uniform, homoge-

terial and industry; for example, standards in construction

neous mixtures of elastomeric polymers or viscoelastic resins,

differ from standards in electronics. Some adhesives will bond

or both, free of lumps or foreign matter.

by bridging without completely filling the gap; others by filling

5.1.1 Workability—When applied to the framing member

the gap completely.

with a caulking gun or notched trowel, or both, in accordance

3.1.2 shear strength, n—in adhesive joint, the maximum

with the manufacturer’s instructions, the adhesive shall exhibit

average stress when a force is applied parallel to the joint.

a consistency capable of ensuring non-sagging properties.

3.1.2.1 Discussion—In most adhesive test methods, the

5.1.2 Open Time—The adhesive shall have an open assem-

shear strength is actually the maximum average stress at failure

bly time of between 10 to 20 min to give the user sufficient

time to apply and, if necessary, reposition the wallboard at

This specification is under the jurisdiction of ASTM Committee D-14 on

ambient temperatures, ranging from 40 to 100°F (4 to 38°C).

Adhesives and is the direct responsibility of Subcommittee D14.70 on Construction

5.1.3 Storage Life—The adhesive shall remain serviceable

Adhesives.

and meet all the requirements of this specification for not less

Current edition approved April 10, 1999. Published June 1999. Originally

published as C 557 – 65 T. Last previous edition C 557 – 93a.

than six months after delivery, when stored in original un-

Annual Book of ASTM Standards, Vol 04.01.

opened containers at temperatures ranging from 40 to 85°F (4

Annual Book of ASTM Standards, Vol 15.09.

4 to 30°C).

Annual Book of ASTM Standards, Vol 15.06.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

C 557

1 3

6. Adhesive Performance Property Requirements 8.13 T-bar Steel Pin—4 ⁄2 by ⁄8 in. (114.0 by 9.5 mm) for

insertion into perforated tensile wood block.

6.1 The adhesives shall conform to the requirements sum-

8.14 Aluminum Tensile Test Jig—4 by 1 ⁄8 in. (102.0 by 41.0

marized in Table 1.

mm) T-bar perforated aluminum fixture with 1-in. (25.4 mm)

7. Sampling 1

long and ⁄4-in. (6.3 mm) diameter screw and hex nut for

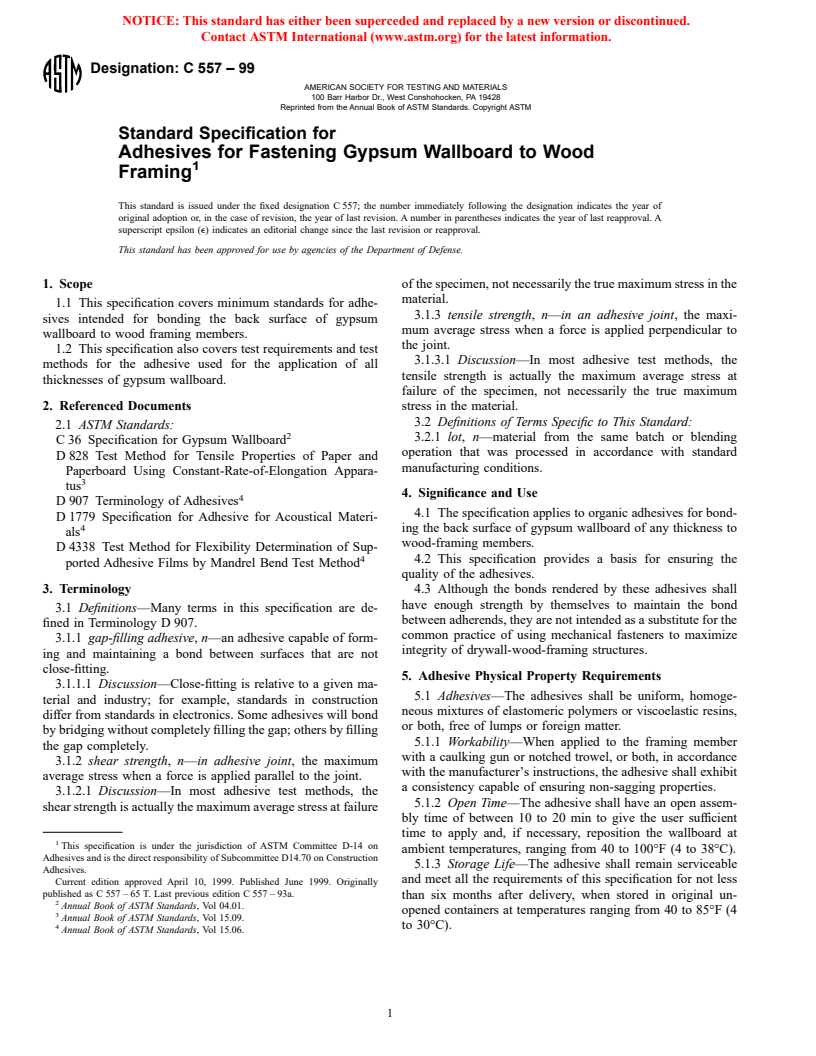

7.1 Sample each selected lot of adhesives in accordance insertion of looped steel cable with a collar (Fig. 1).

with Specification D 1779.

9. Conditioning of Materials and Specimens

8. Materials for Conducting Tests

9.1 Condition the Douglas fir, lumber, plywood, and wall-

8.1 Gypsum Wallboard— ⁄2-in. (12.7 mm) thick, complying

board to a constant weight at 73 6 2°F (23 6 1°C) and 50 6

with Specification C 36; the dimensions are specified in each

5 % relative humidity, unless specified otherwise.

test.

9.2 Subject all test assemblies and adhesives to be evaluated

8.2 Douglas Fir Plywood— ⁄4-in. (19.0 mm) thick

to standard conditioning (24 h at 73 6 2°F (23 6 1°C) and 50

plywood-grade PSI Exterior A-A or A-B; the dimensions are

6 5 % relative humidity) unless specified otherwise.

specified in each test.

1 10. Test Methods

8.3 Douglas Fir Plywood— ⁄4-in. (6.3 mm) thick plywood

10.1 Shear Strength (Rate-of-Shear Strength Development):

grade PSI Exterior A-A or A-B; the dimensions are specified in

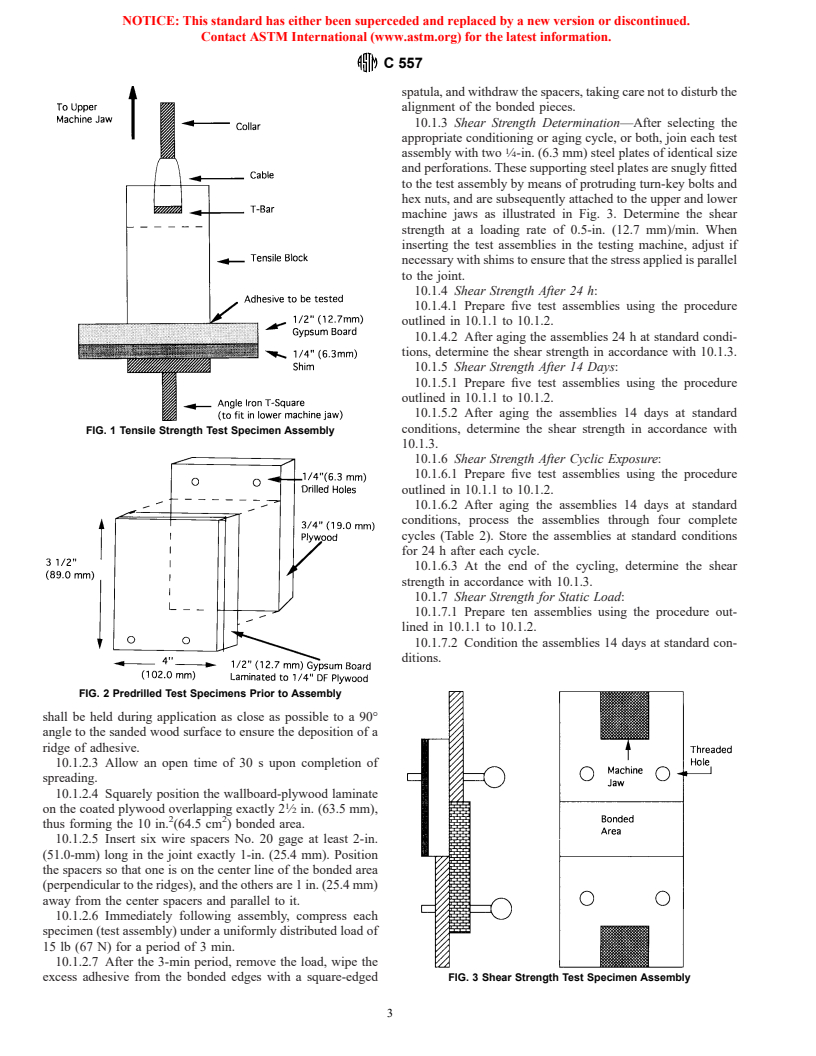

each test. 10.1.1 Preparation of Wallboard-Plywood Laminates—

1 1 1

8.4 Douglas Fir Lumber—1 ⁄2 by 1 ⁄2 by 3 ⁄2in. (38.0 by Prepare each test assembly individually from plywood and a

38.0 by 89.0 mm) in cross section; No. 1 straight-grained, and wallboard-plywood laminate. Each laminate is made by bond-

1 1

knot-free; the dimensions are specified in each test. ing a piece of 4 by 3 ⁄2 by ⁄2 in. (102.0 by 89.0 by 12.7 mm)

8.5 Polyvinyl Acetate Adhesive—Any commercially avail- wallboard to a ⁄4-in. thick (19.0 mm) plywood piece of the

able product. same dimensions with a commercially available PVA adhesive.

1 1

8.6 Steel Plates— ⁄4-in. thick steel with two ⁄4-in. diameter The grain of the wallboard facing paper shall run lengthwise in

1 3

threaded holes; the dimensions are specified in the shear- the 3 ⁄2-in. (89.0) direction. After conditioning the precut ⁄4-in.

strength test method. (19.0 mm) plywood pieces and wallboard-plywood laminates

1 1

8.7 Turn Key ⁄4-in. Diameter Threaded Bolts—With hex as indicated in 9.2, drill at the extremities of each two ⁄4in.

nuts; dimensions are specified in each test. (6.3-mm) diameter holes as shown in Fig. 2. The distance of

8.8 Garnet Paper—No. 120 grit, 3/0. these holes from the pertinent edges is approximately 1.0 in.

8.9 Spacers—No. 20 gage (American Standard or B&S) (25.4 mm).

bronze or brass wire ⁄32-in. (0.8-mm) diameter. 10.1.2 Preparation of Test Assembly—Prepare the test as-

3 1 3

8.10 Trowels—Plastic or metal with ⁄16-in. (4.76 mm) deep sembly by bondinga4by3 ⁄2 by ⁄4in. (102.0 by 89.0 by 19.0

V-notches. mm) piece of the described plywood to the previously prepared

8.11 Overlapping Steel Collar—Two 2 by 1 in. (51.0 by laminate as follows:

1 3

25.4 mm) U-channels welded to a ⁄16-in. (1.6-mm) thick 10.1.2.1 Sand the face of the ⁄4-in. (19.0-mm) thick ply-

galvanized-steel frame and assembled with a flathead screw, wood smooth with garnet paper and wipe the sanded surface

two washers, and a nut. free of dust.

8.12 Wood Shim— ⁄4-in. (19.0 mm) thick plywood with 10.1.2.2 Spread the adhesive on the sanded surface with a

1 1 3

dimensions of 4 by 1 ⁄4-in. (102.0 by 89.0 mm) with two ⁄4-in trowel having ⁄16-in. (4.8-mm) deep V-notches so that the

(6.3 mm) diameter drilled holes. adhesive ridges are parallel to the grain of wood. The trowel

TABLE 1 Adhesive Properties and Performance Requirements

Test Method Reference Number Property Condition Requirements

Rate of shear strength 10.1.4 shear strength 24 h at RT 10 psi (69 kPa) min

10.1.5 shear strength 14 days at RT 40 psi (276 kPa) min

10.1.6 shear strength 14 days at RT, + cyclic 32 psi (220 kPa) min

lab exposure, + 2 days at RT

10.1.7 shear strength (a) 40 lb (178 N) for 24 h at RT no bond separation

(b) 20 lb (89 N) for 24 h at no bond separation

100°F

Rate of strength development 10.2.3 tensile strength 24 h at RT 15 psi (103 kPa) min

10.2.4 tensile strength 14 days at RT 25 psi (172 kPa) min

Adhesive open-time determination 10.3 open-time 24 h at RT 75 % paper transfer, min

Substrate wet-out by adhesive

1. Plywood 10.4.1 wet-out spatula applied good wetting property

2. Wallboard 10.4.2 wet-out spatula applied good wetting property

Bridging 10.5 gap filling 48 h at RT continuous (adhesive) bond line

Adhesive aging 10.6 accelerated aging 500 h at 158°F no cracking or chipping

3 cycles of:

Freeze-thaw stability 10.7 low-temperature storage 24 h at 0°F + 24 h at RT no change in workability; 10 psi (69

kPa) shear strength, min

Suitability as a laminating adhesive for vinyl- 10.8.1 compatibility 24 h at 100°F no blistering, vinyl-film discoloration,

covered wallboard or bond failure

10.8.2 staining 1hatRT no swelling or discoloration

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

C 557

spatula, and withdraw the spacers, taking care not to disturb the

alignment of the bonded pieces.

10.1.3 Shear Strength Determination—After selecting the

appropriate conditioning or aging cycle, or both, join each test

assembly with two ⁄4-in. (6.3 mm) steel plates of identical size

and perforations. These supporting steel plates are snugly fitted

to the test assembly by means of protruding turn-key bolts and

hex nuts, and are subsequently attached to the upper and lower

machine jaws as illustrated in Fig. 3. Determine the shear

strength at a loading rate of 0.5-in. (12.7 mm)/min. When

inserting the test assemblies in the testing machine, adjust if

necessary with shims to ensure that the stress applied is parallel

to the joint.

10.1.4 Shear Strength After 24 h:

10.1.4.1 Prepare five test assemblies using the procedure

outlined in 10.1.1 to 10.1.2.

10.1.4.2 After aging the assemblies 24 h at standard condi-

tions, determine the shear strength in accordance with 10.1.3.

10.1.5 Shear Strength After 14 Days:

10.1.5.1 Prepare five test assemblies using the procedure

outlined in 10.1.1 to 10.1.2.

10.1.5.2 After aging the assemblies 14 days at standard

conditions, determine the shear strength in accordance with

FIG. 1 Tensile Strength Test Specimen Assembly

10.1.3.

10.1.6 Shear Strength After Cyclic Exposure:

10.1.6.1 Prepare five test assemblies using the procedure

outlined in 10.1.1 to 10.1.2.

10.1.6.2 After aging the assemblies 14 days at standard

conditions, process the assemblies through four complete

cycles (Table 2). Store the assemblies at standard conditions

for 24 h after each cycle.

10.1.6.3 At the end of the cycling, determine the shear

strength in accordance with 10.1.3.

10.1.7 Shear Strength for Static Load:

10.1.7.1 Prepare ten assemblies using the procedure out-

lined in 10.1.1 to 10.1.2.

10.1.7.2 Condition the assemblies 14 days at standard con-

ditions.

FIG. 2 Predrilled Test Specimens Prior to Assembly

shall be held during application as close as possible to a 90°

angle to the sanded wood surface to ensure the deposition of a

ridge of adhesive.

10.1.2.3 Allow an open time of 30 s upon completion of

spreading.

10.1.2.4 Squarely position the wallboard-plywood laminate

on the coated plywood overlapping exactly 2 ⁄2 in. (63.5 mm),

2 2

thus forming the 10 in. (64.5 cm ) bonded area.

10.1.2.5 Insert six wire spacers No. 20 gage at least 2-in.

(51.0-mm) long in the joint exactly 1-in. (25.4 mm). Position

the spacers so that one is on the center line of the bonded area

(perpendicular to the ridges), and the others are 1 in. (25.4 mm)

away from the center spacers and parallel to it.

10.1.2.6 Immediately following assembly, compress each

specimen (test assembly) under a uniformly distributed load of

15 lb (67 N) for a period of 3 min.

10.1.2.7 After the 3-min period, remove the load, wipe the

excess adhesive from the bonded edges with a square-edged FIG. 3 Shear Strength Test Specimen Assembly

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

C 557

TABLE 2 Cyclic-Exposure Conditioning for Shear-Test

outlined in 10.2.1. In this test, use plywood for wallboard. The

Assemblies (See 10.1.6)

plywood shall be prepared as outlined in 10.1.2.1.

10.2.4.2 After aging the assemblies 14 days at standard

NOTE 1—Four complete aging cycles to be used.

NOTE 2—Room temperature storage required over weekends.

conditions, determine the tensile strength in accordance with

10.2.2.

Time, h Temperature °F (°C) Relative Humidity, %

10.3 Adhesive Open-Time Determination:

4 100.0 (38.0) 85 6 2

4 40.0 (4.5) uncontrolled 10.3.1 Wallboard—Prepare five assemblies as follows:

16 122.0 (50.0) uncontrolled

10.3.1.1 Using a suitable template (Fig. 4), spread a uniform

3 3

bead of adhesive ⁄8in. (9.5 mm) by ⁄8 in. (9.5 mm) at least 2

10.1.7.3 Subject five test assemblies to a static load of 40 lb

in. (51.0 mm) long on the back surface ofa2by2in. (51.0 by

(178 N) at 73 6 2°F (23 6 1°C) and five assemblies to 20 lbs

51.0 mm) piece of wallboard that has been conditioned for 24

(89 N) at 38 6 1°C (100.2 6 2.0°F) for a period of 24 h. When

h at standard conditions.

testing, clamp the top (wallboard/plywood) of the assembly to

10.3.1.2 After conditioning the assembly for 30 min at

a rigid frame and attach the load to the bottom (plywood),

standard conditions, positiona2by2in. (51.0 by 51.0 mm)

making sure that perfect alignment of the suspended assembly

piece of wallboard centrally over the bead. Immediately

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.