ASTM B654-92(1999)

(Specification)Standard Specification for Niobium-Hafnium Alloy Foil, Sheet, Strip, and Plate

Standard Specification for Niobium-Hafnium Alloy Foil, Sheet, Strip, and Plate

SCOPE

1.1 This specification covers hafnium-alloyed niobium foil, sheet, strip, and plate. Note-Committee B-10 has adopted "niobium" as the designation for Element 41, formerly named "columbium."

1.2 The material covered by this specification is R04295, niobium-base alloy containing approximately 10% hafnium and 1% titanium.

1.3 The following safety hazards caveat pertains only to the test methods portion, Section 15, of this Specification: This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: B 654 – 92 (Reapproved 1999)

Standard Specification for

Niobium-Hafnium Alloy Foil, Sheet, Strip, and Plate

This standard is issued under the fixed designation B 654; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.3 strip—a flat product, may be supplied in coil, less than

6 in. (152.4 mm) wide and from 0.005 in. (0.13 mm) to ⁄16in.

1.1 This specification covers hafnium-alloyed niobium foil,

(4.76 mm) in thickness.

sheet, strip, and plate.

3.1.4 plate—a flat product 6 in. (152.4 mm) or more in

NOTE 1—Committee B-10 has adopted “niobium” as the designation 3

width and more than ⁄16in. (4.76 mm) in thickness.

for Element 41, formerly named “columbium.”

4. Ordering Information

1.2 The material covered by this specification is R04295,

niobium-base alloy containing approximately 10% hafnium

4.1 Orders for material under this specification shall include

and 1% titanium.

the following information as applicable:

1.3 The following safety hazards caveat pertains only to the

4.1.1 Type material (Section 1),

test methods portion, Section 15, of this specification: This

4.1.2 Method of manufacture (Section 5),

standard does not purport to address all of the safety problems,

4.1.3 Quantity in number of pieces, dimensions, and weight,

if any, associated with its use. It is the responsibility of the user

4.1.4 Chemistry (Section 6),

of this standard to establish appropriate safety and health

4.1.5 Temper designation (Section 8),

practices and determine the applicability of regulatory limita-

4.1.6 Mechanical properties (Section 9),

tions prior to use.

4.1.7 Quality and finish (Section 12),

4.1.8 Sampling (Section 13),

2. Referenced Documents

4.1.9 Marking (Section 20),

2.1 ASTM Standards:

4.1.10 Packaging (Section 21),

B 652 Specification for Niobium–Hafnium Alloy Ingots

4.1.11 Required reports (Section 16), and

E 8 Test Methods for Tension Testing of Metallic Materials

4.1.12 Disposition of rejected material (Section 18).

E 29 Practice for Using Significant Digits in Test Data to

5. Materials and Manufacture

Determine Conformance with Specifications

E 195 Methods for Chemical Analysis of Reactor and Com-

5.1 Material covered by this specification shall be made

mercial Columbium

from ingots conforming to Specification B 652, which are

produced by vacuum-arc melting, or electron-beam furnace

3. Terminology

melting, or a combination of the two.

3.1 Definitions of Terms Specific to This Standard:

5.2 The various niobium – hafnium alloy mill products

3.1.1 foil—a flat product less than 6 in. (152.4 mm) wide

covered by this specification are produced by the conventional

and less than 0.005 in. (0.13 mm) in thickness.

extrusion, forging, and rolling equipment normally available in

3.1.2 sheet—a flat product 6 in. (152.4 mm) or more in

metal-working plants.

width and from 0.005 in. (0.13 mm) to ⁄16 in. (4.76 mm) in

6. Chemical Composition

thickness.

6.1 The niobium – hafnium alloy ingots and billets for

conversion to finished products covered by this specification

This specification is under the jurisdiction of Committee B-10 on Reactive and

shall conform to the requirements for chemical composition as

Refractory Metals and Alloys and is the direct responsibility of Subcommittee

prescribed in Table 1. Analysis for elements, not listed in Table

B10.03 on Niobium and Tantalum.

1 and not normally expected in niobium hafnium alloy, shall

Current edition approved Aug. 15, 1992. Published October 1992. Originally

published as B 654 – 79. Last previous edition B 654 – 79.

not be required unless specified at time of purchase.

Annual Book of ASTM Standards, Vol 02.04.

6.2 The manufacturer’s ingot analysis shall be considered

Annual Book of ASTM Standards, Vol 03.01.

the chemical analysis for products supplied under this specifi-

Annual Book of ASTM Standards, Vol 14.02.

Discontinued—See 1984 Annual Book of ASTM Standards, Vol 03.05. cation.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

B 654 – 92 (1999)

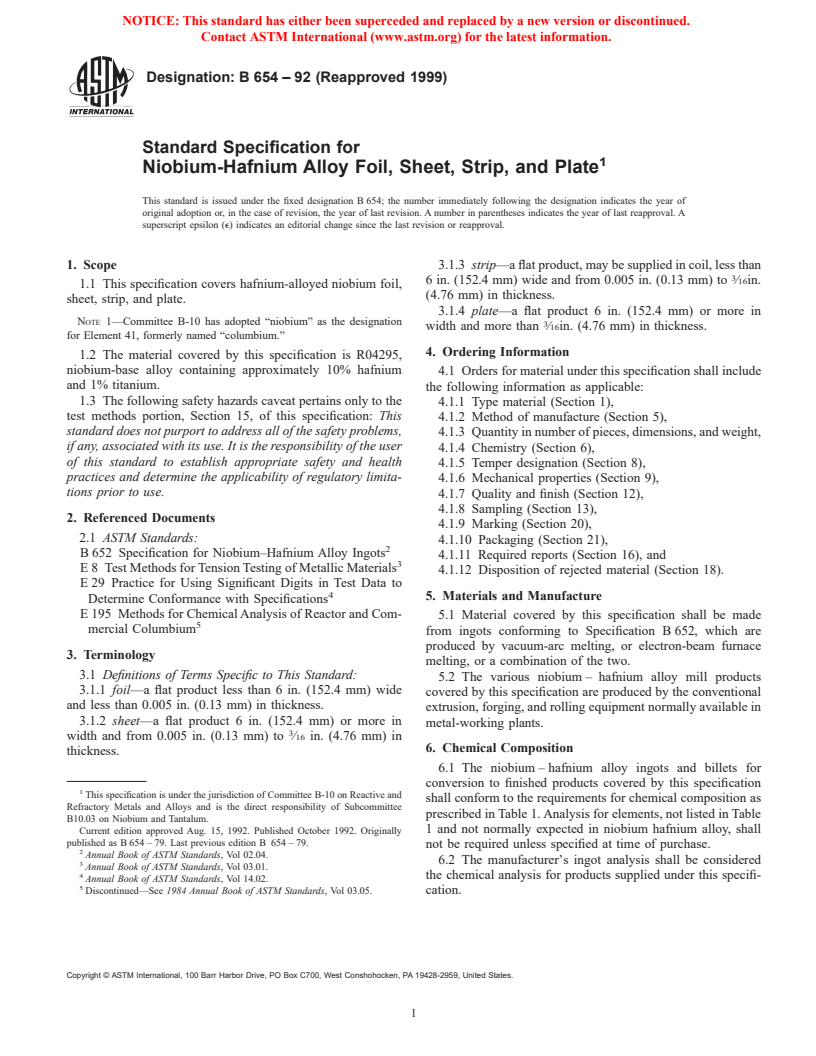

TABLE 1 Chemical Requirements (Ingot)

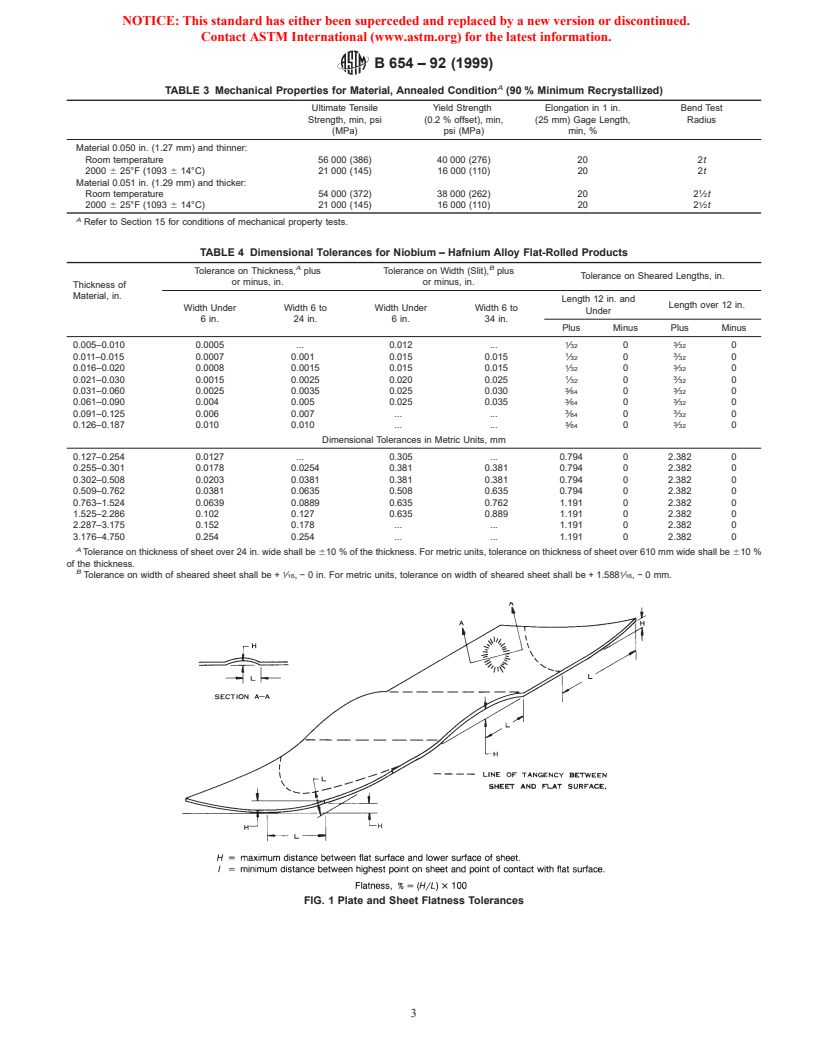

Flatness, % 5 ~H/L! 3 100 (1)

Niobium – Hafnium Alloy R04295

where:

A

Element Content, Weight %

H = maximum vertical distance between a flat reference

C 0.015

surface and the lower surface of the sheet, and

O 0.025

L = minimum horizontal distance between the highest

N 0.010

point on the sheet and the point of contact with a flat

H 0.0015

Hf 9–11

reference surface. (The method for taking measure-

Ti 0.7–1.3

ments for calculation of sheet flatness is shown in Fig.

Zr 0.700

W 0.500 1. However, a value of H less than ⁄32 in. (0.07 mm)

Ta 0.500

shall not be cause for rejection.)

Nb by difference

10.3 Quantity or Weight—For orders requiring up to 100 lb

A

Values are maximum unless otherwise shown.

(45.4 kg), the manufacturer may overship by 20 %. When the

order is for quantities up to 1000 lb (454 kg), the manufacturer

6.3 Upon request of the purchaser at the time of purchase, may overship by 10 %. The permissible overshipment for

the seller shall furnish a report certifying the values of the quantities larger than 1000 lb shall be negotiated between the

interstitial elements (carbon, oxygen, nitrogen, hydrogen) as purchaser and seller.

specified in Table 2 for each lot of material supplied. A lot is

11. Significance of Numerical Limits

defined as that material produced from one ingot, heat treated

at the same time. The cost of this special provision shall be

11.1 The following applies to all specified limits in this

negotiated between the purchaser and the seller at the time of

standard for purposes of determining conformance with this

purchase.

specification: The observed value or a calculated value shall be

rounded off “to the nearest unit” in the last right-hand digit

7. Methods of Chemical Analysis

used in expressing the specification limit, in accordance with

7.1 The chemical compositions enumerated in this specifi-

the rounding-off method of Practice E 29.

cation shall, in the case of disagreement, be determined in

12. Quality and Finish

accordance with the methods approved for referee purposes by

Methods E 195.

12.1 Niobium – hafnium alloy foil, sheet, strip, and plate

shall be free of injurious internal and external imperfections of

8. Temper Designations

a nature that will interfere with the purpose for which it was

8.1 Unless otherwise stated, the materials supplied under

intended. Material may be supplied in the as-rolled and cleaned

this specification shall be in the fully annealed condition.

or ground finish. For material shipped in either condition, the

8.2 Other temper designations, such as cold-worked temper

manufacturer shall be permitted to remove minor surface

or stress-relieved temper, can be specified as agreed upon

imperfections, if such removal does not reduce the dimensions

between the purchaser and the seller at the time of purchase.

below the minimum permitted by the tolerances specified in

Table 4.

9. Mechanical Properties

12.2 Methods of testing for these defects, and the standards

9.1 Materials in the annealed condition supplied under this

of acceptability, shall be as agreed upon between the purchaser

specification shall conform to the requirements for mechanical

and the manufacturer.

properties as specified in Table 3 by test methods specified in

13. Sampling

Section 14.

13.1 Samples shall be taken from the material to determine

10. Permissible Variations

conformity to this specification. The samples shall be taken so

10.1 Tolerances for thickness, width, and length for flat-

as to be representative of the finished products.

rolled products covered by this specification shall be as shown

13.2 Care shall be exercised to ensure that the sample

in Table 4.

selected for testing is representative of the material, and that it

10.2 Flatness tolerance for sheet and plate products supplied

is not contaminated by the sampling procedure. If there is any

under this specification shall be 6 % maximum, as determined

question relating to the sampling technique, or the analysis

by the following equation (see Fig. 1):

thereof, the methods of sampling and analysis shall be as

agreed upon between the purchaser and the manufacturer.

TABLE 2 Additional Chemical Requirements for Finished

14. Retests

Product (When Specified by Purchaser)

Niobium – Hafnium Alloy R04295 14.1 If any sample or specimen exhibits obvious surface

contamination or improper preparation disqualifying it as a

Maximum Content,

Element

Weight %

truly representative sample, it shall be discarded and a new

O 0.035 sample or specimen substituted.

C 0.015

14.2 In case of failure, retest two additional specimens. If

N 0.010

both specimens conform to this specification, discard the

H 0.0015

original values and consider the material acceptable.

NOTICE: This standard has either been superceded and replaced by a new version or discontinu

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.