ASTM D1922-00a

(Test Method)Standard Test Method for Propagation Tear Resistance of Plastic Film and Thin Sheeting by Pendulum Method

Standard Test Method for Propagation Tear Resistance of Plastic Film and Thin Sheeting by Pendulum Method

SCOPE

1.1 This test method covers the determination of the average force to propagate tearing through a specified length of plastic film or nonrigid sheeting. After the tear has been started using an Elmendorf-type tearing tester, two specimens are cited, a rectangular type and one with a constant radius testing length. The latter shall be the preferred or referee specimen.

1.2 Because of (1 ) difficulties in selecting uniformly identical specimens, (2) the varying degree of orientation in some plastic films, and (3 ) the difficulty found in testing highly extensible or highly oriented materials, or both, the reproducibility of the test results may be variable and, in some cases, not good or misleading. Provisions are made in the test method to compensate for oblique directional tearing which may be found with some materials.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in Note 8.

Note 1--This standard and ISO 6383-2 are technically equivalent.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

Designation: D 1922 – 00a

Standard Test Method for

Propagation Tear Resistance of Plastic Film and Thin

Sheeting by Pendulum Method

This standard is issued under the fixed designation D 1922; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (ϵ) indicates an editorial change since the last revision or reapproval.

1. Scope* D 374 Test Methods for Thickness of Solid Electrical Insu-

lation

1.1 This test method covers the determination of the

D 618 Practice for Conditioning Plastics for Testing

averageforcetopropagatetearingthroughaspecifiedlengthof

D 689 Test Method for Internal Tearing Resistance of Pa-

plastic film or nonrigid sheeting after the tear has been started,

per

using an Elmendorf-type tearing tester. Two specimens are

D 1004 Test Method for Initial Tear Resistance of Plastic

cited, a rectangular type, and one with a constant radius testing

Film and Sheeting

length. The latter shall be the preferred or referee specimen.

D 4000 Classification System for Specifying Plastic Mate-

1.2 Because of (1) difficulties in selecting uniformly iden-

rials

tical specimens, (2) the varying degree of orientation in some

E 691 Practice for Conducting an Interlaboratory Study to

plastic films, and (3) the difficulty found in testing highly

Determine the Precision of a Test Method

extensible or highly oriented materials, or both, the reproduc-

2.2 ISO Standard:

ibilityofthetestresultsmaybevariableand,insomecases,not

ISO 6383-2 Plastics—Film and Sheeting—Determination

good or misleading. Provisions are made in the test method to

of Tear Resistance—Part 2 Elmendorf Method

compensateforobliquedirectionaltearingwhichmaybefound

with some materials.

3. Summary of Test Method

1.3 The values stated in SI units are to be regarded as the

3.1 The force in grams required to propagate tearing across

standard. The values given in parentheses are for information

a film or sheeting specimen is measured using a precisely

only.

calibrated pendulum device. Acting by gravity, the pendulum

1.4 This standard does not purport to address all of the

swings through an arc, tearing the specimen from a precut slit.

safety concerns, if any, associated with its use. It is the

The specimen is held on one side by the pendulum and on the

responsibility of the user of this standard to establish appro-

other side by a stationary member. The loss in energy by the

priate safety and health practices and determine the applica-

pendulum is indicated by a pointer. The scale indication is a

bility of regulatory limitations prior to use. Specific precau-

function of the force required to tear the specimen.

tionary statements are given in Note 8.

NOTE 1—This standard and ISO 6383-2 are technically equivalent. 4. Significance and Use

4.1 This test method is of value in ranking relative tearing

2. Referenced Documents

resistance of various plastic films and thin sheeting of compa-

2.1 ASTM Standards:

rable thickness. Experience has shown the test to have its best

reliability on relatively less extensible films and sheeting.

Variable elongation and oblique tearing effects on the more

This test method is under the jurisdiction ofASTM Committee D20 on Plastics

extensiblefilmsprecludeitsuseasapreciseproduction-control

and is the direct responsibility of Subcommittee D20.19 on Film and Sheeting.

tool for these types of plastics.This test method should be used

Current edition approved Nov. 10, 2000. Published January 2001. Originally

for specification acceptance testing only after it has been

published as D 1922 – 61 T. Last previous edition D 1922 – 00.

demonstrated that the data for the particular material are

This test method has been adapted from TAPPI Standard Method T 414M-49,

Internal Tearing Resistance of Paper. In testing certain plastic films, problems of

acceptably reproducible. This test method should be used for

reproducibility and interpretation of results are encountered which require special

treatment to make the test method of most value. This test method is revised here

specifically for use with plastic film and thin sheeting. For more complete

explanation of certain aspects of the equipment, its calibration and adjustment, refer Annual Book of ASTM Standards, Vol 10.01.

to TAPPI Standard Method T 414M-49. Annual Book of ASTM Standards, Vol 08.01.

The following additional references may be of interest in connection with this Annual Book of ASTM Standards, Vol 15.09.

test method: Annual Book of ASTM Standards, Vol 08.02.

Painter,E.V.,Chu,C.C.,andMorgan,H.M.,“TestingTextilesontheElmendorf Annual Book of ASTM Standards, Vol 14.02.

Tear Tester,” Textile Research Journal, Vol XX, No. 6, June 1950, pp. 410–417. Available from American National Standards Institute, 11 W. 42nd St., 13th

Elmendorf, A., “Strength Test for Paper,” Paper, Vol 26, April 21, 1920, p. 302. Floor, New York, NY 10036.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

D 1922 – 00a

service evaluation only after its usefulness for the particular pendulum shall carry a circumferential scale, graduated from 0

application has been demonstrated with a number of different to 100 % of the machine capacity so as to read against the

films. pointer the average force required to tear a specimen 43 mm

4.2 This test method has been widely used as one index of (1.7 in.). The pointer and scale may be replaced by an

the tearing resistance of plastic film and thin sheeting used in electronic digital readout. Digital readouts are available which

packaging applications.While it may not always be possible to will give test results directly in millinewtons, directly in

correlate film tearing data with its other mechanical or tough- grams-force, or in percent of pendulum capacity. With the

ness properties, the apparatus of this test method provides a pendulum in its initial position ready for test, separate the two

controlled means for tearing specimens at straining rates clamps by an interval of 2.54 mm (0.10 in.). So align them that

approximating some of those found in actual packaging ser- the specimen clamped in them lies in a plane perpendicular to

vice. the plane of oscillation of the pendulum with the edges of the

4.3 Due to orientation during their manufacture, plastic jawsgrippingthespecimeninahorizontalline,aperpendicular

films and sheeting frequently show marked anisotropy in their to which through the axis of suspension of the pendulum is

resistancetotearing.Thisisfurthercomplicatedbythefactthat 102.7 6 0.05 mm (4.044 6 0.002 in.) in length and makes an

some films elongate greatly during tearing, even at the rela- angle of 27.5° with the plane of the film specimen. The

tively rapid rates of loading encountered in this test method. clamping surface in each jaw shall be at least 25.4 mm (1 in.)

The degree of this elongation is dependent in turn on film in width and at least 12.7 mm (0.5 in.) in depth.

orientation and the inherent mechanical properties of the 5.1.5 Capacity—Instruments of several capacities, 1960,

polymer from which it is made. These factors make tear 3920, 7840, 15 600, 31 360, 62 720 mN (200, 400, 800, 1600,

resistance of some films reproducible between sets of speci- 3200, 6400 gf), and perhaps others are available. These

mens to 65 % of the mean value, while others may show no capacities can be achieved by individual instruments, inter-

better reproducibility than 650 %. changeable pendulum sectors, or augmenting weights.

4.4 Data obtained by this test method may supplement that 5.2 Template, Die, or Shear-Type Cutter, for cutting

from Test Method D 1004D 1004, wherein the specimen is specimens.

strained at a rate of 50 mm (2 in.) per min. However, specimen 5.3 Razor Blades, single-edged, for cutting specimens

geometry and testing speed of the two test methods are where a template is used.

dissimilar.Therateoftearinginthistestmethod,whilevarying 5.4 Thickness-Measuring Device—A suitable micrometer,

as a function of resistance to tear, is in the range from 7.6 to 46 or other thickness gage, reading to 0.0025 mm (0.0001 in.) for

m (300 to 1800 in.)/min. measuring the thickness of test specimens. The pressure

4.5 There is not a direct, linear relationship between tearing exerted by the gage on the specimen being measured shall not

force and specimen thickness. Data from this test method are distort or deform the specimen. For thin films, ≤0.025 mm

expressed as tearing force in millinewtons (or grams-force, if (0.001 in.), or films that exhibit visual deformation during

desired), with specimen thickness also reported. But sets of measurement, a maximum pressure of 70 kPa (10 psi) is

data from specimens of dissimilar thickness are usually not recommended. For thicker or stiffer films, the pressure shall be

comparable. Therefore, only data at the same thickness can be between 160 and 185 kPa (23 and 27 psi), in accordance with

compared. Method C of Test Methods D D 374374.

4.6 For many materials, there may be a specification that

6. Test Specimens

requires the use of this test method, but with some procedural

modifications that take precedence when adhering to the

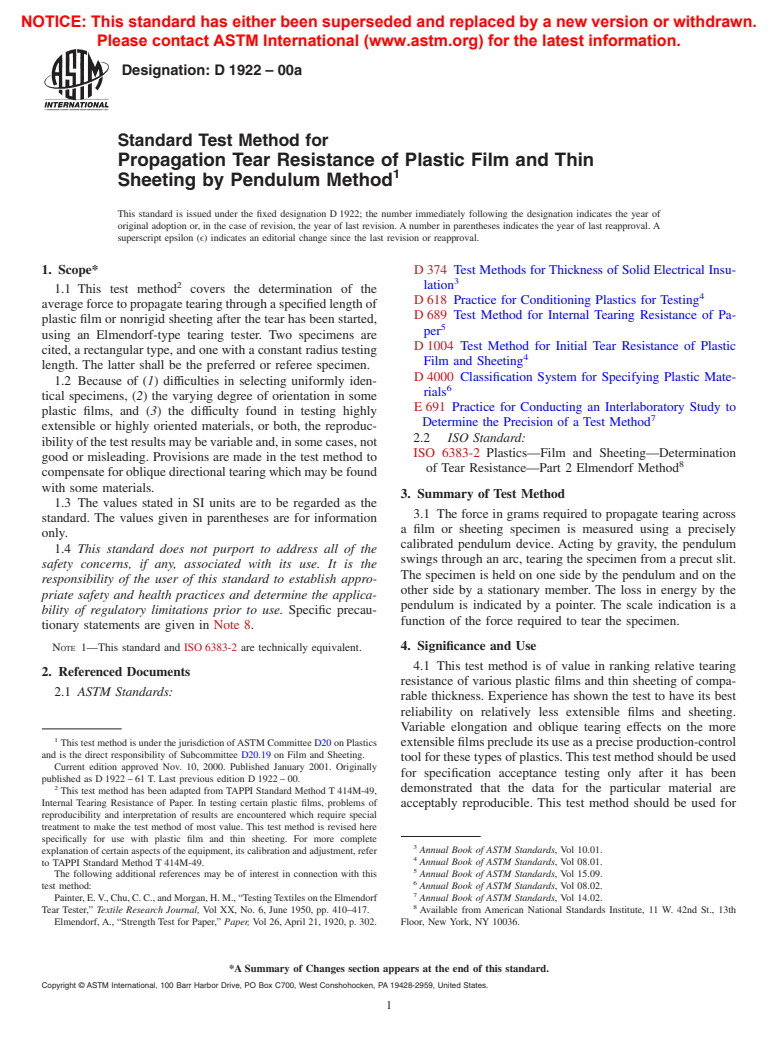

6.1 Test specimens shall be cut, as shown in Fig. 1, to form

specification. Therefore, it is advisable to refer to that material

a constant-radius testing length. This shall be the preferred or

specification before using this test method. Table 1 of Classi-

referee specimen type since its geometry automatically com-

fication System D 4000D 4000 lists the ASTM materials

pensates for the problem of oblique tearing (Note 2 and Note

standards that currently exist.

3).Alternatively, specimens shall be cut to form a rectangle 76

mm (3 in.) or more in width by 63 mm (2.5 in.) in length and

5. Apparatus

plainlymarkedtodenoteintendeddirectionoftear.The63-mm

5.1 Pendulum Impulse-Type Testing Apparatus, consisting specimen dimension shall be the direction of tear. Two sets of

of the following: specimens shall be cut from each sample so that their sides are

5.1.1 Stationary Clamp. parallel to (1) the machine direction and (2) the transverse

5.1.2 Movable Clamp, carried on a pendulum, preferably direction, respectively, of the material being tested. Enough

formed by a sector of a wheel or circle, free to swing on a ball specimens shall be cut in each direction to provide a minimum

bearing or other substantially frictionless bearing. of ten tear strength determinations.

5.1.3 Stop Catch, for holding the pendulum in a raised

NOTE 2—Specimens having constant-radius testing lengths are de-

position and for releasing it instantaneously.

signed to correct for oblique directional tearing encountered in certain

5.1.4 Indicating Device, for registering the maximum arc

anisotropic, elastomeric films, and nonrigid sheeting. For purposes of

through which the pendulum swings when released. The

The TA63 Sample Cutter, Catalog No. 98, available from the Thwing-Albert

Equipment available from the Thwing-Albert Instrument Co., Philadelphia, PA Instrument Co., Philadelphia, PA 19144, has been found satisfactory for cutting

19144, meets the requirements for this apparatus. specimens.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

D 1922 – 00a

This bearing will not necessarily allow the pendulum sector to

make 20 complete oscillations as the older one did. This does

not mean that there is excess friction in the pendulum swing.

These newer bearings should not be oiled. Consult the instruc-

tions supplied with the instrument for guidance.

7.2 Pointer Friction—Check the pointer friction as follows:

Set the pointer at zero reading on the scale before releasing the

sector, and after release see that the pointer is not pushed more

than three scale divisions beyond zero.Areading of more than

three divisions indicates excessive pointer friction and the

pointer should be removed, the bearing wiped clean, and a

trace of oil or petroleum jelly applied. When the pointer

friction has been reduced, finally adjust the pointer stop.

7.3 Pointer Zero Reading—To check the pointer for its zero

point, level the apparatus so that, with the sector free, the line

on the sector indicating the vertical point of suspension

coincides with a corresponding point on the base of the

apparatus, usually placed on the stop mechanism. After level-

ing, operate the apparatus several times with nothing in the

FIG. 1 Constant-Radius Test Specimen for Tear Resistance Test

jaws, the movable jaw being closed, to ascertain whether the

pointer registers zero with no load. If zero is not registered,

adjust the position of the pointer stop by means of the pointer

specimen selection, oblique tearing is defined as tearing in a curved or

stop thumb screw until a zero reading is obtained.

straight line that deviates more than 9.5 mm ( ⁄8 in.) from the vertical line

of intended tear.

NOTE 3—Certain film and sheeting specimens showing oblique tearing

8. Verification of Scale

may yield data of poor reproducibility because the axis of maximum

8.1 The scale may be verified either by the procedure

orientation varies as much as 30° from the nominal machine direction.

When this is suspected, the sample may be examined by crossed Polaroid

described inTest Method D 689D 689 and repeated here, or by

plates to determine this direction of maximum orientation and the

the method which uses the Elmendorf check weights obtain-

specimens cut along the axis of anisotropy for testing parallel and normal

able from the manufacturer. The method in Test Method

to it.

D 689D 689 is relatively time-consuming and complicated.

6.2 Where a metal template is used, the film or sheeting

The check weight method is relatively simple.

shall be placed on a hard surface. The template shall be held

8.2 Test Method D 689D 689 Procedure:

over it and the specimens cut out using a single-edged razor

8.2.1 To verify the scale, first mark the center of gravity of

blade.

the weight (including means of attaching) by a punched dot on

6.3 Whenthespecimeniscutout,aslit20mm(0.8in.)deep

the face of the weight. Then clamp a known weight in grams,

may be made at the center of the edge perpendicular to the

W, to the radial edge of the sector beneath the jaws.

direction to

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.