ASTM D6766-02

(Test Method)Standard Test Method for Evaluation of Hydraulic Properties of Geosynthetic Clay Liners Permeated with Potentially Incompatible Liquids

Standard Test Method for Evaluation of Hydraulic Properties of Geosynthetic Clay Liners Permeated with Potentially Incompatible Liquids

SCOPE

1.1 This test method covers laboratory measurement of both flux and hydraulic conductivity (also referred to as coefficient of permeability) of geosynthetic clay liner (GCL) specimens permeated with chemical solutions and leachates utilizing a flexible wall permeameter.

1.2 This test method may be utilized with GCL specimens that have a hydraulic conductivity less than or equal to 1 10 -5 m/s (1 10-3 cm/s).

1.3 This test method is applicable to GCL products having geotextile backing(s). It may not be applicable to GCL products with geomembrane backing(s).

1.4 This test method provides measurements of flux and hydraulic conductivity under a prescribed set of conditions, as an index test, that can be used for manufacturing quality control. The flux and hydraulic conductivity values determined using this test method under the prescribed set of conditions is not considered to be representative of the in-service conditions of GCLs. However, the test method allows the requester to establish a set of test conditions; thus, the test method also may be used to check performance or conformance, or both.

1.5 The values stated in SI units are to be regarded as the standard, unless other units are specifically given. By tradition in U.S. practice, hydraulic conductivity is reported in centimeters per second, although the common SI units for hydraulic conductivity are meters per second.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D6766–02

Standard Test Method for

Evaluation of Hydraulic Properties of Geosynthetic Clay

Liners Permeated with Potentially Incompatible Liquids

This standard is issued under the fixed designation D 6766; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D 2216 TestMethodforLaboratoryDeterminationofWater

(Moisture) Content of Soil and Rock

1.1 This test method covers laboratory measurement of both

D 4354 Practice for Sampling of Geosynthetics for Testing

flux and hydraulic conductivity (also referred to as coeffıcient

D 4439 Terminology for Geosynthetics

of permeability) of geosynthetic clay liner (GCL) specimens

D 4753 Specification for Evaluating, Selecting and Speci-

permeated with chemical solutions and leachates utilizing a

fying Balances and Scales for Use in Soil and Rock

flexible wall permeameter.

Testing

1.2 This test method may be utilized with GCL specimens

D 4767 Test Method for Consolidated-Undrained Triaxial

that have a hydraulic conductivity less than or equal to

-5 -3

Compression

1 3 10 m/s (1 3 10 cm/s).

D 5084 Test Method for Measurement of Hydraulic Con-

1.3 This test method is applicable to GCL products having

ductivity of Saturated Porous Materials Using a Flexible

geotextile backing(s). It may not be applicable to GCL prod-

Wall Permeameter

ucts with geomembrane backing(s).

D 5887 Test Method for Measurement of Index Flux

1.4 This test method provides measurements of flux and

Through Saturated Geosynthetic Clay Liner Specimens

hydraulic conductivity under a prescribed set of conditions, as

Using a Flexible Wall Permeameter

an index test, that can be used for manufacturing quality

E 145 Specification for Gravity-Convection and Forced-

control.The flux and hydraulic conductivity values determined

Ventilation Ovens

using this test method under the prescribed set of conditions is

not considered to be representative of the in-service conditions

3. Terminology

of GCLs. However, the test method allows the requester to

3.1 Definitions:

establish a set of test conditions; thus, the test method also may

3.1.1 flux, n—the rate of discharge of liquid under laminar

be used to check performance or conformance, or both.

flow conditions through a unit cross-sectional area of a GCL

1.5 The values stated in SI units are to be regarded as the

specimen at a standard temperature condition (22 6 3°C).

standard, unless other units are specifically given. By tradition

3.1.2 geosynthetic clay liner (GCL), n—a factory-

in U.S. practice, hydraulic conductivity is reported in centime-

manufactured geosynthetic hydraulic barrier consisting of clay

ters per second, although the common SI units for hydraulic

supported by geotextiles, geomembranes, or a combination

conductivity are meters per second.

thereof, that are held together by needling, stitching, chemical

1.6 This standard does not purport to address all of the

adhesives or other methods.

safety concerns, if any, associated with its use. It is the

3.1.3 hydraulic conductivity, k, n—the rate of discharge of

responsibility of the user of this standard to establish appro-

liquid under laminar flow conditions through a unit cross-

priate safety and health practices and determine the applica-

sectional area of a GCL specimen under a unit hydraulic

bility of regulatory limitations prior to use.

gradient and standard temperature conditions (22 6 3°C).

2. Referenced Documents 3.1.3.1 Discussion—The term coeffıcient of permeability is

often used instead of hydraulic conductivity but hydraulic

2.1 ASTM Standards:

conductivity is used exclusively in this test method. A more

D 653 Terminology Relating to Soil, Rock, and Contained

Fluids

This test method is under the jurisdiction of ASTM Committee D35 on

GeosyntheticsandisthedirectresponsibilityofSubcommitteeD35.04onHydraulic

Properties.

Current edition approved Feb 10, 2002. Published March 2002. Annual Book of ASTM Standards, Vol 04.09.

2 4

Annual Book of ASTM Standards, Vol 04.08. Annual Book of ASTM Standards, Vol 04.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D6766–02

complete discussion of the terminology associated with Dar- 4.5 The apparatus used in this test method is commonly

cy’s law is given in the literature. used to determine the hydraulic conductivity of soil specimens.

3.1.4 index test, n—a test procedure that may contain bias, However, flux values measured in this test are typically much

but may be used to establish comparable results with respect to lower than those commonly measured for most natural soils. It

the property of interest. is essential that the leakage rate of the apparatus in this test be

3.1.5 pore volume of flow, n—the cumulative quantity of less than 10 % of the flux.

flow into a test specimen divided by the volume of voids in the

5. Apparatus

specimen.

3.2 For definitions of other terms used in this test method,

5.1 Compatibility—All parts in contact with the test liq-

see Terminology D 653 and D 4439.

uid(s) shall be checked/verified for long-term compatibility.

This can be established either based on the available informa-

4. Significance and Use

tion or by in-house testing.

4.1 This test method applies to one-dimensional, laminar 5.2 Hydraulic System—Constant head (Method A), falling

flow of water or other permeation liquids, such as chemical head (Methods B and C), or constant rate of flow (Method D)

solutions, landfill leachate, and contaminated water (here on systems may be utilized provided they meet the criteria

referred to as test liquid), through saturated/hydrated GCL outlined as follows:

specimen that is consolidated and permeated under a pre- 5.2.1 Constant Head (Method A)—The system must be

scribed or requested set of conditions. capable of maintaining constant hydraulic pressures to within

4.2 This test method can be performed to determine if the 65 % and shall include means to measure the hydraulic

flux and/or hydraulic conductivity of a GCLspecimen exceeds pressures to within the prescribed tolerance. In addition, the

the maximum value stated by the manufacturer or required by head loss across the tests specimen must be held constant to

the regulatory agencies, or both. within 65 % and shall be measured with the same accuracy or

4.3 It is assumed that Darcy’s law is valid and that the better. Pressures shall be measured by a pressure gage, elec-

hydraulic conductivity is essentially unaffected by hydraulic tronic pressure transducer, or any other device of suitable

gradient. The validity of Darcy’s law may be evaluated by accuracy.

measuring the hydraulic conductivity of the specimen at three 5.2.2 Falling Head (Methods B and C)—The system shall

different hydraulic gradients; if all measured values are similar allow for measurement of the applied head loss, thus hydraulic

(within about 25 %), then Darcy’s law may be taken as valid. gradient, to within 65 %. In addition, the ratio of initial head

However, when the hydraulic gradient acting on a test speci- loss divided by final head loss over an interval of time shall be

men is changed, the state of stress will also change, and, if the measured such that this computed ratio is accurate to within

specimen is compressible, the volume of the specimen will 65 %. The head loss shall be measured with a pressure gage,

change. Thus, some change in hydraulic conductivity may electronic pressure transducer, engineer’s scale, graduated

occur when the hydraulic gradient is altered, even in cases pipette, or any other device of suitable accuracy. Falling head

where Darcy’s law is valid. tests may be performed with either a falling headwater and

4.4 This test method provides tools for determining flux and constant tailwater elevation (Method B) or a falling headwater

hydraulic conductivity values for a given GCL under the and rising tailwater elevation (Method C).

followingtwodifferentscenarios,whichshouldbespecifiedby 5.2.3 Constant Rate of Flow (Method D)—The system must

the requester: be capable of maintaining a constant rate of flow through the

4.4.1 Scenario 1—Hydrated/Saturated with Water Prior to specimen to within +5 %. Flow measurement shall be by

Contact with Test Liquid —This scenario simulates the field calibrated syringe, graduated pipette, or other device of suit-

conditions where the GCL is well hydrated with water prior to able accuracy. The head loss across the specimen shall be

contact with actual test liquid. It should be noted that initial measured to an accuracy of 5 % or better using an electronic

degree of saturation/hydration greatly affects the hydraulic pressure transducer or other device of suitable accuracy. More

properties of a GCL product. The test has two phases: (Phase information on testing with a constant rate of flow is given in

1) hydrate, saturate, consolidate and permeate with water as the literature.

Test Liquid 1, and (Phase 2) switch to permeation with test 5.2.4 System De-airing—The hydraulic system shall be

liquid as Test Liquid 2. designed to facilitate rapid and complete removal of free air

4.4.2 Scenario 2—Hydrated/Saturated with Test Liquid bubbles from flow lines.

(Worst Case)—This scenario simulates the field conditions 5.2.5 Back Pressure System—The hydraulic system shall

where the GCLis in contact with test liquid prior to being fully have the capability to apply back-pressure to the specimen to

hydrated with water. It should be noted that this scenario may facilitate saturation. The system shall be capable of maintain-

result in higher flux and hydraulic conductivity values com- ing the applied back-pressure throughout the duration of

paredtoScenario1aschemicalspresentintestliquidmayalter hydraulic conductivity measurements. The back-pressure sys-

the hydration and hydraulic properties of a GCL product. tem shall be capable of applying, controlling, and measuring

5 6

Olson, R. E. and Daniel, D. E., “Measurement of the Hydraulic Conductivity of Olson, H. W., Morin, R. H., and Nichols, R. W., “Flow Pump Applications in

Fine-Grained Soils,” Symposium on Permeability and Groundwater Contaminant TriaxialTesting,” Symposium onAdvanced Triaxial Testing of Soil and Rock,ASTM

Transport, ASTM STP 746, ASTM, 1981, pp. 18–64. STP 977, ASTM, 1988, pp. 68–81.

D6766–02

the back-pressure to 5 % or better of the applied pressure. The no specimen inside and then the hydraulic system filled. If a

back-pressure may be provided by a compressed gas supply constant or falling head test is to be used, the hydraulic

(see Note 1), a deadweight acting on a piston, or any other pressures or heads that will be used in testing a specimen shall

method capable of applying and controlling the back-pressure be applied, and the rate of flow measured with an accuracy of

to the tolerance prescribed in this paragraph. 5 %orbetter.Thisrateofflowshallbeatleasttentimesgreater

than the rate of flow that is measured when a GCLspecimen is

NOTE 1—Application of gas pressure directly to a fluid will dissolve

placed inside the permeameter and the same hydraulic pres-

gas in the fluid. Any suitable technique, including separation of gas and

sures or heads are applied. If a constant rate of flow test is to

liquid phases with a bladder, may be used to minimize dissolution of gas

be used, the rate of flow to be used in testing a specimen shall

in the back-pressure fluid.

be supplied to the permeameter and the head loss measured.

5.3 Flow Measurement System—Both inflow and outflow

The head loss without a specimen shall be less than 0.1 times

volumes shall be measured unless the lack of leakage, conti-

the head loss when a GCL specimen is present.

nuity of flow, and cessation of consolidation or swelling can be

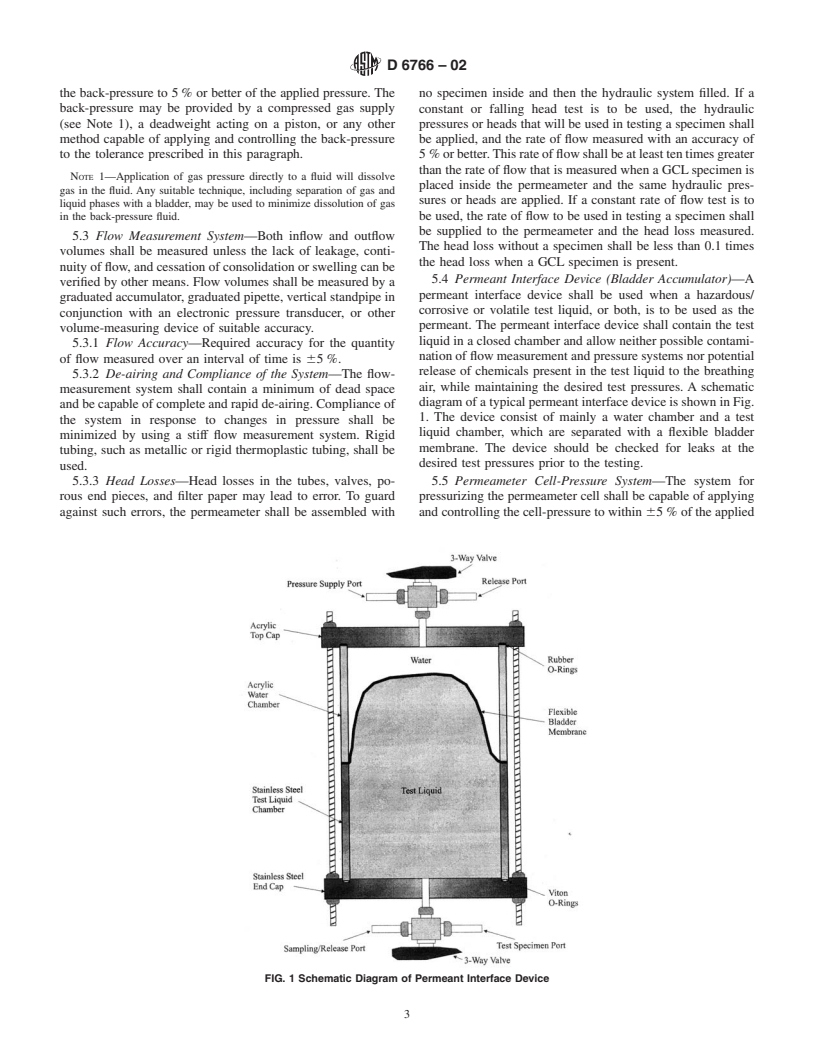

5.4 Permeant Interface Device (Bladder Accumulator)—A

verified by other means. Flow volumes shall be measured by a

permeant interface device shall be used when a hazardous/

graduated accumulator, graduated pipette, vertical standpipe in

corrosive or volatile test liquid, or both, is to be used as the

conjunction with an electronic pressure transducer, or other

permeant. The permeant interface device shall contain the test

volume-measuring device of suitable accuracy.

liquid in a closed chamber and allow neither possible contami-

5.3.1 Flow Accuracy—Required accuracy for the quantity

nation of flow measurement and pressure systems nor potential

of flow measured over an interval of time is 65%.

release of chemicals present in the test liquid to the breathing

5.3.2 De-airing and Compliance of the System—The flow-

air, while maintaining the desired test pressures. A schematic

measurement system shall contain a minimum of dead space

diagram of a typical permeant interface device is shown in Fig.

and be capable of complete and rapid de-airing. Compliance of

1. The device consist of mainly a water chamber and a test

the system in response to changes in pressure shall be

liquid chamber, which are separated with a flexible bladder

minimized by using a stiff flow measurement system. Rigid

membrane. The device should be checked for leaks at the

tubing, such as metallic or rigid thermoplastic tubing, shall be

desired test pressures prior to the testing.

used.

5.3.3 Head Losses—Head losses in the tubes, valves, po- 5.5 Permeameter Cell-Pressure System—The system for

rous end pieces, and filter paper may lead to error. To guard pressurizing the permeameter cell shall be capable of applying

against such errors, the permeameter shall be assembled with and controlling the cell-pressure to within 65 % of the applied

FIG. 1 Schematic Diagram of Permeant Interface Device

D6766–02

pressure. However, the effective stress on the test specimen The piston or extensometer should pass through a bushing and

(which is the difference between the cell-pressure and the pore seal incorporated into the top plate and shall be loaded with

waterpressure)shallbemaintainedtothedesiredvaluewithan

sufficient force to compensate for the cell-pressure acting over

accuracyof 65 %orbetter.Thedeviceforpressurizingthecell the cross-sectional area of the piston where it passes through

may consist of a reservoir connected to the permeameter cell

the seal. If deformations are measured, the deformation indi-

and partially filled with de-aired water, with the upper part of

cator shall be a dial indicator or cathetometer graduated to 0.3

the reservoir connected to a compressed gas supply or other

mm (0.01 in.) or better and ha

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.