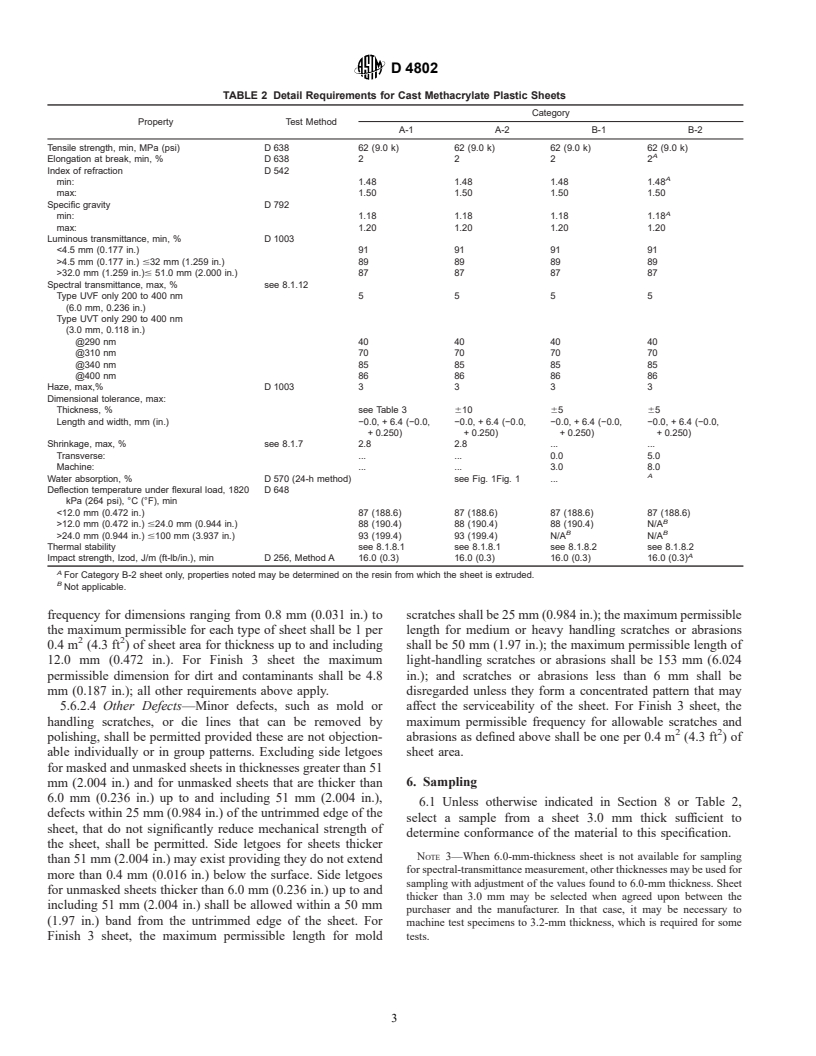

ASTM D4802-01

(Specification)Standard Specification for Poly(Methyl Methacrylate) Acrylic Plastic Sheet

Standard Specification for Poly(Methyl Methacrylate) Acrylic Plastic Sheet

SCOPE

1.1 This specification covers monolithic methacrylate sheets produced by various processes. For this specification, methacrylate sheet shall be composed of polymerized acrylic monomers of which at least 80 % shall be methyl methacrylate.

Note 1—This specification is intended to consolidate the requirements of the Cast Methacrylate Plastic Sheets portion of discontinued Fed. Spec. L-P-391D, discontinued Specification D 702. Cast Methacrylate Plastic Sheets, Rods, Tubes and Shapes, and discontinued Specification D 1547, Extruded Acrylic Plastic Sheet.

1.2 This specification is intended to cover acrylic sheet for general-purpose applications. For specialty applications consult the appropriate use standards.

1.3 The following safety hazards caveat pertains only to the test methods portion, Section 8, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.4 Acrylic sheet is used frequently in applications in which extreme clarity, lack of optical distortion and absence of any foreign particulate matter are of primary significance. Reground material may be used as long as careful control is used to eliminate adverse effects on these properties. The use of recycled material in type B-1 and B-2 sheet, may have adverse effects on these properties which would preclude its use in most cases. The use of recycled or reground material is not possible for type A-1 and A-2 materials since the sheet is produced directly from monomer

Note 2—This standard is similar to ISO 7823-1:1987 (E) in title only. The technical content is significantly different.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

An American National Standard

Designation: D 4802 – 01

Standard Specification for

1

Poly(Methyl Methacrylate) Acrylic Plastic Sheet

This standard is issued under the fixed designation D 4802; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope * D 542 Test Methods for Index of Refraction of Transparent

2

Organic Plastic

1.1 This specification covers monolithic methacrylate sheets

2

D 570 Test Method for Water Absorption of Plastics

produced by various processes. For this specification, meth-

2

D 638 Test Method for Tensile Properties of Plastics

acrylate sheet shall be composed of polymerized acrylic

D 648 Test Method for Deflection Temperature of Plastics

monomers of which at least 80 % shall be methyl methacrylate.

2

Under Flexural Load in the Edgewise Position

NOTE 1—This specification is intended to consolidate the requirements

D 792 Test Methods for Density and Specific Gravity (Rela-

of the Cast Methacrylate Plastic Sheets portion of discontinued Fed. Spec.

2

tive Density) of Plastics by Displacement

L-P-391D, discontinued Specification D 702. Cast Methacrylate Plastic

2

D 883 Terminology Relating to Plastics

Sheets, Rods, Tubes and Shapes, and discontinued Specification D 1547,

D 1003 Test Method for Haze and Luminous Transmittance

Extruded Acrylic Plastic Sheet.

2

of Transparent Plastics

1.2 This specification is intended to cover acrylic sheet for

D 1044 Test Method for Resistance of Transparent Plastics

general-purpose applications. For specialty applications con-

2

to Surface Abrasion

sult the appropriate use standards.

D 1308 Test Method for Effect of Household Chemicals on

1.3 The following safety hazards caveat pertains only to the

3

Clear and Pigmented Organic Finishes

test methods portion, Section 8, of this specification: This

D 2565 Practice for Xenon Arc Exposure of Plastics In-

standard does not purport to address all of the safety concerns,

4

tended for Outdoor Applications

if any, associated with its use. It is the responsibility of the user

D 3002 Guide for Evaluation of Coatings Applied to Plas-

of this standard to establish appropriate safety and health

3

tics

practices and determine the applicability of regulatory limita-

5

D 3359 Test Method for Measuring Adhesion by Tape Test

tions prior to use.

4

D 3892 Practice for Packaging/Packing of Plastics

1.4 Acrylic sheet is used frequently in applications in which

E 29 Practice for Using Significant Digits in Test Data to

extreme clarity, lack of optical distortion and absence of any

6

Determine Conformance with Specifications

foreign particulate matter are of primary significance. Re-

2.2 ISO Standard:

ground material may be used as long as careful control is used

ISO 7823-1:1987 (E) Plastics—Poly(Methyl Methacrylate)

to eliminate adverse effects on these properties. The use of

7

Sheets—Types, Dimensions, and Characteristics

recycled material in type B-1 and B-2 sheet, may have adverse

effects on these properties which would preclude its use in

3. Terminology

most cases. The use of recycled or reground material is not

3.1 Definitions:

possible for type A-1 and A-2 materials since the sheet is

3.1.1 General—The definitions given in Terminology

produced directly from monomer

D 883 are applicable to this specification.

NOTE 2—This standard is similar to ISO 7823-1:1987 (E) in title only.

3.2 Definitions of Terms Specific to This Standard:

The technical content is significantly different.

3.2.1 bow warp, n—distortion in the form of a simple curve

or arc extending across the sheet and displaced from the

2. Referenced Documents

horizontal when the sheet is laying flat.

2.1 ASTM Standards:

3.2.2 edge kink warpage, n—distortion in the form of a

D 256 Test Methods for Determining the Izod Pendulum

twist, wrinkle, or scallop occurring along the perimeter of the

2

Impact Resistance of Plastics

sheet.

1 3

This specification is under the jurisdiction of ASTM Committee D20 on Annual Book of ASTM Standards, Vol 06.02.

4

Plastics and is the direct responsibility of Subcommittee D20.15 on Thermoplastic Annual Book of ASTM Standards, Vol 08.02.

5

Materials. Annual Book of ASTM Standards, Vol 06.01.

6

Current edition approved October 10, 2001. Published December 2001. Origi- Annual Book of ASTM Standards, Vol 14.02.

7

nally published as D 4802 – 88. Last previous edition D 4802 – 94. Available from American National Standards Institute, 25 W. 43rd St., 4th

2

Annual Book of ASTM Standards, Vol 08.01. Floor, New York, NY 10036.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.