ASTM D1777-96(2015)

(Test Method)Standard Test Method for Thickness of Textile Materials

Standard Test Method for Thickness of Textile Materials

SIGNIFICANCE AND USE

5.1 This test method is considered satisfactory for acceptance testing of commercial shipments since current estimates of between-laboratory precision are acceptable, and this test method is used extensively in the trade for acceptance testing.

5.1.1 In case of a dispute arising from differences in reported test results when using this test method for acceptance testing of commercial shipments, the purchaser and the supplier should conduct comparative tests to determine if there is a statistical bias between their laboratories. Competent statistical assistance is recommended for the investigation of bias. As a minimum, the two parties should take a group of test specimens that are as homogeneous as possible and that are from a lot of material of the type in question. Test specimens then should be randomly assigned in equal numbers to each laboratory for testing. The average results from the two laboratories should be compared using the appropriate statistical analysis and an acceptable probability level chosen by the two parties before testing is begun. If a bias is found, either its cause must be found and corrected, or the purchaser and the supplier must agree to interpret future test results with consideration to the known bias.

5.2 Thickness is one of the basic physical properties of textile materials. In certain industrial applications, the thickness may require rigid control within specified limits. Bulk and warmth properties of textile materials are often estimated from their thickness values, and thickness is also useful in measuring some performance characteristics, such as before and after abrasion and shrinkage.

5.3 The thickness value of most textile materials will vary considerably depending on the pressure applied to the specimen at the time the thickness measurement is taken. In all cases, the apparent thickness varies inversely with the pressure applied. For this reason, it is essential that the pressure be specified when discussing or listi...

SCOPE

1.1 This test method covers the measurement of the thickness of most textile materials.

1.2 This test method applies to most fabrics including woven fabrics, air bag fabrics, blankets, napped fabrics, knitted fabrics, layered fabrics, and pile fabrics. The fabrics may be untreated, heavily sized, coated, resin-treated, or otherwise treated. Instructions are provided for testing thickness, except as provided for in another standard such as listed in Section 2.

1.3 The values stated in SI units are to be regarded as the standard. The values stated in inch-pound may be approximate.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D1777 −96 (Reapproved 2015)

Standard Test Method for

Thickness of Textile Materials

This standard is issued under the fixed designation D1777; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 This test method covers the measurement of the thick-

3.1 Definitions—For definitions of textile terms used in this

ness of most textile materials.

test method, see Terminology D123.

1.2 This test method applies to most fabrics including 3.1.1 The following terms are relevant to this standard:

cross-machine direction, machine direction, pressure, and

wovenfabrics,airbagfabrics,blankets,nappedfabrics,knitted

fabrics, layered fabrics, and pile fabrics. The fabrics may be thickness.

untreated, heavily sized, coated, resin-treated, or otherwise

treated. Instructions are provided for testing thickness, except 4. Summary of Test Method

as provided for in another standard such as listed in Section 2.

4.1 A specimen is placed on the base of a thickness gauge

1.3 The values stated in SI units are to be regarded as the

and a weighted presser foot lowered. The displacement be-

standard.Thevaluesstatedininch-poundmaybeapproximate.

tweenthebaseandthepresserfootismeasuredasthethickness

of the specimen.

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

5. Significance and Use

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

5.1 This test method is considered satisfactory for accep-

bility of regulatory limitations prior to use.

tance testing of commercial shipments since current estimates

of between-laboratory precision are acceptable, and this test

2. Referenced Documents

method is used extensively in the trade for acceptance testing.

2.1 ASTM Standards:

5.1.1 In case of a dispute arising from differences in

D123 Terminology Relating to Textiles

reported test results when using this test method for acceptance

D1776 Practice for Conditioning and Testing Textiles

testing of commercial shipments, the purchaser and the sup-

D2904 Practice for Interlaboratory Testing of a Textile Test

plier should conduct comparative tests to determine if there is

Method that Produces Normally Distributed Data (With-

a statistical bias between their laboratories. Competent statis-

drawn 2008)

tical assistance is recommended for the investigation of bias.

D2906 Practice for Statements on Precision and Bias for

As a minimum, the two parties should take a group of test

Textiles (Withdrawn 2008)

specimens that are as homogeneous as possible and that are

from a lot of material of the type in question. Test specimens

2.2 ASTM Adjuncts:

then should be randomly assigned in equal numbers to each

TEX-PAC

laboratory for testing. The average results from the two

laboratories should be compared using the appropriate statis-

tical analysis and an acceptable probability level chosen by the

This test method is under the jurisdiction ofASTM Committee D13 on Textiles

two parties before testing is begun. If a bias is found, either its

and is the direct responsibility of Subcommittee D13.59 on Fabric Test Methods,

cause must be found and corrected, or the purchaser and the

General.

Current edition approved July 1, 2015. Published September 2015. Originally

supplier must agree to interpret future test results with consid-

ɛ1

approved in 1960. Last previous edition approved in 2011 as D1777 – 96(2011) .

eration to the known bias.

DOI: 10.1520/D1777-96R15.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

5.2 Thickness is one of the basic physical properties of

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

textile materials. In certain industrial applications, the thick-

Standards volume information, refer to the standard’s Document Summary page on

ness may require rigid control within specified limits. Bulk and

the ASTM website.

The last approved version of this historical standard is referenced on

warmth properties of textile materials are often estimated from

www.astm.org.

theirthicknessvalues,andthicknessisalsousefulinmeasuring

A PC program on floppy disk for analyzing Committee D13 interlaboratory

1 some performance characteristics, such as before and after

data are available from ASTM Headquarters. For a 3 ⁄2-in. disk, request PCN:12-

429040-18. For a 5 ⁄4-in. disk, request PCN:12-429041-18. abrasion and shrinkage.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D1777−96 (2015)

5.3 The thickness value of most textile materials will vary 7. Sampling and Test Specimens

considerably depending on the pressure applied to the speci-

7.1 Lot Sample—As a lot sample for acceptance testing,

men at the time the thickness measurement is taken. In all

randomly select the number of rolls or pieces of fabric directed

cases, the apparent thickness varies inversely with the pressure

in an applicable material specification or other agreement

applied. For this reason, it is essential that the pressure be

between the purchaser and the supplier. Consider the rolls or

specified when discussing or listing any thickness value.

pieces of fabric to be the primary sampling units. In the

absence of such an agreement, take the number of fabric rolls

5.4 Whenusingthistestmethodformeasuringthethickness

specifed in Table 2.

of textile materials, the primary method for the specific

material such as listed in the Referenced Document section

NOTE 1—An adequate specification or other agreement between the

shall take precedence over the directions described in this test

purchaser and the supplier requires taking into account the variability

method, unless specifically provided for in that test method. between rolls or pieces of fabric and between specimens from a swatch

from a roll or piece of fabric to provide a sampling plan with a meaningful

This test method is used in its entirety when no test method for

producer’s risk, consumer’s risk, acceptable quality level, and limiting

measuring thickness is available for the specific material to be

quality level.

tested or unless otherwise specified in a material specification

7.2 Laboratory Sample—For acceptance testing, take a

or contract order.

swatch extending the width of the fabric and approximately 1

m (1 yd) along the machine direction from each roll or piece in

6. Apparatus

the lot sample. For rolls of fabric, take a sample that will

6.1 Thickness Gauge, having dimensions appropriate to the

exclude fabric from the outer wrap of the roll or the inner wrap

material to be tested as specified in Table 1, unless otherwise

aroundthecoreoftherolloffabric.Forfinishedgarments,take

specifiedinamaterialspecificationorcontractorder.Acircular

a piece of sufficient size to provide the number of specimens

presserfootcommonlyisusedformostmaterials;however,for

required in 7.3.

certain materials, such as narrow tapes, a rectangular foot is

7.3 Test Specimens—From each laboratory sampling unit,

moreappropriatewhenagreeduponbetweenthepurchaserand

taketenspecimens.Usethecuttingdieortemplatedescribedin

the supplier.

6.2. It is permissible to make thickness tests of a textile

6.1.1 Automatic Microprocessor Data Gathering Systems,

material without cutting, providing it can be maintained

optional.

without distortion in a plane parallel to the presser foot and

6.1.2 Spring Force or Compression Test Apparatus, may be

anvil while making measurements.

substituted for the dead-weight-type thickness gauge providing

7.3.1 Cutting Test Specimens—When cutting specimens, cut

they meet the specified conditions cited in Table 1.

having minimum dimensions at least 20 % greater than any

6.2 Cutting Dies or Templates, to cut specimens having dimension of the presser foot to be used. Label to maintain

minimum dimensions at least 20 % greater than any dimension specimen identity.

of the presser foot to be used in measuring the thickness 7.3.1.1 Take specimens, representing a broad distribution

(optional). across the width and length, and preferably along the diagonal,

TABLE 1 Designated Gauges and Gauge Specifications for Measuring Thickness of Textiles

Testing Material Gauge Presser Foot Anvil/Foot Foot to Anvil

Anvil Applied Pressure Readability

A B

Option Type Type Diameter Parallelism Surface Parallelism

1 Woven fabrics dead-weight 28.7 ± 0.02 mm 38 mm D, or greater 0.01 mm 0.002 mm 4.14 ± 0.21 kPa 0.02 mm

Knitted fabrics (1.129 ± 0.001 in.) (1.629 in. D, or greater) (0.0005 in.) (0.0001 in.) (0.60 ± 0.03 psi) (0.001 in.)

Textured fabrics

2 Coated fabrics dead-weight 9.5 ± 0.02 mm 38 mm D, or greater 0.01 mm 0.002 mm 23.4 ± 0.7 kPa 0.02 mm

Narrow fabrics (0.375 ± 0.001 in.) (1.629 in. D, or greater) (0.0005 in.) (0.0001 in.) (3.4± 0.1 psi) (0.001 in.)

Webbings

Tapes

Ribbons

Braids

3 Films dead-weight 6.3 ± 0.02 mm 19 mm D, or greater 0.002 mm 0.002 mm 172 ± 14 kPa 0.002 mm

Glass cloths (0.250 ± 0.001 in.) (0.750 in. D, or greater) (0.0001 in.) (0.0001 in.) (25±2psi) (0.0001 in.)

Glass tapes

4 Glass fiber mat dead-weight (2.25 ± 0.001 in.) (2.75 in. D, or greater) 0.01 mm 0.002 mm 18.9 ± 0.7 kPa 0.02 mm

(0.0005 in.) (0.0001 in.) (2.75 ± 0.1 psi) (0.001 in.)

5 Blankets dead-weight 28.7 ± 0.02 mm 38 mm D, or greater 0.01 mm 0.002 mm 0.7 ± 0.07 kPa 0.02 mm

Pile fabrics (1.129 ± 0.001 in.) (1.629 in. D, or greater) (0.0005 in.) (0.0001 in.) (0.1 ± 0.01 psi) (0.001 in.)

Napped fabrics also 7.58 ± 0.21

kPa (1.1 ± 0.03 psi)

A

When testing fabrics made with textured yarns or open-end spun yarns, primary consideration should be given to the pressure applied in Option 1, with respect to the

size of the presser foot used.

B

Other spring force or compression test apparatus that meet the stated specifications can be used.

D1777−96 (2015)

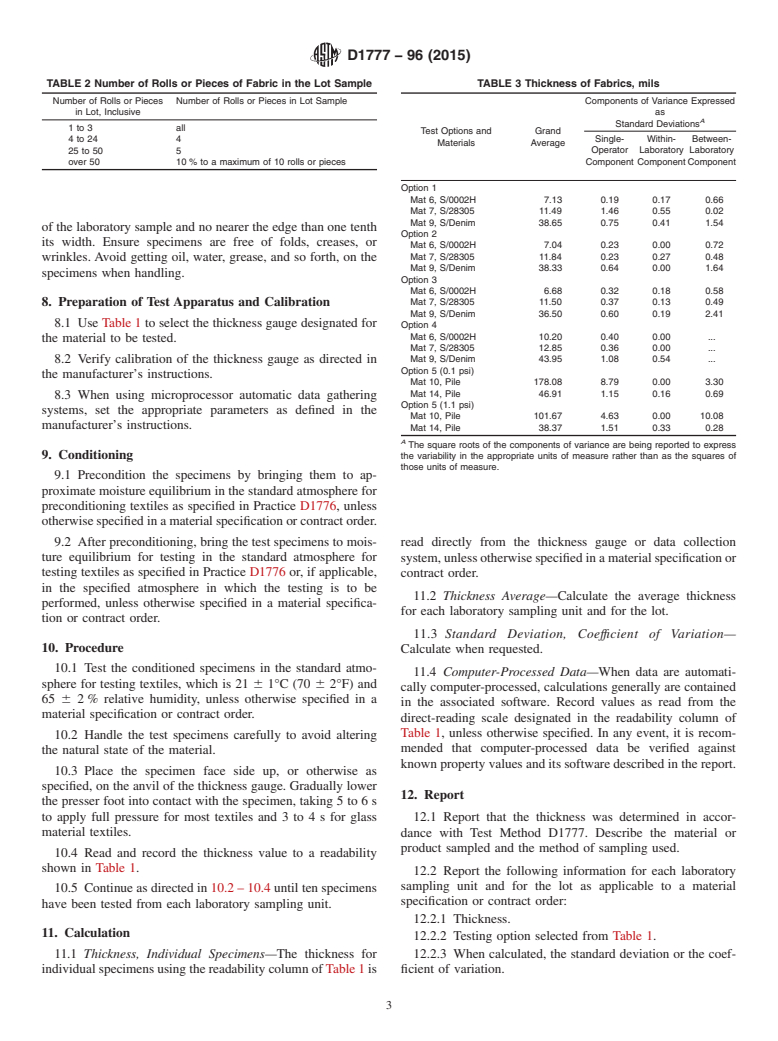

TABLE 2 Number of Rolls or Pieces of Fabric in the Lot Sample TABLE 3 Thickness of Fabrics, mils

Number of Rolls or Pieces Number of Rolls or Pieces in Lot Sample Components of Variance Expressed

in Lot, Inclusive as

A

Standard Deviations

1to3 all

Test Options and Grand

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: D1777 − 96 (Reapproved 2011) D1777 − 96 (Reapproved 2015)

Standard Test Method for

Thickness of Textile Materials

This standard is issued under the fixed designation D1777; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Terminology was removed in order to comply with the D13 Terminology Policy.

1. Scope

1.1 This test method covers the measurement of the thickness of most textile materials.

1.2 This test method applies to most fabrics including woven fabrics, air bag fabrics, blankets, napped fabrics, knitted fabrics,

layered fabrics, and pile fabrics. The fabrics may be untreated, heavily sized, coated, resin-treated, or otherwise treated.

Instructions are provided for testing thickness, except as provided for in another standard such as listed in Section 2.

1.3 The values stated in SI units are to be regarded as the standard. The values stated in inch-pound may be approximate.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

D123 Terminology Relating to Textiles

D1776 Practice for Conditioning and Testing Textiles

D2904 Practice for Interlaboratory Testing of a Textile Test Method that Produces Normally Distributed Data (Withdrawn 2008)

D2906 Practice for Statements on Precision and Bias for Textiles (Withdrawn 2008)

2.2 ASTM Adjuncts:

TEX-PAC

3. Terminology

3.1 Definitions—For definitions of textile terms used in this test method, see Terminology D123.

3.1.1 The following terms are relevant to this standard: cross-machine direction, machine direction, pressure, and thickness.

4. Summary of Test Method

4.1 A specimen is placed on the base of a thickness gauge and a weighted presser foot lowered. The displacement between the

base and the presser foot is measured as the thickness of the specimen.

5. Significance and Use

5.1 This test method is considered satisfactory for acceptance testing of commercial shipments since current estimates of

between-laboratory precision are acceptable, and this test method is used extensively in the trade for acceptance testing.

5.1.1 In case of a dispute arising from differences in reported test results when using this test method for acceptance testing of

commercial shipments, the purchaser and the supplier should conduct comparative tests to determine if there is a statistical bias

between their laboratories. Competent statistical assistance is recommended for the investigation of bias. As a minimum, the two

parties should take a group of test specimens that are as homogeneous as possible and that are from a lot of material of the type

This test method is under the jurisdiction of ASTM Committee D13 on Textiles and is the direct responsibility of Subcommittee D13.59 on Fabric Test Methods, General.

Current edition approved May 1, 2011July 1, 2015. Published January 2007September 2015. Originally approved in 1960. Discontinued in November 1995 and reinstated

ɛ1

as D1777 – 96.Last previous edition approved in 20072011 as D1777 – 96(2007).(2011) . DOI: 10.1520/D1777-96R11E01.10.1520/D1777-96R15.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

The last approved version of this historical standard is referenced on www.astm.org.

4 1

A PC program on floppy disk for analyzing Committee D13 interlaboratory data are available from ASTM Headquarters. For a 3 ⁄2-in. disk, request PCN:12-429040-18.

For a 5 ⁄4-in. disk, request PCN:12-429041-18.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D1777 − 96 (2015)

in question. Test specimens then should be randomly assigned in equal numbers to each laboratory for testing. The average results

from the two laboratories should be compared using the appropriate statistical analysis and an acceptable probability level chosen

by the two parties before testing is begun. If a bias is found, either its cause must be found and corrected, or the purchaser and

the supplier must agree to interpret future test results with consideration to the known bias.

5.2 Thickness is one of the basic physical properties of textile materials. In certain industrial applications, the thickness may

require rigid control within specified limits. Bulk and warmth properties of textile materials are often estimated from their thickness

values, and thickness is also useful in measuring some performance characteristics, such as before and after abrasion and shrinkage.

5.3 The thickness value of most textile materials will vary considerably depending on the pressure applied to the specimen at

the time the thickness measurement is taken. In all cases, the apparent thickness varies inversely with the pressure applied. For

this reason, it is essential that the pressure be specified when discussing or listing any thickness value.

5.4 When using this test method for measuring the thickness of textile materials, the primary method for the specific material

such as listed in the Referenced Document section shall take precedence over the directions described in this test method, unless

specifically provided for in that test method. This test method is used in its entirety when no test method for measuring thickness

is available for the specific material to be tested or unless otherwise specified in a material specification or contract order.

6. Apparatus

6.1 Thickness Gauge, having dimensions appropriate to the material to be tested as specified in Table 1, unless otherwise

specified in a material specification or contract order. A circular presser foot commonly is used for most materials; however, for

certain materials, such as narrow tapes, a rectangular foot is more appropriate when agreed upon between the purchaser and the

supplier.

6.1.1 Automatic Microprocessor Data Gathering Systems, optional.

6.1.2 Spring Force or Compression Test Apparatus, may be substituted for the dead-weight-type thickness gauge providing they

meet the specified conditions cited in Table 1.

6.2 Cutting Dies or Templates, to cut specimens having minimum dimensions at least 20 % greater than any dimension of the

presser foot to be used in measuring the thickness (optional).

7. Sampling and Test Specimens

7.1 Lot Sample—As a lot sample for acceptance testing, randomly select the number of rolls or pieces of fabric directed in an

applicable material specification or other agreement between the purchaser and the supplier. Consider the rolls or pieces of fabric

to be the primary sampling units. In the absence of such an agreement, take the number of fabric rolls specifed in Table 2.

NOTE 1—An adequate specification or other agreement between the purchaser and the supplier requires taking into account the variability between rolls

or pieces of fabric and between specimens from a swatch from a roll or piece of fabric to provide a sampling plan with a meaningful producer’s risk,

consumer’s risk, acceptable quality level, and limiting quality level.

7.2 Laboratory Sample—For acceptance testing, take a swatch extending the width of the fabric and approximately 1 m (1 yd)

along the machine direction from each roll or piece in the lot sample. For rolls of fabric, take a sample that will exclude fabric

TABLE 1 Designated Gauges and Gauge Specifications for Measuring Thickness of Textiles

Testing Material Gauge Presser Foot Anvil/Foot Foot to Anvil

Anvil Applied Pressure Readability

A B

Option Type Type Diameter Parallelism Surface Parallelism

1 Woven fabrics dead-weight 28.7 ± 0.02 mm 38 mm D, or greater 0.01 mm 0.002 mm 4.14 ± 0.21 kPa 0.02 mm

Knitted fabrics (1.129 ± 0.001 in.) (1.629 in. D, or greater) (0.0005 in.) (0.0001 in.) (0.60 ± 0.03 psi) (0.001 in.)

Textured fabrics

2 Coated fabrics dead-weight 9.5 ± 0.02 mm 38 mm D, or greater 0.01 mm 0.002 mm 23.4 ± 0.7 kPa 0.02 mm

Narrow fabrics (0.375 ± 0.001 in.) (1.629 in. D, or greater) (0.0005 in.) (0.0001 in.) (3.4± 0.1 psi) (0.001 in.)

Webbings

Tapes

Ribbons

Braids

3 Films dead-weight 6.3 ± 0.02 mm 19 mm D, or greater 0.002 mm 0.002 mm 172 ± 14 kPa 0.002 mm

Glass cloths (0.250 ± 0.001 in.) (0.750 in. D, or greater) (0.0001 in.) (0.0001 in.) (25 ± 2 psi) (0.0001 in.)

Glass tapes

4 Glass fiber mat dead-weight (2.25 ± 0.001 in.) (2.75 in. D, or greater) 0.01 mm 0.002 mm 18.9 ± 0.7 kPa 0.02 mm

(0.0005 in.) (0.0001 in.) (2.75 ± 0.1 psi) (0.001 in.)

5 Blankets dead-weight 28.7 ± 0.02 mm 38 mm D, or greater 0.01 mm 0.002 mm 0.7 ± 0.07 kPa 0.02 mm

Pile fabrics (1.129 ± 0.001 in.) (1.629 in. D, or greater) (0.0005 in.) (0.0001 in.) (0.1 ± 0.01 psi) (0.001 in.)

Napped fabrics also 7.58 ± 0.21

kPa (1.1 ± 0.03 psi)

A

When testing fabrics made with textured yarns or open-end spun yarns, primary consideration should be given to the pressure applied in Option 1, with respect to the

size of the presser foot used.

B

Other spring force or compression test apparatus that meet the stated specifications can be used.

D1777 − 96 (2015)

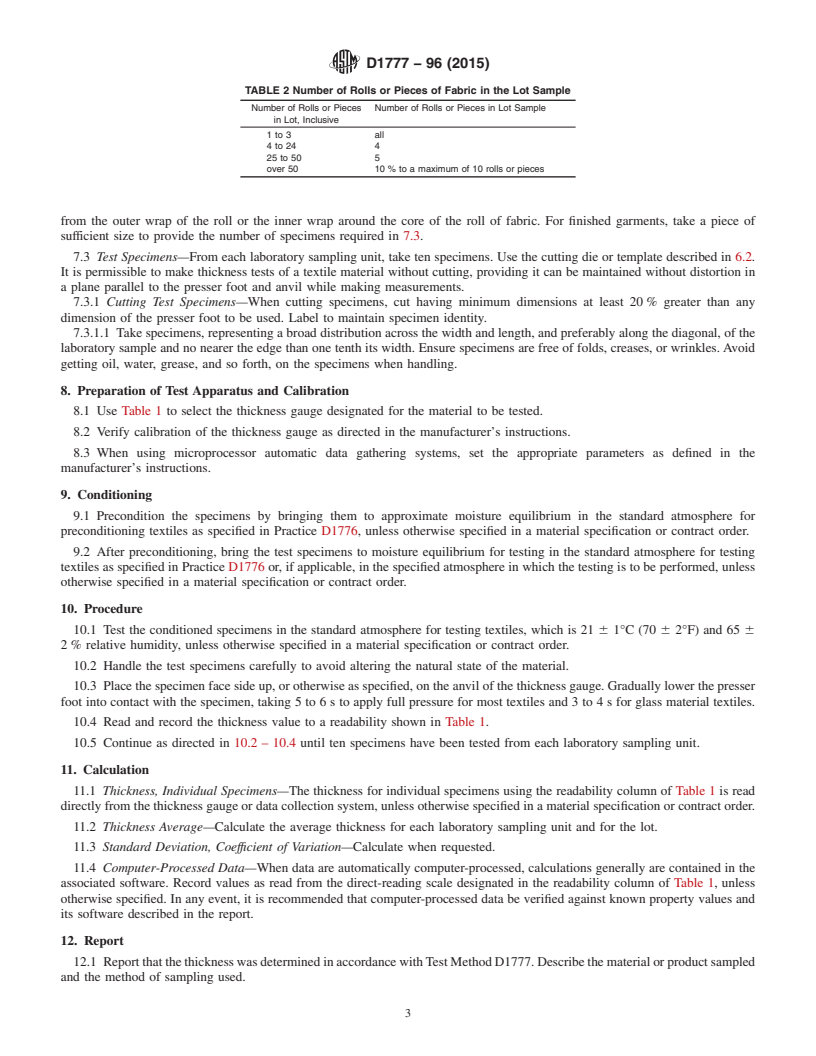

TABLE 2 Number of Rolls or Pieces of Fabric in the Lot Sample

Number of Rolls or Pieces Number of Rolls or Pieces in Lot Sample

in Lot, Inclusive

1 to 3 all

4 to 24 4

25 to 50 5

over 50 10 % to a maximum of 10 rolls or pieces

from the outer wrap of the roll or the inner wrap around the core of the roll of fabric. For finished garments, take a piece of

sufficient size to provide the number of specimens required in 7.3.

7.3 Test Specimens—From each laboratory sampling unit, take ten specimens. Use the cutting die or template described in 6.2.

It is permissible to make thickness tests of a textile material without cutting, providing it can be maintained without distortion in

a plane parallel to the presser foot and anvil while making measurements.

7.3.1 Cutting Test Specimens—When cutting specimens, cut having minimum dimensions at least 20 % greater than any

dimension of the presser foot to be used. Label to maintain specimen identity.

7.3.1.1 Take specimens, representing a broad distri

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.