ASTM C348-02

(Test Method)Standard Test Method for Flexural Strength of Hydraulic-Cement Mortars

Standard Test Method for Flexural Strength of Hydraulic-Cement Mortars

SIGNIFICANCE AND USE

This test method provides a means for determining the flexural strength of hydraulic cement mortars. Portions of the mortar prisms tested in flexure according to this test method may be used for the determination of compressive strength in accordance with Test Method C 349.

The values are determined from this test method for research or reference purposes only and are not used for determining compliance with specification requirements.

SCOPE

1.1 This test method covers the determination of the flexural strength of hydraulic-cement mortars.

1.2 The values stated in SI units are to be regarded as the standard. The values shown in parentheses are for information only.

1.3 Values in SI units shall be obtained by measurement in SI units or by appropriate conversion, using the Rules for Conversion and rounding given in Standard IEEE/ASTM SI 10, of measurements made in other units.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. (Warning— Fresh hydraulic cementitious mixtures are caustic and may cause chemical burns to skin and tissue upon prolonged exposure.)

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C348–02

Standard Test Method for

1

Flexural Strength of Hydraulic-Cement Mortars

This standard is issued under the fixed designation C348; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Summary of Test Method

1.1 Thistestmethodcoversthedeterminationoftheflexural 3.1 The test mortar used consists of 1 part cement and 2.75

strength of hydraulic-cement mortars. parts of sand proportion by mass. Portland or air-entraining

1.2 The values stated in SI units are to be regarded as the portland cements are mixed at specified water-cement ratios.

standard. The values shown in parentheses are for information Water content of other cements is that sufficient to obtain a

only. flowof110 65%with25dropsoftheflowtable.Testprisms,

1.3 Values in SI units shall be obtained by measurement in 40 by 40 by 160-mm are molded by tamping in two layers.

SI units or by appropriate conversion, using the Rules for Prisms are cured one day in the molds and stripped until tested

Conversion and rounding given in Standard IEEE/ASTM SI by center point loading.

10, of measurements made in other units.

4. Significance and Use

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the 4.1 This test method provides a means for determining the

flexural strength of hydraulic cement mortars. Portions of the

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica- mortar prisms tested in flexure according to this test method

may be used for the determination of compressive strength in

bility of regulatory limitations prior to use. (Warning—Fresh

hydraulic cementitious mixtures are caustic and may cause accordance with Test Method C349.

2

4.2 The values are determined from this test method for

chemical burns to skin and tissue upon prolonged exposure. )

research or reference purposes only and are not used for

2. Referenced Documents

determining compliance with specification requirements.

2.1 ASTM Standards:

5. Apparatus

C109/C109M Test Method for Compressive Strength of

Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube 5.1 Weights, Weighing Devices and Glass Graduates, shall

3

conform to the Apparatus Section of Test Method C109/

Specimens)

C230 Specification for Flow Table for Use in Tests of C109M.

3

5.2 Mixer,BowlandPaddle,anelectricallydrivenmechani-

Hydraulic Cement

C305 PracticeforMechanicalMixingofHydraulicCement cal mixer of the type equipped with paddle and mixing bowl,

3

as specified in the Apparatus Section of Practice C305.

Pastes and Mortars of Plastic Consistency

C349 Test Method for Compressive Strength of Hydraulic 5.3 Flow Table and Flow Mold, shall conform to Specifica-

tion C230.

Cement Mortars (Using Portions of Prisms Broken in

3

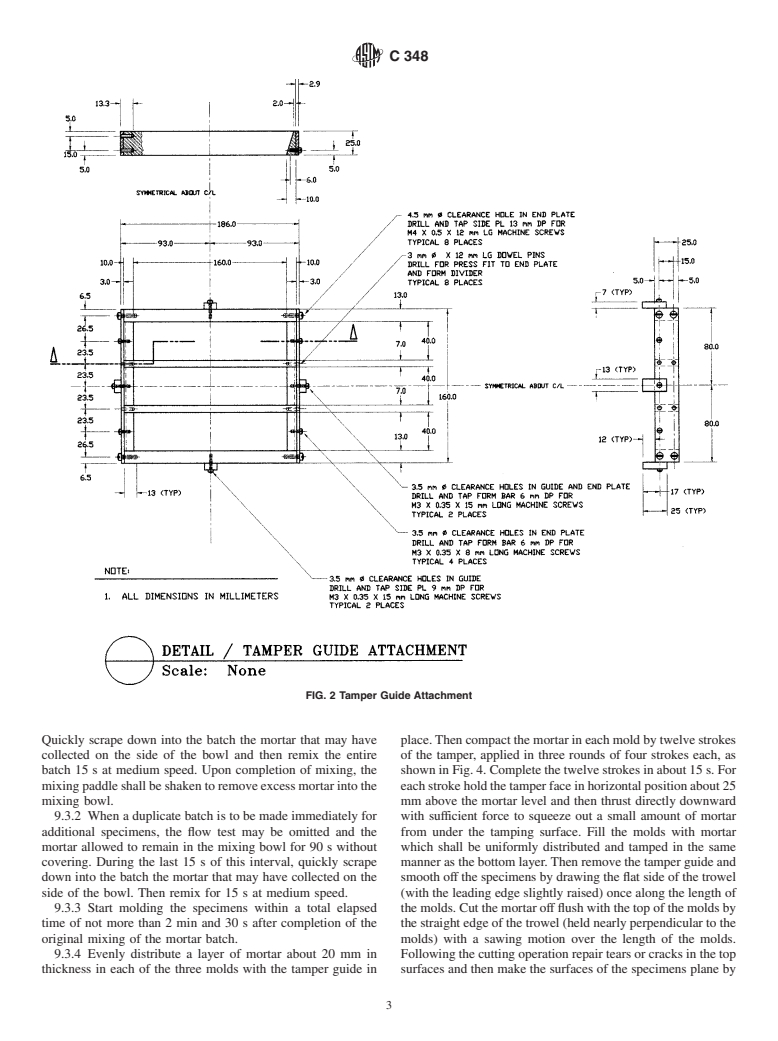

Flexure) 5.4 Specimen Molds—Molds for the 40 by 40 by 160-mm

prism specimens shall be triple-gang molds and shall be so

C670 Practice for Preparing Precision and Bias Statements

4

for Test Methods for Construction Materials designed that the specimens will be molded with their longi-

3

tudinal axes in a horizontal position. The molds shall be made

C778 Specification for Standard Sand

IEEE/ASTM SI 10 Standard for Use of the International of a hard metal, not attacked by cement mortar, and with a

5

Rockwell hardness of not less than HRB 55. The parts of the

System of Units (SI): The Modern Metric System

molds shall be matchmarked and, when assembled, shall be

tight-fittingandpositivelyheldtogether.Thesidesofthemolds

1

ThistestmethodisunderthejurisdictionofASTMCommitteeC01onCement

shall be sufficiently rigid to prevent spreading or warping. The

and is the direct responsibility of Subcommittee C01.27 on Strength.

interior faces of the molds shall be plane surfaces with a

Current edition approved June 10, 2002. Published August 2002. Originally

permissible variation, in any 50-mm line on a surface, of 0.03

published as C348–54 T. Last previous edition C348–97.

2

See the section on Safety, Manual of Cement Testing, Annual Book of ASTM

mmfornewmoldsand0.05mmformoldsinuse.Thedistance

Standards, Vol 04.01.

between opposite sides shall be 40 6 0.13 mm for new molds

3

Annual Book of ASTM Standards, Vol 04.01.

4

and 40 6 0.3 mm for molds in use. The height of the molds

Annual Book of ASTM Standards, Vol 04.02.

5

Annual Book of ASTM Standards, Vol 14.04. shall be 40 mm with permissible variations of+0.25 and−0.15

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 -------

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.