ASTM A513-08a

(Specification)Standard Specification for Electric-Resistance-Welded Carbon and Alloy Steel Mechanical Tubing

Standard Specification for Electric-Resistance-Welded Carbon and Alloy Steel Mechanical Tubing

ABSTRACT

This specification covers round, square, rectangular, and special shape electric-resistance-welded carbon and alloy steel mechanical tubing produced by hot- or cold-rolling. The types of tubing covered here are: Type 1a, as-welded from hot-rolled steel (with mill scale); Type 1b, as-welded from hot-rolled pickled and oiled steel (mill scale removed); Type 2, as-welded from cold-rolled steel; Type 3, sink-drawn hot-rolled steel; Type 4, sink-drawn cold-rolled steel; Type 5, drawn over a mandrel; and Type 6, special smooth inside diameter. Heat and product analyses shall be made to determine the percentages of chemical elements, to which the steel specimens shall conform to. Tubing shall be free of injurious defects and shall have a workmanlike finish. When specified, tubing shall be coated with a film of rust retarding oil before shipping.

SCOPE

1.1 This specification covers electric-resistance-welded carbon and alloy steel tubing for use as mechanical tubing.

1.2 This specification covers mechanical tubing made from hot- or cold-rolled steel.

1.3 This specification covers round, square, rectangular, and special shape tubing.

Type

Size Range

(Round Tubing)

Electric-Resistance-Welded Tubing from Hot-Rolled Steel

outside diameter from ½

to 15 in. (19.0 to 381.0 mm) wall from 0.065 to 0.650 in.

(1.65 to 16.50 mm) Electric-Resistance-Welded Tubing from Cold-Rolled Steel

outside diameter from 3/8to 12 in.

(9.92 to 304.8 mm) wall from 0.022 to 0.134 in. (0.71

to 3.40 mm)

1.4 Optional supplementary requirements are provided and when desired, shall be so stated in the order.

1.5 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A513 – 08a

Standard Specification for

Electric-Resistance-Welded Carbon and Alloy Steel

1

Mechanical Tubing

This standard is issued under the fixed designation A513; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* A1040 Guide for Specifying Harmonized Standard Grade

Compositions for Wrought Carbon, Low-Alloy, and Alloy

1.1 This specification covers electric-resistance-welded car-

Steels

bon and alloy steel tubing for use as mechanical tubing.

E1806 Practice for Sampling Steel and Iron for Determina-

1.2 This specification covers mechanical tubing made from

tion of Chemical Composition

hot- or cold-rolled steel.

E213 Practice for Ultrasonic Testing of Metal Pipe and

1.3 This specification covers round, square, rectangular, and

Tubing

special shape tubing.

E273 Practice for Ultrasonic Testing of the Weld Zone of

Size Range

Welded Pipe and Tubing

Type (Round Tubing)

1

Electric-Resistance-Welded Tubing outside diameter from ⁄2

E309 Practice for Eddy-Current Examination of Steel Tu-

from Hot-Rolled Steel to 15 in. (19.0 to 381.0 mm)

bular Products Using Magnetic Saturation

wall from 0.065 to 0.650 in.

E570 Practice for Flux Leakage Examination of Ferromag-

(1.65 to 16.50 mm)

3

Electric-Resistance-Welded Tubing outside diameter from ⁄8 to 12 in.

netic Steel Tubular Products

from Cold-Rolled Steel (9.92 to 304.8 mm)

2.2 ANSI Standard:

wall from 0.022 to 0.134 in. (0.71

3

to 3.40 mm) B 46.1 Surface Texture

2.3 Military Standards:

1.4 Optional supplementary requirements are provided and

4

MIL-STD-129 Marking for Shipment and Storage

when desired, shall be so stated in the order.

2.4 Federal Standard:

1.5 The values stated in inch-pound units are to be regarded

4

Fed. Std. No. 123 Marking for Shipments (CivilAgencies)

as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only

3. Ordering Information

and are not considered standard.

3.1 Orders for material under this specification should

include the following as required to adequately describe the

2. Referenced Documents

desired material:

2

2.1 ASTM Standards:

3.1.1 Quantity (feet or number of lengths),

A370 Test Methods and Definitions for Mechanical Testing

3.1.2 Name of material (electric resistance-welded carbon

of Steel Products

or alloy steel mechanical tubing),

A700 PracticesforPackaging,Marking,andLoadingMeth-

3.1.3 Types,conditionsandcodeletters,(SeeSections1and

ods for Steel Products for Shipment

12),

3.1.4 Thermal condition, (See 12.2),

3.1.5 Flash condition, (See 12.3),

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

3.1.6 Grade designation, if required, (See Section 5),

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

3.1.7 Report chemical analysis and product analysis, if

A01.09 on Carbon Steel Tubular Products.

required (See Sections 6 and 7),

Current edition approved Oct. 1, 2008. Published November 2008. Originally

approved in 1964. Last previous edition approved in 2008 as A513 – 08. DOI:

10.1520/A0513-08A.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM 4th Floor, New York, NY 10036, http://www.ansi.org.

4

Standards volume information, refer to the standard’s Document Summary page on AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

the ASTM website. Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

A513 – 08a

3.1.8 Individual supplementary requirements, if required 5. Chemical Composition

(S1 to S10, inclusive),

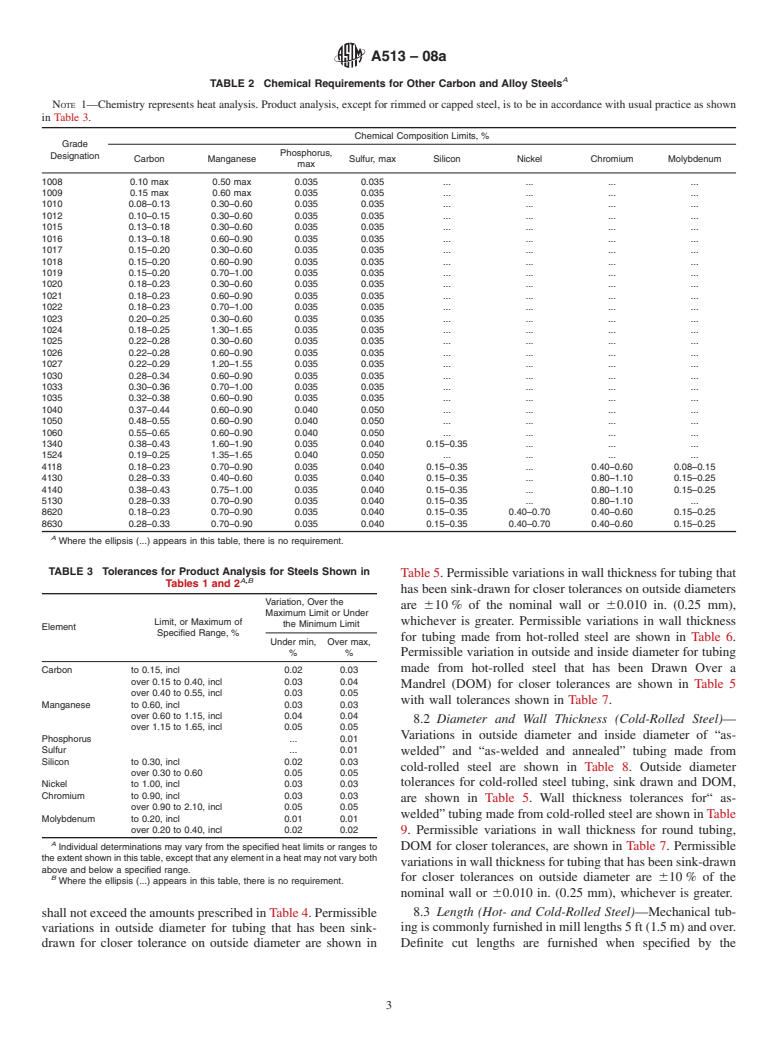

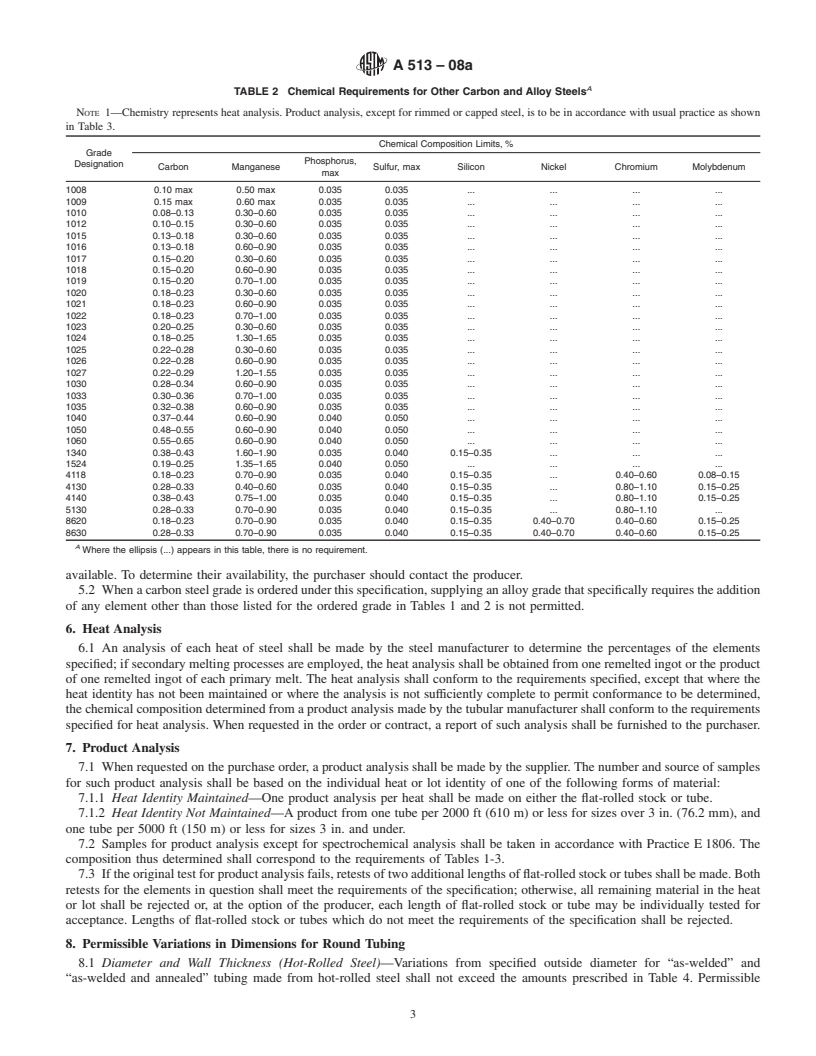

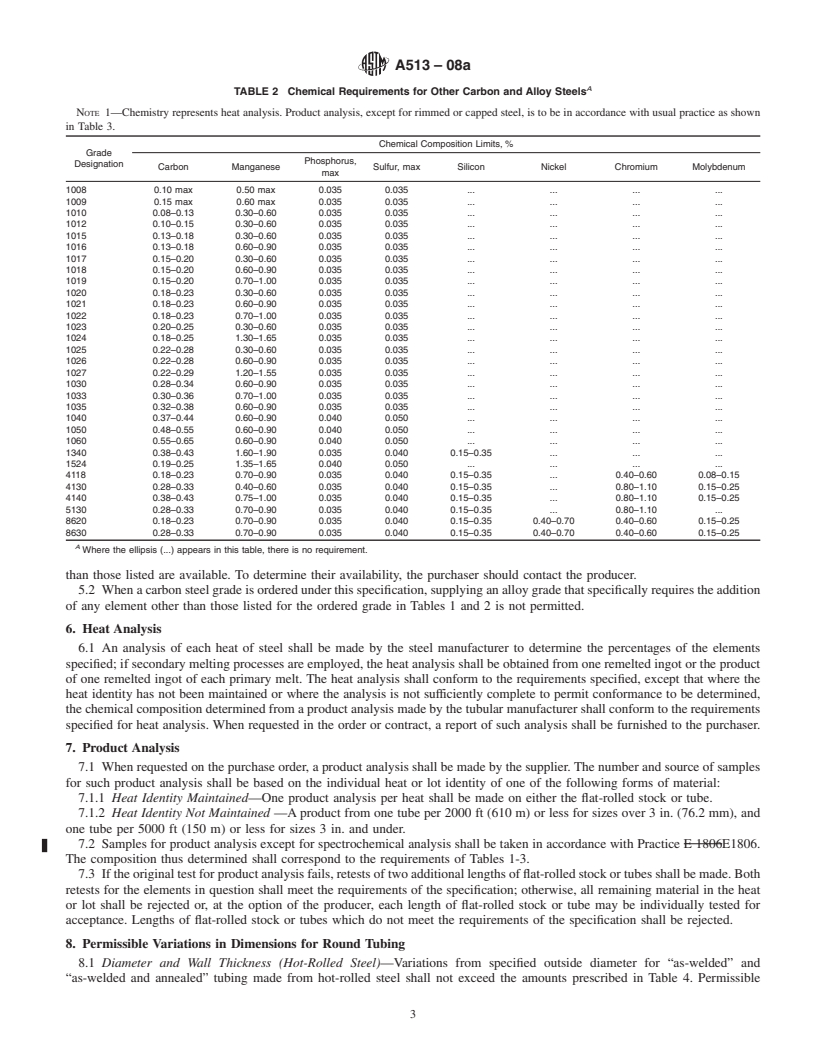

5.1 The steel shall conform to the requirements as to

3.1.9 Cross section (round, square, rectangular and special

chemical composition prescribed in Table 1 or Table 2 (See

shapes),

SpecificationA1040).Ifnogradeisspecified,GradesMT1010

3.1.10 Dimensions, round, outside and inside and wall

to MT 1020 may be furnished. Analyses of steels other than

thickness (See 8.1 and 8.2) or square and rectangular, outside

those listed are available. To determine their availability, the

dimension and wall thickness and corner radii, if required (See

purchaser should contact the producer

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:A 513–08 Designation: A 513 – 08a

Standard Specification for

Electric-Resistance-Welded Carbon and Alloy Steel

1

Mechanical Tubing

This standard is issued under the fixed designation A 513; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope*

1.1 This specification covers electric-resistance-welded carbon and alloy steel tubing for use as mechanical tubing.

1.2 This specification covers mechanical tubing made from hot- or cold-rolled steel.

1.3 This specification covers round, square, rectangular, and special shape tubing.

Size Range

Type (Round Tubing)

1

Electric-Resistance-Welded Tubing outside diameter from ⁄2

from Hot-Rolled Steel to 15 in. (19.0 to 381.0 mm)

wall from 0.065 to 0.650 in.

(1.65 to 16.50 mm)

3

Electric-Resistance-Welded Tubing outside diameter from ⁄8 to 12 in.

from Cold-Rolled Steel (9.92 to 304.8 mm)

wall from 0.022 to 0.134 in. (0.71

to 3.40 mm)

1.4 Optional supplementary requirements are provided and when desired, shall be so stated in the order.

1.5 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

2. Referenced Documents

2

2.1 ASTM Standards:

A 370 Test Methods and Definitions for Mechanical Testing of Steel Products

A 700 Practices for Packaging, Marking, and Loading Methods for Steel Products for Shipment

A 1040 Guide for Specifying Harmonized Standard Grade Compositions for Wrought Carbon, Low-Alloy, and Alloy Steels

E 1806 Practice for Sampling Steel and Iron for Determination of Chemical Composition

E 213 Practice for Ultrasonic Examination of Metal Pipe and Tubing

E 273 Practice for Ultrasonic Examination of the Weld Zone of Welded Pipe and Tubing

E 309 Practice for Eddy-Current Examination of Steel Tubular Products Using Magnetic Saturation

E 570 Practice for Flux Leakage Examination of Ferromagnetic Steel Tubular Products

2.2 ANSI Standard:

3

B 46.1 Surface Texture

2.3 Military Standards:

44

MIL-STD-129 Marking for Shipment and StorageMIL-STD-163Steel Mill Products Preparation for Shipment and Storage

2.4 Federal Standard:

4

Fed. Std. No. 123 Marking for Shipments (Civil Agencies)

3. Ordering Information

3.1 Orders for material under this specification should include the following as required to adequately describe the desired

material:

1

This specification is under the jurisdiction ofASTM CommitteeA01 on Steel, Stainless Steel and RelatedAlloys and is the direct responsibility of SubcommitteeA01.09

on Carbon Steel Tubular Products.

Current edition approved MayOct. 1, 2008. Published JuneNovember 2008. Originally approved in 1964. Last previous edition approved in 20072008 as A 513 – 078.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. ForAnnualBookofASTMStandards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

4

Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700 Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

A 513 – 08a

3.1.1 Quantity (feet or number of lengths),

3.1.2 Name of material (electric resistance-welded carbon or alloy steel mechanical tubing),

3.1.3 Types, conditions and code letters, (See Sections 1 and 12),

3.1.4Thermal condition, (

3.1.4 Thermal condition, (See 12.2),

3.1.5Flash condition, (

3.1.5 Flash condition, (See 12.3),

3.1.6Grade designation, if required, (Section

3.1.6 Grade designation, if required, (See Section 5),

3.1.7 Report chemical analysis and product analysis, if required (See Sections 6 and 7),

3.1.8 Individual supplementary requirements, if required (S1 to S10, inclusive),

3.1.9 Cross section (round, square, rectangular and special shapes),

3.1.10 Dimensions, round, outside and inside and wall thi

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:A 513–08 Designation: A513 – 08a

Standard Specification for

Electric-Resistance-Welded Carbon and Alloy Steel

1

Mechanical Tubing

This standard is issued under the fixed designation A513; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope*

1.1 This specification covers electric-resistance-welded carbon and alloy steel tubing for use as mechanical tubing.

1.2 This specification covers mechanical tubing made from hot- or cold-rolled steel.

1.3 This specification covers round, square, rectangular, and special shape tubing.

Size Range

Type (Round Tubing)

1

Electric-Resistance-Welded Tubing outside diameter from ⁄2

from Hot-Rolled Steel to 15 in. (19.0 to 381.0 mm)

wall from 0.065 to 0.650 in.

(1.65 to 16.50 mm)

3

Electric-Resistance-Welded Tubing outside diameter from ⁄8 to 12 in.

from Cold-Rolled Steel (9.92 to 304.8 mm)

wall from 0.022 to 0.134 in. (0.71

to 3.40 mm)

1.4 Optional supplementary requirements are provided and when desired, shall be so stated in the order.

1.5 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

2. Referenced Documents

2

2.1 ASTM Standards:

A370 Test Methods and Definitions for Mechanical Testing of Steel Products

A700 Practices for Packaging, Marking, and Loading Methods for Steel Products for Shipment

A1040 Guide for Specifying Harmonized Standard Grade Compositions for Wrought Carbon, Low-Alloy, and Alloy Steels

E1806 Practice for Sampling Steel and Iron for Determination of Chemical Composition

E213 Practice for Ultrasonic Testing of Metal Pipe and Tubing

E273 Practice for Ultrasonic Testing of the Weld Zone of Welded Pipe and Tubing

E309 Practice for Eddy-Current Examination of Steel Tubular Products Using Magnetic Saturation

E570 Practice for Flux Leakage Examination of Ferromagnetic Steel Tubular Products

2.2 ANSI Standard:

3

B 46.1 Surface Texture

2.3 Military Standards:

44

MIL-STD-129 Marking for Shipment and StorageMIL-STD-163Steel Mill Products Preparation for Shipment and Storage

2.4 Federal Standard:

4

Fed. Std. No. 123 Marking for Shipments (Civil Agencies)

3. Ordering Information

3.1 Orders for material under this specification should include the following as required to adequately describe the desired

material:

1

This specification is under the jurisdiction ofASTM CommitteeA01 on Steel, Stainless Steel and RelatedAlloys and is the direct responsibility of SubcommitteeA01.09

on Carbon Steel Tubular Products.

Current edition approved MayOct. 1, 2008. Published JuneNovember 2008. Originally approved in 1964. Last previous edition approved in 20072008 as A

513–07.A513 – 08. DOI: 10.1520/A0513-08A.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. ForAnnualBookofASTMStandards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

4

Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700 Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

A513 – 08a

3.1.1 Quantity (feet or number of lengths),

3.1.2 Name of material (electric resistance-welded carbon or alloy steel mechanical tubing),

3.1.3 Types, conditions and code letters, (See Sections 1 and 12),

3.1.4Thermal condition, (

3.1.4 Thermal condition, (See 12.2),

3.1.5Flash condition, (

3.1.5 Flash condition, (See 12.3),

3.1.6Grade designation, if required, (Section

3.1.6 Grade designation, if required, (See Section 5),

3.1.7 Report chemical analysis and product analysis, if required (See Sections 6 and 7),

3.1.8 Individual supplementary requirements, if required (S1 to S10, inclusive),

3.1.9 Cross section (round, square, rectangular and special shapes),

3.1.10 Dimensions, round, outside and inside

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.