ASTM D2647-09

(Specification)Standard Specification for Crosslinkable Ethylene Plastics

Standard Specification for Crosslinkable Ethylene Plastics

ABSTRACT

This specification covers a general classification system for crosslinkable ethylene plastics compounds. Two types of compounds are covered, namely, mechanical types in which mechanical strength properties are of prime importance in applications, and electrical types in which electrical insulating or conducting properties also are of prime importance in applications. These compounds shall be classified as: Type I; Type II; and Grade A. Tests shall be performed to determine the properties in accordance with the following test methods: conditioning; test conditions; ultimate elongation; elongation retention after aging; apparent modulus of rigidity; brittleness temperature; dielectric constant; dissipation factor; and degree of crosslinking.

SCOPE

1.1 This specification covers a general classification system for crosslinkable ethylene plastics compounds (Note 1). The requirements specified herein are not necessarily applicable for use as criteria in determining suitability for the end use of a fabricated product.

Note 1—It is to be noted that this specification describes materials that are available commercially in their uncrosslinked form. Therefore, they are crosslinkable compounds despite the fact that measurement of the parameters used for their classification and specification will usually be carried out after curing has been effected.

1.2 Two types of compounds are covered, namely, mechanical types in which mechanical strength properties are of prime importance in applications, and electrical types in which electrical insulating or conducting properties also are of prime importance in applications.

1.3 The parameters used to classify and specify the mechanical types are ultimate elongation, elongation retention after aging, apparent modulus of rigidity, and brittleness temperature.

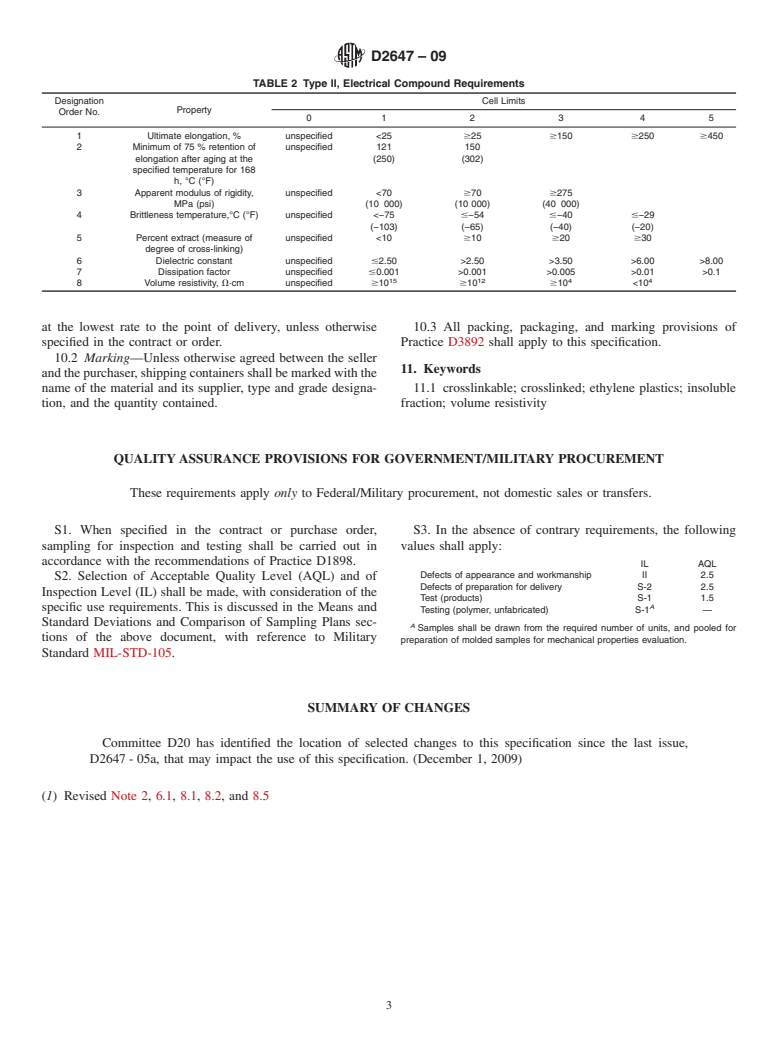

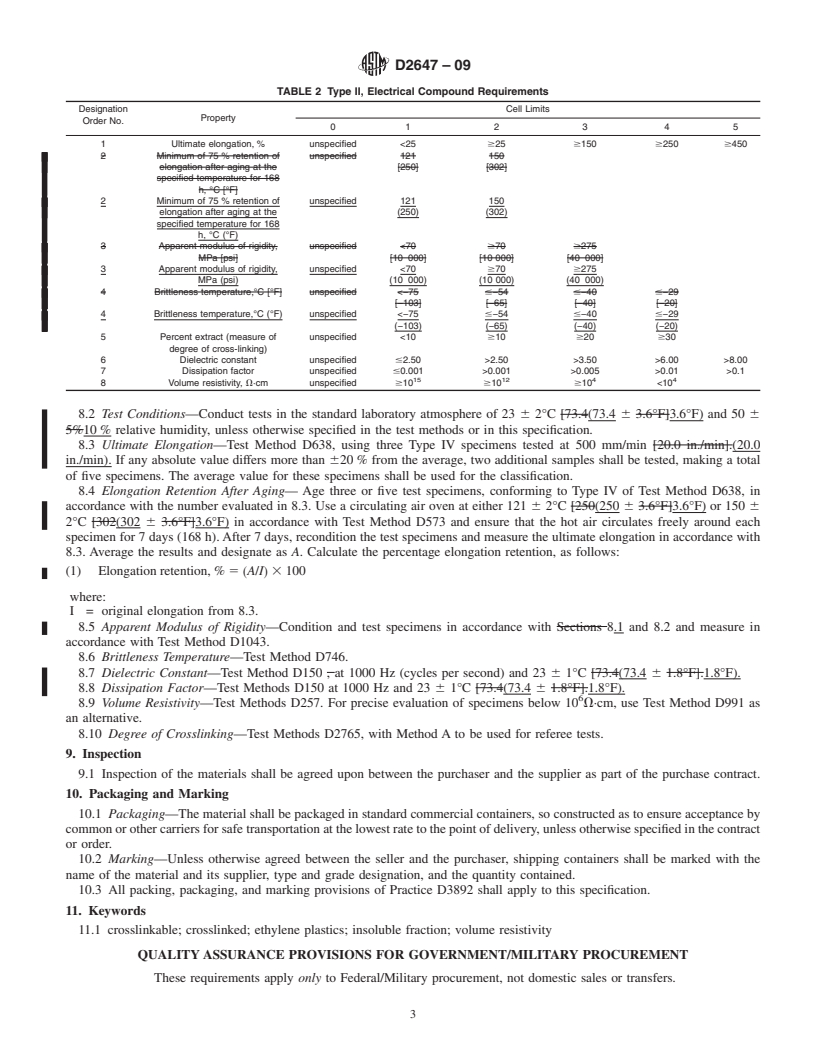

1.4 The parameters used to classify and specify the electrical types are ultimate elongation, elongation retention after aging, apparent modulus of rigidity, brittleness temperature, dielectric constant, dissipation factor, and volume resistivity.

1.5 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.6 The following safety hazards caveat pertains only to the test methods portion, Section 7, of this specification: This specification does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this specification to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Note 2—There is no known ISO equivalent to this standard.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D2647 – 09

Standard Specification for

1

Crosslinkable Ethylene Plastics

This standard is issued under the fixed designation D2647; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

NOTE 2—There is no known ISO equivalent to this standard.

1. Scope*

1.1 This specification covers a general classification system

2. Referenced Documents

for crosslinkable ethylene plastics compounds (Note 1). The

2

2.1 ASTM Standards:

requirements specified herein are not necessarily applicable for

D150 Test Methods for AC Loss Characteristics and Per-

use as criteria in determining suitability for the end use of a

mittivity (Dielectric Constant) of Solid Electrical Insula-

fabricated product.

tion

NOTE 1—It is to be noted that this specification describes materials that

D257 Test Methods for DC Resistance or Conductance of

are available commercially in their uncrosslinked form. Therefore, they

Insulating Materials

are crosslinkable compounds despite the fact that measurement of the

D573 Test Method for Rubber—Deterioration in an Air

parameters used for their classification and specification will usually be

Oven

carried out after curing has been effected.

D618 Practice for Conditioning Plastics for Testing

1.2 Two types of compounds are covered, namely, mechani-

D638 Test Method for Tensile Properties of Plastics

cal types in which mechanical strength properties are of prime

D746 Test Method for Brittleness Temperature of Plastics

importance in applications, and electrical types in which

and Elastomers by Impact

electrical insulating or conducting properties also are of prime

D883 Terminology Relating to Plastics

importance in applications.

D991 Test Method for Rubber Property—Volume Resistiv-

1.3 The parameters used to classify and specify the me-

ity Of Electrically Conductive and Antistatic Products

chanical types are ultimate elongation, elongation retention

D1043 Test Method for Stiffness Properties of Plastics as a

after aging, apparent modulus of rigidity, and brittleness

Function of Temperature by Means of a Torsion Test

temperature.

D2765 Test Methods for Determination of Gel Content and

1.4 The parameters used to classify and specify the electri-

Swell Ratio of Crosslinked Ethylene Plastics

cal types are ultimate elongation, elongation retention after

D3892 Practice for Packaging/Packing of Plastics

aging, apparent modulus of rigidity, brittleness temperature,

IEEE/ASTM SI-10 Standard for Use of the International

dielectric constant, dissipation factor, and volume resistivity.

System of Units (SI): (The Modernized Metric System)

1.5 The values stated in SI units are to be regarded as the

2.2 Military Standard:

standard. The values given in parentheses are for information

MIL-STD-105 Sampling Procedures and Tables for Inspec-

only. 3

tion by Attributes (Obsolete 1995)

1.6 The following safety hazards caveat pertains only to the

test methods portion, Section 7, of this specification: This 3. Terminology

specification does not purport to address all of the safety

3.1 Definitions: For definitions of plastics terms used in this

concerns, if any, associated with its use. It is the responsibility

specification, see Terminology D883.

of the user of this specification to establish appropriate safety

3.2 Abbreviations:Units, Symbols, and Abbreviations—For

and health practices and determine the applicability of regu-

units, symbols, and abbreviations used in this specification see

latory limitations prior to use.

IEEE/ASTM SI-10.

1 2

This specification is under the jurisdiction of ASTM Committee D20 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Plastics and is the direct responsibility of Subcommittee D20.15 on Thermoplastic contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Materials. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Dec. 1, 2009. Published December 2009. Originally the ASTM website.

3

approved in 1967. Last previous edition approved in 2005 as D2647 - 05a. DOI: AvailablefromDefenseAutomationandProductionService,Bldg.4SectionD,

10.1520/D2647-09. 700 Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

*A Summary of Changes section appears at the end of this standard.

Copyright ©ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D2647 – 09

4. Classification relative humidity, unless otherwise specified in the test meth-

ods or in this specification.

4.1 Classification System—Table 1 and Table

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D2647–05a Designation: D2647 – 09

Standard Specification for

1

Crosslinkable Ethylene Plastics

This standard is issued under the fixed designation D2647; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This specification covers a general classification system for crosslinkable ethylene plastics compounds (Note 1). The

requirements specified herein are not necessarily applicable for use as criteria in determining suitability for the end use of a

fabricated product.

NOTE 1—It is to be noted that this specification describes materials that are available commercially in their uncrosslinked form. Therefore, they are

crosslinkablecompoundsdespitethefactthatmeasurementoftheparametersusedfortheirclassificationandspecificationwillusuallybecarriedoutafter

curing has been effected.

1.2 Two types of compounds are covered, namely, mechanical types in which mechanical strength properties are of prime

importance in applications, and electrical types in which electrical insulating or conducting properties also are of prime importance

in applications.

1.3 The parameters used to classify and specify the mechanical types are ultimate elongation, elongation retention after aging,

apparent modulus of rigidity, and brittleness temperature.

1.4 The parameters used to classify and specify the electrical types are ultimate elongation, elongation retention after aging,

apparent modulus of rigidity, brittleness temperature, dielectric constant, dissipation factor, and volume resistivity.

1.5 The values stated in SI units are to be regarded as the standard. The values given in bracketsparentheses are for information

only.

1.6 The following safety hazards caveat pertains only to the test methods portion, Section 7, of this specification: This

specification does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the

user of this specification to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

NOTE2—There is no similar or equivalent ISO standard. 2—There is no known ISO equivalent to this standard.

2. Referenced Documents

2

2.1 ASTM Standards:

D150 Test Methods for AC Loss Characteristics and Permittivity (Dielectric Constant) of Solid Electrical Insulation

D257 Test Methods for DC Resistance or Conductance of Insulating Materials

D573 Test Method for RubberDeterioration in an Air Oven

D618 Practice for Conditioning Plastics for Testing

D638 Test Method for Tensile Properties of Plastics

D746 Test Method for Brittleness Temperature of Plastics and Elastomers by Impact

D883 Terminology Relating to Plastics

D991 Test Method for Rubber PropertyVolume Resistivity Of Electrically Conductive and Antistatic Products

D1043 Test Method for Stiffness Properties of Plastics as a Function ofTemperature by Means of aTorsionTest D1898Practice

for Sam-

pling of

Plastics

D2765 Test Methods for Determination of Gel Content and Swell Ratio of Crosslinked Ethylene Plastics

D3892 Practice for Packaging/Packing of Plastics

IEEE/ASTM SI-10 Standard for Use of the International System of Units (SI): (The Modernized Metric System)

1

This specification is under the jurisdiction of ASTM Committee D20 on Plastics and is the direct responsibility of Subcommittee D20.15 on Thermoplastic Materials.

Current edition approved JulyDec. 1, 2005.2009. Published July 2005.December 2009. Originally approved in 1967. Last previous edition approved in 2005 as

D2647 - 05a. DOI: 10.1520/D2647-05A.10.1520/D2647-09.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D2647 – 09

2.2 Military Standard:

3

MIL-STD-105 Sampling Procedures and Tables for Inspection by Attributes (Obsolete 1995)

3. Terminology

3.1 Definitions: For definitions of plastics terms used in this specification, see Terminology D883.

3.2 Abbreviations:Units,

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.