ASTM F526-97(2003)

(Test Method)Standard Test Method for Measuring Dose for Use in Linear Accelerator Pulsed Radiation Effects Tests

Standard Test Method for Measuring Dose for Use in Linear Accelerator Pulsed Radiation Effects Tests

SIGNIFICANCE AND USE

An accurate measure of the dose during radiation-effects testing is necessary to ensure the validity of the data taken, to enable comparison to be made of data taken at different facilities, and to verify that components or circuits are tested to the radiation specification applied to the system for which they are to be used.

The primary value of a calorimetric method for measuring dose is that the results are absolute. They are based only on physical properties of materials, that is, the specific heat of the calorimeter-block material and the Seebeck emf of the thermocouple used or the temperature coefficient of resistance (α) of the thermistor used, all of which can be established with non-radiation measurements.

The method permits repeated measurements to be made during a radiation effects test without requiring entry into the radiation cell between measurements.

SCOPE

1.1 This test method covers a calorimetric measurement of the dose delivered in a single pulse of electrons from an electron linear accelerator used as an ionizing source in radiation-effects testing. The test method is designed for use with pulses of electrons in the energy range from 10 to 50 MeV and is only valid for cases in which both the calorimeter and the test specimen to be irradiated are" thin" compared to the range of these electrons in the materials of which they are constructed.

1.2 The procedure described can be used in those cases in which (1) the dose delivered in a single pulse is 5 Gy (500 rad) or greater, or (2) multiple pulses of a lower dose can be delivered in a time short compared to the thermal time constant of the calorimeter. The minimum dose per pulse that can be acceptably monitored depends on the variables of the particular test, including pulse rate, pulse uniformity, and the thermal time constant of the calorimeter.

1.3 A determination of the dose is made directly for the material of which the calorimeter block is made. The dose in other materials can be calculated from this measured value by formulas presented in this test method. The need for such calculations and the choice of materials for which calculations are to be made shall be subject to agreement by the parties to the test.

1.4 The values stated in SI units are to be regarded as the standard. The values in parenthesis are provided for information only.

1.5 This standard does not purport to address the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F526 – 97 (Reapproved 2003)

Standard Test Method for

Measuring Dose for Use in Linear Accelerator Pulsed

Radiation Effects Tests

ThisstandardisissuedunderthefixeddesignationF526;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 2. Referenced Documents

1.1 This test method covers a calorimetric measurement of 2.1 ASTM Standards:

the dose delivered in a single pulse of electrons from an E230 Specification and Temperature-Electromotive Force

electron linear accelerator used as an ionizing source in (EMF) Tables for Standardized Thermocouples

radiation-effects testing. The test method is designed for use

3. Terminology

withpulsesofelectronsintheenergyrangefrom10to50MeV

3.1 Definitions:

and is only valid for cases in which both the calorimeter and

the test specimen to be irradiated are“ thin” compared to the 3.1.1 thermal time constant of a calorimeter—the time for

the temperature excursion of the calorimeter resulting from a

range of these electrons in the materials of which they are

constructed. radiation pulse to drop to 1/e of its initial maximum value.

1.2 The procedure described can be used in those cases in

2 4. Summary of Test Method

which (1) the dose delivered in a single pulse is 5 Gy (500

4.1 Single-Pulse Method—This method consists of (1) irra-

rad) or greater, or (2) multiple pulses of a lower dose can be

diating, with a single pulse of high-energy electrons from an

deliveredinatimeshortcomparedtothethermaltimeconstant

electron linear accelerator (linac), a small block of material to

of the calorimeter. The minimum dose per pulse that can be

which either a thermistor or a thermocouple made from

acceptablymonitoreddependsonthevariablesoftheparticular

small-diameter wire is attached; (2) recording and measuring

test, including pulse rate, pulse uniformity, and the thermal

the resulting signal from a bridge circuit or directly from the

time constant of the calorimeter.

thermocouple; (3) calculating the dose deposited in the block

1.3 A determination of the dose is made directly for the

based on the temperature rise and the specific heat of the

material of which the calorimeter block is made. The dose in

material; and (4) if required, calculating the equivalent dose in

other materials can be calculated from this measured value by

other specified materials.

formulas presented in this test method. The need for such

4.2 Multiple-PulseMethod—Ifthedoseavailableinasingle

calculations and the choice of materials for which calculations

pulse is not large enough to give measurable results, the linac

are to be made shall be subject to agreement by the parties to

is pulsed repeatedly within a time short compared to the

the test.

thermaltimeconstantofthecalorimeter.Thismethodissimilar

1.4 The values stated in SI units are to be regarded as the

to the single-pulse method except that the average dose

standard. The values in parenthesis are provided for informa-

delivered in each pulse is calculated from the measured

tion only.

cumulative dose of all the pulses.

1.5 This standard does not purport to address the safety

concerns, if any, associated with its use. It is the responsibility

5. Significance and Use

of the user of this standard to establish appropriate safety and

5.1 Anaccuratemeasureofthedoseduringradiation-effects

health practices and determine the applicability of regulatory

testing is necessary to ensure the validity of the data taken, to

limitations prior to use.

enable comparison to be made of data taken at different

This test method is under the jurisdiction of ASTM Committee F01 on

Electronics and is the direct responsibility of Subcommittee F01.11 on Nuclear &

Space Radiation Effects.

Current edition approved June 10, 2003. Published March 1998. Originally

published as F526–77 T. Last previous edition F526–91. DOI: 10.1520/F0526- For referenced ASTM standards, visit the ASTM website, www.astm.org, or

97R03. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

In1975theGeneralConferenceonWeightsandMeasuresadoptedtheunitgray Standards volume information, refer to the standard’s Document Summary page on

(symbol—Gy) for absorbed dose; 1 Gy=100 rad. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F526 – 97 (2003)

material, the temperature will quickly equilibrate to that of the block, and

facilities,andtoverifythatcomponentsorcircuitsaretestedto

the subsequent temperature record will be that of the calorimeter-block

theradiationspecificationappliedtothesystemforwhichthey

material (see Appendix X1).

are to be used.

6.3 Pulse Reproducibility—If pulse-to-pulse reproducibility

5.2 The primary value of a calorimetric method for measur-

of the radiation source varies more than 620%, a good

ingdoseisthattheresultsareabsolute.Theyarebasedonlyon

measure of the dose per pulse may not be attainable from the

physical properties of materials, that is, the specific heat of the

average value calculated in the multiple-pulse method.

calorimeter-blockmaterialandtheSeebeckemfofthethermo-

couple used or the temperature coefficient of resistance (a)of

7. Apparatus

the thermistor used, all of which can be established with

7.1 Linac—Electron linear accelerator and associated in-

non-radiation measurements.

strumentation and controls suitable for use as an ionizing

5.3 The method permits repeated measurements to be made

source in radiation-effects testing.

during a radiation effects test without requiring entry into the

7.2 Calorimeter—Specialinstrumentsuitableformeasuring

radiation cell between measurements.

the dose delivered by the linac and constructed in accordance

withanyofseveraldesignsutilizinganyofseveralmaterialsas

6. Interferences

indicated in Appendix X1. Although measurement differences

6.1 Thermal Isolation—If the thermal isolation of the calo-

resulting from the use of different designs should not be

rimeter is not sufficient, the thermal time constant of the

significant, all parties to the test shall agree to a single design

calorimeter response will be too short for it to be useful.

utilizing a single calorimeter-block material and a specific

NOTE 1—This condition can be caused by insufficient insulation mate-

thermocouple or thermistor. The calorimeter design shall be

rial or by heat loss through the thermocouple wires themselves.

such that the surface density in the beam path is less than or

equal to no more than 20% of the range of the beam-energy

6.2 Thermal Equilibrium—The initial value of the transient

temperature change following a radiation pulse may not reflect electrons (see Fig. 1).

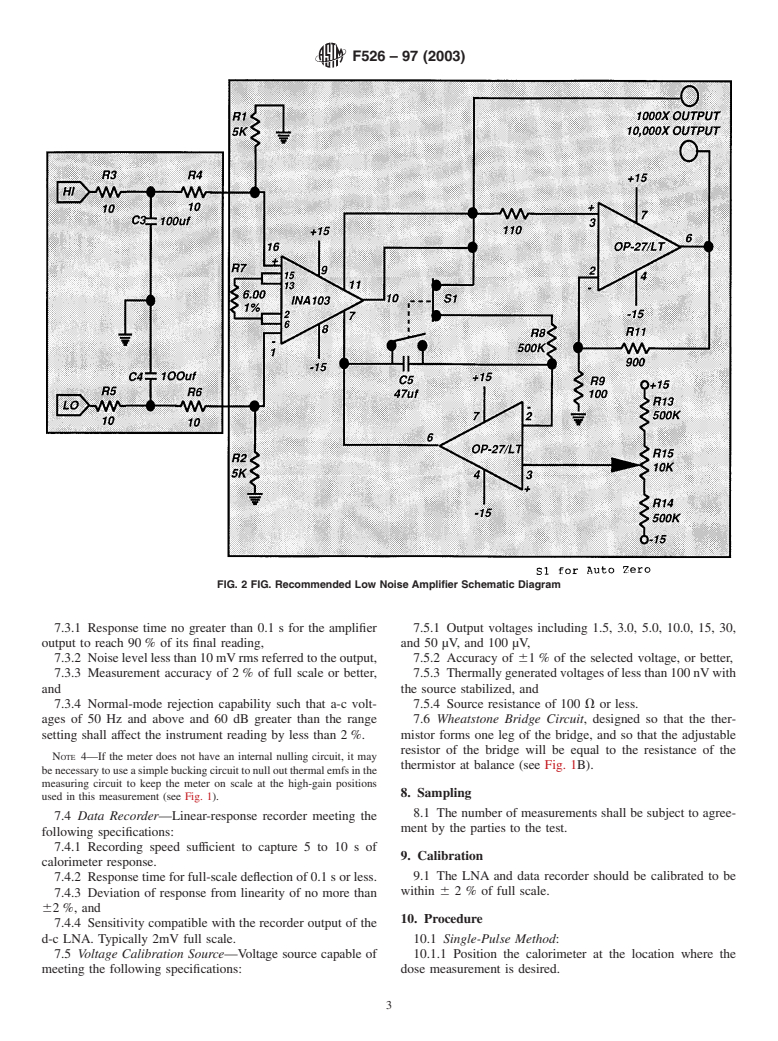

7.3 D-C Low Noise Amplifier (LNA), with a gain of 1000 to

the true temperature change of the calorimeter-block material.

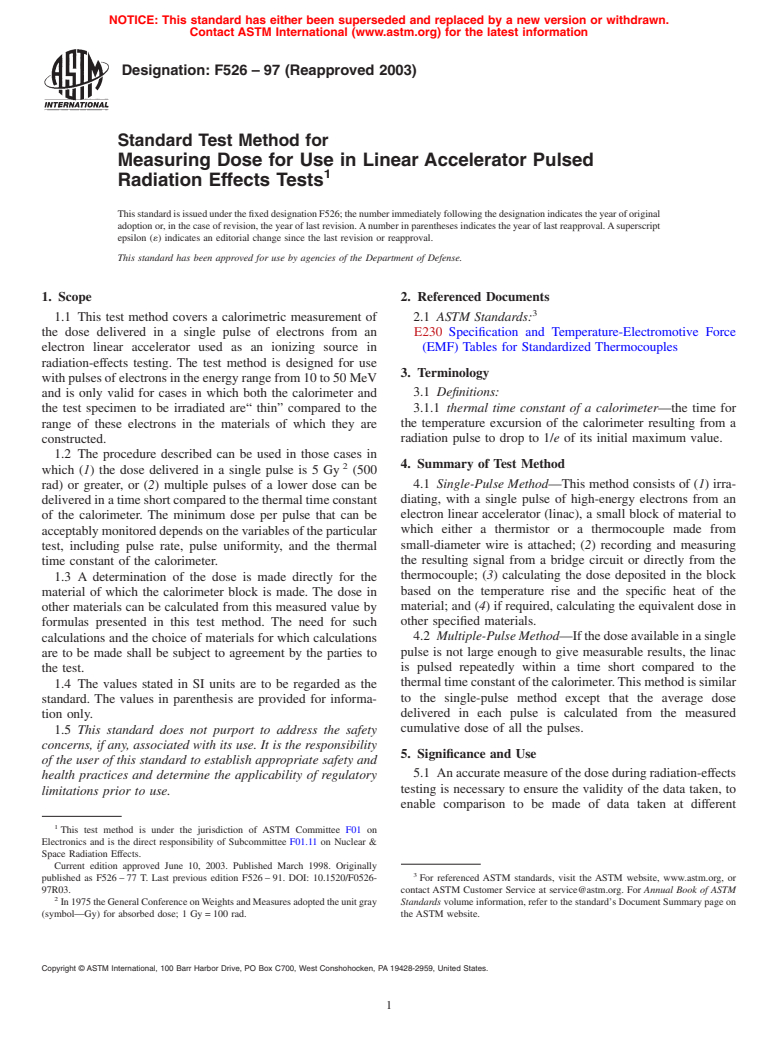

10 000 (see Fig. 2).

NOTE 2—This situation can be brought about by a temperature rise

occurring in the materials at the point of attachment of the thermocouple NOTE 3—An analog nanovoltmeter with a recorder output can also be

or the thermistor different from that in the calorimeter-block material.As used as a low noise amplifier. These devices produce a 1–V output for a

long as the calorimeter block comprises the great bulk of the calorimeter full scale reading.

FIG. 1 Block Diagram of Calorimeter Dosimeter Circuit

F526 – 97 (2003)

FIG. 2 FIG. Recommended Low Noise Amplifier Schematic Diagram

7.3.1 Response time no greater than 0.1 s for the amplifier 7.5.1 Output voltages including 1.5, 3.0, 5.0, 10.0, 15, 30,

output to reach 90% of its final reading, and 50 µV, and 100 µV,

7.3.2 Noiselevellessthan10mVrmsreferredtotheoutput, 7.5.2 Accuracy of 61% of the selected voltage, or better,

7.3.3 Measurement accuracy of 2% of full scale or better, 7.5.3 Thermallygeneratedvoltagesoflessthan100nVwith

and the source stabilized, and

7.3.4 Normal-mode rejection capability such that a-c volt- 7.5.4 Source resistance of 100 V or less.

ages of 50 Hz and above and 60 dB greater than the range 7.6 Wheatstone Bridge Circuit, designed so that the ther-

setting shall affect the instrument reading by less than 2%. mistor forms one leg of the bridge, and so that the adjustable

resistor of the bridge will be equal to the resistance of the

NOTE 4—If the meter does not have an internal nulling circuit, it may

thermistor at balance (see Fig. 1B).

benecessarytouseasimplebuckingcircuittonulloutthermalemfsinthe

measuring circuit to keep the meter on scale at the high-gain positions

8. Sampling

used in this measurement (see Fig. 1).

8.1 The number of measurements shall be subject to agree-

7.4 Data Recorder—Linear-response recorder meeting the

ment by the parties to the test.

following specifications:

7.4.1 Recording speed sufficient to capture 5 to 10 s of

9. Calibration

calorimeter response.

9.1 The LNA and data recorder should be calibrated to be

7.4.2 Responsetimeforfull-scaledeflectionof0.1sorless.

within 6 2 % of full scale.

7.4.3 Deviation of response from linearity of no more than

62%, and

10. Procedure

7.4.4 Sensitivity compatible with the recorder output of the

d-c LNA. Typically 2mV full scale. 10.1 Single-Pulse Method:

7.5 Voltage Calibration Source—Voltage source capable of 10.1.1 Position the calorimeter at the location where the

meeting the following specifications: dose measurement is desired.

F526 – 97 (2003)

10.1.2 Connect all components of the calorimetric dosim- 10.1.7 Repeat 10.1.5 and 10.1.6 until a range is found for

eter system in accordance with the circuit shown in Fig. 1. which the greater-than-10% criterion is met, or until there are

10.1.3 Set the LNAfor a gain of 10 000 (1000), if using the

no more ranges to try.

thermistor circuit).

10.1.7.1 When a range is found for which this greater-than-

10.1.4 For the thermocouple measurements, adjust either

10% criterion is met, annotate the data recorder output beside

the internal nulling circuit of the LNAor the external bucking

the recorded transient with the shot number, date, LNA gain,

circuit so that the meter deflection caused by the quiescent

calorimeter identification, and description of irradiation geom-

level of the calorimeter output is less than full scale. For

etry (including scatterer thickness and distance of the calorim-

thermistor measurements adjust the bridge for a null. Use the

eter from the scatterer) as shown in Fig. 3 and Fig. 4.

zero-adjust capability of the data recorder to position the

10.1.7.2 If no range if found for which a 10% deflection is

recorder trace near the center of the recorder chart.

obtained which is easily distinguishable from noise, use the

NOTE 5—With either system, there will likely be a drift as the

multiple-pulse method beginning with 10.2.2.

temperature of the calorimeter equilibrates. This drift is compensated for

10.1.7.3 Otherwise, repeat 10.1.7.1 four more times.

in data reduction and may be neglected if the rate of change is much less

10.2 Multiple-Pulse Method:

than that caused by the radiation pulse.

10.2.1 Carry out 10.1.1 through 10.1.4.

10.1.5 With the data recorder sweep speed set within the

10.2.2 With the recorder chart speed set within the range

range from 0.5 to 2.0 cm/s, inclusive, trigger the recorder and

pulse the linac. from 0.5 to 2.0 cm/s, inclusive, pulse the Linac repeatedly

within a time that is short compared to the thermal time

10.1.6 If the transient deflection of the recorder is less than

10% of full scale, set the recorder range to the next lower constantofthecalorimetertogivearecorderdeflectiongreater

range and repeat 10.1.5. than 10% of full scale.

FIG. 3 Typical Chart Record of Calorimeter Dosimetry Using Single-Pulse Method

F526 – 97 (2003)

FIG. 4 Typical Digital Oscilloscope Recording of the Calorimeter Response

10.2.2.1 From the data, measure the voltage rise resulting 11.1.2.2 If such a feature is present, draw a line extrapolat-

from this series of pulses.

10.2.2.2 For the time interval beginning with the cessation

of the radiation and equal in duration to the total time during TABLE 1 Physical Properties of Some Calorimeter-Block

Materials

which the radiation dose was accumulated, measure the ther-

A B B 3

Energy Loss dE/dx Specific Heat, c Density, r (10

mocouple voltage drop.

p

Material

−14 2 3

(10 J·m /kg) (J/kg·K) kg/m )

10.2.2.3 Calculate the ratio of the voltage from 10.2.2.2 to

C 2.92 711 2.10

that of 10.2.2.1.

Al 2.74 900 2.70

10.2.2.4 If this ratio is less than 0.15, continue with 10.2.3

Si 2.84 711 2.33

(the thermal time constant of the calorimeter is sufficiently Fe 2.52 452 7.87

Cu 2.42 385 8.96

greater than the radiation time for the dose to be determined

Ge 2.45 322 5.32

accurately).

W 2.08 134 19.3

Au 2.06 130 19.3

10.2.2.5 If this ratio is equal to or greater than 0.15, repeat

Pb 2.07 128 11.4

10.2.2 through 10.2.2.5 using a higher pulse repetition rate for

A

The data are given for 20-MeV electrons, but ratios based on these values are

a shorter radiation time period.

good to better than 2 % over the energy range from 10 to 50 MeV, inclusive. These

10.2.3 Annotate the data recorder output, as well as the

values have been converted to SI units from data given in the tables of Berger and

Seltzer: Tables of Energy Losses and Ranges of Electrons and Positrons, NASA

number of pulses used (see Fig. 5, Fig. 6, and Fig. 7).

SP-3012 (1964); and Additional Stopping Powers and Range Tables for Protons,

10.2.4 Repeat 10.2.2 and 10.2.3 four more times, omitting

Mesons, and Electrons, NASA SP-3036 (1966).

B

the time constant determination (10.2.2.1 through 10.2.2.5).

These values have been converted to SI units from data given in theHandbook

of Tables for Applied Engineering Science, 2nd ed., CRC Press, Cleveland, OH

(1973). (The specific heat values are applicable in the range from 18 to 30°C,

11. Calculation and Interpretation of Results

inclusive.)

11.1 Single-Pulse Method:

11.1.1 On the recorder output, determine the perpendicular

to the time axis at the start of each transient, as shown in Fig. ing from the slope of the curve where a smooth cooling trend

3.

resumes. Do this for each pulse.

11.1.2 Determine whether a period of time was required for

NOTE 7—These lines are dashed in Fig. 5.

the temperature to equilibrate after the pulse, as indicated by

thepresenceofaspike(Fig.5a)oraflatportion(Fig.5b)ofthe

11.1.3 Measure along each perpendicular line the length

data recorde

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.