ASTM E1461-92

(Test Method)Standard Test Method for Thermal Diffusivity of Solids by the Flash Method

Standard Test Method for Thermal Diffusivity of Solids by the Flash Method

SCOPE

1.1 This test method covers the determination of the thermal diffusivity of primarily homogeneous isotropic solid materials. Thermal diffusivity values ranging from 10-7 to 10-3 m 2/s are readily measurable by this test method from about 75 to 2800 K.

1.2 This test method is a more detailed form of Test Method C 714, but has applicability to much wider ranges of materials, applications, and temperatures, with improved accuracy of measurements.

1.3 This test method is applicable to the measurements performed on materials opaque to the spectrum of the energy pulse, but with special precautions can be used on fully or partially transparent materials (see Appendix X1).

1.4 This test method is intended to allow a wide variety of apparatus designs. It is not practical in a test method of this type to establish details of construction and procedures to cover all contingencies that might offer difficulties to a person without pertinent technical knowledge, or to stop or restrict research and development for improvements in the basic technique.

1.5 This test method is applicable to the measurements performed on essentially fully dense materials; however, in some cases it has shown to produce acceptable results when used with porous samples. Since the magnitude of porosity, pore shapes, sizes and parameters of pore distribution influence the behavior of the thermal diffusivity, extreme caution must be exercised when analyzing data. Special caution is advised when other properties, such as thermal conductivity, are derived from thermal diffusivity obtained by this method.

1.6 This test method can be considered an absolute (or primary) method of measurement, since no reference standards are required. It is advisable to use reference materials to verify the performance of the instrument used.

1.7 This method is applicable only for homogeneous solid materials, in the strictest sense; however, in some cases it has shown to produce data which may be useful in certain applications.

1.7.1 Testing of Composite Materials--When substantial inhomogeneity and anisotropy is present in a material, the thermal diffusivity data obtained with this method may be substantially in error. Nevertheless, such data, while usually lacking absolute accuracy, may be useful in comparing materials of similar structure. Extreme caution must be exercised when related properties, such as thermal conductivity, are derived, as composites may have heat flow patterns substantially different than uniaxial.

1.7.2 Testing Liquids--This method has found an especially useful application in determining thermal diffusivity of molten materials. For this technique, specially constructed sample enclosures must be used.

1.7.3 Testing Layered Materials--This method has also been extended to test certain layered structures made of dissimilar materials, where one of the layers is considered unknown. In some cases, contact conductance of the interface may also be determined.

1.8 The values stated in SI units are to be regarded as the standard.

1.9 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: E 1461 – 92

Standard Test Method for

Thermal Diffusivity of Solids by the Flash Method

This standard is issued under the fixed designation E 1461; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

,

2 3

1. Scope parison Techniques

E 230 Temperature-Electromotive Force (EMF) Tables for

1.1 This test method covers the determination of the thermal

Thermocouples

diffusivity of homogeneous solid materials. Thermal diffusivity

values ranging from 0.1 to 1000 mm /s are readily measurable

3. Terminology

by this test method and measurements can be made from about

3.1 Definitions:

100 to 2500 K normally in a vacuum or inert gas environment.

3.1.1 thermal conductivity, l, of a solid material—the time

1.2 This test method is a more detailed form of Test Method

rate of steady heat flow through unit thickness of an infinite

C 714 but has applicability to much wider ranges of materials,

slab of a homogeneous material in a direction perpendicular to

applications, and temperatures with improved accuracy of

the surface, induced by unit temperature difference.

measurement.

3.1.1.1 Discussion—Where other modes of heat transfer are

1.3 This test method is applicable to the measurement of a

present in addition to conduction, this property is often referred

wide variety of homogeneous opaque materials and, with

to as apparent or effective thermal conductivity, e or app.

special precautions, can be used on transparent and some

3.1.1.2 Discussion—For practical purposes, the lateral ex-

porous and composite materials.

tent of a slab is considered to be infinite when heat flow

1.4 This test method is intended to allow a wide variety of

laterally is less than 2 % of the transverse flow.

apparatus design and design accuracies to satisfy the require-

3.1.1.3 Discussion—The property must be identified with

ments of specific measurements problems. It is not practical in

both a specific mean temperature, since it varies with tempera-

a test method of this type to establish details of construction

ture, and for a direction and orientation of thermal transmission

and procedures to cover all contingencies that might offer

since some bodies are not isotropic with respect to the thermal

difficulties to a person without pertinent technical knowledge

conductivity.

or to stop or restrict research and development for improve-

3.1.2 thermal diffusivity, a, of a solid material—the prop-

ments in the basic technique.

erty given by the thermal conductivity divided by the product

1.5 This test method can be considered an absolute (or

of the density and heat capacity per unit mass.

primary) method of measurement since no heat flux reference

3.2 Definitions:

standards are required except for verification purposes and to

3.2.1 a—1/(1 + 0.667 l /l ).

T s

confirm accuracy statements.

3.2.2 D—diameter, meters.

1.6 The values stated in SI units are to be regarded as the

3.2.3 k—constants in solution to diffusion equation.

standard.

3.2.4 L—specimen thickness, meters.

1.7 This standard does not purport to address all of the

3.2.5 t—response time, seconds.

safety problems, if any, associated with its use. It is the

3.2.6 t*—dimensionless time ( t*=4a t/D T).

s

responsibility of the user of this standard to establish appro-

3.2.7 T—temperature, Kelvins.

priate safety and health practices and determine the applica-

3.2.8 a—thermal diffusivity, m /s.

bility of regulatory limitations prior to use.

3.2.9 l—thermal conductivity, W/m.K.

2. Referenced Documents 3.2.10 b—fraction of pulse duration required to reach

maximum intensity.

2.1 ASTM Standards:

3.2.11 Dt —T (5t ⁄2 /T (t ⁄2)).

C 714 Test Method for Thermal Diffusivity of Carbon and 5

1 1

3.2.12 Dt —T (10t ⁄2/T (t ⁄2 )).

Graphite by a Thermal Pulse Method

3.3 Definitions:

E 220 Method for Calibration of Thermocouples by Com-

3.3.1 o—ambient.

3.3.2 s—specimen.

3.3.3 T—thermocouple.

This test method is under the jurisdiction of ASTM Committee E-37 on

3.3.4 x—percent rise.

Thermal Measurements and is the direct responsibility of Subcommittee E37.05 on

Thermophysical Properties.

Current edition approved Feb. 15, 1992. Published April 1992.

2 3

Annual Book of ASTM Standards, Vol 15.01. Annual Book of ASTM Standards, Vol 14.03.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

E 1461

3.3.5 C—Cowan. 6. Interferences

3.3.6 R—ratio.

6.1 Experimental results are subject to two general types of

3.3.7 m—maximum.

errors:

3.3.8 t—time.

6.1.1 Measurement errors associated with uncertainties that

exist in measured quantities used to compute the thermal

4. Summary of Test Method

diffusivity from experimental data. The units of thermal

4.1 A small, thin, disc specimen mounted horizontally or diffusivity are length and time. Because test specimens are

vertically is subjected to a high-intensity short duration thermal relatively thin (generally 1.5 to 4 mm) and the thickness enters

pulse. The energy of the pulse is absorbed on the front surface as a squared term, uncertainties in the determination of the

of a specimen and the resulting rear face temperature rise is thickness can be very significant. The time is that observed for

measured. The ambient temperature of the specimen is con- the rear face temperature to attain a certain percentage of the

trolled by a furnace or cryostat. Thermal diffusivity values are maximum rise. This latter measurement involves determining a

calculated from the specimen thickness and the time required base line, the maximum rise above the base line, and the time

for the rear face temperature rise to reach certain percentages of initiation of the heat pulse as an integral part of the time

of its maximum value. This test method is described in detail

determination. Response times of the detectors and amplifiers

in a number of publications (1, 2) and review articles (3, 4, 5) are extremely important. Response time effects are considered

and has been standardized in Test Method C 714 in a more

in detail in 7.1.3. Measurement errors have been discussed in

simple form for carbons and graphites. some detail (5, 14, 15).

6.1.2 Non-measurement errors associated with deviations of

NOTE 1—While this test method was developed for and applied

actual experimental conditions as they exist during the experi-

originally to homogeneous opaque solids, in which a large front face

ment from the boundary conditions assumed in the mathemati-

temperature excursion was not detrimental, it can be extended under

appropriate conditions to a wide variety of materials and situations. These cal model used to derive the equation for computing the

include heterogeneous specimens of dispersed composites (6), layered

thermal diffusivity. The major sources of non-measurement

structures (7, 8) translucent materials, liquids and coatings (9, 10) and the

errors are finite pulse time effect, heat losses or gains, and

measurement of contact conductance and resistance (11, 12).

non-uniform heating. The mathematical derivation assumes

that the energy pulse is delivered in times short compared to

4.2 The pulse raises the temperature of the specimen only a

the rise time. The case where this is not true is called the finite

few degrees above its initial ambient value. However, initially

pulse time effect and it becomes important when the duration

all of this energy is deposited on the front surface and this

of the energy pulse is greater than 2 % of the half rise time. It

temperature may rise many degrees. If this should damage the

should be noted that these three effects are not strictly classified

specimen, a layer of a material with known properties (thermal

as errors (may be determined experimentally) but are merely

diffusivity, specific heat and density) and measured thickness

deviations from an ideal situation in which these effects are

can be attached to the front surface and results on the

assumed to be negligible. It is assumed that the material is

composite specimen analyzed using a two-layer method. This

opaque, that is, radiation from the energy source heats only the

requires that the specific heat and density of the specimen also

specimen surface. Furthermore, it is assumed that the tempera-

be known (13).

ture sensor follows accurately the rear surface temperature

excursion. Thus, if an i.r. detector is used, it must not view into

5. Significance and Use

the specimen interior. Specimens of translucent/transparent

5.1 Thermal diffusivity is an important property required for

materials require special techniques similar to those used for

such purposes as design applications under transient heat flow

layered structures.

conditions, determination of safe operating temperature, pro-

cess control, and quality assurance.

7. Apparatus

5.2 The flash method is used to measure values of thermal

7.1 The essential features of the apparatus are shown in Fig.

diffusivity (a) of a wide range of solid materials. It is

1. These are the flash source, sample holder and environmental

particularly advantageous because of the simple specimen

geometry, small specimen size requirements, rapidity of mea-

surement, and ease of handling materials having a wide range

of thermal diffusivity values over a large temperature range

with a single apparatus. The short measurement times involved

reduce the chances of contamination and change of specimen

properties due to exposure to high temperature environments.

5.3 Thermal diffusivity results in many cases can be com-

bined with values for specific heat (C ) and density (r) and

p

used to derive thermal conductivity (l) from the relation l = a

C r.

p

The boldface numbers given in parentheses refer to a list of references at the

end of the text. FIG. 1 Flash Diffusivity Apparatus (Schematic)

E 1461

system, temperature response detector, and data collection and behavior is best represented by Eq 2:

analysis components.

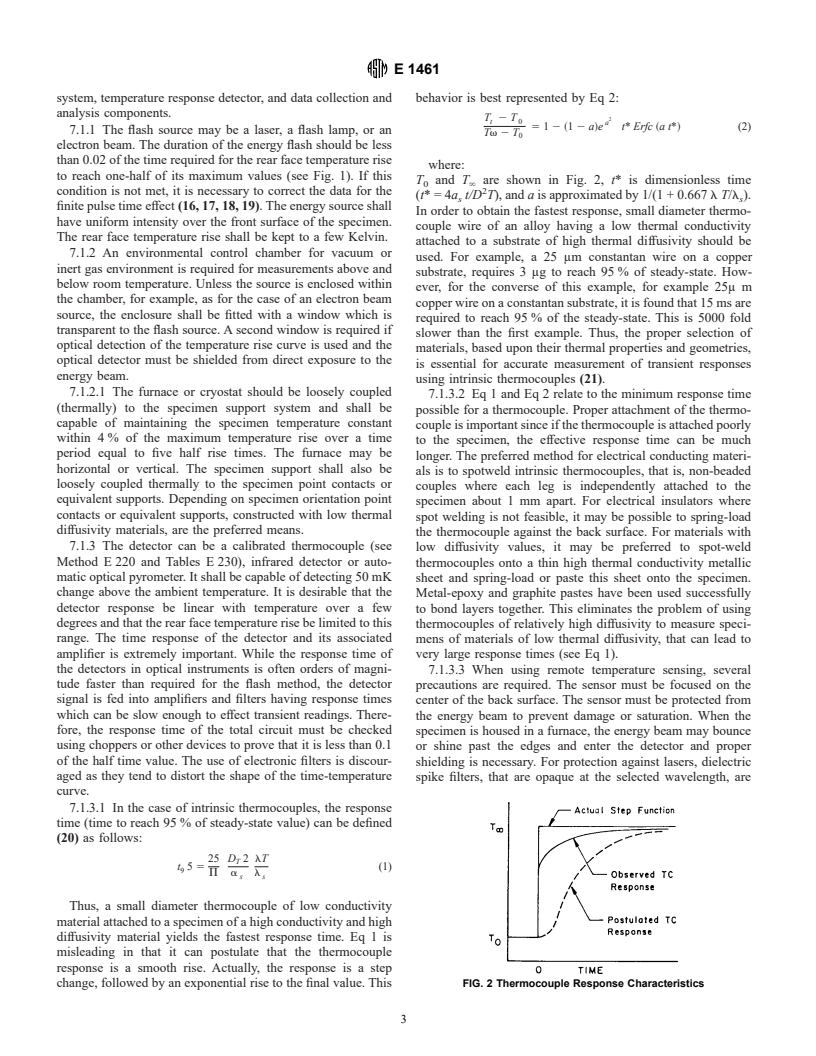

T 2 T 2

t 0

a

5 1 2 ~1 2 a!e t* Erfc ~at*! (2)

7.1.1 The flash source may be a laser, a flash lamp, or an

Tv2 T

electron beam. The duration of the energy flash should be less

than 0.02 of the time required for the rear face temperature rise

where:

to reach one-half of its maximum values (see Fig. 1). If this

T and T are shown in Fig. 2, t* is dimensionless time

0 ‘

condition is not met, it is necessary to correct the data for the

(t*=4a t/D T), and a is approximated by 1/(1 + 0.667 l T/l ).

s s

finite pulse time effect (16, 17, 18, 19). The energy source shall

In order to obtain the fastest response, small diameter thermo-

have uniform intensity over the front surface of the specimen.

couple wire of an alloy having a low thermal conductivity

The rear face temperature rise shall be kept to a few Kelvin.

attached to a substrate of high thermal diffusivity should be

7.1.2 An environmental control chamber for vacuum or

used. For example, a 25 μm constantan wire on a copper

inert gas environment is required for measurements above and

substrate, requires 3 μg to reach 95 % of steady-state. How-

below room temperature. Unless the source is enclosed within

ever, for the converse of this example, for example 25μ m

the chamber, for example, as for the case of an electron beam

copper wire on a constantan substrate, it is found that 15 ms are

source, the enclosure shall be fitted with a window which is

required to reach 95 % of the steady-state. This is 5000 fold

transparent to the flash source. A second window is required if

slower than the first example. Thus, the proper selection of

optical detection of the temperature rise curve is used and the

materials, based upon their thermal properties and geometries,

optical detector must be shielded from direct exposure to the

is essential for accurate measurement of transient responses

energy beam.

using intrinsic thermocouples (21).

7.1.2.1 The furnace or cryostat should be loosely coupled

7.1.3.2 Eq 1 and Eq 2 relate to the minimum response time

(thermally) to the specimen support system and shall be

possible for a thermocouple. Proper attachment of the thermo-

capable of maintaining the specimen temperature constant

couple is important since if the thermocouple is attached poorly

within 4 % of the maximum temperature rise over a time

to the specimen, the effective response time can be much

period equal to five half rise times. The furnace may be

longer. The preferred method for electrical conducting materi-

horizontal or vertical. The specimen support shall also be

als is to spotweld intrinsic thermocouples, that is, non-beaded

loosely coupled thermally to the specimen point contacts or

couples where each leg is independently attached to the

equivalent supports. Depending on specimen orientation point

specimen about 1 mm apart. For electrical insulators where

contacts or equivalent supports, constructed with low thermal

spot welding is not feasible, it may be possible to spring-load

diffusivity materials, are the preferred means.

the thermocouple against the back surface. For materials with

7.1.3 The detector can be a calibrated thermocouple (see

low diffusivity values, it may be preferred to spot-weld

Method E 220 and Tables E 230), infrared detector or auto- thermocouples onto a thin high thermal conductivity metallic

matic optical pyrometer. It shall be capable of detecting 50 mK

sheet and spring-load or paste this sheet onto the specimen.

change above the ambient temperature. It is desirable that the Metal-epoxy and graphite pastes have been used successfully

detector response be linear with temperature over a few

to bond layers together. This eliminates the problem of using

degrees and that the rear face temperature rise be limited to this thermocouples of relatively high diffusivity to measure speci-

range. The time response of the detector and its associated

mens of materials of low thermal diffusivity, that can lead to

amplifier is extremely important. While the response time of very large response times (see Eq 1).

the detectors in optical instruments is often orders of magni-

7.1.3.3 When using remote temperature sensing, several

tude faster than required for the flash method, the detector precautions are required. The sensor must be focused on the

signal is fed into amplifiers and filters having response times

center of the back surface. The sensor must be protected from

which can be slow enough to effect transient readings. There- the energy beam to prevent damage or saturation. When the

fore, the response time of the total circuit must be checked

specimen is housed in a furnace, the energy

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.