ASTM E2067-00a

(Practice)Standard Practice for Full-Scale Oxygen Consumption Calorimetry Fire Tests

Standard Practice for Full-Scale Oxygen Consumption Calorimetry Fire Tests

SCOPE

1.1 This practice deals with methods to construct, calibrate, and use full scale oxygen consumption calorimeters to help minimize testing result discrepancies between laboratories.

1.2 The methodology described herein is used in a number of ASTM test methods, in a variety of unstandardized test methods, and for research purposes. This practice will facilitate coordination of generic requirements, which are not specific to the item under test.

1.3 The principal fire-test-response characteristics obtained from the test methods using this technique are those associated with heat release from the specimens tested, as a function of time. Other fire-test-response characteristics also are determined.

1.4 This practice is intended to apply to the conduction of different types of tests, including both some in which the objective is to assess the comparative fire performance of products releasing low amounts of heat or smoke and some in which the objective is to assess whether flashover will occur.

1.5 This practice does not provide pass/fail criteria that can be used as a regulatory tool, nor does it describe a test method for any material or product.

1.6 For use of the SI system of units in referee decisions, see IEEE/ASTM SI-10. The units given in parentheses are provided for information only.

1.7 This standard is used to measure and describe the response of materials, products, or assemblies to heat and flame under controlled conditions, but does not by itself incorporate all factors required for fire hazard or fire risk assessment of the materials, products, or assemblies under actual fire conditions.

Note 1--This is the standard caveat described in section F2.2.2.1 of the Form and Style for ASTM Standards manual for fire-test-response standards. In actual fact, this practice does not provide quantitative measures.

1.8 Fire testing of products and materials is inherently hazardous, and adequate safeguards for personnel and property shall be employed in conducting these tests. Fire testing involves hazardous materials, operations, and equipment. See also Section 7.

1.9 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: E 2067 – 00a

Standard Practice for

Full-Scale Oxygen Consumption Calorimetry Fire Tests

This standard is issued under the fixed designation E 2067; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 1.9 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.1 This practice deals with methods to construct, calibrate,

responsibility of the user of this standard to establish appro-

and use full scale oxygen consumption calorimeters to help

priate safety and health practices and determine the applica-

minimize testing result discrepancies between laboratories.

bility of regulatory limitations prior to use.

1.2 The methodology described herein is used in a number

of ASTM test methods, in a variety of unstandardized test

2. Referenced Documents

methods, and for research purposes. This practice will facilitate

2.1 ASTM Standards:

coordination of generic requirements, which are not specific to

D 5424 Test Method for Smoke Obscuration of Insulating

the item under test.

Materials Contained in Electrical or Optical Fiber Cables

1.3 The principal fire-test-response characteristics obtained

When Burning in a Vertical Cable Tray Configuration

from the test methods using this technique are those associated

D 5537 Test Method for Heat Release, Flame Spread and

with heat release from the specimens tested, as a function of

Mass Loss Testing of Insulating Materials Contained in

time. Other fire-test-response characteristics also are deter-

Electrical or Optical Fiber Cables When Burning in a

mined.

Vertical Cable Tray Configuration

1.4 This practice is intended to apply to the conduction of

D 6113 Test Method for Using a Cone Calorimeter to

different types of tests, including both some in which the

Determine Fire-Test-Response Characteristics of Insulat-

objective is to assess the comparative fire performance of

ing Materials Contained in Electrical or Optical Fiber

products releasing low amounts of heat or smoke and some in

Cables

which the objective is to assess whether flashover will occur.

E 84 Test Method for Surface Burning Characteristics of

1.5 This practice does not provide pass/fail criteria that can

Building Materials

be used as a regulatory tool, nor does it describe a test method

E 176 Terminology of Fire Standards

for any material or product.

E 603 Guide for Room Fire Experiments

1.6 For use of the SI system of units in referee decisions, see

E 662 Test Method for Specific Optical Density of Smoke

IEEE/ASTM SI-10. The units given in parentheses are pro-

Generated by Solid Materials

vided for information only.

E 906 Test Method for Heat and Visible Smoke Release

1.7 This standard is used to measure and describe the

Rates for Materials and Products

response of materials, products, or assemblies to heat and flame

E 1354 Test Method for Heat and Visible Smoke Release

under controlled conditions, but does not by itself incorporate

Rates for Materials and Products Using an Oxygen Con-

all factors required for fire hazard or fire risk assessment of the

sumption Calorimeter

materials, products, or assemblies under actual fire conditions.

E 1474 Test Method for Determining the Heat Release Rate

NOTE 1—This is the standard caveat described in section F2.2.2.1 of the

of Upholstered Furniture and Mattress Components or

Form and Style for ASTM Standards manual for fire-test-response

Composites Using a Bench Scale Oxygen Consumption

standards. In actual fact, this practice does not provide quantitative

Calorimeter

measures.

E 1537 Test Method for Fire Testing of Upholstered Seating

1.8 Fire testing of products and materials is inherently

Furniture

hazardous, and adequate safeguards for personnel and property 3

E 1590 Test Method for Fire Testing of Mattresses

shall be employed in conducting these tests. Fire testing

E 1623 Test Method for Determining Fire and Thermal

involves hazardous materials, operations, and equipment. See

Parameters of Materials, Products and Systems Using and

also Section 7.

Intermediate Scale Calorimeter (ICAL)

E 1740 Test Method for Determining the Heat Release Rate

and Other Fire-Test-Response Characteristics of Wallcov-

This practice is under the jurisdiction of ASTM Committee E-5 on Fire

ering Composites Using a Cone Calorimeter

Standards and is the direct responsibility of Subcommittee E05.13 on Large Scale

Fire Tests.

Current edition approved Oct. 10, 2000. Published October 2000. Originally Annual Book of ASTM Standards, Vol 10.02.

published as E 2067–00. Last previous edition E 2067–00. Annual Book of ASTM Standards, Vol 04.07.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

E 2067

E 1822 Test Method for Fire Testing of Stacked Chairs 3.1.3 oxygen consumption principle, n—the expression of

IEEE/ASTM SI-10, International System of Units (SI) The the relationship between the mass of oxygen consumed during

Modernized Metric System combustion and the heat released. (E 176)

2.2 ISO Standards: 3.1.4 smoke, n—the airborne solid and liquid particulates

and gases evolved when a material undergoes pyrolysis or

ISO Guide 52 - Glossary of Fire Terms and Definitions

combustion. (E 176)

ISO 3261 Fire Tests - Vocabulary

3.1.5 smoke obscuration, n—reduction of light transmission

ISO 5660-1, Fire Tests—Reaction to Fire—Rate of Heat

by smoke, as measured by light attenuation. (E 176)

Release from Building Products (Cone Calorimeter

3.2 Definitions of Terms Specific to This Standard:

Method)

3.2.1 composite, n—a combination of materials, which

ISO 9705, Fire Tests - Full-Scale Room Test for Surface

generally are recognized as distinct entities, for example,

Products

coated or laminated materials.

2.3 California Bureau of Home Furnishings and Thermal

3.2.2 continuous (as related to data acquisition), adj—

Insulation Standards:

conducted at data collection intervals of6sor less.

CA Technical Bulletin 129 (October 1992), Flammability

3.2.3 sample, n—an amount of the material, product, or

Test Procedure for Mattresses for Use in Public Buildings

assembly, to be tested, which is representative of the item as a

CA Technical Bulletin 133 (January 1991), Flammability

whole.

Test Procedure for Seating Furniture for Use in Public

3.2.4 specimen, n—representative piece of the product,

Occupancies

which is to be tested together with any substrate or treatment.

2.4 NFPA Standards:

NFPA 265 Standard Methods of Fire Tests for Evaluating

4. Significance and Use

Room Fire Growth Contribution of Textile Wall Coverings

4.1 The oxygen consumption principle, used for the mea-

NFPA 266 Standard Method of Test for Fire Characteristics

surements described here, is based on the observation that,

of Upholstered Furniture Exposed to Flaming Ignition

generally, the net heat of combustion is directly related to the

Source

amount of oxygen required for combustion (1). Approxi-

NFPA 267 Standard Method of Test for Fire Characteristics

mately 13.1 MJ of heat are released per 1-kg of oxygen

of Mattresses and Bedding Assemblies Exposed to Flam-

consumed. Test specimens in the test are burned in ambient air

ing Ignition Source

conditions, while being subjected to a prescribed external

NFPA 286 Standard Methods of Fire Tests for Evaluating

heating source.

Room Fire Growth Contribution of Wall and Ceiling

4.1.1 This technique is not appropriate for use on its own

Interior Finish

when the combustible fuel is an oxidizer or an explosive agent,

2.5 UL Standards:

which release oxygen. Further analysis is required in such

UL 1685, Standard Vertical Tray Fire Propagation and

cases (see Appendix X2).

Smoke Release Test for Electrical and Optical Fiber

4.2 The heat release is determined by the measurement of

Cables

the oxygen consumption, as determined by the oxygen con-

UL 1975, Standard Fire Tests for Foamed Plastics Used for

centration and the flow rate in the combustion product stream,

Decorative Purposes

in a full scale environment.

4.3 The primary measurements are oxygen concentration

3. Terminology

and exhaust gas flow rate. Additional measurements include

3.1 Definitions—For definitions of terms used in this prac-

the specimen ignitability, the smoke obscuration generated, the

tice, refer to Terminology E 176 and ISO 3261. In case of

specimen mass loss rate, the effective heat of combustion and

conflict, the definitions given in Terminology E 176 shall

the yields of combustion products from the test specimen.

prevail.

4.4 The oxygen consumption technique is used in different

3.1.1 heat release rate, n—the heat evolved from the

types of test methods. Intermediate scale (Test Method E 1623,

specimen, per unit of time. (E 176)

UL 1975) and full scale (Test Method D 5424, Test Method

3.1.2 ignition, n—the initiation of combustion. (E 176)

D 5537, Test Method E 1537, Test Method E 1590, Test

3.1.2.1 Discussion—The combustion may be evidenced by

Method E 1822, ISO 9705, NFPA 265, NFPA 266, NFPA 267,

glow, flame, detonation or explosion. The combustion may be

NFPA 286, UL 1685) test methods, as well as unstandardized

sustained or transient.

room scale experiments following Guide E 603, using this

technique involve a large instrumented exhaust hood, where

oxygen concentration is measured, either standing alone or

Annual Book of ASTM Standards, Vol 14.02. positioned outside a doorway. A large test specimen is placed

Available from International Standardization Organization, P.O. Box 56,

either under the hood or inside the room. This practice is

CH-1211; Geneva 20, Switzerland.

intended to address issues associated with equipment requiring

Available from California Bureau of Home Furnishings and Thermal Insula-

a large instrumented hood and not stand-alone test apparatuses

tion, State of California, Department of Consumer Affairs, 3485 Orange Grove

Avenue, North Highlands, CA 95660–5595.

with small test specimens.

Available from National Fire Protection Association (NFPA), 1 Batterymarch

Park, Quincy, MA 02269–9101.

8 9

Available from Underwriters Laboratories, Inc., 333 Pfingsten Rd., Northbrook, The boldface numbers in parentheses refers to the list of references at the end

IL 60062. of this standard.

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

E 2067

If the wallboard is thicker, it will not affect the results of this test. Gypsum

4.4.1 Small scale test methods using this technique, such as

wallboard is likely to generate a measurable amount of heat or smoke

Test Methods D 6113, E 1354, E 1474 and E 1740, as well as,

release at high heat inputs, due primarily to its paper facer.

ISO 5660 internationally, are based on a stand-alone apparatus,

5.1.2.1 Install an additional layer of fire rated wallboard on

wherein a small specimen is tested within the equipment.

4.5 Throughout this practice, test equipment is referenced to the portions of the walls or ceiling directly adjacent to the test

specimen location. Cover at least 1.22 by 1.22 m (4 by 4 ft) of

provide helpful guidance to test facilities. Substitution of

equivalent, or better, test measuring devices is permissible. the ceiling with the added wallboard, but do not place an

additional layer of wallboard under the test specimen. This

5. Test Room Layout

ceiling surface is the most severely exposed to flames and heat

5.1 Standard Rooms:

and needs frequent replacement. Replace any portion of the

5.1.1 Three standard room configurations have been in

lining if cracks occur or severe burn damage is observed.

common use for many years, often designated as the “ASTM”/

5.1.2.2 Frequently, whenever there is a single test specimen,

“ISO” room (cited in Guide E 603 and in ISO 9705), and the

such as Test Method E 1537, Test Method E 1590, or Test

“California” room (used in CA TB 129 and CA TB 133, as well

Method E 1822, the test specimen location is the corner of the

as, Test Methods E 1537, E 1590, and E 1822), and the cable

room furthest away from the doorway. The test specimen also

tray test room (used in Test Methods D 5424 and D 5537, as

is usually placed on a weighing platform. This test room is

well as, in UL 1685).

unsuitable for Test Method D 5424 or Test Method D 5537.

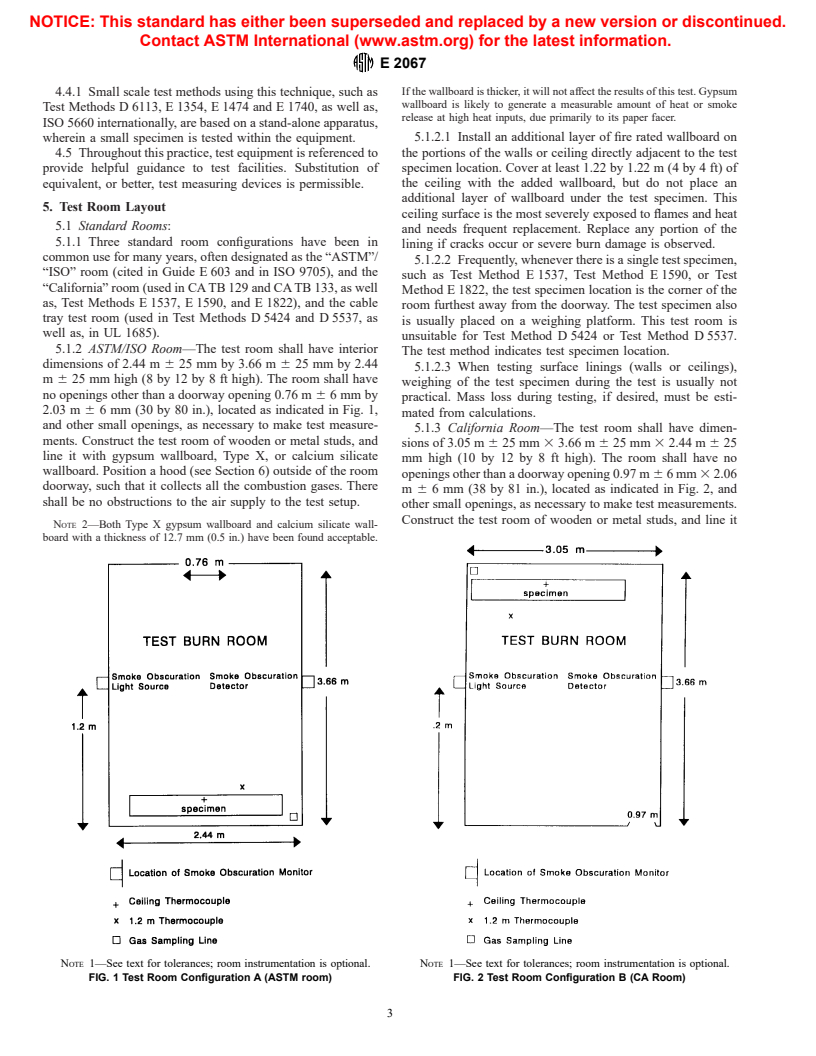

5.1.2 ASTM/ISO Room—The test room shall have interior

The test method indicates test specimen location.

dimensions of 2.44 m 6 25 mm by 3.66 m 6 25 mm by 2.44

5.1.2.3 When testing surface linings (walls or ceilings),

m 6 25 mm high (8 by 12 by 8 ft high). The room shall have

weighing of the test specimen during the test is usually not

no openings other than a doorway opening 0.76 m 6 6mmby

practical. Mass loss during testing, if desired, must be esti-

2.03 m 6 6 mm (30 by 80 in.), located as indicated in Fig. 1,

mated from calculations.

and other small openings, as necessary to make test measure-

5.1.3 California Room—The test room shall have dimen-

ments. Construct the test room of wooden or metal studs, and

sions of 3.05 m 6 25 mm 3 3.66 m 6 25 mm 3 2.44 m 6 25

line it with gypsum wallboard, Type X, or calcium silicate

mm high (10 by 12 by 8 ft high). The room shall have no

wallboard. Position a hood (see Section 6) outside of the room

openings other than a doorway opening 0.97 m 66mm 3 2.06

doorway, such that it collects all the combustion gases. There

m 6 6 mm (38 by 81 in.), located as indicated in Fig. 2, and

shall be no obstructions to the air supply to the test setup.

other small openings, as necessary to make test measurements.

Construct the test room of wooden or metal studs, and line it

NOTE 2—Both Type X gypsum wallboard and calcium silicate wall-

board with a thickness of 12.7 mm (0.5 in.) have been found acceptable.

NOTE 1—See text for tolerances; room instrumentation is optional. NOTE 1—See text for tolerances; room instrumentation is optional.

FIG. 1 Test Room Configuration A (ASTM room) FIG. 2 Test Room Configuration B (CA Room)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

E 2067

with gypsum wallboard, Type X, or calcium silicate wallboard. equal. The air intakes are 559 mm by 343 mm high (22

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.