ASTM F1909-98(2020)

(Specification)Standard Specification for Preformed Open–Cell Sponge Rubber Pail and Drum Gaskets

Standard Specification for Preformed Open–Cell Sponge Rubber Pail and Drum Gaskets

ABSTRACT

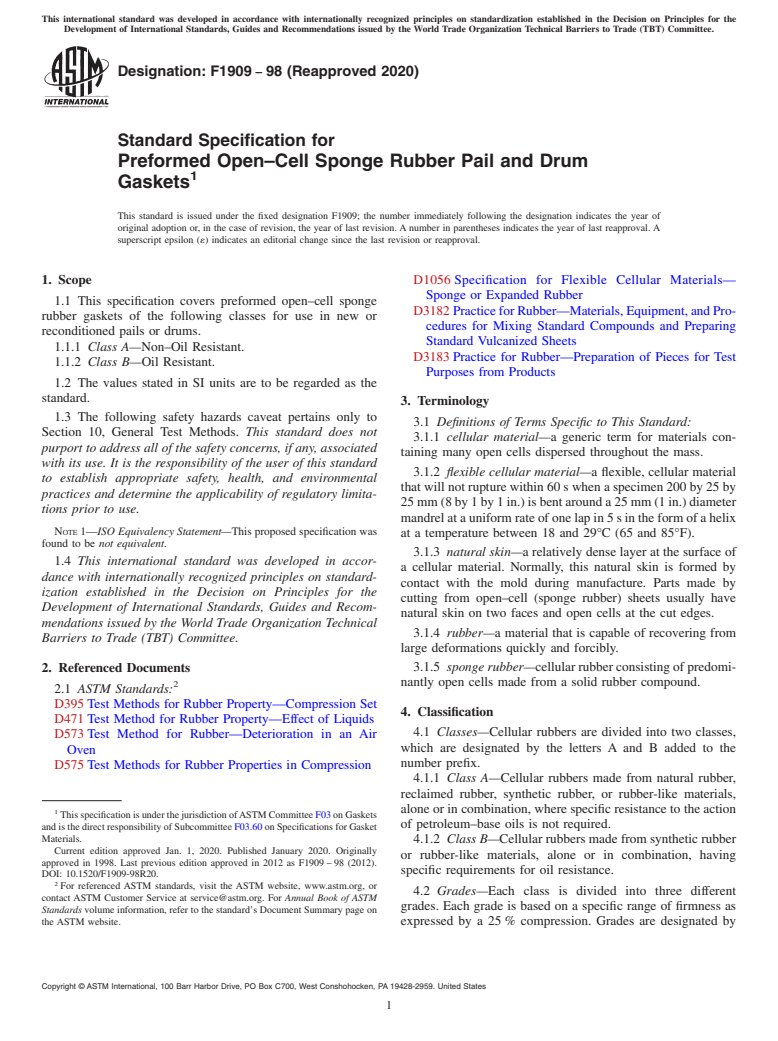

This specification covers preformed open-cell sponge rubber gaskets, for use in new or reconditioned pails or drums, of the following classes: Class A and Class B, each divided into Grade 1, Grade 2, and Grade 3. Cellular sponge rubber gaskets shall be made by incorporating a blowing agent into the compound, such as sodium bicarbonate, that gives off a gas which expands the mass during the vulcanization process, and shall be manufactured from natural rubber, synthetic rubber, or rubber-like materials, together with added compounding ingredients. Unless otherwise specified, gasket sponge rubber shall have a natural skin on both the top and bottom surfaces. Cellular rubber shall conform to the prescribed requirements as to physical properties such as (1) compression at deflection, (2) change in volume upon oil immersion, (3) change in compression value after heat aging, (4) compression set, and (5) color (tan or black). The following test methods shall be used: (1) compression deflection test, (2) oil immersion test, (3) heat oven aging test, and (4) compression set test under constant deflection. The formula for calculating the compression set is given. The requirements for sampling, test specimens and slabs, and measurements of test specimen such as width and thickness are detailed as well. The location from which standard test specimens are to be cut when testing standard test slabs or commercial flat sheets and the four-cavity frame for standard test slabs of cellular rubbers are illustrated.

SCOPE

1.1 This specification covers preformed open–cell sponge rubber gaskets of the following classes for use in new or reconditioned pails or drums.

1.1.1 Class A—Non–Oil Resistant.

1.1.2 Class B—Oil Resistant.

1.2 The values stated in SI units are to be regarded as the standard.

1.3 The following safety hazards caveat pertains only to Section 10, General Test Methods. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

Note 1: ISO Equivalency Statement—This proposed specification was found to be not equivalent.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:F1909 −98 (Reapproved 2020)

Standard Specification for

Preformed Open–Cell Sponge Rubber Pail and Drum

Gaskets

This standard is issued under the fixed designation F1909; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D1056 Specification for Flexible Cellular Materials—

Sponge or Expanded Rubber

1.1 This specification covers preformed open–cell sponge

D3182 PracticeforRubber—Materials,Equipment,andPro-

rubber gaskets of the following classes for use in new or

cedures for Mixing Standard Compounds and Preparing

reconditioned pails or drums.

Standard Vulcanized Sheets

1.1.1 Class A—Non–Oil Resistant.

D3183 Practice for Rubber—Preparation of Pieces for Test

1.1.2 Class B—Oil Resistant.

Purposes from Products

1.2 The values stated in SI units are to be regarded as the

standard.

3. Terminology

1.3 The following safety hazards caveat pertains only to

3.1 Definitions of Terms Specific to This Standard:

Section 10, General Test Methods. This standard does not

3.1.1 cellular material—a generic term for materials con-

purport to address all of the safety concerns, if any, associated

taining many open cells dispersed throughout the mass.

with its use. It is the responsibility of the user of this standard

3.1.2 flexible cellular material—a flexible, cellular material

to establish appropriate safety, health, and environmental

that will not rupture within 60 s when a specimen 200 by 25 by

practices and determine the applicability of regulatory limita-

25mm(8by1by1in.)isbentarounda25mm(1in.)diameter

tions prior to use.

mandrelatauniformrateofonelapin5sintheformofahelix

NOTE 1—ISO Equivalency Statement—This proposed specification was

at a temperature between 18 and 29°C (65 and 85°F).

found to be not equivalent.

3.1.3 natural skin—a relatively dense layer at the surface of

1.4 This international standard was developed in accor-

a cellular material. Normally, this natural skin is formed by

dance with internationally recognized principles on standard-

contact with the mold during manufacture. Parts made by

ization established in the Decision on Principles for the

cutting from open–cell (sponge rubber) sheets usually have

Development of International Standards, Guides and Recom-

natural skin on two faces and open cells at the cut edges.

mendations issued by the World Trade Organization Technical

3.1.4 rubber—a material that is capable of recovering from

Barriers to Trade (TBT) Committee.

large deformations quickly and forcibly.

3.1.5 sponge rubber—cellularrubberconsistingofpredomi-

2. Referenced Documents

2 nantly open cells made from a solid rubber compound.

2.1 ASTM Standards:

D395 Test Methods for Rubber Property—Compression Set

4. Classification

D471 Test Method for Rubber Property—Effect of Liquids

4.1 Classes—Cellular rubbers are divided into two classes,

D573 Test Method for Rubber—Deterioration in an Air

which are designated by the letters A and B added to the

Oven

number prefix.

D575 Test Methods for Rubber Properties in Compression

4.1.1 Class A—Cellular rubbers made from natural rubber,

reclaimed rubber, synthetic rubber, or rubber-like materials,

alone or in combination, where specific resistance to the action

ThisspecificationisunderthejurisdictionofASTMCommitteeF03onGaskets

of petroleum–base oils is not required.

andisthedirectresponsibilityofSubcommitteeF03.60onSpecificationsforGasket

Materials.

4.1.2 Class B—Cellular rubbers made from synthetic rubber

Current edition approved Jan. 1, 2020. Published January 2020. Originally

or rubber-like materials, alone or in combination, having

approved in 1998. Last previous edition approved in 2012 as F1909 – 98 (2012).

specific requirements for oil resistance.

DOI: 10.1520/F1909-98R20.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

4.2 Grades—Each class is divided into three different

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

grades. Each grade is based on a specific range of firmness as

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. expressed by a 25 % compression. Grades are designated by

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F1909−98 (2020)

TABLE 1 Physical Requirements of Open–Cell Sponge Rubber TABLE 2 Tolerances on Dimensions for Open–Cell Sponge

Pail and Drum Gaskets Rubber Pail or Drum Gaskets

Requirements Thickness

Class/ Compression Oil Heat Aged 7 Compression mm (in.) Tolerance ± mm (in.)

Grade at 25 % Immersion Days at Set, 22 h 4.8 (0.188) 1.5 (0.062)

Number Deflection 22hat 70°C at 70°C 6.4 (0.250) 1.5 (0.062)

(Limits), kPa 70°C (158°F), (158°F) 50 %

7.9 (0.313) 1.5 (0.062)

(psi) (158°F), Change in Deflection, 9.5 (0.375) 1.5 (0.062)

Change in Original Max %

11.1 (0.438) 1.5 (0.062)

Volume in Compression 12.7 (0.500) 1.5 (0.062)

ASTM Oil Values

Width

IRM 903 (Limits), % mm (in.) Tolerance ± mm (in.)

(Limits), %

4.8 (0.188) 1.5 (0.062)

Class A, Non-Oil Resistant 6.4 (0.250) 1.5 (0.062)

A1 15–50 (2–7) — ±20 15

7.9 (0.313) 1.5 (0.062)

A2 50–85 (7–12) — ±20 15

9.5 (0.375) 1.5 (0.062)

A3 85–120 (12–17) — ±20 15

11.1 (0.438) 1.5 (0.062)

Class B, Oil-Resistant, Medium Swell

12.7 (0.500) 1.5 (0.062)

B1 15–50 (2–7) +10 to +60 ±20 50 Length

B2 50–85 (7–12) +10 to +60 ±20 50

Dimension mm (in.)

B3 85–120 (12–17) +10 to +60 ±20 50 As Required—Circular open–cell sponge rubber pail and drum gaskets are

manufactured to fit specified pail or drum flanges by cutting to the specified

length and sealing the cut ends together.

digit, the softer grades being identified with the lower numbers

8. Workmanship, Finish, and Appearance

andthehardergradesbeingidentifiedwiththehighernumbers.

4.2.1 Grade 1—A compression deflection range from 15 to

8.1 Cellular rubber gaskets under this specification shall be

50 kPa (2 to 7 psi).

manufactured from natural rubber, synthetic rubber, or rubber-

4.2.2 Grade 2—A compression deflection range from 50 to

likematerials,togetherwithaddedcompoundingingredientsof

85 kPa (7 to 12 psi).

such nature and quality that the finished product complies with

4.2.3 Grade 3—A compression deflection range from 85 to

the specification requirements. In permitting choice in the use

120 kPa (12 to 17 psi).

of materials by the producer, it is not intended to imply that the

different rubber materials are equivalent in respect to all

5. Materials and Manufacture

physical properties. Any special characteristics that may be

desired for specific applications other than those prescribed in

5.1 Sponge rubber gaskets are made by incorporating a

this specification, shall be stated in the product specifications

blowing agent into the compound, such as sodium bicarbonate,

as they may influence the choice of the type of rubber material

that gives off a gas which expands the mass during the

or other ingredients used.All materials and workmanship shall

vulcanization process.

be in accordance with good commercial practice, and the

5.2 Sponge rubber gaskets are manufactured to specified

resulting cellular rubbers shall be free from defects affecting

dimensions. Unless otherwise specified, gasket sponge rubber

serviceability.

shall have a natural skin on both the top and bottom surfaces.

Fabric surface impressions are not objectionable.

9. Sampling

9.1 When possible, the completed manufactured product

6. Physical Properties

shall be used for the tests specified. Representative samples of

6.1 The various grades of cellular rubber shall conform to

the lot being examined shall be selected at random as required.

the requirements as to physical properties in Table 1 and Table

9.2 When the finished product does not lend itself to testing

2.

ortothetakingoftestspecimensbecauseofcomplicatedshape

6.2 Color—Unless otherwise specified, the color of cellular

or other reasons, standard test slabs shall be prepared. When

rubber gaskets shall be tan or black.

differences due to the difficulty in obtaining suitable test

specimens from the finished part arise, manufacturer and

7. Tolerances on Dimensions

purchaser may agree on acceptable deviations. Agreement on

7.1 Tolerances on dimensions of cellular rubber gaskets

acceptable deviations can be achieved by comparing results of

shall be as specified in Table 2.

standard test specimens with those obtained on actual parts.

7.2 Measurements of Test Specimens—Thickness and width

3 10. General Test Methods

shall be measured using a dial–type gage , having a maximum

stemandcircularfootmassof25gandacircularfoot31.8mm 10.1 Except as otherwise specified in these test methods for

(1.250 in.) in diameter. open-cell rubber, the following test methods shall be complied

with as required and are hereby made a part of this specifica-

tion.

10.1.1 General Physical Test Requirements—Practices

Agage similar to Federal Products Co. No. 57 B-1Y7692 is satisfactory for this

purpose. D3182 and D3183.

F1909−98 (2020)

In all cases the natural surface skin shall be left intact on both

top and bottom faces of the test slab.

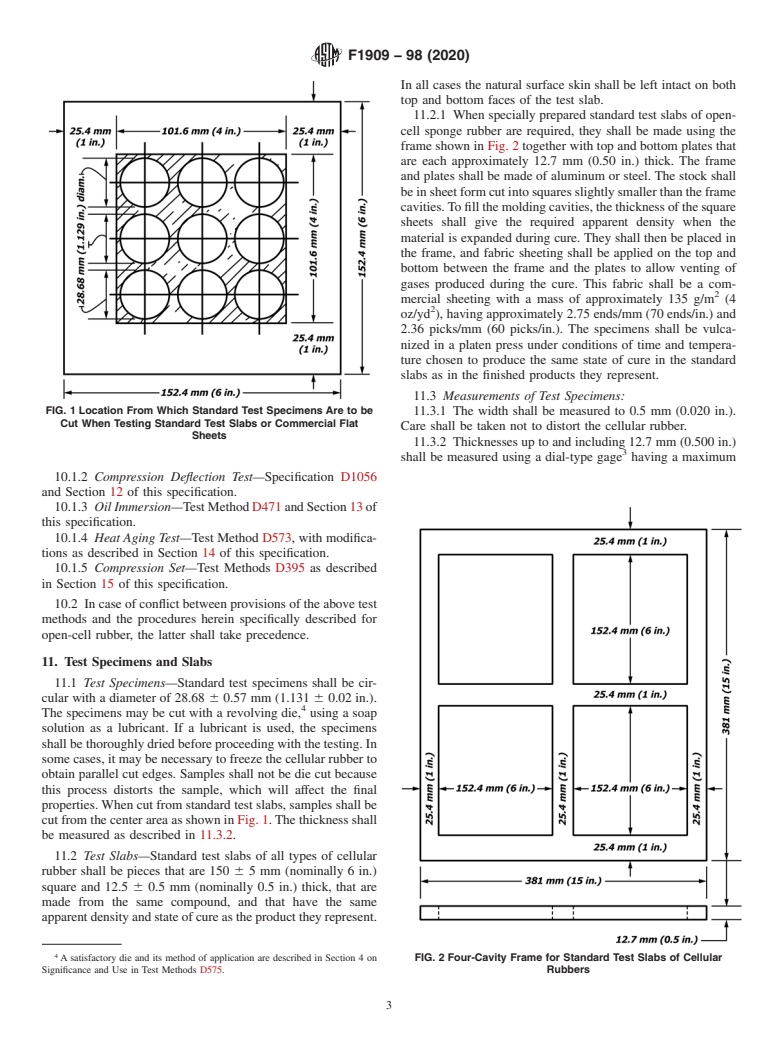

11.2.1 When specially prepared standard test slabs of open-

cell sponge rubber are required, they shall be made using the

frame shown in Fig. 2 together with top and bottom plates that

are each approximately 12.7 mm (0.50 in.) thick. The frame

and plates shall be made of aluminum or steel. The stock shall

beinsheetformcutintosquaresslightlysmallerthantheframe

cavities.Tofillthemoldingcavities,thethicknessofthesquare

sheets shall giv

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.