ASTM C368-88(2020)

(Test Method)Standard Test Method for Impact Resistance of Ceramic Tableware

Standard Test Method for Impact Resistance of Ceramic Tableware

SIGNIFICANCE AND USE

3.1 The purpose of this test method is to predict product resistance to impact breakage in service.

SCOPE

1.1 This test method covers the following tests:

1.1.1 Impact tests at the center of both flatware and hollow ware and at the rim of hollow ware, and

1.1.2 Chipping tests at the rim of flatware. Specimens may be either glazed or unglazed.

Note 1: The impact test at the center of the specimen is used to determine: (1) the magnitude of a blow that will produce initial fracture, and (2) the amount of energy necessary to produce complete failure. In the first case, the initial fracture shows on the side of the piece opposite from that being struck and appears to be a function of the square of the thickness and of the inherent brittleness of the body or body-glaze combination; it is relatively independent of the size or design of the specimen. The second factor is more dependent upon design and often is subject to wide variation within a given group of pieces.

Note 2: The impact test at the rim of hollow ware is similar to a chipping test, and the type of failure that is obtained is useful in evaluating the effect of the shape of the object.

Note 3: In addition to the inherent strength of the body, chipping test results are greatly affected by contour of rim and to a lesser extent by thickness of rim, inclination of leaf, and fit of glaze.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: C368 − 88 (Reapproved 2020)

Standard Test Method for

Impact Resistance of Ceramic Tableware

This standard is issued under the fixed designation C368; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2.1 ASTM Adjuncts:

1.1 This test method covers the following tests:

ADJC0368 Machine for Testing Chinaware

1.1.1 Impact tests at the center of both flatware and hollow

ware and at the rim of hollow ware, and

3. Significance and Use

1.1.2 Chipping tests at the rim of flatware. Specimens may

3.1 The purpose of this test method is to predict product

be either glazed or unglazed.

resistance to impact breakage in service.

NOTE 1—The impact test at the center of the specimen is used to

4. Apparatus

determine: (1) the magnitude of a blow that will produce initial fracture,

and (2) the amount of energy necessary to produce complete failure. In the

4.1 Impact Tester, Pendulum Type—The impact test appara-

first case, the initial fracture shows on the side of the piece opposite from

tus (Figs. 1 and 2) shall consist of a device having the

that being struck and appears to be a function of the square of the

following essential features:

thickness and of the inherent brittleness of the body or body-glaze

4.1.1 Asteel tup of specified size and of hardness Rockwell

combination; it is relatively independent of the size or design of the

specimen. The second factor is more dependent upon design and often is C55,

subject to wide variation within a given group of pieces.

4.1.2 Support of a tup by a V-suspension,

NOTE 2—The impact test at the rim of hollow ware is similar to a

4.1.3 Provision for a means of release from fixed heights so

chipping test, and the type of failure that is obtained is useful in evaluating

astogivereproducibleresults,independentoftheoperator,and

the effect of the shape of the object.

4.1.4 Provision for holding the test specimen in place by

NOTE 3—In addition to the inherent strength of the body, chipping test

spring clamps against rigid metal supports.

results are greatly affected by contour of rim and to a lesser extent by

thickness of rim, inclination of leaf, and fit of glaze.

4.2 Micrometer—For measuring thickness of test

specimens, a micrometer caliper that can be read to 0.001 in.

1.2 The values stated in inch-pound units are to be regarded

(0.03 mm) shall be used.

as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only

5. Test Specimens

and are not considered standard.

5.1 Specimens shall be selected so as to be representative of

1.3 This standard does not purport to address all of the

thelotbeingsampled.Ingeneral,impacttestsshallbebasedon

safety concerns, if any, associated with its use. It is the

a minimum of ten specimens and chipping tests on at least five

responsibility of the user of this standard to establish appro-

specimens. Specimens shall be inspected for soundness and

priate safety, health, and environmental practices and deter-

obvious physical defects before testing.

mine the applicability of regulatory limitations prior to use.

6. Procedure for Impact Testing of Flatware

1.4 This international standard was developed in accor-

dance with internationally recognized principles on standard-

6.1 Mount the cylindrical tube shown in Fig. 2 (Note 4)on

ization established in the Decision on Principles for the

the backstop, C, Fig. 1, and set at a height such that the three

Development of International Standards, Guides and Recom-

ball bearings mounted in the end of the cylindrical tube are in

mendations issued by the World Trade Organization Technical contact and symmetrical with the central portion of the

Barriers to Trade (TBT) Committee.

specimen, which shall be stood on edge on the base plate. The

specimen may be tested with either the face or the back toward

the hammer; in general, a lower failure value is obtained when

the face is struck. Adjust the backstop so that the spherical

This test method is under the jurisdiction ofASTM Committee C21 on Ceramic

surface of the tup, D, just touches the surface of the specimen

Whitewares and Related Products and is the direct responsibility of Subcommittee

C21.03 on Methods for Whitewares and Environmental Concerns.

Current edition approved Nov. 1, 2020. Published December 2020. Originally

approved in 1955. Last previous edition approved in 2016 as C368 – 88 (2016). Detailed working drawings of the apparatus are available from ASTM

DOI: 10.1520/C0368-88R206. International Headquarters. Order Adjunct No. ADJC0368.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C368 − 88 (2020)

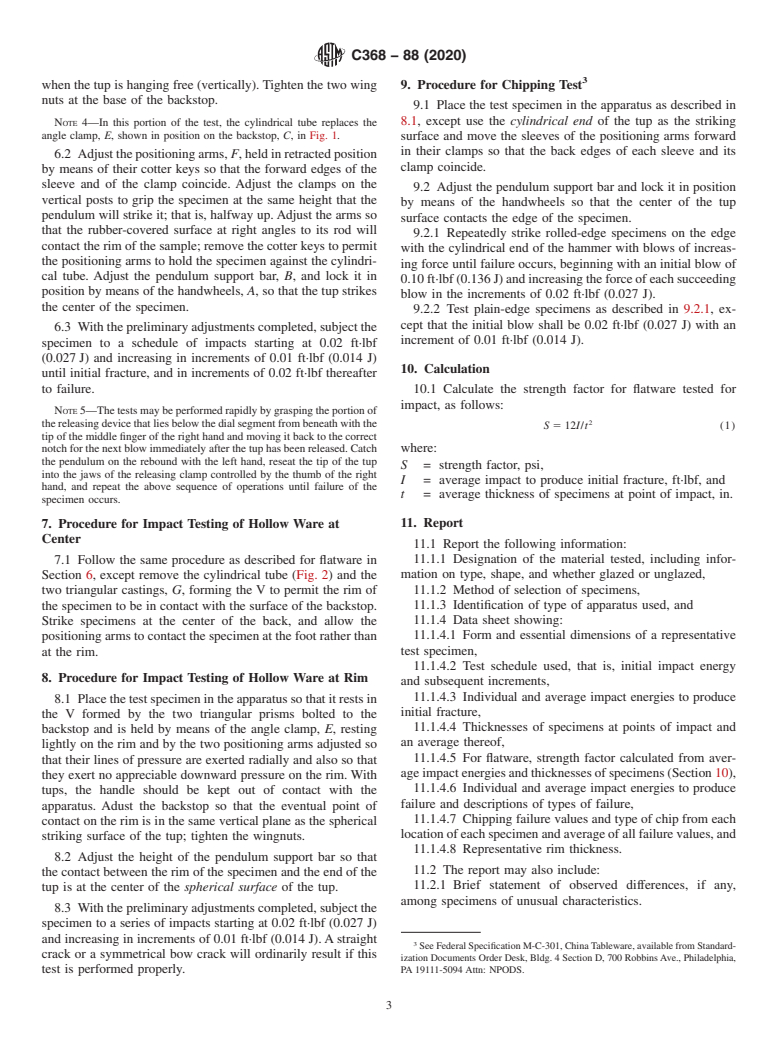

FIG. 1 Impact Test Apparatus

FIG. 2 Tube to Support Flatware Specimen

C368 − 88 (2020)

when the tup is hanging free (vertically). Tighten the two wing 9. Procedure for Chipping Test

nuts at the base of the backstop.

9.1 Place the test specimen in the apparatus as described in

8.1, except use the cylindrical end of the tup as the striking

NOTE 4—In this portion of the test, the cylindrical tube replaces the

angle clamp, E, shown in position on the backstop, C,in Fig. 1.

surface and move the sleeves of the positioning arms forward

in their clamps so that the back edges of each sleeve and its

6.2 Adjust the positioning arms,F, held in retracted position

clamp coincide.

by means of their cotter keys so that the forward edges of the

sleeve and of the clamp coincide. Adjust the clamps on the

9.2 Adjust the pendulum support bar and lock it in position

vertical posts to grip the specimen at the same height that the

by means of the handwheels so that the center of the tup

pendulum will strike it; that is, halfway up.Adjust the arms so

surface contacts the edge of the specimen.

that the rubber-covered surface at right angles to its rod will

9.2.1 Repeatedly strike rolled-edge specimens on the edge

contact

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.