ASTM D4024-22

(Specification)Standard Specification for Machine Made “Fiberglass” (Glass-Fiber-Reinforced Thermosetting Resin) Flanges

Standard Specification for Machine Made “Fiberglass” (Glass-Fiber-Reinforced Thermosetting Resin) Flanges

ABSTRACT

This specification deals with the testing and performance requirements of machine made "fiberglass" (glass-fiber-reinforced thermosetting resin) flanges, other than those that are contact-molded. Flanges may be produced integrally with a pipe or fitting, may be produced with a socket for adhesive bonding to a pipe or fitting, or may be of the type used in conjunction with either a metallic or nonmetallic backup ring. Flanges are defined by type (method of manufacture), grade (generic type of resin), class (configuration of joining system), and pressure rating. Flanges are also given numerical classifications relating to rupture pressure, sealing test pressure, and bolt torque limit. Included are requirements for materials, workmanship, performance, and dimensions.

SCOPE

1.1 This specification covers reinforced-thermosetting resin flanges other than contact-molded flanges. Included are requirements for materials, workmanship, performance, and dimensions.

1.2 Flanges may be produced integrally with a pipe or fitting, may be produced with a socket for adhesive bonding to a pipe or fitting, or may be of the type used in conjunction with either a metallic or nonmetallic backup ring.

1.3 The values stated in inch-pound units are to be regarded as the standard. The values in parentheses are given for information only. In cases where materials, products, or equipment are available only in SI units, inch-pound units are omitted.

1.4 The following precautionary caveat pertains only to the test methods portion, Section 10, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

Note 1: Contact molded flanges are covered in Specification D5421 and referenced in Specification D5685.

Note 2: There is no known ISO equivalent to this standard.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D4024 −22

Standard Specification for

Machine Made “Fiberglass” (Glass-Fiber-Reinforced

1

Thermosetting Resin) Flanges

This standard is issued under the fixed designation D4024; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 2. Referenced Documents

2

2.1 ASTM Standards:

1.1 This specification covers reinforced-thermosetting resin

D618 Practice for Conditioning Plastics for Testing

flanges other than contact-molded flanges. Included are re-

D883 Terminology Relating to Plastics

quirements for materials, workmanship, performance, and

dimensions. D1599 Test Method for Resistance to Short-Time Hydraulic

Pressure of Plastic Pipe, Tubing, and Fittings

1.2 Flanges may be produced integrally with a pipe or

D1600 Terminology forAbbreviatedTerms Relating to Plas-

fitting, may be produced with a socket for adhesive bonding to

tics

a pipe or fitting, or may be of the type used in conjunction with

D5421 Specification for Contact Molded “Fiberglass”

either a metallic or nonmetallic backup ring.

(Glass-Fiber-Reinforced Thermosetting Resin) Flanges

1.3 The values stated in inch-pound units are to be regarded

D5685 Specification for “Fiberglass” (Glass-Fiber-

as the standard. The values in parentheses are given for

Reinforced Thermosetting-Resin) Pressure Pipe Fittings

information only. In cases where materials, products, or equip-

F412 Terminology Relating to Plastic Piping Systems

3

ment are available only in SI units, inch-pound units are

2.2 ANSI Standards:

omitted.

B 16.1 Cast Iron Pipe Flanges and Flanged Fittings

B 16.5 Pipe Flanges and Flanged Fittings

1.4 The following precautionary caveat pertains only to the

test methods portion, Section 10, of this specification: This

3. Terminology

standard does not purport to address all of the safety concerns,

3.1 Definitions:

if any, associated with its use. It is the responsibility of the user

3.1.1 General—Definitions are in accordance with Termi-

of this standard to establish appropriate safety, health, and

nology D883 or Terminology F412. Abbreviations are in

environmental practices and determine the applicability of

accordance with Terminology D1600, unless otherwise indi-

regulatory limitations prior to use.

cated.The abbreviation for reinforced-thermosetting-resin pipe

NOTE 1—Contact molded flanges are covered in Specification D5421

is RTRP.

and referenced in Specification D5685.

NOTE 2—There is no known ISO equivalent to this standard.

4. Classification

1.5 This international standard was developed in accor-

4.1 General—This specification covers machine-made

dance with internationally recognized principles on standard-

reinforced-thermosetting-resinflangesdefinedbytype(method

ization established in the Decision on Principles for the

of manufacture), grade (generic type of resin), class (configu-

Development of International Standards, Guides and Recom-

ration of joining system), and pressure rating. Flanges com-

mendations issued by the World Trade Organization Technical

plying with this specification are also given numerical classi-

Barriers to Trade (TBT) Committee.

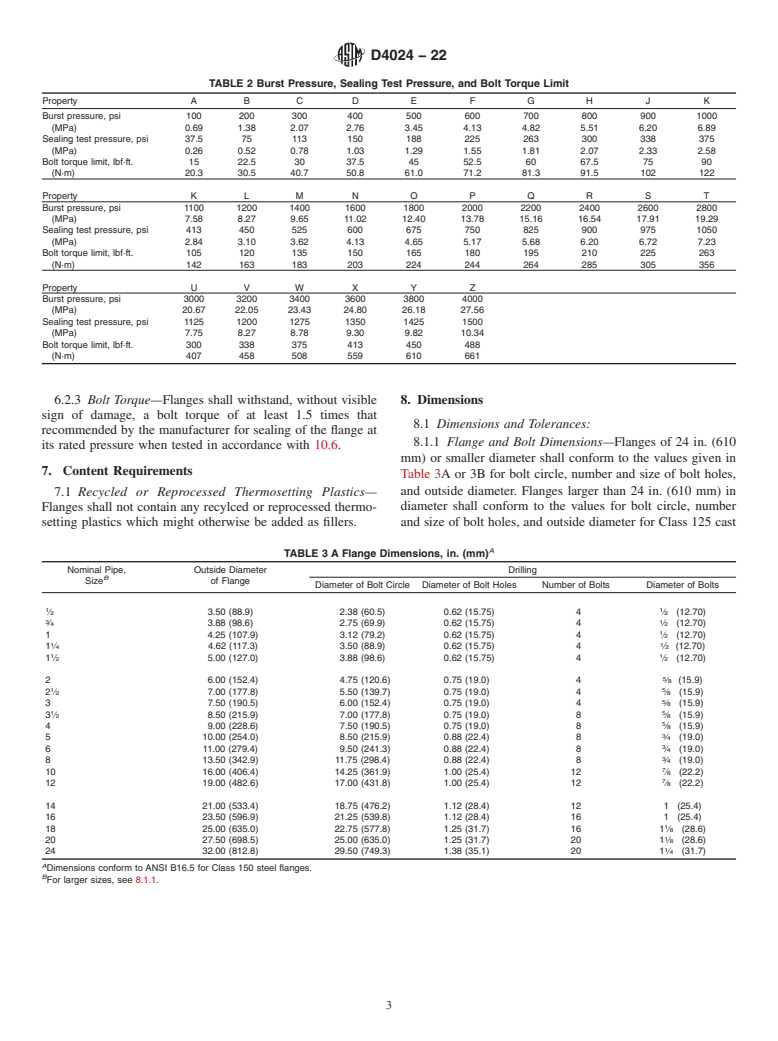

fications relating to burst pressure, sealing test pressure, and

bolt torque limit.

1 2

This specification is under the jurisdiction of ASTM Committee D20 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Plastics and is the direct responsibility of Subcommittee D20.23 on Reinforced contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Thermosetting Resin Piping Systems and Chemical Equipment. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved July 1, 2022. Published July 2022. Originally approved the ASTM website.

3

in 1981. Last previous edition approved in 2015 as D4024 – 15. DOI: 10.1520/ Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

D4024-22. 4th Floor, New York, NY 10036, http://www.ansi.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D4024 − 22

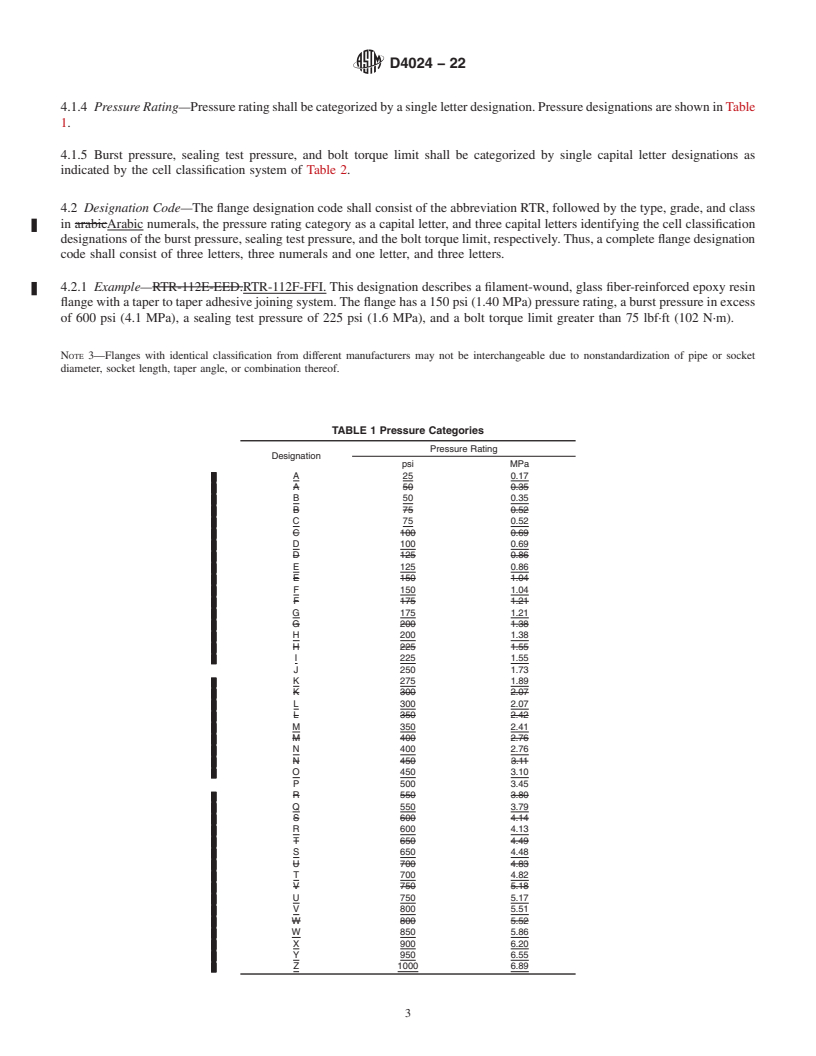

TABLE 1 Pressure Categories

4.1.1 Types:

4.1.1.1 Type 1—Filament-wound flanges manufactured by Pressure Rating

Designation

psi MPa

winding continuous fibrous glass strand roving or roving tape,

A 25 0.17

either preimpregnated or impregnated during winding, onto

B 50 0.35

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D4024 − 15 D4024 − 22

Standard Specification for

Machine Made “Fiberglass” (Glass-Fiber-Reinforced

1

Thermosetting Resin) Flanges

This standard is issued under the fixed designation D4024; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This specification covers reinforced-thermosetting resin flanges other than contact-molded flanges. Included are requirements

for materials, workmanship, performance, and dimensions.

1.2 Flanges may be produced integrally with a pipe or fitting, may be produced with a socket for adhesive bonding to a pipe or

fitting, or may be of the type used in conjunction with either a metallic or nonmetallic backup ring.

1.3 The values stated in inch-pound units are to be regarded as the standard. The values in parentheses are given for information

only. In cases where materials, products, or equipment are available only in SI units, inch-pound units are omitted.

1.4 The following precautionary caveat pertains only to the test methods portion, Section 10, of this specification: This standard

does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this

standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory

limitations prior to use.

NOTE 1—Contact molded flanges are covered in Specification D5421 and referenced in Specification D5685.

NOTE 2—There is no known ISO equivalent to this standard.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D618 Practice for Conditioning Plastics for Testing

D883 Terminology Relating to Plastics

D1599 Test Method for Resistance to Short-Time Hydraulic Pressure of Plastic Pipe, Tubing, and Fittings

D1600 Terminology for Abbreviated Terms Relating to Plastics

D5421 Specification for Contact Molded “Fiberglass” (Glass-Fiber-Reinforced Thermosetting Resin) Flanges

D5685 Specification for “Fiberglass” (Glass-Fiber-Reinforced Thermosetting-Resin) Pressure Pipe Fittings

1

This specification is under the jurisdiction of ASTM Committee D20 on Plastics and is the direct responsibility of Subcommittee D20.23 on Reinforced Plastic

Thermosetting Resin Piping Systems and Chemical Equipment.

Current edition approved May 1, 2015July 1, 2022. Published June 2015July 2022. Originally approved in 1981. Last previous edition approved in 20122015 as

D4024 – 12.D4024 – 15. DOI: 10.1520/D4024-15.10.1520/D4024-22.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D4024 − 22

F412 Terminology Relating to Plastic Piping Systems

3

2.2 ANSI Standards:

B 16.1 Cast Iron Pipe Flanges and Flanged Fittings

B 16.5 Pipe Flanges and Flanged Fittings

3. Terminology

3.1 Definitions:

3.1.1 General—Definitions are in accordance with Terminology D883 or Terminology F412. Abbreviations are in accordance with

Terminology D1600, unless otherwise indicated. The abbreviation for reinforced-thermosetting-resin pipe is RTRP.

4. Classification

4.1 General—This specification covers machine-made reinforced-thermosetting-resin flanges defined by type (method of

manufacture), grade (generic type of resin), class (configuration of joining system), and pressure rating. Flanges complying with

this specification are also given numerical classifications relating to burst pressure, sealing test pressure, and bolt torque limit.

4.1.1 Types:

4.1.1.1 Type 1—Filament-wound flanges manufactured by winding continuous fibrous glass strand roving or roving tape, either

preimpregnated or impregnated during winding, into a onto flange cavitytooling under cont

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.