ASTM A228/A228M-00

(Specification)Standard Specification for Steel Wire, Music Spring Quality

Standard Specification for Steel Wire, Music Spring Quality

SCOPE

1.1 This specification covers a high quality, round, cold-drawn steel music spring quality wire, uniform in mechanical properties, intended specially for the manufacture of springs subject to high stresses or requiring good fatigue properties.

1.2 The values stated in either SI (metric) units or inch-pound units are to be regarded separately as standard. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

An American National Standard

Designation: A 228/A 228M – 00

Standard Specification for

Steel Wire, Music Spring Quality

This standard is issued under the fixed designation A 228/A 228M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope Fed. Std. No. 123, Marking for Shipment (Civil Agencies)

2.4 American National Standard:

1.1 This specification covers a high quality, round, cold-

B32.4 Preferred Metric Sizes for Round, Square, Rectangle,

drawn steel music spring quality wire, uniform in mechanical

and Hexagon Metal Products

properties, intended especially for the manufacture of springs

2.5 AIAG Standard:

subject to high stresses or requiring good fatigue properties.

AIAG B-5 02.00 Primary Metals Identification Tag Appli-

1.2 The values stated in either SI (metric) units or inch-

cation Standard

pound units are to be regarded separately as standard. The

values stated in each system are not exact equivalents; there-

3. Terminology

fore, each system must be used independently of the other.

3.1 Definitions—For definitions of terms used in this speci-

2. Referenced Documents fication, refer to Terminology A 941.

2.1 ASTM Standards:

4. Ordering Information

A 370 Test Methods and Definitions for Mechanical Testing

2 4.1 It shall be the responsibility of the purchaser to specify

of Steel Products

all requirements that are necessary for material under this

A 510 Specification for General Requirements for Wire

2 specification. Such requirements may include, but are not

Rods and Coarse Round Wire, Carbon Steel

limited to, the following information:

A 510M Specification for General Requirements for Wire

2 4.1.1 Quantity (mass),

Rods and Coarse Round Wire, Carbon Steel [Metric]

4.1.2 Name of material (music steel spring wire),

A 700 Practices for Packaging, Marking, and Loading

4.1.3 Dimensions (Table 1 and Section 9),

Methods for Steel Products for Domestic Shipment

4.1.4 Finish (see 10.2),

A 751 Test Methods, Practices, and Terminology for

4.1.5 Packaging (Section 15),

Chemical Analysis of Steel Products

4.1.6 Heat analysis report, if requested (see 6.2),

A 941 Terminology Relating to Steel, Stainless Steel, Re-

4.1.7 Certification or test report, or both, if specified (Sec-

lated Alloys, and Ferroalloys

tion 14), and

E 29 Practice for Using Significant Digits in Test Data to

4.1.8 ASTM designation and year of issue.

Determine Conformance with Specifications

E 1077 Test Method for Estimating the Depth of Decarbur-

NOTE 1—A typical metric ordering description is as follows: 2500 kg

ization of Steel Specimens Music Spring Wire, 1.40 mm diameter, phosphate coated in 25 kg coils to

ASTM A 288M dated _____, or for inch-pound units, 5000 lb Music

2.2 Military Standard:

Spring Wire, 0.055 in. diameter, phosphate coated in 50 lb coils to ASTM

MIL-STD-163 Steel Mill Products, Preparation for Ship-

A 288 dated _____.

ment and Storage

2.3 Federal Standard:

5. Materials and Manufacture

5.1 The steel may be made by any commercially accepted

1 steel-making process. The steel may be either ingot cast or

This specification is under the jurisdiction of ASTM Committee A-1 on Steel,

strand cast. The rod to be used in the manufacture of wire

Stainless Steel, and Related Alloys and is the direct responsibility of Subcommittee

A01.03 on Steel Rod and Wire.

furnished to this specification shall be in accordance with

Current edition approved June 10, 2000. Published August 2000. Originally

Specification A 510 or A 510M.

published as A 228 – 39 T. Last previous edition A 228/A 228M – 93.

5.2 The finished wire shall be free from detrimental pipe

Annual Book of ASTM Standards, Vol 01.03.

Annual Book of ASTM Standards, Vol 01.05.

Annual Book of ASTM Standards, Vol 01.01.

5 8

Annual Book of ASTM Standards, Vol 14.02. Available from American National Standards Institute, 11 West 42nd Street,

Annual Book of ASTM Standards, Vol 03.01. 13th Floor, New York, NY 10036.

7 9

Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700 Available from the Automotive Industry Action Group, 26200 Lahser, Suite

Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS. 200, Southfield, MI 48034.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

A 228/A 228M

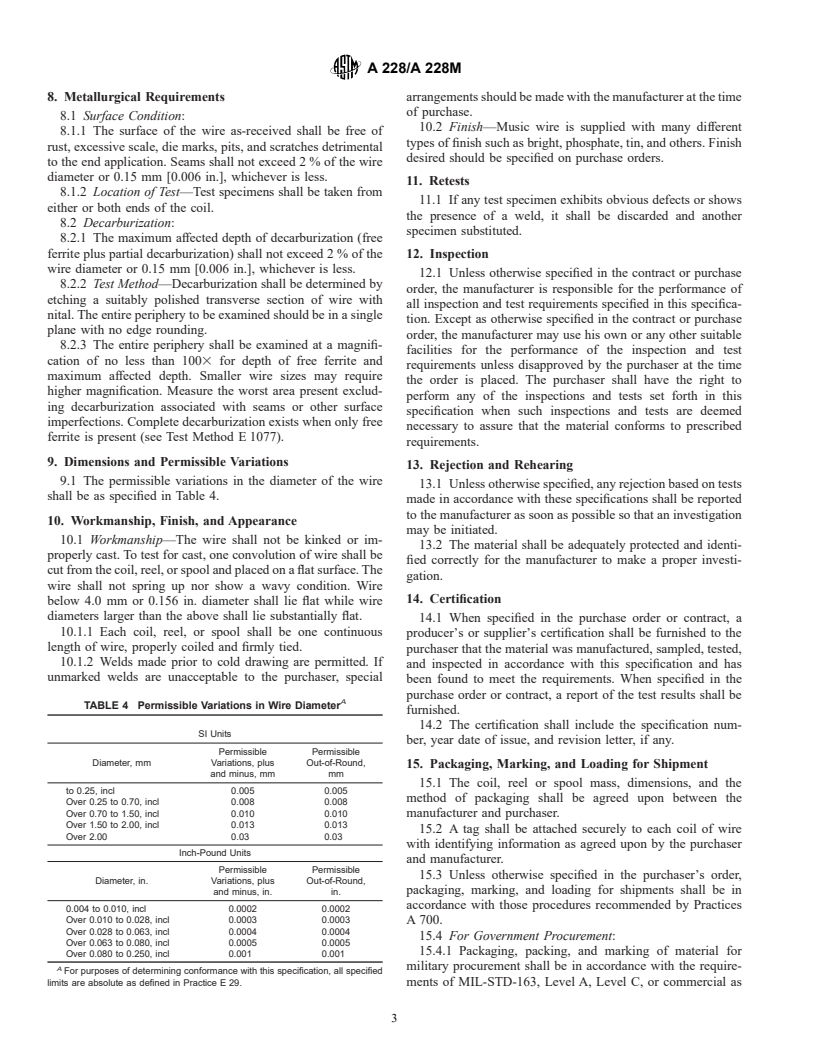

TABLE 1 Tensile Requirements TABLE 2 Chemical Requirements

SI Units Element Composition, %

Diameter, Tensile Strength, Tensile Strength, Carbon 0.70–1.00

A,B

mm MPa MPa Manganese 0.20–0.60

Diameter,

Phosphorus, max 0.025

A,B

min max mm min max

Sulfur, max 0.030

0.10 3000 3300 0.90 2200 2450

Silicon 0.10–0.30

0.11 2950 3250 1.00 2150 2400

0.12 2900 3200 1.1 2120 2380

0.14 2850 3150 1.2 2100 2350

prescribed in Table 2. This analysis shall be made from a test

0.16 2800 3100 1.4 2050 2300

specimen preferably taken during the pouring of the heat.

0.18 2750 3050 1.6 2000 2250

0.20 2700 3000 1.8 1980 2220

When requested in the purchase order, the heat analysis shall

0.22 2680 2980 2.0 1950 2200

be reported to the purchaser.

0.25 2650 2950 2.2 1900 2150

6.3 Product Analysis—An analysis may be made by the

0.28 2620 2920 2.5 1850 2100

0.30 2600 2900 2.8 1820 2050

purchaser from finished wire representing each heat of steel.

0.35 2550 2820 3.0 1800 2000

The chemical composition thus determined, as to elements

0.40 2500 2750 3.2 1780 1980

required or restricted, shall conform to the product analysis

0.45 2450 2700 3.5 1750 1950

0.50 2400 2650 3.8 1720 1920

requirements specified in Table 10 of Specification A 510M or

0.55 2380 2620 4.0 1700 1900

A 510.

0.60 2350 2600 4.5 1680 1880

6.4 For referee purposes, Test Methods, Practices, and

0.65 2320 2580 5.0 1650 1850

0.70 2300 2550 5.5 1620 1820

Terminology A 751 shall be used.

0.80 2250 2500 6.0 1600 1800

7. Mechanical Properties

Inch-Pound Units

Diameter, Tensile Strength, Tensile Strength, 7.1 Tension Test:

A

in. ksi ksi

7.1.1 Requirements—The material as represented by tension

Diameter,

A

min max in. min max

test specimens shall conform to the requirements prescribed in

0.004 439 485 0.055 300 331

Table 1.

0.005 426 471 0.059 296 327

7.1.2 Number of Tests—One test specimen shall be taken

0.006 415 459 0.063 293 324

from each end of every coil or from the top or outside end of

0.007 407 449 0.067 290 321

0.008 399 441 0.072 287 317

each reel or spool.

0.009 393 434 0.076 284 314

7.1.3 Test Method—The tension test shall be made in

0.010 387 428 0.080 282 312

accordance with Test Methods and Definitions A 370.

0.011 382 422 0.085 279 308

0.012 377 417 0.090 276 305

7.2 Coiling Test:

0.013 373 412 0.095 274 303

7.2.1 Requirements—The coiling test shall be applied only

0.014 369 408 0.100 271 300

to sizes 2.6 mm or 0.105 in. and smaller in diameter.

0.015 365 404 0.102 270 299

0.016 362 400 0.107 268 296

7.2.2 Number of Tests—Specimens taken from each end of

0.018 356 393 0.110 267 295

every coil or from the top or outside end of each reel or spool

0.020 350 387 0.112 266 294

shall be tested for conformance.

0.022 345 382 0.121 263 290

0.024 341 377 0.125 261 288

7.2.3 Test Method—A length of wire as shown in Table 3

0.026 337 373 0.130 259 286

shall be closed wound on an arbor three to three and one-half

0.028 333 368 0.135 258 285

times the diameter of the wire. The closed coil shall be

0.030 330 365 0.140 256 283

0.032 327 361 0.145 254 281

stretched so that it sets to approximately three times its original

0.034 324 358 0.150 253 279

length. The wire so tested shall show a uniform pitch with no

0.036 321 355 0.156 251 277

splits or fractures.

0.038 318 352 0.162 249 275

0.040 315 349 0.177 245 270

0.042 313 346 0.192 241 267

TABLE 3 Closed Coil Lengths vs Wire Diameter

0.045 309 342 0.207 238 264

0.048 306 339 0.225

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.