ASTM F3008-13

(Specification)Standard Specification for Cork Floor Tile

Standard Specification for Cork Floor Tile

ABSTRACT

This specification defines the requirements for the compound and physical characteristics of cork floor coverings made from agglomerated composition cork supplied in tile form, to be used with a factory finish or an in situ finish, or both. Cork floor tile covered by this specification shall have a smooth surface and be classified as Class I (Types A and B) and Class II (Types A and B). The standard covers information in the invitation to bid or purchase order, materials and manufacture, physical properties, performance requirements, workmanship, finish and appearance, sampling for testing physical characteristics, inspection, certification, product marking, and packaging and package marking.

SCOPE

1.1 This specification covers requirements for the compound and physical characteristics of cork floor tile. This standard specifies the requirements for cork floor coverings made from agglomerated composition cork supplied in tile form, which are designed to be used with a factory finish or an in situ finish, or both.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F3008 −13

StandardSpecification for

Cork Floor Tile

This standard is issued under the fixed designation F3008; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope of Resilient Floor Tile after Exposure to Heat

2.2 European Standards:

1.1 This specification covers requirements for the com-

pound and physical characteristics of cork floor tile. This EN 672 Resilient floor coverings - Determination of appar-

standard specifies the requirements for cork floor coverings ent density of agglomerated cork

made from agglomerated composition cork supplied in tile EN 434 Resilient floor coverings - Determination of dimen-

form, which are designed to be used with a factory finish or an sional stability and curling after exposure to heat

in situ finish, or both. 4

2.3 ISO Standards:

1.2 The values stated in inch-pound units are to be regarded ISO 4918 Resilient textile, and laminate floor coverings –

as standard. The values given in parentheses are mathematical Castor Chair Test

conversions to SI units that are provided for information only ISO 24338 Laminate floor coverings – Determination of

and are not considered standard. abrasion resistance

1.3 This standard does not purport to address all of the

2.4 ANSI/ASQC Standard:

safety concerns, if any, associated with its use. It is the

ANSI/ASQC XZ1.4 Sampling Procedures and Tables for

responsibility of the user of this standard to establish appro-

Inspection by Attributes

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

3. Terminology

3.1 Definitions—For definitions of terms used in this

2. Referenced Documents

standard, see Terminology F141.

2.1 ASTM Standards:

3.2 agglomerated cork—productobtainedfromtheblending

F137 Test Method for Flexibility of Resilient Flooring Ma-

of cork granules with the addition of a binder. The percentage

terials with Cylindrical Mandrel Apparatus

of cork, by weight, shall be >90 %.

F141 Terminology Relating to Resilient Floor Coverings

F386 Test Method for Thickness of Resilient Flooring Ma-

4. Classification

terials Having Flat Surfaces

F710 Practice for Preparing Concrete Floors to Receive

4.1 Class—Type: cork floor tile covered by this specifica-

Resilient Flooring

tion shall have a smooth surface and be classified as follows:

F925 Test Method for Resistance to Chemicals of Resilient

4.1.1 Class I—Homogeneous Cork Tile (6.1)

Flooring

4.1.1.1 Type A—Unfinished (specify details of staining or

F970 Test Method for Static Load Limit

site finishing, or both)

F1914 Test Methods for Short-Term Indentation and Re-

4.1.1.2 Type B—Factory finished (specify per manufactur-

sidual Indentation of Resilient Floor Covering

er’s product information)

F2055 Test Method for Size and Squareness of Resilient

Floor Tile by Dial Gage Method

4.1.2 Class II—Heterogeneous Cork Tile (6.2)

F2199 Test Method for Determining Dimensional Stability

4.1.2.1 Type A—Unfinished (specify details of staining or

site finishing, or both)

4.1.2.2 Type B—Factory finished (specify per manufactur-

This specification is under the jurisdiction of ASTM Committee F06 on

er’s product information)

Resilient Floor Coverings and is the direct responsibility of Subcommittee F06.80

on Specifications.

Current edition approved Sept. 1, 2013. Published September 2013. DOI:

10.1520/F3008-13.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from European Committee for Standardization (CEN), Avenue

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Marnix 17, B-1000, Brussels, Belgium, http://www.cen.eu.

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

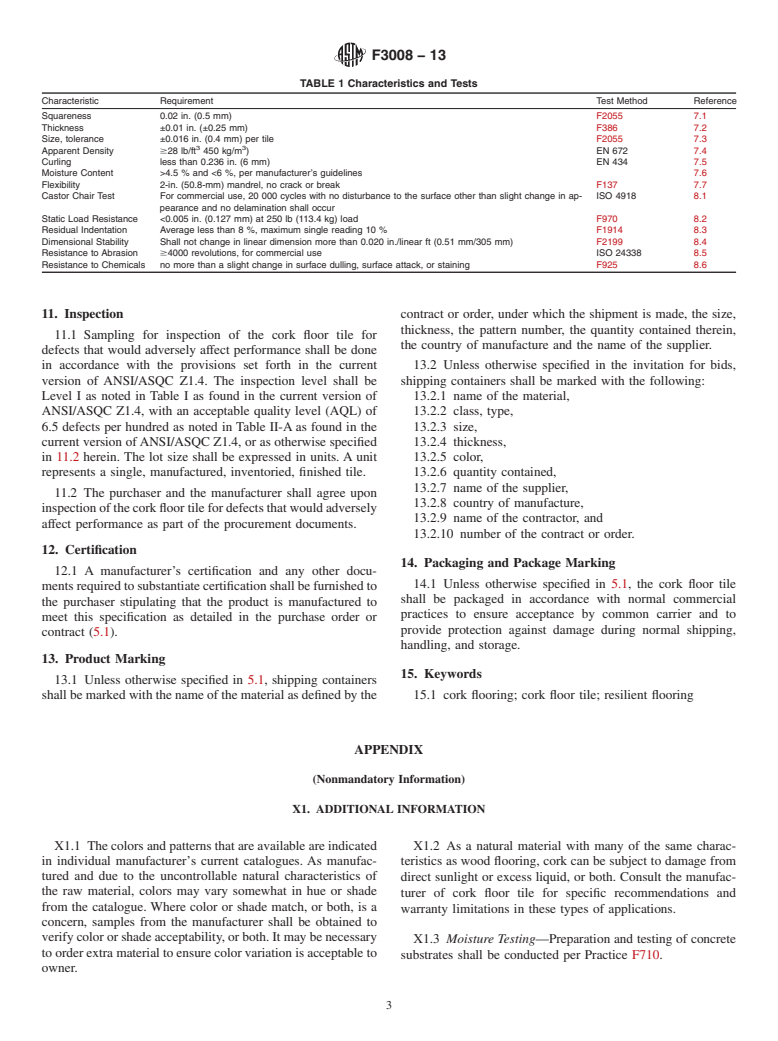

F3008−13

5. Ordering Information 8.2 Static Load Resistance—When tested in accordance

with Test Method F970, with an applied load of 250 lb (113.4

5.1 Purchaser shall state whether this specification is to be

kg), the residual indentation shall not be greater than 0.005 in.

used, select the preferred options permitted herein, and include

(0.127 mm).

the following information in the invitation to bid or purchase

order: 8.3 Residual Indentation—When tested in accordance with

5.1.1 Title, number, and date of this specification. Test Method F1914, under 30-lb (13-kg) load, 0.25-in. (6.35-

5.1.2 Class, type, pattern, and wearing surface (Section 4). mm) flat foot and 10 min indentation, the average residual

5.1.3 Quantity, in square feet, square metres, or cartons. indentationattheendof60-minrecoveryshallnotexceed8%,

5.1.4 Size required. and the maximum residual indentation of any single specimen

5.1.5 Thickness required. shall not exceed 10 %.

5.1.6 Resistance to chemicals (8.6).

8.4 Dimensional Stability—When tested in accordance with

5.1.7 Lot information; if other than as specified in ANSI/

Test Method F2199, the tile shall not change in linear dimen-

ASQC Z1.4 (11.1).

sion more than 0.020 in./linear ft (0.51 mm/305 mm).

5.1.8 Packing requirements, if other than as specified (Sec-

8.5 Abrasion Resistance—When tested per the method de-

tion 14).

scribed in ISO 24338, cork floor tile shall pass at ≥4000

5.1.9 Palletizing, if required.

revolutions for commercial use.

5.1.10 Marking required, if other than specified (Section

13).

8.6 Resistance to Chemicals—The chemical resistance of

5.1.11 Other requirements.

cork floor tile shall be determined in accordance with Test

Method F925. The cork floor tile shall have no more than a

6. Materials and Manufacture

slight change in surface dulling, surface attack, or staining

6.1 Class I—Homogeneous Cork Tile – Homogeneous cork when exposed to the following chemicals:

tile shall be of uniform structure and composition throughout,

8.6.1 White Vinegar (5 % acetic acid).

consisting of cork granules thoroughly and uniformly bonded 8.6.2 Rubbing Alcohol (70 % isopropyl alcohol).

together.

8.6.3 White mineral oil (medicinal grade).

8.6.4 Household ammonia solution (5 % NH OH).

6.2 Class II—Heterogeneous CorkTile –The pattern of this 4

8.6.5 Household bleach (5.25 % NaOCl).

tilecomprisesaveneerlayerofcorkandabaselayerconsisting

8.6.6 Disinfectant – phenol type (5 % active phenol).

of cork granules thoroughly and uniformly bonded together.

NOTE 1—These chemicals are representative of those most likely to be

The pattern of this tile need not extend throughout the entire

found in domestic, commercial, and institutional use. Many proprietary

thickness of the tile.

compounds contain one or more of these chemicals. Should the flooring

for an unusual application need to be resistant to a specific chemical, this

7. Physical Properties

additional requirement should be part of the procurement document.

7.1 Squareness—When tested in accordance with Test

9. Workmanship, Finish, and Appearance

Method F2055, cork floor tile squareness variation shall not

exceed 0.02 in. (0.5 mm).

9.1 The product shall be free of defects that adversely affect

performance or appearance. See Appendix X1 for information

7.2 Thickness—When tested

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.