ASTM F2412-05

(Test Method)Standard Test Methods for Foot Protection

Standard Test Methods for Foot Protection

SIGNIFICANCE AND USE

The purpose of these test methods is to provide measurable criteria for various hazards.

The protection that can be demonstrated by evaluation of footwear includes the following:

4.2.1 The effectiveness of impact resistant footwear to eliminate or diminish the severity of injury to the toe area of the foot when subjected to a falling object.

4.2.2 The effectiveness of compression resistant footwear to eliminate or diminish the severity of injury to the toe area of the foot when subjected to a compressive force.

4.2.3 The effectiveness of metatarsal protective footwear to eliminate or diminish the severity of injury to the metatarsal area adjacent to where the toes and the bones of the upper foot intersect.

4.2.4 The effectiveness of conductive footwear to safely reduce the buildup of static electricity from wearer to ground so as to reduce the possibility of ignition of explosives and volatile chemicals.

4.2.5 The effectiveness of electric shock resistant footwear to provide resistance to electric shock when accidental contact is made with live wires.

4.2.6 The effectiveness of static dissipative footwear to reduce the hazards due to excessively low footwear electrical resistance that may exist where SD footwear is required.

4.2.7 The effectiveness of puncture resistant footwear to reduce the possibility of puncture injury to the bottom of the human foot.

4.2.8 The effectiveness of chain saw cut resistant footwear to reduce the chance of injury when exposed to a running power chain saw.

4.2.9 The effectiveness of dielectric insulative footwear to reduce the possibility of injury when exposed to a high voltage charge.

SCOPE

1.1 These test methods measure the resistance of footwear to a variety of hazards that can potentially result in injury.

1.2 These test methods may be used to test for compliance to minimum performance requirements in established safety standards.

1.2.1 By agreement between the purchaser and the supplier, or as required by established safety standards, these test methods can be used to determine any one, or all of the following: (1) impact resistance, (2) compression resistance, (3) metatarsal impact resistance, (4) resistance to electrical conductivity, (5) resistance to electric shock, (6) static dissipative performance, (7) puncture resistance of outsoles, (8) chain saw cut resistance, and (9) dielectric insulation.

1.3 &si-value;

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F2412–05

Standard Test Methods for

Foot Protection

This standard is issued under the fixed designation F2412; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

For more than sixty years, the predecessor to these test methods, ANSI Z41, established the

performance criteria for a wide range of footwear to protect from the hazards that affect the personal

safetyofworkers.ThevalueofthesestandardswasrecognizedearlyinthehistoryoftheOccupational

Safety and Health Administration (OSHA) and incorporated as a reference standard in the Code of

Federal Regulation (CFR) Section 1910.

ThesetestmethodscontainstestprotocolsdevelopedinconjunctionwithANSIZ41aswellasother

ASTM standards that are used to evaluate the performance of footwear when exposed to a variety of

hazards: (1) impact resistance for the toe area of footwear; (2) compression resistance for the toe area

of footwear; (3) metatarsal impact protection that reduces the chance of injury to the metatarsal bones

at the top of the foot; (4) conductive properties that reduces hazards that may result from static

electricity buildup and reduce the possibility of ignition of explosives and volatile chemicals; (5)

electric shock resistant non-conductive; (6) static dissipative (SD) properties to reduce hazards due to

excessively low footwear resistance that may exist where SD footwear is required; (7) puncture

resistance of foot bottoms; (8) chain saw cut resistance hazards; and (9) dielectric hazard.

1. Scope priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

1.1 These test methods measure the resistance of footwear

to a variety of hazards that can potentially result in injury.

2. Referenced Documents

1.2 These test methods may be used to test for compliance

2.1 ASTM Standards:

to minimum performance requirements in established safety

B117 Practice for Operating Salt Spray (Fog) Apparatus

standards.

F1116 Test Method for Determining Dielectric Strength of

1.2.1 By agreement between the purchaser and the supplier,

Dielectric Footwear

or as required by established safety standards, these test

F1458 Test Method for Measurement of Cut Resistance to

methods can be used to determine any one, or all of the

Chain Saw of Foot Protective Devices

following: (1) impact resistance, (2) compression resistance,

2.2 CSA Standard:

(3) metatarsal impact resistance, (4) resistance to electrical

CAN/CSA Z195 Protective Footwear

conductivity, (5) resistance to electric shock, (6) static dissipa-

tive performance, (7) puncture resistance of outsoles, (8) chain

3. Terminology

saw cut resistance, and (9) dielectric insulation.

3.1 Definitions:

1.3 The values stated in SI units are to be regarded as

3.1.1 footwear, n—wearing apparel for the feet (such as

standard. The values given in parentheses are for information

shoes, boots, slippers, or overshoes), excluding hosiery.

only.

3.1.1.1 Discussion—Thistermcanrefertoeitherleftfootor

1.4 This standard does not purport to address all of the

right foot units or pairs.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

These test methods are under the jurisdiction of ASTM Committee F13 on contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Pedestrian/Walkway Safety and Footwear and are the direct responsibility of Standards volume information, refer to the standard’s Document Summary page on

Subcommittee F13.30 on Footwear. the ASTM website.

Current edition approved March 1, 2005. Published March 2005. DOI: 10.1520/ Available from Canadian Standards Association (CSA), 178 Rexdale Blvd.,

F2412-05. Toronto, ON Canada M9W1R3.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F2412–05

3.1.2 insert, n—footbed normally made of a foam product 4.2.4 The effectiveness of conductive footwear to safely

with leather or fabric cover shaped to cover the entire insole reduce the buildup of static electricity from wearer to ground

which can be inserted between the foot and insole board. so as to reduce the possibility of ignition of explosives and

volatile chemicals.

3.1.3 insole, n—foundation of the shoe; the inner sole of the

shoe which is next to the foot, under the sock liner or insert, 4.2.5 The effectiveness of electric shock resistant footwear

to provide resistance to electric shock when accidental contact

onto which the upper is lasted.

is made with live wires.

3.1.4 last, n—solid hinged form, in the general shape of a

foot, around which footwear is constructed. 4.2.6 The effectiveness of static dissipative footwear to

reduce the hazards due to excessively low footwear electrical

3.1.5 lasting, v—building of footwear around a specific foot

resistance that may exist where SD footwear is required.

form.

4.2.7 The effectiveness of puncture resistant footwear to

3.1.6 lining, n—term used to describe all components that

reduce the possibility of puncture injury to the bottom of the

can be used to construct the interior of the upper portion of the

human foot.

footwear.

4.2.8 The effectiveness of chain saw cut resistant footwear

3.1.7 outsole and heel, n—exterior bottom platform of the

to reduce the chance of injury when exposed to a running

footwear; the bottom surface.

power chain saw.

3.1.8 product category, n—description for a type of foot-

4.2.9 The effectiveness of dielectric insulative footwear to

wear designed and manufactured for a specific hazard or

reduce the possibility of injury when exposed to a high voltage

hazards.

charge.

3.1.9 product classification, n—footwear manufactured to

meet a minimum performance requirement for a specific

5. Impact Resistance

hazard or hazards.

3.1.10 protective footwear, n—footwear that is designed, 5.1 Summary of Method:

constructed, and classified to protect the wearer from a

5.1.1 Footwear with a protective toe cap is impacted with a

potential hazard or hazards.

specified force.

3.1.11 protective toe cap, n—component designed to pro- 5.1.2 After impact, the height of the clay cylinder is

vide toe protection that is an integral and permanent part of the

measured.

footwear.

5.2 Apparatus:

3.1.12 quarter, n—entire back portion of the footwear

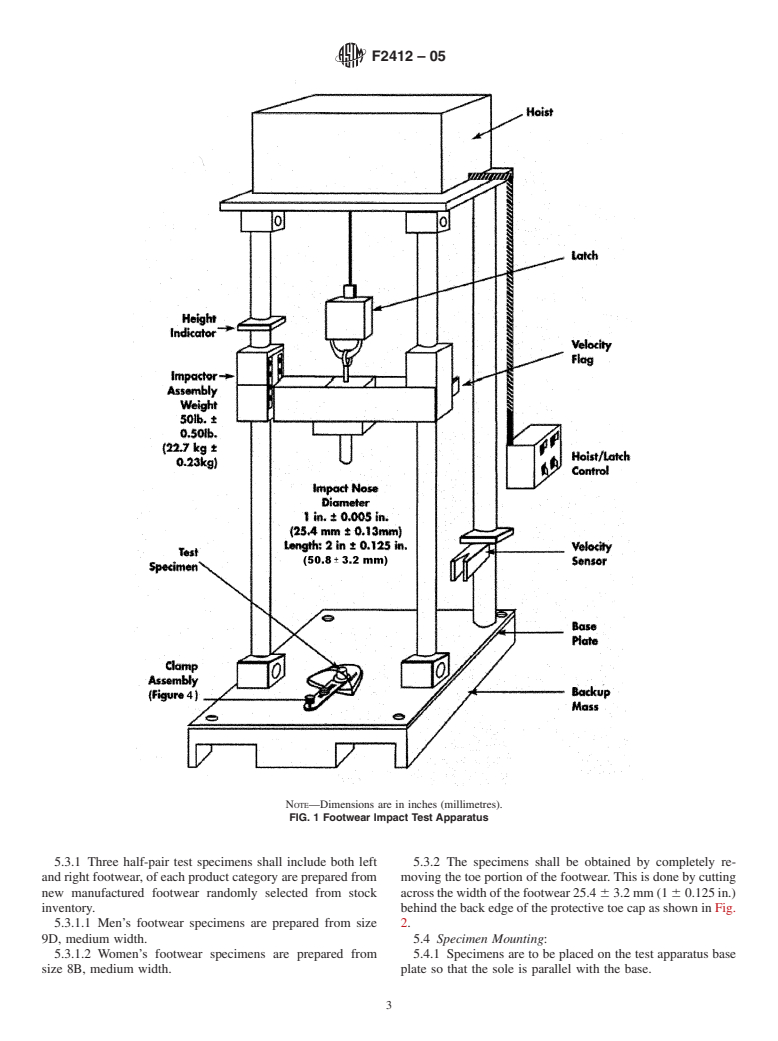

5.2.1 The apparatus as shown in Fig. 1 consists of a frame

upper.

structure that permits the impactor to be constrained to fall

3.1.13 size, n—length and breadth measurements of foot- along a known and repeatable path.

wear determined by using a specific grading; the American

5.2.1.1 The impactor consists of a steel weight having a

system of footwear grading.

massof22.7 60.23kg(50 60.5lb).Thenoseoftheimpactor

3.1.14 socklining, n—material placed over the insole which is a steel cylinder having a diameter of 25.4 6 0.8 mm (1 6

is imprinted with a brand name or other designation. 0.03in.)andlengthof50.8mm(2.0in.).Theimpactsideofthe

cylinder has a smooth spherical surface with a radius of 25.4 6

3.1.15 specimen, for protective footwear, n—footwear units

0.127mm(1.00 60.005in.).Thelongitudinalcenterlineofthe

evaluated for various hazards.

cylinderisparallelandcoincidentwith3.175mm(0.125in.)to

3.1.15.1 Discussion—Footwear units may be a left foot, a

the symmetry of its vertical axis.

right foot, or a matched pair. The exact number and type of

5.2.1.2 Apparatus incorporates a means of measuring the

footwear units is indicated by test method.

velocity at impact with a tolerance of 62 %. The use of a

3.1.16 upper, n—parts of a shoe or boot that are above the

velocity metering system allows for determining the time

sole.

required for a 25.4-mm (1-in.) wide blade to pass completely

through a beam of light prior to the impactor striking the

4. Significance and Use

specimen. The result, referred to as gate time, is measured in

4.1 The purpose of these test methods is to provide measur-

ms. The speed in in./s can be calculated using the following

able criteria for various hazards.

formula:

4.2 The protection that can be demonstrated by evaluation

of footwear includes the following:

V 5 (1)

t

g

4.2.1 The effectiveness of impact resistant footwear to

eliminate or diminish the severity of injury to the toe area of

where:

the foot when subjected to a falling object.

V = velocity in in./s, and

4.2.2 The effectiveness of compression resistant footwear to t = gate time in ms.

g

eliminate or diminish the severity of injury to the toe area of 5.2.2 The base of the apparatus consists of a steel plate with

2 2

the foot when subjected to a compressive force. a minimum area 0.3 m (1 ft ) and minimum thickness of 25.4

mm (1 in.). The base is anchored to a structure having a

4.2.3 The effectiveness of metatarsal protective footwear to

minimum mass of 909.1 kg (2000 lb) to provide sufficient

eliminate or diminish the severity of injury to the metatarsal

stability to the apparatus before, during, and after testing.

area adjacent to where the toes and the bones of the upper foot

intersect. 5.3 Sampling:

F2412–05

NOTE—Dimensions are in inches (millimetres).

FIG. 1 Footwear Impact Test Apparatus

5.3.1 Three half-pair test specimens shall include both left 5.3.2 The specimens shall be obtained by completely re-

and right footwear, of each product category are prepared from moving the toe portion of the footwear. This is done by cutting

new manufactured footwear randomly selected from stock acrossthewidthofthefootwear25.4 63.2mm(1 60.125in.)

inventory. behind the back edge of the protective toe cap as shown in Fig.

5.3.1.1 Men’s footwear specimens are prepared from size 2.

9D, medium width. 5.4 Specimen Mounting:

5.3.1.2 Women’s footwear specimens are prepared from 5.4.1 Specimens are to be placed on the test apparatus base

size 8B, medium width. plate so that the sole is parallel with the base.

F2412–05

FIG. 2 Specimen Prepared for Compression Testing

either the bottom side or top side of the cylinder to prevent the clay from

5.4.1.1 The specimen is positioned so that the longitudinal

adhering to either the insert/sock liner or dome.

center of the nose of the impactor strikes the approximate

centeroftheprotectivetoecapatapointthatis12.7 61.6mm

5.5.1.2 The diameter of the cylinder shall not exceed 25.4

(0.50 60.0625in.)towardthefrontasmeasuredfromtheback

mm (1 in.).

edge of the protective toe cap (see Fig. 3).

5.5.2 After impact, carefully remove the clay cylinder from

5.4.2 The specimen is held in position during test by use of

inside the specimen and measure the height of the cylinder at

a clamping device as shown in Fig. 4.

its lowest point using a measuring device capable of measuring

5.4.2.1 The stabilizing fork clamp device rests on the insert

to the nearest 0.1 mm (0.004 in.).

and can be adjusted by means of a screw.

5.5.2.1 This value is reported as the impact minimum

5.4.2.2 The adjustment secures the specimen parallel to the

interior height clearance for the specimen.

base plate and prevents movement when the impactor strikes

5.5.3 To measure Class 75 product classification footwear,

the specimen.

the impactor is dropped from a height that results in an impact

5.4.2.3 Clamping screw shall be tightened using a force less

velocity of 2995 6 61 mm/s (117.9 6 2.4 in./s), creating a

than 28 Nm (25 in. lbs).

force of 101.75 J (75 ft-lbf).

5.5 Procedure:

NOTE 2—In a vacuum, the distance would be 457 mm (18 in.). Due to

5.5.1 Prior to impact testing, a lump of modeling clay

friction and air resistance, the height used for the test is somewhat greater.

formed as a vertical cylinder is positioned inside the specimens

directly under the point of impact (see Fig. 3). 5.5.4 To measure Class 50 Product Classification footwear,

5.5.1.1 The clay shall be shaped so that the cylinder the impactor is dropped from a height that results in an impact

velocity of 2438 6 48.3 mm/s (96 6 1.9 in./s), creating a force

simultaneously makes contact with the insole/sock of the

footwear and the dome of the protective toe cap. of 67.8 J (50 ft-lbf).

NOTE 1—A small piece of wax paper or cellophane can be placed on NOTE 3—In a vacuum, the distance would be 305 mm (12 in.). Due to

FIG. 3 Specimen Prepared for Impact Testing

F2412–05

NOTE—Dimensions are in inches (millimetres).

FIG. 4 Position/Clamping/Impact Arrangement

friction and air resistance, the height used for the test is somewhat greater.

6.1.1 Footwear with a protective toe cap is exposed to a

compressive force.

5.6 Test Report—Report the minimum height of the clay

cylinder,withoutroundingup,tothenearest0.1mm(0.004in.) 6.1.2 During application of the compressive force, the

as the clearance result for the product category for all three

interior space of the toe cap is measured using a clay cylinder.

specimens.

6.2 Apparatus:

6.2.1 Compression testing equipment that is equipped with

6. Compression Resistance

smooth steel compression test surfaces.

6.1 Summary of Method:

F2412–05

6.2.1.1 Test surfaces must remain parallel during applica- 7.2 Apparatus:

tion of force up to 44 482 N (10 000 lbf).

7.2.1 The same apparatus as used in 5.2 (Fig. 1) for impact

6.2.1.2 Pressure head has a minimum diameter of 76.2 mm

testing of protective footwear, with certain modifications, is

(3 in.) and a bed plate with a minimum width of 152.4 mm (6

used for metatarsal impact testing. The modifications to the

in.).

apparatus are shown in Fig. 5 and Fig. 6.

6.2.1.3 Equipment must be graduated in increments so as to

7.2.1.1 The striking surface that impacts the metatarsal

measure compressive force between 222.4 N (50 lbf) to 44 482

protection is a horizontal bar that is perpendicular to the

N (10 000 lbf).

vertical traverse of the test apparatus. The bar of polished steel

6.3 Sampling:

has a diameter of 25.4 6 0.5 mm (1 6 0.02 in.) and a length

6.3.1 A total of three half pair specimens, which shall

of 152.4 6 3.2 mm (6 6 0.125 in.).

include both left and right footwear of each product category,

7.2.1.2 The striking bar is positioned so that the impact is

are prepared from new manufactured footwear randomly

perpendicular to the longitudinal plane of the heel/toe axis at

selected from stock inventory.

the appropriate impact point for men’s and women’s footwear

6.3.1.1 Men’s footwear specimens are

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.