ASTM E1171-99

(Test Method)Standard Test Method for Photovoltaic Modules in Cyclic Temperature and Humidity Environments

Standard Test Method for Photovoltaic Modules in Cyclic Temperature and Humidity Environments

SCOPE

1.1 These test methods provide procedures for stressing photovoltaic modules in simulated temperature and humidity environments. Environmental testing is used to simulate aging of module materials on an accelerated basis.

1.2 Three individual environmental test procedures are defined by these test methods: a thermal cycling procedure, a humidity-freeze cycling procedure, and an extended duration damp heat procedure. Electrical biasing is utilized during the thermal cycling procedure to simulate stresses that are known to occur in field-deployed modules.

1.3 These test methods define mounting methods for modules undergoing environmental testing, and specify parameters that must be recorded and reported.

1.4 These test methods do not establish pass or fail levels. The determination of acceptable or unacceptable results is beyond the scope of these test methods.

1.5 Any of the individual environmental tests may be performed singly, or may be combined into a test sequence with other environmental or non-environmental tests, or both. Certain pre-conditioning tests such as annealing or light soaking may also be necessary or desirable as part of such a sequence. The determination of any such sequencing and pre-conditioning is beyond the scope of this test method.

1.6 These test procedures are limited in duration and therefore the results of these tests cannot be used to determine photovoltaic module lifetimes.

1.7 There is no similar or equivalent ISO standard.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: E 1171 – 99 An American National Standard

Standard Test Methods for

Photovoltaic Modules in Cyclic Temperature and Humidity

Environments

This standard is issued under the fixed designation E 1171; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope E 1462 Test Methods for Insulation Integrity and Ground

Path Continuity of Photovoltaic Modules

1.1 These test methods provide procedures for determining

E 1799 Practice for Visual Inspections of Photovoltaic

the ability of photovoltaic modules to withstand simulated

Modules

temperature and humidity environments. Environmental test-

E 1830M Test Methods for Determining the Mechanical

ing is used to simulate aging of module materials on an

Integrity of Photovoltaic Modules

accelerated basis.

1.2 Three individual environmental test procedures are de-

3. Terminology

fined by these test methods: a thermal cycling procedure, a

3.1 Definitions—definitions of terms used in this standard

humidity-freeze cycling procedure, and an extended duration

may be found in Terminology E 772 and in Terminology

damp heat procedure.

E 1328.

1.3 These test methods define mounting methods for mod-

3.2 Definitions of Terms Specific to This Standard:

ules undergoing environmental testing, and specify parameters

3.2.1 ground fault—a module fault where any portion of the

that must be recorded and reported.

module circuitry between the output terminals becomes elec-

1.4 These test methods do not establish pass or fail levels.

trically connected to the module grounding point.

The determination of acceptable or unacceptable results is

3.2.2 open circuit—a module fault where any portion of the

beyond the scope of these test methods.

module circuitry between the output terminals becomes elec-

1.5 Any of the individual environmental tests may be

trically discontinuous.

performed singly, or may be combined into a test sequence

with other environmental or non-environmental tests, or both.

4. Significance and Use

Certain pre-conditioning tests such as annealing or light

4.1 The useful life of photovoltaic modules may depend on

soaking may also be necessary or desirable as part of such a

their ability to withstand repeated temperature cycling with

sequence. The determination of any such sequencing and

varying amounts of moisture in the air. These test methods

pre-conditioning is beyond the scope of this test method.

provide procedures for simulating the effects of cyclic tem-

1.6 There is no similar or equivalent ISO standard.

perature and humidity environments. An extended duration

1.7 This standard does not purport to address all of the

damp heat procedure is provided to simulate the effects of long

safety concerns, if any, associated with its use. It is the

term exposure to high humidity.

responsibility of the user of this standard to establish appro-

4.2 These test methods describe procedures for mounting

priate safety and health practices and determine the applica-

test modules, conducting the environmental tests, and reporting

bility of regulatory limitations prior to use.

the results.

2. Referenced Documents 4.2.1 Test modules are mounted so that they are electrically

isolated from each other, and in such a manner to allow free air

2.1 ASTM Standards:

2 circulation around the front and back surfaces of the modules.

E 772 Terminology Relating to Solar Energy Conversion

4.3 Data generated using these test methods may be used to

E 1036 Methods of Testing Electrical Performance of Non-

evaluate and compare the effects of simulated environment on

concentrator Terrestrial Photovoltaic Modules and Arrays

2 test specimens. These test methods require determination of

Using Reference Cells

both visible effects and electrical performance effects.

E 1328 Terminology Relating to Photovoltaic Solar Energy

2 4.3.1 Effects on modules may vary from none to significant

Conversion

changes. Some physical changes in the module may be visible

when there are no apparent electrical changes in the module.

This test method is under the jurisdiction of ASTM Committee E-44 on Solar,

Similarly, electrical changes may occur with no visible changes

Geothermal, and Other Alternative Energy Sources and is the direct responsibility of

in the module.

Subcommittee E44.09 on Photovoltaic Electrical Power Systems.

Current edition approved Oct. 10, 1999. Published November 1999. Originally

4.3.2 All conditions of measurement, effects of cycling, and

published as E 1171–87. Last previous edition E 1171–97.

any deviations from this test method must be described in the

Annual Book of ASTM Standards, Vol 12.02.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

E 1171

report so that an assessment of their significance can be made. temperature cycling, humidity-freeze cycling, and damp heat

4.4 If these test methods are performed as part of a procedures may be performed individually, the requirements of

combined sequence with other environmental or non- any test sequence (see 1.5 and 4.4) may determine the order in

environmental tests, the results of the final electrical tests (7.2) which the environmental tests are performed, and also may

and visual inspection (7.3) determined at the end of one test impose restrictions on which test modules are to be subjected

may be used as the initial electrical tests and visual inspection to individual procedures. The sequencing may also specify

for the next test; duplication of these tests is not necessary when modules undergo electrical testing (see 6.2) and visual

unless so specified. inspections (see 6.3).

6.1.1 A typical combined thermal and humidity-freeze cy-

5. Apparatus

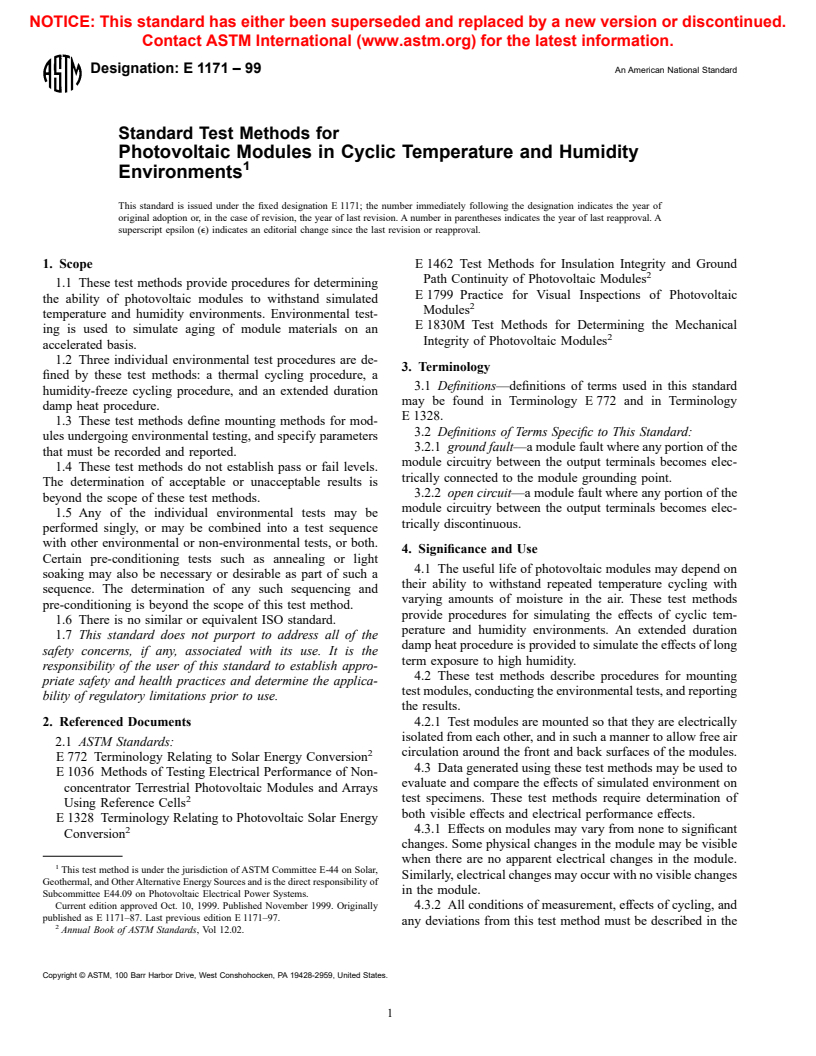

cling sequence is illustrated in Fig. 1.

5.1 In addition to the apparatus required for Test Methods

6.2 Electrical Tests—Perform the following electrical tests

E 1036 and E 1462 the following apparatus is required.

before and after each of the test procedures.

5.2 Environmental Chamber(s)—A chamber or chambers in

6.2.1 Electrical Performance—Measure and record the

which modules are mounted during the environmental tests.

electrical performance of each module. A suitable method for

5.2.1 Air temperature throughout the working volume shall

nonconcentrator modules is Test Methods E 1036.

be within 62°C of that specified.

6.2.2 Ground Path Continuity—Test any module with a

5.2.2 Relative humidity shall be controlled within 65% of

grounding terminal identified by the module manufacturer to

that specified. For temperatures below 80°C, relative humidity

determine the maximum resistance between the grounding

control is not required.

terminal or lead and any accessible conductive part using 7.3 of

5.2.3 Provisions for monitoring and recording the chamber Test Methods E 1462.

temperature and relative humidity throughout the environmen-

6.2.3 Insulation Integrity—Subject each module to a test of

tal testing shall be provided. the electrical isolation capability according to 7.1 and 7.2 of

5.3 Tempe

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.