ASTM F303-02

(Practice)Standard Practices for Sampling for Particles in Aerospace Fluids and Components

Standard Practices for Sampling for Particles in Aerospace Fluids and Components

SIGNIFICANCE AND USE

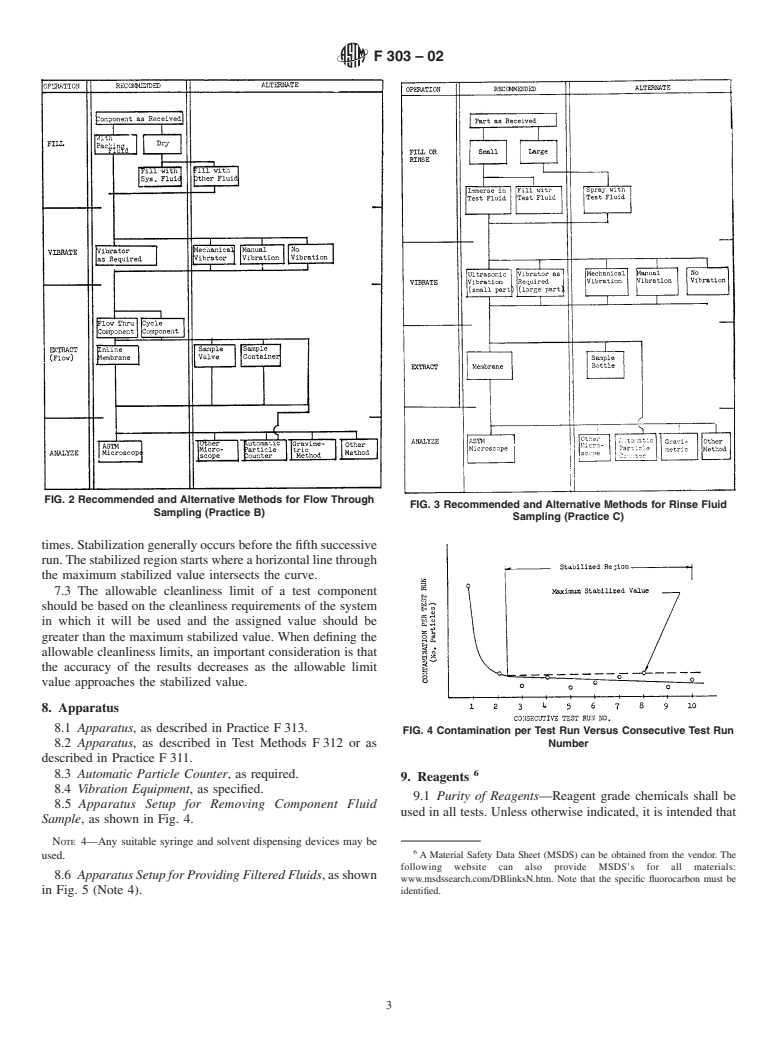

Although a cleaning action is imparted to the test component, it is not the intent of this practice to serve as a cleaning procedure. Components are normally cleaner after each consecutive test; thus repeated tests may be used to establish process limits for a given component (Fig. 4). A specific set of test parameters must be supplied by the agency specifying cleanliness limits. Fig. 1, Fig. 2, and Fig. 3 may be used as a guide to establish the desired parameters of test fluid, vibration, extraction, and analysis.

The curve in Fig. 4 shows the typical behavior of a component when tested for cleanliness several consecutive times. Stabilization generally occurs before the fifth successive run. The stabilized region starts where a horizontal line through the maximum stabilized value intersects the curve.

The allowable cleanliness limit of a test component should be based on the cleanliness requirements of the system in which it will be used and the assigned value should be greater than the maximum stabilized value. When defining the allowable cleanliness limits, an important consideration is that the accuracy of the results decreases as the allowable limit value approaches the stabilized value.

FIG. 4 Contamination per Test Run Versus Consecutive Test Run Number

SCOPE

1.1 These practices cover sampling procedures for use in determining the particle cleanliness of liquids and liquid samples from components. Three practices, A, B, and C, have been developed on the basis of component geometry in order to encompass the wide variety of configurations. These practices establish guidelines to be used in preparing detailed procedures for sampling specific components.

Note 1—The term cleanliness used in these practices refers to solid particles in the liquid. It does not generally cover other foreign matter such as gases, liquids, and products of chemical degradation. Cleanliness with respect to particulate contamination does not necessarily give any indication of the other types of contamination.

1.2 All components, regardless of application, may be tested provided (1) the fluid medium selected is completely compatible with the materials, packing and fluid used in the test component, and test apparatus, and (2) the fluid is handled in accordance with the manufacturer's recommendations and precautions. A liquid shall be used as the test fluid medium. These test fluids may be flushing, rinsing, packing, end use operating, or suitable substitutes for end use operating fluids. (Warning—Practices for sampling surface cleanliness by the vacuum cleaner technique (used on clean room garments and large storage tanks) sampling gaseous fluids and handling hazardous fluids such as oxidizers, acids, propellants, and so forth, are not within the scope of the practices presented; however, they may be included in addendums or separate practices at a later date.

Substitute fluids are recommended in place of end item fluids for preassembly cleanliness determinations on components using hazardous end item fluids. After obtaining the sample, the substitute fluid must be totally removed from the test part with particular caution given to the possibility of trapped fluid. It is hazardous to use a substitute fluid for testing assembled parts where the fluid can be trapped in dead ends, behind seals, and so forth.)

Note 2—The word fluid used in these practices shall be assumed to be a liquid unless otherwise stated.

1.3 The cleanliness of assemblies with or without moving parts may be determined at the time of test; however, movement of internal component parts during the test will create unknown quantities of contamination from wear. Practice B covers configurations requiring dynamic actuation to achieve a sample. The practice does not differentiate between built-in particles and wear particles.

Note 3—Defining allowable cleanliness limits is not within the scope of these practices.

1.4 The three practices...

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F303–02

Standard Practices for

Sampling for Particles in Aerospace Fluids and

1

Components

This standard is issued under the fixed designation F 303; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

NOTE 2—The word fluid used in these practices shall be assumed to be

1. Scope

a liquid unless otherwise stated.

1.1 These practices cover sampling procedures for use in

1.3 The cleanliness of assemblies with or without moving

determining the particle cleanliness of liquids and liquid

parts may be determined at the time of test; however, move-

samples from components. Three practices, A, B, and C, have

ment of internal component parts during the test will create

beendevelopedonthebasisofcomponentgeometryinorderto

unknown quantities of contamination from wear. Practice B

encompass the wide variety of configurations. These practices

covers configurations requiring dynamic actuation to achieve a

establishguidelinestobeusedinpreparingdetailedprocedures

sample. The practice does not differentiate between built-in

for sampling specific components.

particles and wear particles.

NOTE 1—The term cleanliness used in these practices refers to solid

NOTE 3—Defining allowable cleanliness limits is not within the scope

particlesintheliquid.Itdoesnotgenerallycoverotherforeignmattersuch

of these practices.

as gases, liquids, and products of chemical degradation. Cleanliness with

respect to particulate contamination does not necessarily give any indica-

1.4 The three practices included are as follows:

tion of the other types of contamination.

Sections

1.2 Allcomponents,regardlessofapplication,maybetested Practice A—Static Fluid Sampling (Method for extract- 5-13

ing fluid from the test article for analysis. This ap-

provided (1) the fluid medium selected is completely compat-

plies to components that have a cavity from which

ible with the materials, packing and fluid used in the test

fluid may be extracted)

component, and test apparatus, and (2) the fluid is handled in Practice B—Flowing Fluid Sampling (Method for flush- 14-22

ing contaminants from the test article for analysis.

accordance with the manufacturer’s recommendations and

This applies to components which fluid can pass (1)

precautions. A liquid shall be used as the test fluid medium.

directly through, or (2) pass into and out of by cy-

cling)

These test fluids may be flushing, rinsing, packing, end use

Practice C—Rinse Fluid Sampling (Method for rinsing 23-31

operating, or suitable substitutes for end use operating fluids.

contaminants from the test article’s surfaces. The

(Warning—Practices for sampling surface cleanliness by the

rinse fluid is analyzed for contamination. This ap-

plies to components that do not have a fluid cavity

vacuum cleaner technique (used on clean room garments and

or for other reasons are not adaptable to Practices

large storage tanks) sampling gaseous fluids and handling

A and B)

hazardous fluids such as oxidizers, acids, propellants, and so

1.5 This standard does not purport to address all of the

forth, are not within the scope of the practices presented;

safety concerns, if any, associated with its use. It is the

however, they may be included in addendums or separate

responsibility of the user of this standard to establish appro-

practices at a later date.

priate safety and health practices and determine the applica-

Substitutefluidsarerecommendedinplaceofenditemfluids

bility of regulatory limitations prior to use.

for preassembly cleanliness determinations on components

using hazardous end item fluids. After obtaining the sample,

2. Referenced Documents

the substitute fluid must be totally removed from the test part

2.1 ASTM Standards:

with particular caution given to the possibility of trapped fluid.

2

D 1836 Specification for Commercial Hexanes

It is hazardous to use a substitute fluid for testing assembled

F 311 PracticeforProcessingAerospaceLiquidSamplesfor

parts where the fluid can be trapped in dead ends, behind seals,

Particulate Contamination Analysis Using Membrane Fil-

and so forth.)

3

ters

F 312 Test Methods for Microscopical Sizing and Counting

3

Particles from Aerospace Fluids on Membrane Filters

1

These practices are under the jurisdiction of ASTM Committee E21 on Space

Simulation and Applications of Space Technology and are the direct responsibility

of Subcommittee E21.05 on Contamination.

Current edition approved Oct. 10, 2002. Published November 2002. Originally

2

published as D 2429–65 T. Redesignated F 303 in 1970. Last previous edition Annual Book of ASTM Standards, Vol 06.04.

3

F 303 – 78 (1996). Annual Book of ASTM Standards,

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.