ASTM D600-90(2001)

(Specification)Standard Specification for Liquid Paint Driers

Standard Specification for Liquid Paint Driers

SCOPE

1.1 This specification covers liquids for use in paints, varnishes, enamels, and similar organic coatings and are solutions of metallic salts of:

1.1.1 Class A—2-Ethyl hexanoic acids in petroleum spirits.

1.1.2 Class B—Naphthenic acids in petroleum spirits.

1.1.3 Class C—Neodecanoic acids in petroleum spirits.

1.1.4 Class D—Tall oil fatty acids in petroleum spirits.

1.1.5 Class E—Any of the above acids or acid blends, but containing additives that make the liquid drier water dispersible. Some other driers may also contain complexing agents.

1.1.6 Class F—Other acids and acid blends unidentified by their producers.

1.2 For specific hazard information and guidance, see the supplier's Material Safety Data Sheets for materials listed in this specification.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 600 – 90 (Reapproved 2001)

Standard Specification for

Liquid Paint Driers

This standard is issued under the fixed designation D 600; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope by Bubble Time Method

2.2 U.S. Federal Specification:

1.1 This specification covers liquids for use in paints,

PPP-C-2020 Chemicals, Liquid, Dry, and Paste: Packaging

varnishes, enamels, and similar organic coatings and are

of

solutions of metallic salts of:

1.1.1 Class A—2-Ethyl hexanoic acids in petroleum spirits.

3. Chemical and Physical Requirements

1.1.2 Class B—Naphthenic acids in petroleum spirits.

3.1 Quantitative Requirements—The drier shall conform to

1.1.3 Class C—Neodecanoic acids in petroleum spirits.

the quantitative requirements as specified in Table 1 for

1.1.4 Class D—Tall oil fatty acids in petroleum spirits.

metallic content, color, and viscosity.

1.1.5 Class E—Any of the above acids or acid blends, but

3.2 Physical Appearance—Each type of drier shall be a

containing additives that make the liquid drier water dispers-

mobile liquid free of sediment and suspended matter and shall

ible. Some other driers may also contain complexing agents.

be stable and miscible with oil as listed inTest Methods D 564.

1.1.6 Class F—Other acids and acid blends unidentified by

their producers.

4. Significance and Use

1.2 For specific hazard information and guidance, see the

4.1 This specification covers the general requirements for

supplier’s Material Safety Data Sheets for materials listed in

liquid paint driers used in paints, varnishes, enamels, and

this specification.

similar organic coatings.

4.2 The values listed should be considered as general guides

2. Referenced Documents

to the character of the products, rather than reproducible

2.1 ASTM Standards:

2 constants.

D 564 Test Methods for Liquid Paint Driers

D 1544 Test Method for Color of Transparent Liquids

5. Test Methods

(Gardner Color Scale)

5.1 The properties enumerated in this specification shall be

D 1545 Test Method for Viscosity of Transparent Liquids

determined in accordance with Test Methods D 564, except as

otherwise provided in this specification.

This specification is under the jurisdiction of ASTM Committee D01 on Paint

and Related Coatings, Materials, andApplications and is the direct responsibility of

Subcommittee D01.35 on Solvents, Plasticizers, and Chemical Intermediates.

Current edition approved May 25, 1990. Published July 1990. Originally Annual Book of ASTM Standards, Vol 06.03.

published as D 600 – 73 (1978). Last previous edition D 600 – 85. Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700

Annual Book of ASTM Standards, Vol 06.01. Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

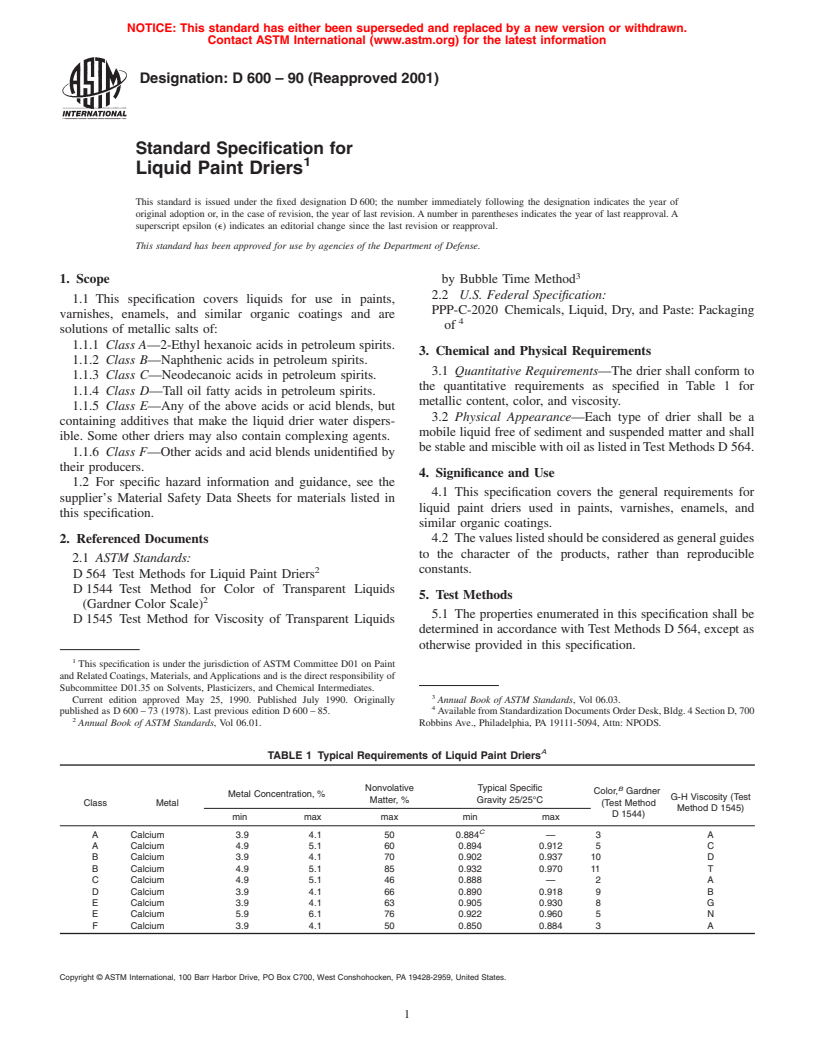

A

TABLE 1 Typical Requirements of Liquid Paint Driers

Nonvolative Typical Specific B

Color, Gardner

Metal Concentration, %

G-H Viscosity (Test

Matter, % Gravity 25/25°C

Class Metal (Test Method

Method D 1545)

D 1544)

min max max min max

C

A Calcium 3.9 4.1 50 0.884 —3 A

A Calcium 4.9 5.1 60 0.894 0.912 5 C

B Calcium 3.9 4.1 70 0.902 0.937 10 D

B Calcium 4.9 5.1 85 0.932 0.970 11 T

C Calcium 4.9 5.1 46 0.888 — 2 A

D Calcium 3.9 4.1 66 0.890 0.918 9 B

E Calcium 3.9 4.1 63 0.905 0.930 8 G

E Calcium 5.9 6.1 76 0.922 0.960 5 N

F Calcium 3.9 4.1 50 0.850 0.884 3 A

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 600

TABLE

1 Continued

Nonvolative Typical Specific B

Color, Gardner

Metal Concentration, %

G-H Viscosity (Test

Matter, % Gravity 25/25°C

Class Metal (Test Method

Method D 1545)

D 1544)

min max max min max

F Calcium 4.9 5.1 60 0.900 0.936 4 B

F Calcium 5.9 6.1 74 0.873 0.948 6 N

F Calcium 7.9 8.1 70 0.958 — 5 B

F Calcium 9.9 10.1 65 1.000 1.030 7–8 K

A Cerium 5.9 6.1 30 0.856 — 8 A

B Cerium 5.9 6.1 57 0.925 —

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.