ASTM C645-14

(Specification)Standard Specification for Nonstructural Steel Framing Members

Standard Specification for Nonstructural Steel Framing Members

ABSTRACT

This specification covers nonstructural steel framing members in interior construction assemblies. Members shall be manufactured from steel and shall have a protective coating. Studs and rigid furring channels shall have a configuration and steel thickness such that the system in which they are used will carry the design transverse loads without exceeding either the allowable stress of the steel or the allowable design deflection. Members shall be manufactured in such a fashion as to minimize burrs and sharp edges. Penetration test shall be done for performance requirements, where members shall be capable of pulling the head of the screw below the surface of the gypsum board without spin out. Apparatus and materials shall satisfy the testing requirements of the specification.

SCOPE

1.1 This specification covers nonstructural steel framing members in interior construction assemblies.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 The following safety hazards caveat pertains only to the test methods portion, Sections 9 and 10, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C645 −14

StandardSpecification for

Nonstructural Steel Framing Members

This standard is issued under the fixed designation C645; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* Plaster Bases to Wood Studs or Steel Studs

C1396/C1396M Specification for Gypsum Board

1.1 This specification covers nonstructural steel framing

2.2 AISI Standards:

members in interior construction assemblies.

S100 North American Specification for the Design of Cold-

1.2 The values stated in inch-pound units are to be regarded

Formed Steel Structural Members, 2007 edition

as standard. The values given in parentheses are mathematical

S220 North American Standard for Cold-Formed Steel

conversions to SI units that are provided for information only

Framing—Nonstructural Members, 2011 Edition

and are not considered standard.

2.3 ICC-ES Document

1.3 The following safety hazards caveat pertains only to the

ICC-ES-AC86 Acceptance Criteria for Cold-formed Steel

test methods portion, Sections 9 and 10, of this specification:

Framing Members—Interior Nonload-bearing Wall

This standard does not purport to address all of the safety

Assemblies—Approved May 2012

concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and

3. Terminology

health practices and determine the applicability of regulatory

3.1 Definitions—Definitions shall be in accordance with

limitations prior to use.

Terminology C11.

3.2 Definitions of Terms Specific to This Standard:

2. Referenced Documents

3.2.1 members, n—in screw application of gypsum board,

2.1 ASTM Standards:

studs, runners (track), hat furring channels, main beams, and

A653/A653M Specification for Steel Sheet, Zinc-Coated

cross furring members of grid suspension systems or other

(Galvanized) or Zinc-Iron Alloy-Coated (Galvannealed)

items manufactured in accordance with this specification.

by the Hot-Dip Process

3.2.2 nonstructural wall stud, n—a member in a steel

A1003/A1003M Specification for Steel Sheet, Carbon,

framed wall system which is limited to a lateral (transverse)

Metallic- and Nonmetallic-Coated for Cold-Formed

load of not more than 10 lb/ft (480 Pa), a superimposed

Framing Members

verticalload,exclusiveofsheathingmaterials,ofnotmorethan

C11 Terminology Relating to Gypsum and Related Building

100 lbf/ft (1460 N/m), or a superimposed vertical load of not

Materials and Systems

more than 200 lbs (890 N).

C475/C475M Specification for Joint Compound and Joint

Tape for Finishing Gypsum Board

4. Materials and Manufacture

C754 Specification for Installation of Steel Framing Mem-

4.1 Members shall be manufactured from steel meeting the

bers to Receive Screw-Attached Gypsum Panel Products

requirements of Specification A1003/A1003M.

C1002 Specification for Steel Self-Piercing Tapping Screws

for Application of Gypsum Panel Products or Metal

4.2 Members shall have a protective coating conforming to

Specification A653/A653M G40 minimum or shall have a

protective coating with an equivalent corrosion resistance.

This specification is under the jurisdiction of ASTM Committee C11 on

4.3 Members shall be manufactured from steel having a

Gypsum and Related Building Materials and Systems and is the direct responsibility

of Subcommittee C11.02 on Specifications and Test Methods for Accessories and minimum thickness, individual measurement of 0.0179 in.

Related Products.

(0.455 mm), before application of protective coating.

Current edition approved Nov. 1, 2014. Published November 2014. Originally

approved in 1970. Last previous edition approved in 2013 as C645 – 13. DOI:

10.1520/C0645-14.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from American Iron and Steel Institute (AISI), 1140 Connecticut

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Ave., NW, Suite 705, Washington, DC 20036, http://www.steel.org.

Standards volume information, refer to the standard’s Document Summary page on Available from ICC Evaluation Services, Inc., 5360 Workman Mill Road,

the ASTM website. Whittier, CA 90601, www.icc-es.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C645−14

TABLE 1 Manufacturing Tolerances

5. Dimensions and Permissible Variations

Drywall Studs, Drywall Track,

A

5.1 Studs and rigid furring channels shall have a configu- Dimension Item Checked

in. (mm) in. (mm)

ration and steel thickness such that the system in which they

A length + ⁄8 (3.18) + 1 (25.40)

1 1

are used will carry the design transverse loads without exceed-

− ⁄4 (6.35) − ⁄4 (6.35)

B

1 1

B web width + ⁄32 (0.79) + ⁄8 (3.18)

ing either the allowable stress of the steel or the allowable

− ⁄32 (0.79) −0(0)

design deflection. Main beams and cross furring of grid

C flare + ⁄16 (1.59) + 0 (0)

suspension systems shall be limited to a deflection of L/240. 1 3

overbend − ⁄16 (1.59) − ⁄16 (4.76)

D hole center + ⁄8 (3.18) NA

The manufacturer shall supply sufficient data for calculating

width − ⁄8 (3.18)

design performance.

E hole center + ⁄4 (6.35) NA

length − ⁄4 (6.35)

NOTE 1—Allowable deflection varies depending on the cladding used

1 1

F crown + ⁄8 (3.18) + ⁄8 (3.18)

and architectural requirements. Detailed requirements shall be specified in

1 1

− ⁄8 (3.18) − ⁄8 (3.18)

application specifications. 1 1

G camber ⁄32 per ft (0.79) ⁄32 per ft (0.79)

1 1

⁄2 max (12.7) ⁄2 max (12.7)

5.1.1 Members, except main beams of grid suspension

1 1

H bow ⁄32 per ft (0.79) ⁄32 per ft (0.79)

systems, shall be sufficiently rigid to permit penetration of the

1 1

⁄2 max (12.7) ⁄2 max (12.7)

1 1

I twist ⁄32 per ft (0.79) ⁄32 per ft (0.79)

screw.

1 1

⁄2 max (12.7) ⁄2 max (12.7)

5.1.2 Minimum width of face to which gypsum board is

A

1 All measurements shall be taken not less than 1 ft (305 mm) from the end.

screw-attached shall be not less than 1 ⁄4 in. (32 mm).

B

Outside dimension for stud; inside for track.

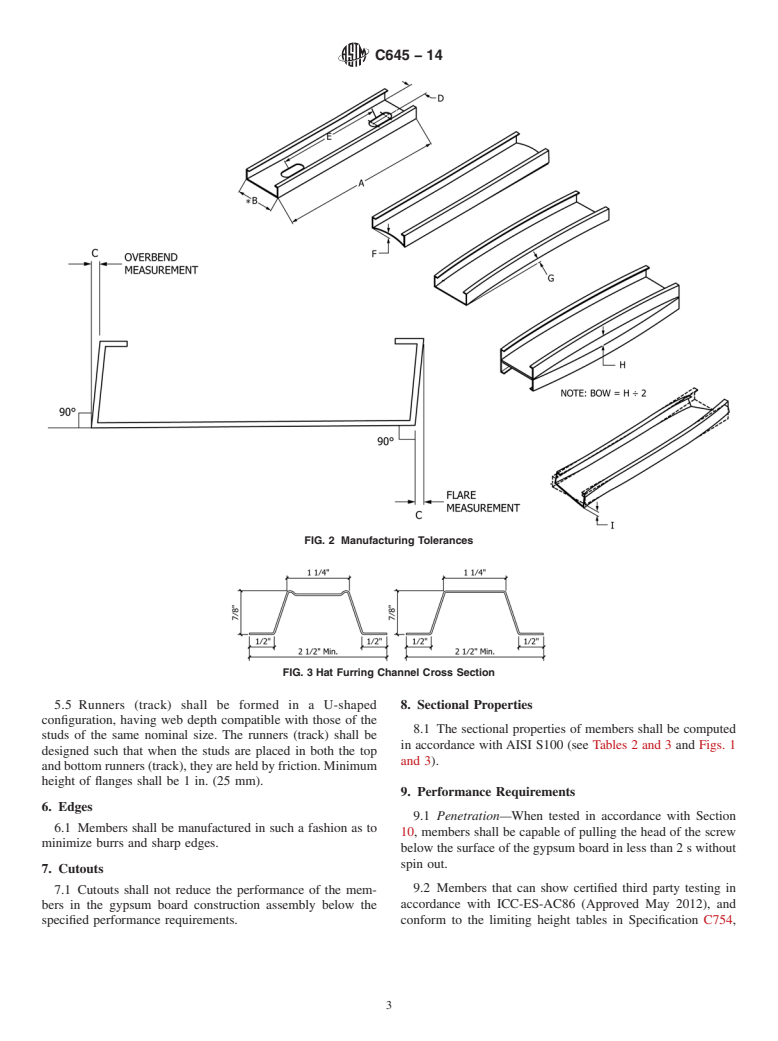

5.1.3 Minimum lip dimension shall be ⁄16 in. (5 mm). (See

Fig. 1.)

5.2 Members shall be manufactured within the limits as

shown in Table 1 and Fig. 2.

5.4 Grid suspension systems include main beams and cross

5.3 RigidFurringChannels—Minimumdepthshallbe ⁄8in. furring members which mechanically interlock to form a

(22 mm). Minimum width of furring attachment flanges (see modular supporting network. Length tolerance for grid suspen-

1 1

Fig. 3) shall be ⁄2 in. (12.7 mm). sion members shall be 6 ⁄16 in. (1.59 mm).

FIG. 1 Minimum Drywall Stud Cross Section

C645−14

FIG. 2 Manufacturing Tolerances

FIG. 3Hat Furring Channel Cross Section

5.5 Runners (track) shall be formed in a U-shaped 8. Sectional Properties

configuration, having web depth compatible with those of the

8.1 The sectional properties of members shall be computed

studs of the same nominal size. The runners (track) shall be

in accordance with AISI S100 (see Tables 2 and 3 and Figs. 1

designed such that when the studs are placed in both the top

and 3).

and bottom runners (track), they are held by friction. Minimum

height of flanges shall be 1 in. (25 mm).

9. Performance Requirements

6. Edges

9.1 Penetration—When tested in accordance with Section

6.1 Members shall be manufactured in such a fashion as to

10, members shall be capable of pulling the head of the screw

minimize burrs and sharp edges.

below the surface of the gypsum board in less than 2 s without

spin out.

7. Cutouts

9.2 Members that can show certified third party testing in

7.1 Cutouts shall not reduce the performance of the mem-

accordance with ICC-ES-AC86 (Approved May 2012), and

bers in the gypsum board construction assembly below the

specified performance requirements. conform to the limiting height tables in Specification C754,

C645−14

TABLE 2 Minimum Section Properties for Various Studs

C C,D

Section Stud Design Minimum Base Steel Gross Area Effective Properties

A B E F

Designator Depth Thickness Thickness Ix Mn/Ω

2 2 4 4

in. (mm) in. (mm) in. (mm) in (mm)in (1000 mm ) (in-k) (N-m)

162S125-18 1.625 41 0.0188 0.478 0.0179 0.454 0.080 52 0.034 14 0.61 69

162S125-30 1.625 41 0.0312 0.792 0.0296 0.752 0.132 85 0.060 25 1.19 134

162S125-33 1.625 41 0.0346 0.879 0.0329 0.835 0.145 94 0.066 27 1.37 155

250S125-18 2.500 64 0.0188 0.478 0.0179 0.454 0.097 63 0.910 38 1.03 116

250S125-30 2.500 64 0.0312 0.792 0.0296 0.752 0.159 102 0.159 66 2.09 236

250S125-33 2.500 64 0.0346 0.879 0.0329 0.835 0.176 114 0.175 73 2.40 272

350S125-18 3.500 89 0.0188 0.478 0.0179 0.454 0.115 74 0.203 84 1.42 161

350S125-30 3

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C645 − 13 C645 − 14

Standard Specification for

Nonstructural Steel Framing Members

This standard is issued under the fixed designation C645; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope*

1.1 This specification covers nonstructural steel framing members in interior construction assemblies.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.3 The following safety hazards caveat pertains only to the test methods portion, Sections 99 and 10 and 10, of this

specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of

regulatory limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

A653/A653M Specification for Steel Sheet, Zinc-Coated (Galvanized) or Zinc-Iron Alloy-Coated (Galvannealed) by the

Hot-Dip Process

A1003/A1003M Specification for Steel Sheet, Carbon, Metallic- and Nonmetallic-Coated for Cold-Formed Framing Members

C11 Terminology Relating to Gypsum and Related Building Materials and Systems

C475/C475M Specification for Joint Compound and Joint Tape for Finishing Gypsum Board

C1396/C1396M Specification for Gypsum Board

C754 Specification for Installation of Steel Framing Members to Receive Screw-Attached Gypsum Panel Products

C1002 Specification for Steel Self-Piercing Tapping Screws for Application of Gypsum Panel Products or Metal Plaster Bases

to Wood Studs or Steel Studs

C1396/C1396M Specification for Gypsum Board

2.2 AISI Standards:

S100 North American Specification for the Design of Cold-Formed Steel Structural Members, 2007 edition

S220 North American Standard for Cold-Formed Steel Framing – Nonstructural Framing—Nonstructural Members, 2011

Edition

2.3 ICC-ES Document

ICC-ES-AC86 Acceptance Criteria for Steel Studs and Gypsum-Board Interior Nonload-Bearing Walls—Complete

Construction—AC86—Approved July 1995 (Editorially revised September 2005) (Formerly ICBO AC86 dated July

1995)Cold-formed Steel Framing Members—Interior Nonload-bearing Wall Assemblies—Approved May 2012

3. Terminology

3.1 Definitions—Definitions shall be in accordance with Terminology C11.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 members, n—in screw application of gypsum board, studs, runners (track), hat furring channels, main beams, and cross

furring members of grid suspension systems or other items manufactured in accordance with this specification.

This specification is under the jurisdiction of ASTM Committee C11 on Gypsum and Related Building Materials and Systems and is the direct responsibility of

Subcommittee C11.02 on Specifications and Test Methods for Accessories and Related Products.

Current edition approved July 1, 2013Nov. 1, 2014. Published July 2013November 2014. Originally approved in 1970. Last previous edition approved in 20112013 as

C645 – 11a.C645 – 13. DOI: 10.1520/C0645-13.10.1520/C0645-14.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Available from American Iron and Steel Institute (AISI), 1140 Connecticut Ave., NW, Suite 705, Washington, DC 20036, http://www.steel.org.

Available from ICC Evaluation Services, Inc., 5360 Workman Mill Road, Whittier, CA 90601, www.icc-es.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C645 − 14

3.2.2 nonstructural wall stud, n—a member in a steel framed wall system which is limited to a lateral (transverse) load of not

more than 10 lb/ft (480 Pa), a superimposed vertical load, exclusive of sheathing materials, of not more than 100 lbf/ft (1460

N/m), or a superimposed vertical load of not more than 200 lbs (890 N).

4. Materials and Manufacture

4.1 Members shall be manufactured from steel meeting the requirements of Specification A1003/A1003M.

4.2 Members shall have a protective coating conforming to Specification A653/A653M – G 40 G40 minimum or shall have a

protective coating with an equivalent corrosion resistance.

4.3 Members shall be manufactured from steel having a minimum thickness, individual measurement of 0.0179 in. (0.455

mm)mm), before application of protective coating.

5. Dimensions and Permissible Variations

5.1 Studs and rigid furring channels shall have a configuration and steel thickness such that the system in which they are used

will carry the design transverse loads without exceeding either the allowable stress of the steel or the allowable design deflection.

Main beams and cross furring of grid suspension systems shall be limited to a deflection of L/240. The manufacturer shall supply

sufficient data for calculating design performance.

NOTE 1—Allowable deflection varies depending on the cladding used and architectural requirements. Detailed requirements shall be specified in

application specifications.

5.1.1 Members, except main beams of grid suspension systems, shall be sufficiently rigid to permit penetration of the screw.

5.1.2 Minimum width of face to which gypsum board is screw-attached shall be not less than 1 ⁄4 in. (32 mm).

5.1.3 Minimum lip dimension shall be ⁄16 in. (5 mm). See(See Fig. 1. .)

5.2 Members shall be manufactured within the limits as shown in Table 1 and Fig. 2.

FIG. 1 Minimum Drywall Stud Cross Section

C645 − 14

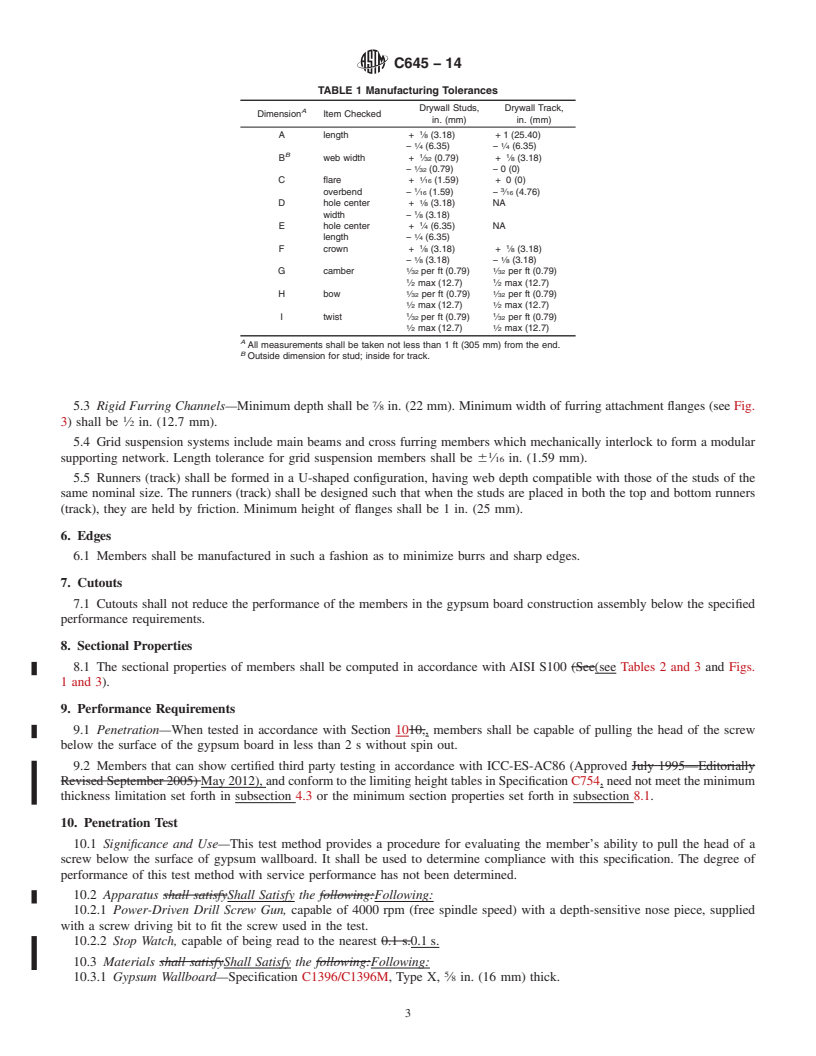

TABLE 1 Manufacturing Tolerances

Drywall Studs, Drywall Track,

A

Dimension Item Checked

in. (mm) in. (mm)

A length + ⁄8 (3.18) + 1 (25.40)

1 1

− ⁄4 (6.35) − ⁄4 (6.35)

B

1 1

B web width + ⁄32 (0.79) + ⁄8 (3.18)

− ⁄32 (0.79) − 0 (0)

C flare + ⁄16 (1.59) + 0 (0)

1 3

overbend − ⁄16 (1.59) − ⁄16 (4.76)

D hole center + ⁄8 (3.18) NA

width − ⁄8 (3.18)

E hole center + ⁄4 (6.35) NA

length − ⁄4 (6.35)

1 1

F crown + ⁄8 (3.18) + ⁄8 (3.18)

1 1

− ⁄8 (3.18) − ⁄8 (3.18)

1 1

G camber ⁄32 per ft (0.79) ⁄32 per ft (0.79)

1 1

⁄2 max (12.7) ⁄2 max (12.7)

1 1

H bow ⁄32 per ft (0.79) ⁄32 per ft (0.79)

1 1

⁄2 max (12.7) ⁄2 max (12.7)

1 1

I twist ⁄32 per ft (0.79) ⁄32 per ft (0.79)

1 1

⁄2 max (12.7) ⁄2 max (12.7)

A

All measurements shall be taken not less than 1 ft (305 mm) from the end.

B

Outside dimension for stud; inside for track.

5.3 Rigid Furring Channels—Minimum depth shall be ⁄8 in. (22 mm). Minimum width of furring attachment flanges (see Fig.

3) shall be ⁄2 in. (12.7 mm).

5.4 Grid suspension systems include main beams and cross furring members which mechanically interlock to form a modular

supporting network. Length tolerance for grid suspension members shall be 6 ⁄16 in. (1.59 mm).

5.5 Runners (track) shall be formed in a U-shaped configuration, having web depth compatible with those of the studs of the

same nominal size. The runners (track) shall be designed such that when the studs are placed in both the top and bottom runners

(track), they are held by friction. Minimum height of flanges shall be 1 in. (25 mm).

6. Edges

6.1 Members shall be manufactured in such a fashion as to minimize burrs and sharp edges.

7. Cutouts

7.1 Cutouts shall not reduce the performance of the members in the gypsum board construction assembly below the specified

performance requirements.

8. Sectional Properties

8.1 The sectional properties of members shall be computed in accordance with AISI S100 (See(see Tables 2 and 3 and Figs.

1 and 3).

9. Performance Requirements

9.1 Penetration—When tested in accordance with Section 1010,, members shall be capable of pulling the head of the screw

below the surface of the gypsum board in less than 2 s without spin out.

9.2 Members that can show certified third party testing in accordance with ICC-ES-AC86 (Approved July 1995—Editorially

Revised September 2005) May 2012), and conform to the limiting height tables in Specification C754, need not meet the minimum

thickness limitation set forth in subsection 4.3 or the minimum section properties set forth in subsection 8.1.

10. Penetration Test

10.1 Significance and Use—This test method provides a procedure for evaluating the member’s ability to pull the head of a

screw below the surface of gypsum wallboard. It shall be used to determine compliance with this specification. The degree of

performance of this test method with service performance has not been determined.

10.2 Apparatus shall satisfyShall Satisfy the following:Following:

10.2.1 Power-Driven Drill Screw Gun, capable of 4000 rpm (free spindle speed) with a depth-sensitive nose piece, supplied

with a screw driving bit to fit the screw used in the test.

10.2.2 Stop Watch, capable of bein

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.