ASTM D8136-17

(Test Method)Standard Test Method for Determining Plastic Film Thickness and Thickness Variability Using a Non-Contact Capacitance Thickness Gauge

Standard Test Method for Determining Plastic Film Thickness and Thickness Variability Using a Non-Contact Capacitance Thickness Gauge

SIGNIFICANCE AND USE

5.1 This test method provides precise dimensions necessary for the calculation of properties expressed in physical units.

5.2 This test method provides a means to characterize the variability of the material thickness in the transverse and machine directions for quality control purposes, production process support and analysis, incoming product inspection and for defining variability for buying/selling film.

5.3 This test method provides a method for instrument calibration utilizing traceable standards available from the National Institute of Standards and Technology (NIST).

5.4 It is not intended to replace other thickness measurements based on commercial portable tools, nor is it implied that thickness measurements made by different procedures will exactly agree.

SCOPE

1.1 This test method covers the determination of the thickness of plastic film, ranging in thickness from 2.5 to 250 µm, with a non-contact thickness gauge that uses capacitance-based technology. It includes a method to generate a series of thickness data points that can be used to characterize the variability patterns of film for both transverse or machine direction (profiling).

Note 1: Thicker specimens, typically 250 µm to 2500 µm thick, can utilize this test method if the apparatus is designed to measure and handle materials of this thickness range, and the apparatus complies with the requirements as defined in this standard.

1.2 This test method provides a method for buyers and sellers of film to communicate the thickness and pattern of thickness variability of the product they are buying/selling.

1.3 This test method does not apply to textured or porous films or films that are conductive or coated with a conductive substance.

Note 2: Films that contain excessive levels of anti-static additive can be conductive and need to be tested to verify that they do not cause a negative reading on the instrument.

1.4 Units—The values stated in SI units are to be regarded as the standard. No other units of measurement are included in this standard.

Note 3: There is no known ISO equivalent to this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D8136 − 17

Standard Test Method for

Determining Plastic Film Thickness and Thickness

Variability Using a Non-Contact Capacitance Thickness

1

Gauge

This standard is issued under the fixed designation D8136; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

1.1 This test method covers the determination of the thick-

ness of plastic film, ranging in thickness from 2.5 to 250 µm,

2. Referenced Documents

withanon-contactthicknessgaugethatusescapacitance-based

2

technology. It includes a method to generate a series of

2.1 ASTM Standards:

thickness data points that can be used to characterize the

D618 Practice for Conditioning Plastics for Testing

variability patterns of film for both transverse or machine

D883 Terminology Relating to Plastics

direction (profiling).

D1505 Test Method for Density of Plastics by the Density-

Gradient Technique

NOTE 1—Thicker specimens, typically 250 µm to 2500 µm thick, can

D4805 Terminology for Plastics Standards (Withdrawn

utilize this test method if the apparatus is designed to measure and handle

3

materials of this thickness range, and the apparatus complies with the 2002)

requirements as defined in this standard.

D6988 GuideforDeterminationofThicknessofPlasticFilm

Test Specimens

1.2 This test method provides a method for buyers and

E177 Practice for Use of the Terms Precision and Bias in

sellers of film to communicate the thickness and pattern of

ASTM Test Methods

thickness variability of the product they are buying/selling.

E252 Test Method for Thickness of Foil, Thin Sheet, and

1.3 This test method does not apply to textured or porous

Film by Mass Measurement

films or films that are conductive or coated with a conductive

E691 Practice for Conducting an Interlaboratory Study to

substance.

Determine the Precision of a Test Method

NOTE 2—Films that contain excessive levels of anti-static additive can

2.2 ISO Standard:

be conductive and need to be tested to verify that they do not cause a

4

ISO 472 Plastics—Vocabulary

negative reading on the instrument.

1.4 Units—The values stated in SI units are to be regarded

3. Terminology

as the standard. No other units of measurement are included in

this standard. 3.1 Definitions—See Terminologies D883, D4805, D6988,

and ISO 472 for definitions pertinent to this test method.

NOTE 3—There is no known ISO equivalent to this standard.

3.2 Definitions of Terms Specific to This Standard:

1.5 This standard does not purport to address all of the

3.2.1 calibration, n—set of operations that establishes, un-

safety concerns, if any, associated with its use. It is the

der specified conditions, the relationship between values mea-

responsibility of the user of this standard to establish appro-

sured or indicated by an instrument or system and the corre-

priate safety, health, and environmental practices and deter-

sponding reference standard or known values derived from the

mine the applicability of regulatory limitations prior to use.

appropriate reference standards.

1.6 This international standard was developed in accor-

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom- 2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

1

This is under the jurisdiction of ASTM Committee D20 on Plastics and is the the ASTM website.

3

direct responsibility of Subcommittee D20.19 on Film, Sheeting, and Molded The last approved version of this historical standard is referenced on

Products. www.astm.org.

4

Current edition approved Sept. 1, 2017. Published September 2017. DOI: Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

10.1520/D8136-17. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

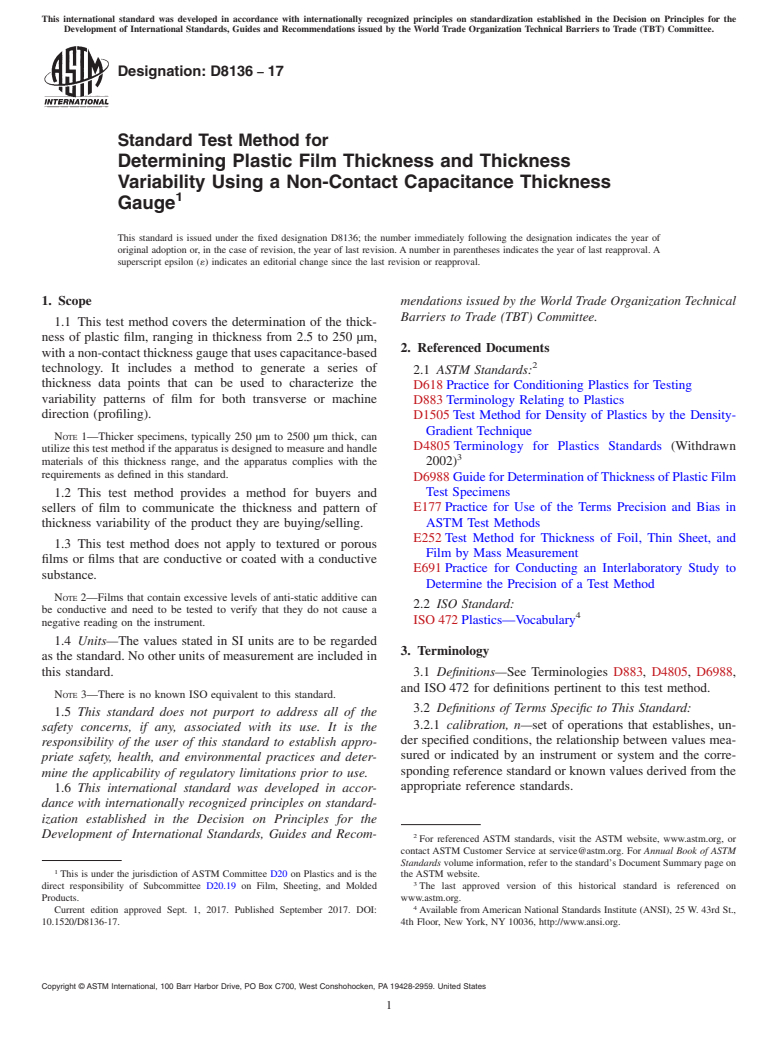

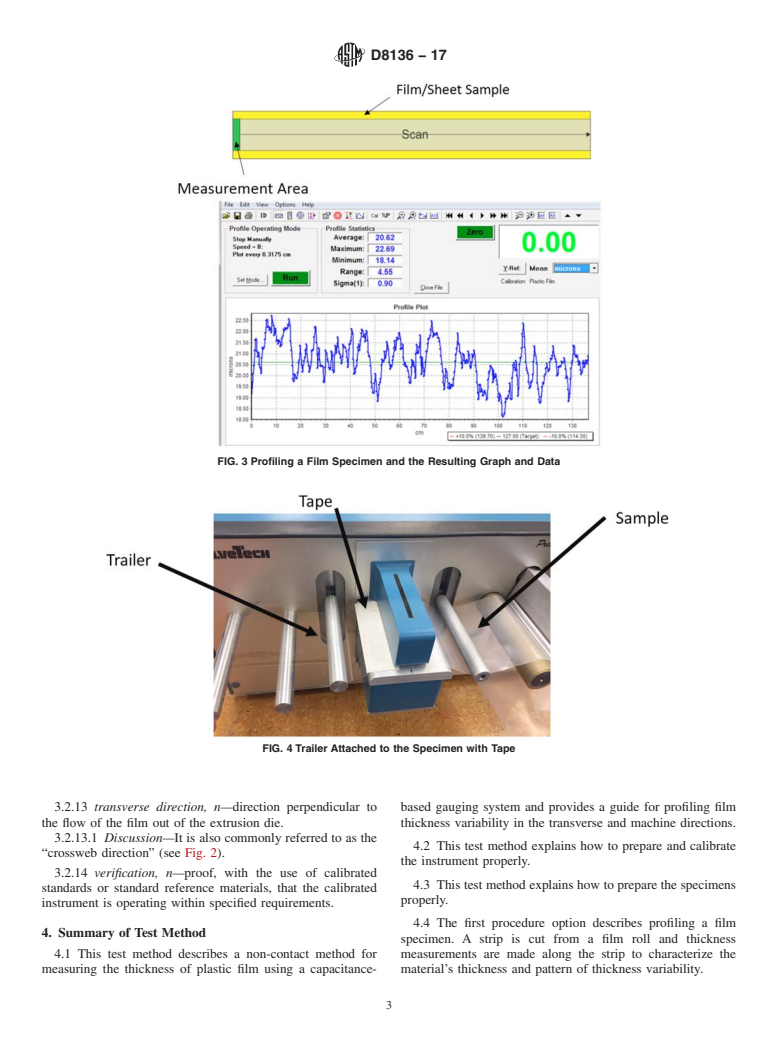

D8136 − 17

FIG. 1 Leader Attached to a Specimen with Tape

FIG. 2 Illustration of the Machine/Downweb Direction and the Transverse/Crossweb Direction

3.2.2 calibration recipe, n—computer-storedcalibrationthat 3.2.8 measurem

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.